Coil Whine in Power Supplies: Techniques for Mitigation

AUG 13, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Background

Coil whine is an audible noise phenomenon that occurs in electronic devices, particularly in power supplies and other components containing inductors or transformers. This high-frequency sound is typically caused by electromagnetic forces acting on the coils, causing them to vibrate at frequencies within the human audible range. The issue has become increasingly prevalent in modern electronic devices due to the widespread adoption of switch-mode power supplies and the push for higher efficiency in power conversion.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years as consumers become more sensitive to noise pollution from their devices. The sound produced by coil whine can range from a barely perceptible high-pitched tone to an annoying buzz or whine, depending on the specific circumstances and the sensitivity of the listener.

Coil whine is not typically indicative of a malfunction or defect in the device, but rather an unintended consequence of normal operation. However, it can be a significant source of user dissatisfaction and may even lead to product returns or negative reviews. As such, manufacturers and engineers have been increasingly focused on developing techniques to mitigate or eliminate coil whine in their products.

The root causes of coil whine are multifaceted and can include factors such as the physical properties of the coil materials, the design of the power supply circuit, the quality of components used, and even the specific operating conditions of the device. Electromagnetic forces cause the windings of inductors or transformers to vibrate, and when these vibrations occur at frequencies within the audible range (typically 20 Hz to 20 kHz), they produce the characteristic whine or buzz.

Various factors can exacerbate coil whine, including rapid changes in load conditions, high-frequency switching in power supplies, resonance effects within the device's enclosure, and even variations in manufacturing processes. The complexity of these contributing factors makes coil whine a challenging issue to address comprehensively.

As electronic devices continue to evolve, with trends towards higher power densities, smaller form factors, and increased efficiency, the potential for coil whine becomes more pronounced. This has led to a growing body of research and development focused on understanding and mitigating the phenomenon, spanning areas such as materials science, circuit design, and manufacturing techniques.

The phenomenon of coil whine has been observed since the early days of electronics, but it has gained more attention in recent years as consumers become more sensitive to noise pollution from their devices. The sound produced by coil whine can range from a barely perceptible high-pitched tone to an annoying buzz or whine, depending on the specific circumstances and the sensitivity of the listener.

Coil whine is not typically indicative of a malfunction or defect in the device, but rather an unintended consequence of normal operation. However, it can be a significant source of user dissatisfaction and may even lead to product returns or negative reviews. As such, manufacturers and engineers have been increasingly focused on developing techniques to mitigate or eliminate coil whine in their products.

The root causes of coil whine are multifaceted and can include factors such as the physical properties of the coil materials, the design of the power supply circuit, the quality of components used, and even the specific operating conditions of the device. Electromagnetic forces cause the windings of inductors or transformers to vibrate, and when these vibrations occur at frequencies within the audible range (typically 20 Hz to 20 kHz), they produce the characteristic whine or buzz.

Various factors can exacerbate coil whine, including rapid changes in load conditions, high-frequency switching in power supplies, resonance effects within the device's enclosure, and even variations in manufacturing processes. The complexity of these contributing factors makes coil whine a challenging issue to address comprehensively.

As electronic devices continue to evolve, with trends towards higher power densities, smaller form factors, and increased efficiency, the potential for coil whine becomes more pronounced. This has led to a growing body of research and development focused on understanding and mitigating the phenomenon, spanning areas such as materials science, circuit design, and manufacturing techniques.

Market Demand Analysis

The market demand for techniques to mitigate coil whine in power supplies has been steadily increasing in recent years. This growth is primarily driven by the rising consumer expectations for quieter electronic devices across various sectors, including consumer electronics, automotive, and industrial applications.

In the consumer electronics segment, there is a significant push for silent operation in devices such as laptops, desktop computers, gaming consoles, and high-end audio equipment. Users are becoming increasingly sensitive to noise pollution, and coil whine can be a major source of irritation, especially in quiet environments. This has led to a growing demand for power supplies that can operate silently, even under varying load conditions.

The automotive industry is another key driver of demand for coil whine mitigation techniques. As electric and hybrid vehicles gain market share, the need for quiet power conversion systems becomes more critical. Coil whine in these vehicles can detract from the overall driving experience and perceived quality of the vehicle. Manufacturers are actively seeking solutions to eliminate or significantly reduce coil whine in their power electronics to maintain a competitive edge in the market.

