The Influence of Dual-Stage Turbo Systems on B58 Engine Performance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

B58 Engine Evolution

The B58 engine, developed by BMW, has undergone significant evolution since its introduction in 2015. This inline-six turbocharged engine has become a cornerstone of BMW's powertrain strategy, featuring in various models across the BMW and Toyota lineups. The engine's development has been driven by the need for increased performance, improved fuel efficiency, and reduced emissions.

Initially, the B58 engine was introduced as a replacement for the N55 engine, offering improved power output and efficiency. The first generation B58 engines featured a single twin-scroll turbocharger, direct fuel injection, and BMW's Valvetronic variable valve lift system. These early versions produced around 320 horsepower and 330 lb-ft of torque, marking a significant improvement over their predecessors.

As emissions regulations tightened and market demands evolved, BMW continued to refine the B58 engine. The second generation, introduced in 2019, saw several key improvements. These included an upgraded cooling system, redesigned pistons, and a more efficient turbocharger. The result was an increase in power output to approximately 380 horsepower in some applications, while simultaneously improving fuel economy and emissions performance.

The most recent evolution of the B58 engine has seen the introduction of mild hybrid technology. This system, which incorporates a 48-volt electrical system and an integrated starter-generator, allows for improved efficiency and performance. The mild hybrid system enables features such as energy recuperation during braking and smoother start-stop functionality, contributing to further reductions in fuel consumption and emissions.

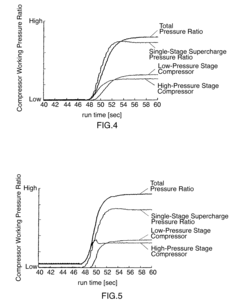

One of the most significant developments in the B58 engine's evolution has been the exploration of dual-stage turbo systems. This technology, which combines a smaller turbocharger for low-end response with a larger turbocharger for high-end power, has shown promising results in enhancing overall engine performance. The dual-stage turbo system allows for improved low-end torque and reduced turbo lag, while still providing substantial top-end power.

The integration of advanced materials and manufacturing techniques has also played a crucial role in the B58's evolution. The use of lighter, more heat-resistant materials in key components has allowed for improved thermal management and increased durability. Additionally, precision manufacturing techniques have enabled tighter tolerances and more efficient operation, contributing to the engine's overall performance and reliability.

Looking forward, the B58 engine is likely to continue evolving to meet future challenges. Areas of focus may include further electrification, advanced combustion strategies, and the potential integration of sustainable fuels. As BMW and other manufacturers push towards increasingly stringent emissions targets, the B58 engine's adaptability and potential for improvement will be crucial in maintaining its relevance in the automotive landscape.

Initially, the B58 engine was introduced as a replacement for the N55 engine, offering improved power output and efficiency. The first generation B58 engines featured a single twin-scroll turbocharger, direct fuel injection, and BMW's Valvetronic variable valve lift system. These early versions produced around 320 horsepower and 330 lb-ft of torque, marking a significant improvement over their predecessors.

As emissions regulations tightened and market demands evolved, BMW continued to refine the B58 engine. The second generation, introduced in 2019, saw several key improvements. These included an upgraded cooling system, redesigned pistons, and a more efficient turbocharger. The result was an increase in power output to approximately 380 horsepower in some applications, while simultaneously improving fuel economy and emissions performance.

The most recent evolution of the B58 engine has seen the introduction of mild hybrid technology. This system, which incorporates a 48-volt electrical system and an integrated starter-generator, allows for improved efficiency and performance. The mild hybrid system enables features such as energy recuperation during braking and smoother start-stop functionality, contributing to further reductions in fuel consumption and emissions.

One of the most significant developments in the B58 engine's evolution has been the exploration of dual-stage turbo systems. This technology, which combines a smaller turbocharger for low-end response with a larger turbocharger for high-end power, has shown promising results in enhancing overall engine performance. The dual-stage turbo system allows for improved low-end torque and reduced turbo lag, while still providing substantial top-end power.

The integration of advanced materials and manufacturing techniques has also played a crucial role in the B58's evolution. The use of lighter, more heat-resistant materials in key components has allowed for improved thermal management and increased durability. Additionally, precision manufacturing techniques have enabled tighter tolerances and more efficient operation, contributing to the engine's overall performance and reliability.

Looking forward, the B58 engine is likely to continue evolving to meet future challenges. Areas of focus may include further electrification, advanced combustion strategies, and the potential integration of sustainable fuels. As BMW and other manufacturers push towards increasingly stringent emissions targets, the B58 engine's adaptability and potential for improvement will be crucial in maintaining its relevance in the automotive landscape.

Market Demand Analysis

The market demand for dual-stage turbo systems in B58 engines has been steadily increasing, driven by the automotive industry's push for enhanced performance and fuel efficiency. This trend is particularly evident in the premium and high-performance vehicle segments, where consumers are increasingly seeking powerful yet efficient engines.

The B58 engine, primarily used in BMW vehicles, has gained significant popularity due to its robust performance and potential for tuning. The introduction of dual-stage turbo systems to this platform has further amplified market interest, as it addresses the inherent limitations of single-turbo setups, such as turbo lag and power delivery across a broader RPM range.

In recent years, stringent emissions regulations and the shift towards electrification have paradoxically increased demand for advanced internal combustion engine technologies. Dual-stage turbo systems offer a compelling solution by improving engine efficiency while maintaining or enhancing performance, thus extending the viability of internal combustion engines in an increasingly eco-conscious market.

The aftermarket tuning sector has shown particular enthusiasm for dual-stage turbo systems on B58 engines. This niche but influential market segment drives innovation and often serves as a precursor to wider adoption in production vehicles. The ability to significantly boost power output while maintaining drivability has made dual-stage turbo upgrades a sought-after modification among enthusiasts.

Original Equipment Manufacturers (OEMs) are also recognizing the potential of dual-stage turbo systems to meet both performance targets and emissions standards. This has led to increased research and development investments, with several manufacturers exploring the integration of such systems into their production models.

The commercial vehicle sector, although not the primary market for B58 engines, has shown interest in the technology's potential applications. The improved low-end torque and overall efficiency offered by dual-stage turbo systems align well with the demands of commercial transport, suggesting potential for market expansion beyond personal vehicles.

As the automotive industry continues to evolve, the market for dual-stage turbo systems in B58 engines is expected to grow. This growth is likely to be sustained by ongoing advancements in materials science and manufacturing techniques, which promise to make these systems more cost-effective and reliable for mass production.

The B58 engine, primarily used in BMW vehicles, has gained significant popularity due to its robust performance and potential for tuning. The introduction of dual-stage turbo systems to this platform has further amplified market interest, as it addresses the inherent limitations of single-turbo setups, such as turbo lag and power delivery across a broader RPM range.

In recent years, stringent emissions regulations and the shift towards electrification have paradoxically increased demand for advanced internal combustion engine technologies. Dual-stage turbo systems offer a compelling solution by improving engine efficiency while maintaining or enhancing performance, thus extending the viability of internal combustion engines in an increasingly eco-conscious market.

The aftermarket tuning sector has shown particular enthusiasm for dual-stage turbo systems on B58 engines. This niche but influential market segment drives innovation and often serves as a precursor to wider adoption in production vehicles. The ability to significantly boost power output while maintaining drivability has made dual-stage turbo upgrades a sought-after modification among enthusiasts.

Original Equipment Manufacturers (OEMs) are also recognizing the potential of dual-stage turbo systems to meet both performance targets and emissions standards. This has led to increased research and development investments, with several manufacturers exploring the integration of such systems into their production models.

The commercial vehicle sector, although not the primary market for B58 engines, has shown interest in the technology's potential applications. The improved low-end torque and overall efficiency offered by dual-stage turbo systems align well with the demands of commercial transport, suggesting potential for market expansion beyond personal vehicles.

As the automotive industry continues to evolve, the market for dual-stage turbo systems in B58 engines is expected to grow. This growth is likely to be sustained by ongoing advancements in materials science and manufacturing techniques, which promise to make these systems more cost-effective and reliable for mass production.

Turbo Tech Challenges

The implementation of dual-stage turbo systems in the B58 engine presents several significant technical challenges that require innovative solutions. One of the primary hurdles is the complex integration of two turbochargers operating in sequence, which demands precise control over boost pressure and exhaust gas flow management. Engineers must develop sophisticated algorithms and control systems to seamlessly transition between the smaller, quick-spooling turbo for low-end response and the larger turbo for high-end power.

Thermal management poses another critical challenge in dual-stage turbo setups. The compact engine bay of modern vehicles leaves limited space for heat dissipation, and the increased heat generated by two turbochargers exacerbates this issue. Developing efficient cooling solutions without compromising packaging or adding excessive weight is crucial for maintaining optimal performance and longevity of the B58 engine.

Material selection and durability present ongoing challenges in turbo technology. The high temperatures and pressures experienced in dual-stage systems push materials to their limits, requiring the use of advanced alloys and coatings to withstand the extreme conditions. Balancing cost-effectiveness with the need for high-performance materials remains a constant struggle for engineers working on these systems.

Minimizing turbo lag is a persistent challenge in dual-stage setups. While the smaller turbo helps improve low-end response, the transition to the larger turbo can still introduce a noticeable lag if not carefully managed. Engineers must fine-tune the turbo sizing, wastegate control, and variable geometry technologies to ensure smooth power delivery across the entire rev range.

Emissions compliance adds another layer of complexity to dual-stage turbo development. The increased boost pressure and higher combustion temperatures can lead to elevated NOx emissions, requiring advanced aftertreatment systems and precise engine calibration to meet stringent environmental regulations without sacrificing performance.

Packaging constraints present a significant hurdle in implementing dual-stage turbo systems. Fitting two turbochargers, along with the necessary plumbing, intercoolers, and control systems, into the limited engine bay space of modern vehicles requires innovative design solutions and careful consideration of component placement to maintain serviceability and thermal efficiency.

Lastly, cost management remains a persistent challenge in dual-stage turbo development. The additional components and complexity inherent in these systems increase production costs, which must be balanced against the performance gains to ensure market viability. Engineers must continuously seek ways to optimize designs and manufacturing processes to make dual-stage turbo systems more cost-effective for widespread adoption in the B58 engine platform.

Thermal management poses another critical challenge in dual-stage turbo setups. The compact engine bay of modern vehicles leaves limited space for heat dissipation, and the increased heat generated by two turbochargers exacerbates this issue. Developing efficient cooling solutions without compromising packaging or adding excessive weight is crucial for maintaining optimal performance and longevity of the B58 engine.

Material selection and durability present ongoing challenges in turbo technology. The high temperatures and pressures experienced in dual-stage systems push materials to their limits, requiring the use of advanced alloys and coatings to withstand the extreme conditions. Balancing cost-effectiveness with the need for high-performance materials remains a constant struggle for engineers working on these systems.

Minimizing turbo lag is a persistent challenge in dual-stage setups. While the smaller turbo helps improve low-end response, the transition to the larger turbo can still introduce a noticeable lag if not carefully managed. Engineers must fine-tune the turbo sizing, wastegate control, and variable geometry technologies to ensure smooth power delivery across the entire rev range.

Emissions compliance adds another layer of complexity to dual-stage turbo development. The increased boost pressure and higher combustion temperatures can lead to elevated NOx emissions, requiring advanced aftertreatment systems and precise engine calibration to meet stringent environmental regulations without sacrificing performance.

Packaging constraints present a significant hurdle in implementing dual-stage turbo systems. Fitting two turbochargers, along with the necessary plumbing, intercoolers, and control systems, into the limited engine bay space of modern vehicles requires innovative design solutions and careful consideration of component placement to maintain serviceability and thermal efficiency.

Lastly, cost management remains a persistent challenge in dual-stage turbo development. The additional components and complexity inherent in these systems increase production costs, which must be balanced against the performance gains to ensure market viability. Engineers must continuously seek ways to optimize designs and manufacturing processes to make dual-stage turbo systems more cost-effective for widespread adoption in the B58 engine platform.