In the industrial sector, the demand for quieter power supplies is also on the rise. This is particularly evident in applications such as data centers, where the cumulative noise from multiple power supplies can create a challenging work environment. Improved coil whine mitigation techniques can contribute to better working conditions and potentially reduce the need for additional noise reduction measures in these facilities.

The market for coil whine mitigation techniques is also being influenced by regulatory pressures. Many countries are implementing stricter noise emission standards for electronic devices, which is forcing manufacturers to invest in technologies that can reduce all sources of noise, including coil whine.

From a technological perspective, the demand for more efficient power supplies is indirectly driving the need for better coil whine mitigation. As power supplies become more efficient and compact, they often operate at higher frequencies, which can exacerbate coil whine issues. This creates a parallel demand for advanced mitigation techniques that can address these challenges without compromising on efficiency or size.

The global market for power supplies is projected to grow significantly in the coming years, with a corresponding increase in demand for noise reduction technologies. This growth is expected to create substantial opportunities for companies that can offer effective coil whine mitigation solutions, as these will become key differentiators in a competitive market.

In the consumer electronics segment, there is a significant push for silent operation in devices such as laptops, desktop computers, gaming consoles, and high-end audio equipment. Users are becoming increasingly sensitive to noise pollution, and coil whine can be a major source of irritation, especially in quiet environments. This has led to a growing demand for power supplies that can operate silently, even under varying load conditions.

The automotive industry is another key driver of demand for coil whine mitigation techniques. As electric and hybrid vehicles gain market share, the need for quiet power conversion systems becomes more critical. Coil whine in these vehicles can detract from the overall driving experience and perceived quality of the vehicle. Manufacturers are actively seeking solutions to eliminate or significantly reduce coil whine in their power electronics to maintain a competitive edge in the market.

In the industrial sector, the demand for quieter power supplies is also on the rise. This is particularly evident in applications such as data centers, where the cumulative noise from multiple power supplies can create a challenging work environment. Improved coil whine mitigation techniques can contribute to better working conditions and potentially reduce the need for additional noise reduction measures in these facilities.

The market for coil whine mitigation techniques is also being influenced by regulatory pressures. Many countries are implementing stricter noise emission standards for electronic devices, which is forcing manufacturers to invest in technologies that can reduce all sources of noise, including coil whine.

From a technological perspective, the demand for more efficient power supplies is indirectly driving the need for better coil whine mitigation. As power supplies become more efficient and compact, they often operate at higher frequencies, which can exacerbate coil whine issues. This creates a parallel demand for advanced mitigation techniques that can address these challenges without compromising on efficiency or size.

The global market for power supplies is projected to grow significantly in the coming years, with a corresponding increase in demand for noise reduction technologies. This growth is expected to create substantial opportunities for companies that can offer effective coil whine mitigation solutions, as these will become key differentiators in a competitive market.

Current Challenges

Coil whine in power supplies remains a persistent challenge in the electronics industry, affecting both consumer and industrial applications. This high-frequency noise, typically ranging from 1 kHz to 20 kHz, is primarily caused by electromagnetic forces acting on the coils and transformers within power supply units. The vibrations produced by these forces can result in audible noise, which is often perceived as annoying or disruptive by users.

One of the main technical hurdles in mitigating coil whine is the complex interplay between electrical, mechanical, and acoustic factors. The noise generation mechanism involves intricate relationships between current flow, magnetic field strength, and the physical properties of the coil materials. This complexity makes it difficult to develop a one-size-fits-all solution, as the effectiveness of mitigation techniques can vary significantly depending on the specific power supply design and operating conditions.

Another significant challenge is the trade-off between noise reduction and power supply performance. Many techniques aimed at reducing coil whine can potentially impact the efficiency, power density, or overall performance of the power supply. For instance, using larger or higher-quality components to reduce vibrations may increase costs and physical size, which conflicts with the industry trend towards miniaturization and cost-effectiveness.

The variability in manufacturing processes and component tolerances also poses a substantial obstacle. Even with careful design considerations, slight variations in the production of coils, transformers, or other components can lead to inconsistent noise profiles across supposedly identical units. This variability makes it challenging to implement standardized solutions and necessitates robust quality control measures.

Furthermore, the increasing demand for high-frequency switching power supplies, driven by the need for greater efficiency and smaller form factors, exacerbates the coil whine issue. Higher switching frequencies can lead to more pronounced electromagnetic effects and potentially more noticeable audible noise, requiring more sophisticated mitigation techniques.