Current Turbo Solutions

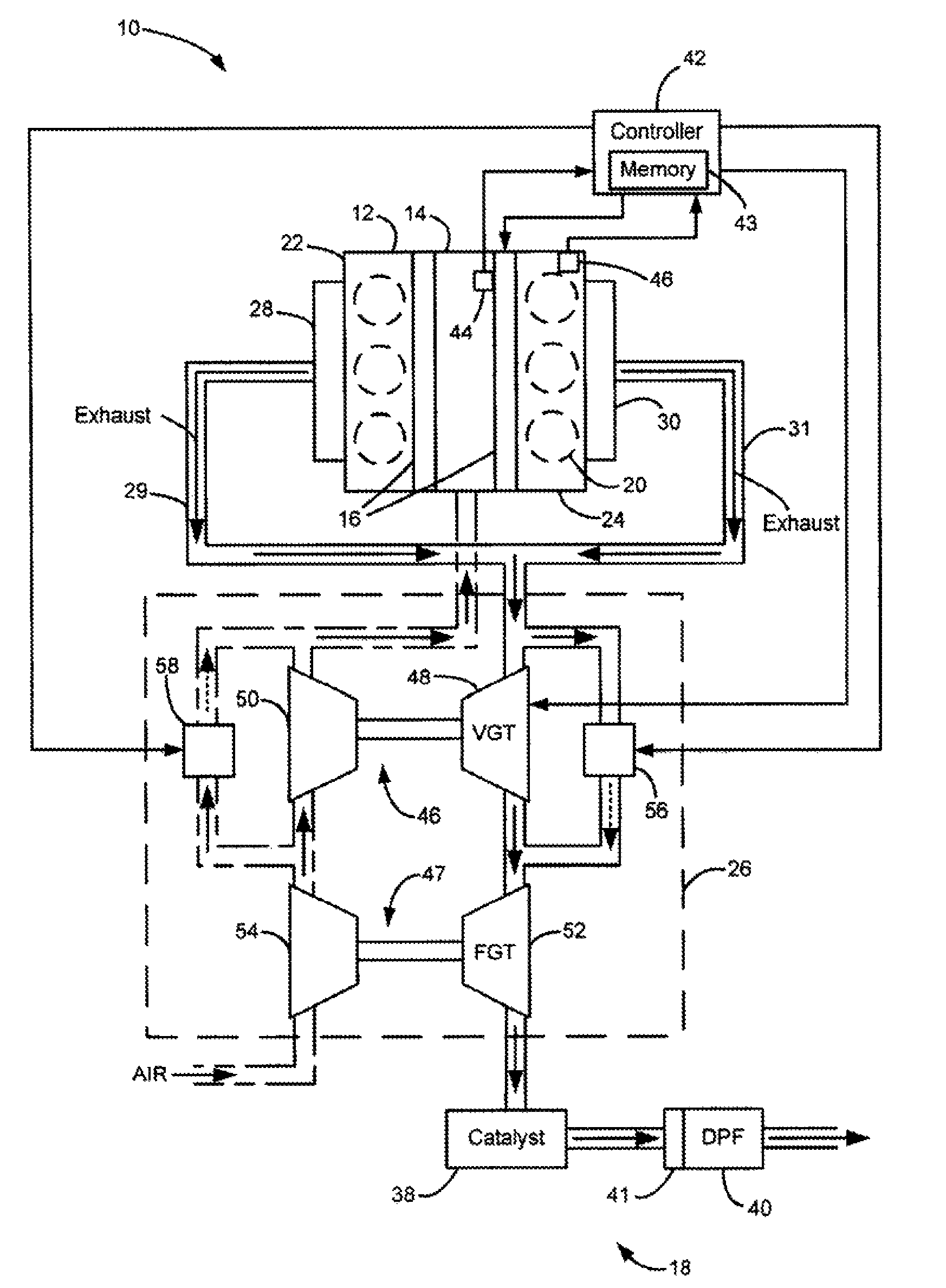

01 Turbocharger design and configuration

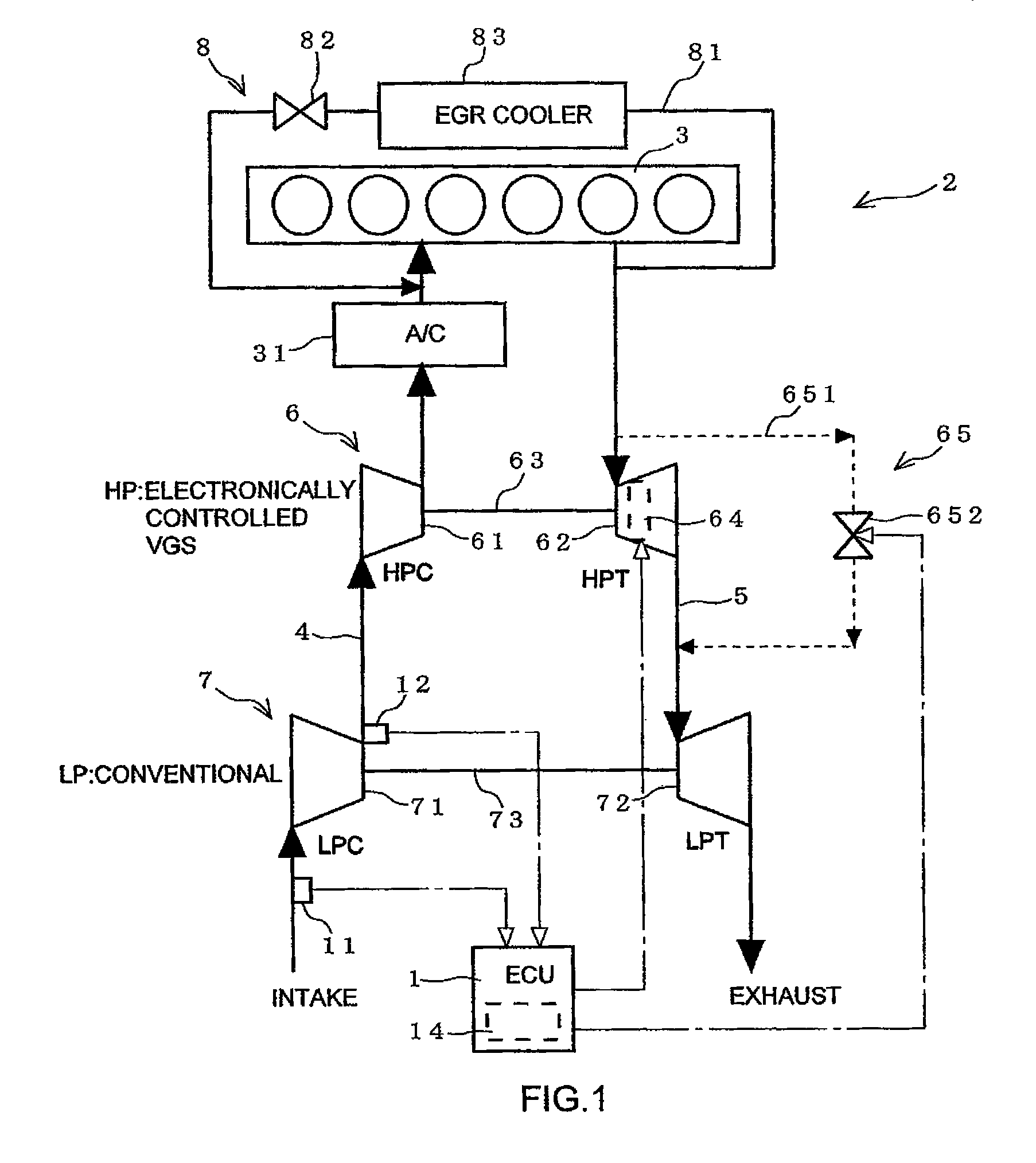

Dual-stage turbo systems involve specific designs and configurations to optimize performance. This includes arrangements of low-pressure and high-pressure turbos, intercoolers, and bypass valves to enhance engine efficiency and power output across various operating conditions.- Turbocharger configuration and control: Dual-stage turbo systems utilize two turbochargers arranged in series or parallel to enhance engine performance. Advanced control strategies are implemented to optimize the operation of both turbochargers, managing boost pressure and airflow for improved efficiency and power output across various engine operating conditions.

- Intercooling and charge air cooling: Intercoolers are integrated into dual-stage turbo systems to cool the compressed air between stages, increasing air density and reducing the risk of engine knock. This improves overall system efficiency and allows for higher boost pressures, resulting in increased power output and better fuel economy.

- Variable geometry turbochargers: Some dual-stage turbo systems incorporate variable geometry turbochargers, which can adjust their geometry to optimize performance across a wide range of engine speeds and loads. This technology enhances low-end torque, reduces turbo lag, and improves overall system responsiveness and efficiency.

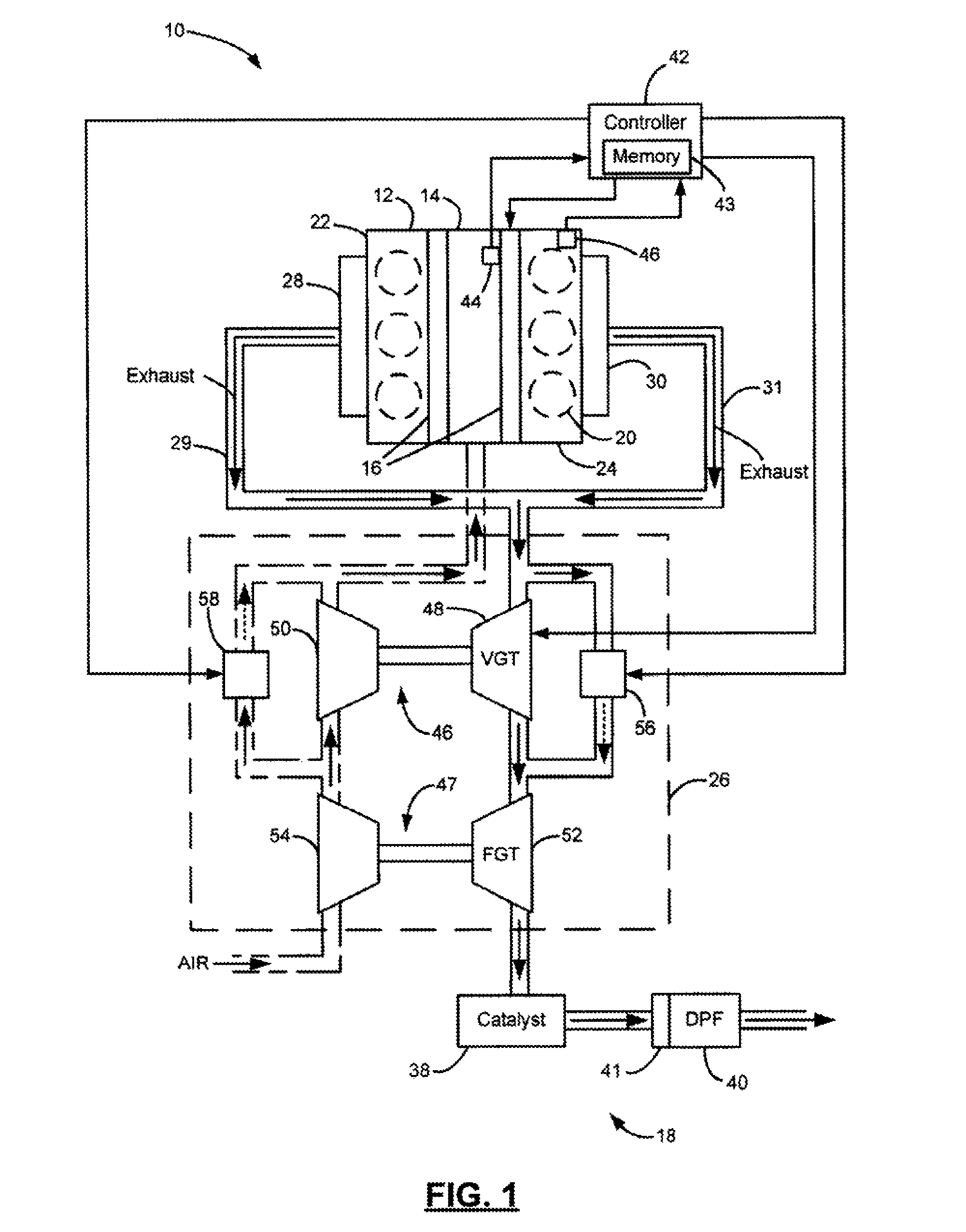

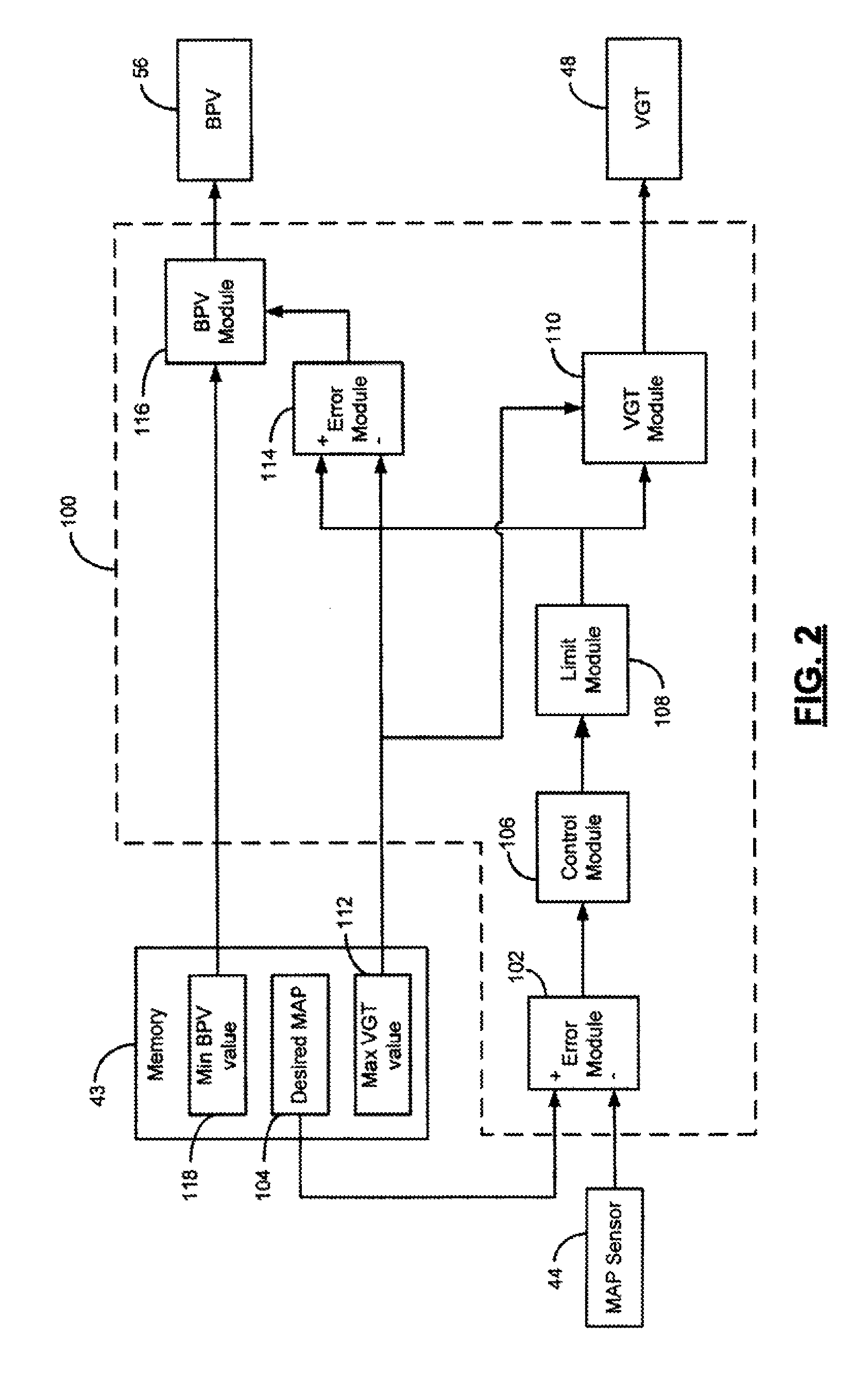

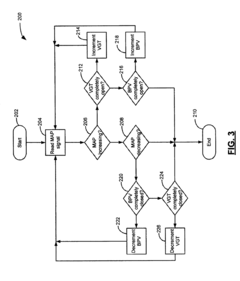

- Wastegate and bypass valve control: Precise control of wastegates and bypass valves in dual-stage turbo systems is crucial for managing boost pressure and preventing over-boosting. Advanced control algorithms are employed to regulate these components, ensuring optimal performance and protecting the engine from excessive pressure.

- Integration with engine management systems: Dual-stage turbo systems are closely integrated with engine management systems to optimize overall powertrain performance. This integration allows for real-time adjustments to turbocharger operation based on factors such as engine load, speed, and environmental conditions, resulting in improved fuel efficiency and emissions control.

02 Control strategies for dual-stage turbo systems

Advanced control strategies are crucial for managing dual-stage turbo systems. These may include electronic control units, sensors, and actuators to regulate boost pressure, airflow, and fuel injection timing. Such control systems optimize performance while maintaining engine reliability and efficiency.Expand Specific Solutions03 Performance enhancement techniques

Various techniques are employed to enhance the performance of dual-stage turbo systems. These may include variable geometry turbines, wastegate control, and advanced materials for turbine and compressor wheels. Such enhancements aim to improve throttle response, reduce turbo lag, and increase overall system efficiency.Expand Specific Solutions04 Integration with engine management systems

Effective integration of dual-stage turbo systems with engine management systems is crucial for optimizing performance. This involves coordinating turbocharger operation with fuel injection, ignition timing, and exhaust gas recirculation to achieve the desired power output while meeting emissions standards.Expand Specific Solutions05 Thermal management and efficiency improvements