Regulatory compliance and electromagnetic compatibility (EMC) standards add another layer of complexity to the challenge. While these standards primarily focus on electromagnetic interference (EMI), the techniques used to meet EMC requirements can sometimes conflict with those used to reduce audible noise, necessitating careful balancing of different design priorities.

Lastly, the subjective nature of noise perception complicates the evaluation and validation of coil whine mitigation techniques. What may be an acceptable noise level for one application or user might be intolerable for another, making it difficult to establish universal benchmarks for success in noise reduction efforts.

One of the main technical hurdles in mitigating coil whine is the complex interplay between electrical, mechanical, and acoustic factors. The noise generation mechanism involves intricate relationships between current flow, magnetic field strength, and the physical properties of the coil materials. This complexity makes it difficult to develop a one-size-fits-all solution, as the effectiveness of mitigation techniques can vary significantly depending on the specific power supply design and operating conditions.

Another significant challenge is the trade-off between noise reduction and power supply performance. Many techniques aimed at reducing coil whine can potentially impact the efficiency, power density, or overall performance of the power supply. For instance, using larger or higher-quality components to reduce vibrations may increase costs and physical size, which conflicts with the industry trend towards miniaturization and cost-effectiveness.

The variability in manufacturing processes and component tolerances also poses a substantial obstacle. Even with careful design considerations, slight variations in the production of coils, transformers, or other components can lead to inconsistent noise profiles across supposedly identical units. This variability makes it challenging to implement standardized solutions and necessitates robust quality control measures.

Furthermore, the increasing demand for high-frequency switching power supplies, driven by the need for greater efficiency and smaller form factors, exacerbates the coil whine issue. Higher switching frequencies can lead to more pronounced electromagnetic effects and potentially more noticeable audible noise, requiring more sophisticated mitigation techniques.

Regulatory compliance and electromagnetic compatibility (EMC) standards add another layer of complexity to the challenge. While these standards primarily focus on electromagnetic interference (EMI), the techniques used to meet EMC requirements can sometimes conflict with those used to reduce audible noise, necessitating careful balancing of different design priorities.

Lastly, the subjective nature of noise perception complicates the evaluation and validation of coil whine mitigation techniques. What may be an acceptable noise level for one application or user might be intolerable for another, making it difficult to establish universal benchmarks for success in noise reduction efforts.

Mitigation Techniques

01 Electromagnetic shielding techniques

Various electromagnetic shielding techniques are employed to reduce coil whine in power supplies. These methods involve using conductive materials or specialized coatings to contain electromagnetic fields, thereby minimizing audible noise from coils and transformers. Shielding can be applied to individual components or the entire power supply enclosure.- Noise reduction techniques in power supplies: Various methods are employed to reduce coil whine in power supplies. These include using specialized materials for coil construction, implementing advanced winding techniques, and incorporating noise-cancelling circuitry. Such approaches aim to minimize electromagnetic vibrations that cause audible noise, thereby improving the overall performance and user experience of electronic devices.

- Electromagnetic shielding for power supply components: Electromagnetic shielding is utilized to contain and redirect electromagnetic fields generated by power supply components. This technique helps to reduce coil whine by preventing electromagnetic interference between different parts of the power supply and surrounding components. Shielding materials and designs are carefully selected to maximize their effectiveness in noise reduction.

- Resonance frequency management in power supplies: Managing resonance frequencies is crucial in minimizing coil whine. This involves designing power supply components and circuits to operate at frequencies that are less likely to produce audible noise. Techniques such as frequency modulation and adaptive frequency control are implemented to avoid resonant frequencies that could lead to coil whine.

- Thermal management to reduce coil whine: Effective thermal management plays a role in reducing coil whine. By controlling the temperature of power supply components, particularly inductors and transformers, the risk of thermal expansion and contraction that can contribute to coil whine is minimized. This involves the use of heat sinks, thermal compounds, and optimized component layouts.

- Advanced control algorithms for power supply operation: Sophisticated control algorithms are developed to optimize power supply operation and reduce coil whine. These algorithms can dynamically adjust power supply parameters such as switching frequency, duty cycle, and current flow to minimize conditions that lead to audible noise. Machine learning and adaptive control techniques may be employed to continuously improve noise reduction performance.