Thermal management plays a significant role in dual-stage turbo system performance. This includes strategies for managing heat dissipation, reducing thermal stress on components, and improving overall system efficiency. Advanced cooling systems and heat-resistant materials may be employed to enhance durability and performance.Expand Specific Solutions

Key Industry Players

The dual-stage turbo system market for B58 engines is in a growth phase, with increasing demand driven by the automotive industry's focus on performance and efficiency. The market size is expanding as more manufacturers adopt this technology. Companies like BorgWarner, Mitsubishi Heavy Industries, and IHI Corporation are at the forefront, leveraging their extensive experience in turbocharger technology. BMW, as the primary user of B58 engines, collaborates closely with these suppliers. The technology is maturing rapidly, with continuous improvements in design and materials, leading to enhanced engine performance and fuel efficiency.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed advanced dual-stage turbo systems specifically tailored for B58 engine performance enhancement. Their solution incorporates a high-pressure turbocharger for quick low-end response and a larger low-pressure turbocharger for sustained high-end power[1]. The system utilizes variable geometry technology in the high-pressure stage, allowing for precise boost control across the entire engine speed range[3]. BorgWarner's dual-stage turbo system also integrates advanced materials such as titanium aluminide in the turbine wheels, enabling higher temperature operation and improved durability[5].

Strengths: Excellent low-end torque and high-end power, reduced turbo lag, and improved fuel efficiency. Weaknesses: Increased complexity and potential higher manufacturing costs.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a proprietary dual-stage turbocharging system for their version of the B58 engine, focusing on seamless power delivery and efficiency. Their approach utilizes a compact high-pressure turbo with variable turbine geometry for low-end responsiveness, combined with a larger low-pressure turbo for high-end power[7]. The system incorporates advanced bearing technology to reduce friction and improve turbo spool-up times[8]. Mercedes-Benz has also implemented a sophisticated electronic boost control system that optimizes the interaction between both turbochargers, ensuring smooth transitions and minimizing turbo lag[9].

Strengths: Smooth power delivery, reduced turbo lag, and improved overall efficiency. Weaknesses: Potentially higher complexity in control systems and maintenance requirements.

Core Turbo Innovations

Dual stage turbocharger control system

PatentActiveUS7735320B2

Innovation

- A control system that generates coordinated turbo and bypass control signals based on manifold absolute pressure and desired boost pressure, ensuring the VGT is in a predetermined position before the bypass valve opens, using a control module, VGT module, and bypass valve module to actuate the vanes and valve accordingly.

Control device for multi-stage turbochargers

PatentInactiveUS8176735B2

Innovation

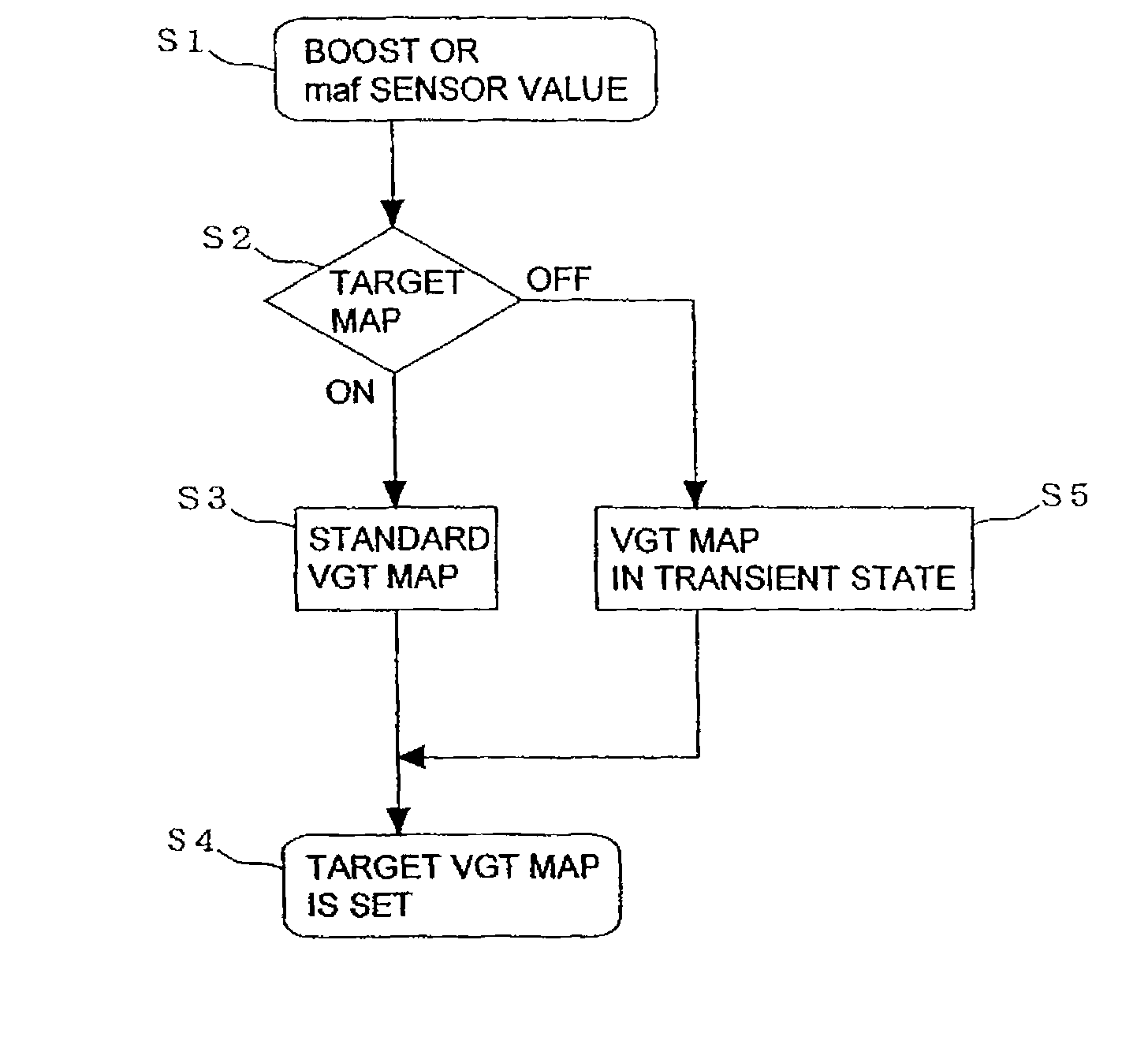

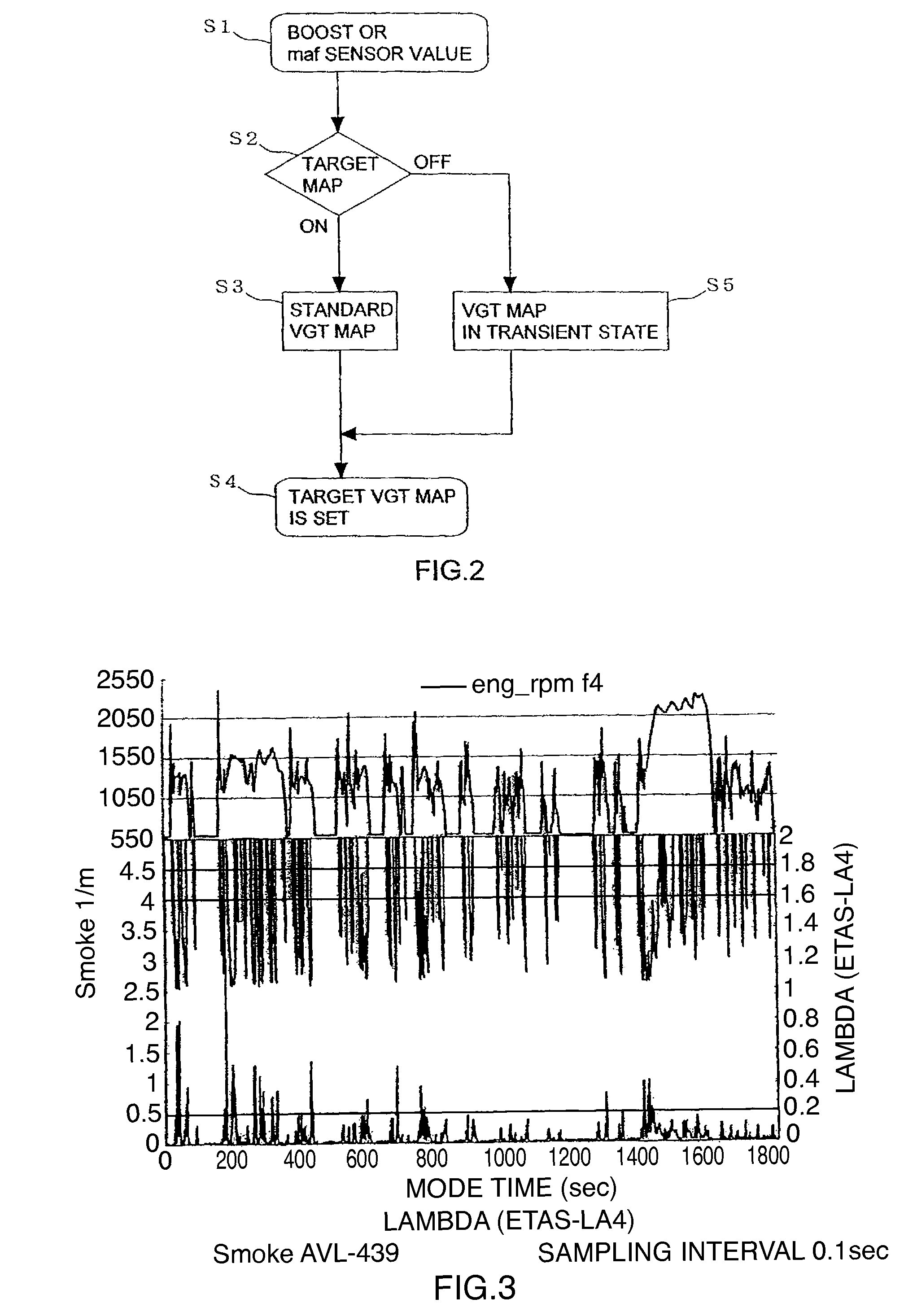

- A control device for multi-stage turbochargers that includes detection means for boost pressure or intake air amount, allowing the opening degree of the variable vane to be controlled based on specific maps for stationary and transient states, preventing unnecessary reduction in the opening degree during transient conditions.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of automotive technologies, including dual-stage turbo systems for the B58 engine. These regulations have become increasingly stringent over the years, driving manufacturers to innovate and adopt advanced technologies to meet the required standards.