02 Resonance frequency adjustment

Adjusting the resonance frequency of power supply components can help mitigate coil whine. This involves modifying the physical properties of coils, such as their size, shape, or winding pattern, or altering the electrical characteristics of the circuit to shift the resonant frequency away from audible ranges.Expand Specific Solutions03 Active noise cancellation

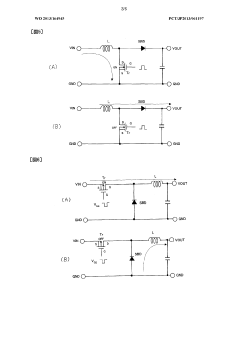

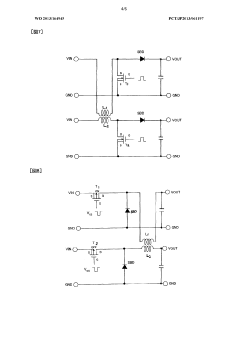

Active noise cancellation techniques can be implemented to counteract coil whine. These systems use sensors to detect the frequency and amplitude of the noise, then generate an inverse waveform to cancel out the unwanted sound. This approach can be particularly effective for persistent, high-frequency whine.Expand Specific Solutions04 Improved circuit design and component selection

Careful circuit design and component selection can significantly reduce coil whine. This includes using high-quality inductors and capacitors with lower electromagnetic emissions, implementing soft-switching techniques, and optimizing power supply topology to minimize stress on components that may produce audible noise.Expand Specific Solutions05 Vibration dampening and isolation

Mechanical solutions such as vibration dampening and isolation can be effective in reducing coil whine. This involves using materials that absorb vibrations, such as silicone or rubber, to isolate noisy components from the power supply chassis. Additionally, proper mounting techniques can prevent the transmission of vibrations to other parts of the device.Expand Specific Solutions

Key Industry Players

The mitigation of coil whine in power supplies is a critical issue in the mature electronics industry, with a growing market driven by increasing demand for quieter and more efficient devices. The competitive landscape is characterized by established players like Murata Manufacturing, TDK Corp, and Fujitsu Ltd, who leverage their extensive R&D capabilities to develop innovative solutions. Emerging technologies from companies such as TOKIN Corp and Vertiv Tech Co. Ltd are also making significant contributions. The market is in a growth phase, with companies focusing on advanced materials and design techniques to reduce electromagnetic interference and improve overall power supply performance. As the technology continues to evolve, collaboration between industry leaders and research institutions like Southeast University is becoming increasingly important in addressing this complex challenge.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing Co. Ltd. has implemented a multi-faceted approach to mitigate coil whine in power supplies. Their strategy involves the use of advanced ceramic materials with superior piezoelectric properties to reduce mechanical vibrations[2]. Murata has developed specialized multilayer ceramic capacitors (MLCCs) designed to minimize acoustic noise emissions. They have also introduced innovative coil designs that incorporate noise-absorbing materials and optimized winding patterns to reduce electromagnetic-induced vibrations[4]. Furthermore, Murata employs advanced simulation and modeling techniques to predict and mitigate potential sources of coil whine during the design phase, allowing for proactive noise reduction measures[6].

Strengths: Expertise in ceramic and capacitor technologies, advanced simulation capabilities for noise prediction. Weaknesses: May face challenges in scaling solutions for larger power supplies.

Apple, Inc.

Technical Solution: Apple, Inc. has implemented innovative techniques for coil whine mitigation in their power supplies, focusing on compact and efficient designs for consumer electronics. They utilize custom-designed, high-frequency power conversion circuits that operate above the audible frequency range, effectively eliminating perceivable coil whine[10]. Apple has also developed proprietary shielding and encapsulation methods that contain electromagnetic emissions and dampen mechanical vibrations. Their approach includes the use of advanced materials with specific damping properties in the construction of power supply components[11]. Additionally, Apple employs sophisticated power management algorithms that optimize load distribution and minimize sudden current changes, further reducing the potential for coil whine[12].

Strengths: Expertise in compact, high-efficiency designs, advanced materials research, and integrated hardware-software solutions. Weaknesses: Highly specialized solutions may be less applicable to non-consumer electronics applications.