In the context of the B58 engine and dual-stage turbo systems, emissions regulations have a significant impact on performance optimization. The primary focus of these regulations is to reduce harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). As a result, manufacturers must balance the pursuit of increased engine performance with the need to comply with these strict emissions standards.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations are among the most influential emissions frameworks affecting the automotive industry. These standards set specific limits on various pollutants and require manufacturers to implement advanced emission control technologies. For the B58 engine equipped with a dual-stage turbo system, this means integrating sophisticated exhaust gas recirculation (EGR) systems, selective catalytic reduction (SCR) technology, and particulate filters.

Dual-stage turbo systems offer potential advantages in meeting emissions regulations while maintaining or improving engine performance. By providing more precise control over boost pressure across a wider range of engine speeds, these systems can optimize combustion efficiency and reduce emissions. The ability to use a smaller turbocharger for low-end responsiveness and a larger one for high-end power allows for better overall engine management and potentially lower emissions throughout the operating range.

However, the implementation of dual-stage turbo systems must be carefully calibrated to ensure compliance with emissions regulations. This involves extensive testing and refinement of engine control strategies to optimize the interplay between the turbochargers, fuel injection, and exhaust aftertreatment systems. Manufacturers must also consider the impact of these systems on real-world driving conditions, as emissions testing procedures have evolved to include more representative driving cycles.

The challenge for engineers working on the B58 engine with dual-stage turbo systems is to leverage the technology's potential for improved performance while simultaneously meeting or exceeding emissions standards. This often requires a holistic approach to engine design, integrating advanced materials, precise manufacturing techniques, and sophisticated control algorithms to achieve the desired balance between power output and environmental compliance.

As emissions regulations continue to evolve, the development of dual-stage turbo systems for the B58 engine will likely focus on further refinements in efficiency and emissions reduction. This may include the integration of electrified components, such as electric compressors or mild hybrid systems, to complement the dual-stage turbo setup and provide additional emissions benefits. The ongoing push for cleaner vehicles will continue to drive innovation in this area, potentially leading to even more advanced turbocharging solutions in the future.

In the context of the B58 engine and dual-stage turbo systems, emissions regulations have a significant impact on performance optimization. The primary focus of these regulations is to reduce harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM). As a result, manufacturers must balance the pursuit of increased engine performance with the need to comply with these strict emissions standards.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations are among the most influential emissions frameworks affecting the automotive industry. These standards set specific limits on various pollutants and require manufacturers to implement advanced emission control technologies. For the B58 engine equipped with a dual-stage turbo system, this means integrating sophisticated exhaust gas recirculation (EGR) systems, selective catalytic reduction (SCR) technology, and particulate filters.

Dual-stage turbo systems offer potential advantages in meeting emissions regulations while maintaining or improving engine performance. By providing more precise control over boost pressure across a wider range of engine speeds, these systems can optimize combustion efficiency and reduce emissions. The ability to use a smaller turbocharger for low-end responsiveness and a larger one for high-end power allows for better overall engine management and potentially lower emissions throughout the operating range.

However, the implementation of dual-stage turbo systems must be carefully calibrated to ensure compliance with emissions regulations. This involves extensive testing and refinement of engine control strategies to optimize the interplay between the turbochargers, fuel injection, and exhaust aftertreatment systems. Manufacturers must also consider the impact of these systems on real-world driving conditions, as emissions testing procedures have evolved to include more representative driving cycles.

The challenge for engineers working on the B58 engine with dual-stage turbo systems is to leverage the technology's potential for improved performance while simultaneously meeting or exceeding emissions standards. This often requires a holistic approach to engine design, integrating advanced materials, precise manufacturing techniques, and sophisticated control algorithms to achieve the desired balance between power output and environmental compliance.

As emissions regulations continue to evolve, the development of dual-stage turbo systems for the B58 engine will likely focus on further refinements in efficiency and emissions reduction. This may include the integration of electrified components, such as electric compressors or mild hybrid systems, to complement the dual-stage turbo setup and provide additional emissions benefits. The ongoing push for cleaner vehicles will continue to drive innovation in this area, potentially leading to even more advanced turbocharging solutions in the future.

Thermal Management

Thermal management plays a crucial role in optimizing the performance of dual-stage turbo systems on B58 engines. The increased heat generation from the twin-turbocharger setup necessitates advanced cooling strategies to maintain engine efficiency and longevity. One of the primary challenges is managing the heat produced by the turbos themselves, as well as the compressed air they generate.

To address these thermal challenges, engineers have implemented several innovative solutions. Intercoolers are extensively used to cool the compressed air before it enters the engine, reducing intake temperatures and improving overall engine efficiency. These intercoolers are often larger and more efficient in dual-stage turbo systems compared to single-turbo setups, to cope with the increased heat load.

Water-to-air charge cooling systems have gained popularity in recent B58 engine designs with dual-stage turbos. These systems offer more consistent cooling performance across various operating conditions compared to traditional air-to-air intercoolers. By circulating coolant through a dedicated radiator, they can maintain lower intake temperatures even under high-load scenarios.

The placement of turbos in the engine bay is another critical aspect of thermal management. Engineers often position the turbos as close to the exhaust manifold as possible to reduce heat loss and improve response times. However, this proximity to other engine components requires careful insulation and heat shielding to prevent thermal soak and protect sensitive electronics.

Oil cooling systems have also been enhanced to cope with the increased thermal stress on dual-stage turbo B58 engines. Larger oil coolers and improved oil circulation pathways help maintain optimal oil temperatures, crucial for turbocharger longevity and performance. Some advanced systems incorporate thermostat-controlled oil cooling, allowing for quicker warm-up times while still providing adequate cooling during high-performance driving.

Electronic water pumps and advanced coolant flow management systems are increasingly common in these engines. These allow for precise control of coolant flow rates and temperatures across different engine components, optimizing thermal efficiency and reducing parasitic losses associated with traditional mechanical pumps.

Exhaust gas recirculation (EGR) systems in dual-stage turbo B58 engines also play a role in thermal management. By recirculating a portion of exhaust gases back into the intake, EGR systems can help control combustion temperatures, reducing the overall thermal load on the engine and emissions control systems.

As dual-stage turbo systems continue to evolve, emerging technologies such as electric turbochargers and advanced materials like ceramic turbine wheels are being explored. These innovations promise to further improve thermal efficiency and reduce the challenges associated with heat management in high-performance turbocharged engines.

To address these thermal challenges, engineers have implemented several innovative solutions. Intercoolers are extensively used to cool the compressed air before it enters the engine, reducing intake temperatures and improving overall engine efficiency. These intercoolers are often larger and more efficient in dual-stage turbo systems compared to single-turbo setups, to cope with the increased heat load.

Water-to-air charge cooling systems have gained popularity in recent B58 engine designs with dual-stage turbos. These systems offer more consistent cooling performance across various operating conditions compared to traditional air-to-air intercoolers. By circulating coolant through a dedicated radiator, they can maintain lower intake temperatures even under high-load scenarios.

The placement of turbos in the engine bay is another critical aspect of thermal management. Engineers often position the turbos as close to the exhaust manifold as possible to reduce heat loss and improve response times. However, this proximity to other engine components requires careful insulation and heat shielding to prevent thermal soak and protect sensitive electronics.

Oil cooling systems have also been enhanced to cope with the increased thermal stress on dual-stage turbo B58 engines. Larger oil coolers and improved oil circulation pathways help maintain optimal oil temperatures, crucial for turbocharger longevity and performance. Some advanced systems incorporate thermostat-controlled oil cooling, allowing for quicker warm-up times while still providing adequate cooling during high-performance driving.

Electronic water pumps and advanced coolant flow management systems are increasingly common in these engines. These allow for precise control of coolant flow rates and temperatures across different engine components, optimizing thermal efficiency and reducing parasitic losses associated with traditional mechanical pumps.

Exhaust gas recirculation (EGR) systems in dual-stage turbo B58 engines also play a role in thermal management. By recirculating a portion of exhaust gases back into the intake, EGR systems can help control combustion temperatures, reducing the overall thermal load on the engine and emissions control systems.

As dual-stage turbo systems continue to evolve, emerging technologies such as electric turbochargers and advanced materials like ceramic turbine wheels are being explored. These innovations promise to further improve thermal efficiency and reduce the challenges associated with heat management in high-performance turbocharged engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!