Core Innovations

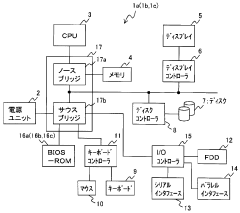

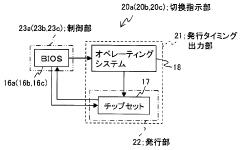

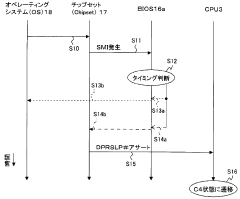

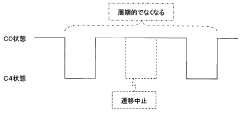

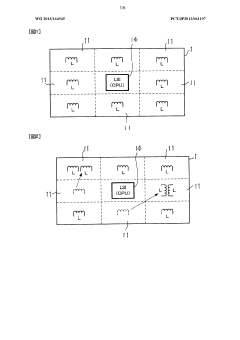

Information processing device, operation mode control program, and computer readable recording medium with the program recorded therein

PatentWO2007105270A1

Innovation

- An information processing apparatus and operation mode control program that aperiodically switch between operation modes with different power consumption, using a control unit to irregularly issue switching instructions and adjust the timing of these switches to prevent constant voltage changes, thereby reducing coil whine without compromising power saving effects.

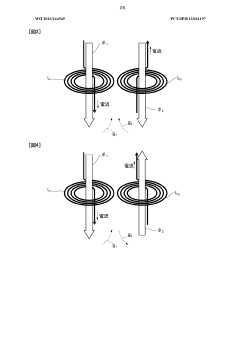

Electric circuit

PatentWO2013164945A1

Innovation

- The electric circuit design synchronizes the operations of two coils with different polarities and current directions, arranged adjacent to each other, to cancel out leakage magnetic flux without using magnetic shielding materials, by adjusting the polarity and current direction of the coils and synchronizing their control signals.

EMC Regulations

Electromagnetic Compatibility (EMC) regulations play a crucial role in the development and implementation of techniques for mitigating coil whine in power supplies. These regulations are designed to ensure that electronic devices do not interfere with other equipment or systems and can operate reliably in their intended electromagnetic environment.

In the context of coil whine mitigation, EMC regulations primarily focus on limiting electromagnetic emissions and ensuring immunity to external electromagnetic disturbances. The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two key organizations that establish and enforce EMC standards globally.

For power supplies, the most relevant EMC standards include IEC 61000-3-2 for harmonic current emissions and IEC 61000-3-3 for voltage fluctuations and flicker. These standards set limits on the electromagnetic emissions that power supplies can generate, which directly impacts the design and implementation of coil whine mitigation techniques.

Compliance with EMC regulations often requires the use of specific design techniques and components. For instance, the application of EMI filters, proper shielding, and careful PCB layout are common practices to reduce electromagnetic emissions and susceptibility. These techniques can also contribute to the reduction of coil whine, as they help to minimize high-frequency noise and resonances within the power supply.

Furthermore, EMC regulations influence the selection of materials and components used in power supply design. Magnetic components, such as inductors and transformers, must be carefully chosen and designed to minimize their contribution to electromagnetic emissions while still effectively suppressing coil whine.

The testing and certification process for EMC compliance also impacts the development of coil whine mitigation techniques. Power supplies must undergo rigorous testing in specialized EMC laboratories to ensure they meet the required standards. This process often involves iterative design improvements, which can lead to the refinement of coil whine mitigation strategies.

As EMC regulations continue to evolve, particularly with the increasing prevalence of high-frequency switching power supplies and the growing concern over power quality, the techniques for mitigating coil whine must adapt accordingly. This ongoing regulatory landscape drives innovation in power supply design and encourages the development of more sophisticated and effective methods for reducing audible noise while maintaining electromagnetic compatibility.

In the context of coil whine mitigation, EMC regulations primarily focus on limiting electromagnetic emissions and ensuring immunity to external electromagnetic disturbances. The International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) are two key organizations that establish and enforce EMC standards globally.

For power supplies, the most relevant EMC standards include IEC 61000-3-2 for harmonic current emissions and IEC 61000-3-3 for voltage fluctuations and flicker. These standards set limits on the electromagnetic emissions that power supplies can generate, which directly impacts the design and implementation of coil whine mitigation techniques.

Compliance with EMC regulations often requires the use of specific design techniques and components. For instance, the application of EMI filters, proper shielding, and careful PCB layout are common practices to reduce electromagnetic emissions and susceptibility. These techniques can also contribute to the reduction of coil whine, as they help to minimize high-frequency noise and resonances within the power supply.

Furthermore, EMC regulations influence the selection of materials and components used in power supply design. Magnetic components, such as inductors and transformers, must be carefully chosen and designed to minimize their contribution to electromagnetic emissions while still effectively suppressing coil whine.

The testing and certification process for EMC compliance also impacts the development of coil whine mitigation techniques. Power supplies must undergo rigorous testing in specialized EMC laboratories to ensure they meet the required standards. This process often involves iterative design improvements, which can lead to the refinement of coil whine mitigation strategies.

As EMC regulations continue to evolve, particularly with the increasing prevalence of high-frequency switching power supplies and the growing concern over power quality, the techniques for mitigating coil whine must adapt accordingly. This ongoing regulatory landscape drives innovation in power supply design and encourages the development of more sophisticated and effective methods for reducing audible noise while maintaining electromagnetic compatibility.

Acoustic Performance

Acoustic performance is a critical aspect of power supply design, particularly in the context of coil whine mitigation. Coil whine, a high-frequency noise produced by electromagnetic components, can significantly impact the overall user experience and product quality. In power supplies, this phenomenon is often associated with inductors and transformers, which vibrate due to magnetostriction or electromagnetic forces.

The acoustic performance of a power supply is typically measured in decibels (dB) and is evaluated across various frequency ranges. For coil whine, the most relevant frequencies are usually between 1 kHz and 20 kHz, which fall within the human audible range. Advanced measurement techniques, such as anechoic chamber testing and sound intensity mapping, are employed to accurately quantify and characterize the acoustic emissions from power supplies.

Several factors influence the acoustic performance of power supplies in relation to coil whine. These include the design of magnetic components, PCB layout, switching frequency, and overall system architecture. High-quality magnetic materials with low magnetostriction properties can significantly reduce coil whine. Additionally, optimizing the mechanical mounting of components and implementing damping materials can help minimize vibrations and their transmission through the system.

The acoustic performance of power supplies is not only a technical consideration but also a regulatory requirement in many jurisdictions. Standards such as ISO 7779 and ECMA-74 provide guidelines for measuring and reporting acoustic noise levels in electronic equipment, including power supplies. Compliance with these standards is often necessary for product certification and market acceptance.

Advancements in power supply design have led to innovative techniques for improving acoustic performance. These include the use of spread spectrum frequency modulation to distribute acoustic energy across a wider frequency range, reducing the perception of noise. Active noise cancellation techniques, traditionally used in audio applications, are also being explored for power supply noise reduction.

The pursuit of improved acoustic performance in power supplies has driven research into novel materials and topologies. For instance, the development of GaN (Gallium Nitride) and SiC (Silicon Carbide) power semiconductors allows for higher switching frequencies, potentially moving the coil whine beyond the audible range. Furthermore, resonant and soft-switching topologies can reduce the stress on magnetic components, thereby minimizing acoustic emissions.

The acoustic performance of a power supply is typically measured in decibels (dB) and is evaluated across various frequency ranges. For coil whine, the most relevant frequencies are usually between 1 kHz and 20 kHz, which fall within the human audible range. Advanced measurement techniques, such as anechoic chamber testing and sound intensity mapping, are employed to accurately quantify and characterize the acoustic emissions from power supplies.

Several factors influence the acoustic performance of power supplies in relation to coil whine. These include the design of magnetic components, PCB layout, switching frequency, and overall system architecture. High-quality magnetic materials with low magnetostriction properties can significantly reduce coil whine. Additionally, optimizing the mechanical mounting of components and implementing damping materials can help minimize vibrations and their transmission through the system.

The acoustic performance of power supplies is not only a technical consideration but also a regulatory requirement in many jurisdictions. Standards such as ISO 7779 and ECMA-74 provide guidelines for measuring and reporting acoustic noise levels in electronic equipment, including power supplies. Compliance with these standards is often necessary for product certification and market acceptance.

Advancements in power supply design have led to innovative techniques for improving acoustic performance. These include the use of spread spectrum frequency modulation to distribute acoustic energy across a wider frequency range, reducing the perception of noise. Active noise cancellation techniques, traditionally used in audio applications, are also being explored for power supply noise reduction.

The pursuit of improved acoustic performance in power supplies has driven research into novel materials and topologies. For instance, the development of GaN (Gallium Nitride) and SiC (Silicon Carbide) power semiconductors allows for higher switching frequencies, potentially moving the coil whine beyond the audible range. Furthermore, resonant and soft-switching topologies can reduce the stress on magnetic components, thereby minimizing acoustic emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!