The Role of Flywheel Design in LS Engine Dynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Flywheel Evolution

The evolution of flywheel design in LS engines has been a critical factor in enhancing engine dynamics and overall performance. Initially, LS engine flywheels were primarily designed for durability and basic functionality, with less emphasis on optimizing engine dynamics. These early designs were typically heavy, single-mass flywheels made of cast iron, which provided adequate inertia for engine starting and smooth idling but limited high-rpm performance.

As LS engines gained popularity and were increasingly used in high-performance applications, flywheel design underwent significant changes. The introduction of lightweight steel and aluminum flywheels marked a turning point in LS engine dynamics. These materials allowed for reduced rotational mass, resulting in quicker engine response and improved acceleration. The reduced weight also contributed to lower overall vehicle weight, further enhancing performance characteristics.

Dual-mass flywheels emerged as a notable innovation in LS engine flywheel evolution. This design incorporated two separate masses connected by a spring damping system, effectively isolating the engine's torsional vibrations from the transmission. Dual-mass flywheels significantly improved NVH (Noise, Vibration, and Harshness) characteristics, particularly in high-torque LS applications, while maintaining smooth power delivery.

The advent of computer-aided design and advanced manufacturing techniques enabled more precise flywheel balancing and optimized moment of inertia. Engineers could now fine-tune flywheel designs to match specific engine configurations and performance goals. This led to the development of application-specific flywheels, tailored for drag racing, road racing, or street performance, each optimized for its intended use case.

Recent advancements in flywheel technology for LS engines have focused on integrating additional functionalities. Some modern designs incorporate integral ring gears for improved starter engagement reliability. Others feature built-in counterweights or unique mass distribution patterns to complement engine balance and reduce harmonic vibrations. These innovations not only enhance engine dynamics but also contribute to improved durability and longevity of LS powerplants.

The trend towards hybrid and electric vehicle technologies has also influenced LS engine flywheel design. Some experimental setups have explored the use of high-inertia flywheels as energy storage devices, capable of capturing and releasing kinetic energy to supplement engine power output. While not yet mainstream in LS applications, this concept demonstrates the ongoing evolution and potential future directions of flywheel technology in engine dynamics.

As LS engines gained popularity and were increasingly used in high-performance applications, flywheel design underwent significant changes. The introduction of lightweight steel and aluminum flywheels marked a turning point in LS engine dynamics. These materials allowed for reduced rotational mass, resulting in quicker engine response and improved acceleration. The reduced weight also contributed to lower overall vehicle weight, further enhancing performance characteristics.

Dual-mass flywheels emerged as a notable innovation in LS engine flywheel evolution. This design incorporated two separate masses connected by a spring damping system, effectively isolating the engine's torsional vibrations from the transmission. Dual-mass flywheels significantly improved NVH (Noise, Vibration, and Harshness) characteristics, particularly in high-torque LS applications, while maintaining smooth power delivery.

The advent of computer-aided design and advanced manufacturing techniques enabled more precise flywheel balancing and optimized moment of inertia. Engineers could now fine-tune flywheel designs to match specific engine configurations and performance goals. This led to the development of application-specific flywheels, tailored for drag racing, road racing, or street performance, each optimized for its intended use case.

Recent advancements in flywheel technology for LS engines have focused on integrating additional functionalities. Some modern designs incorporate integral ring gears for improved starter engagement reliability. Others feature built-in counterweights or unique mass distribution patterns to complement engine balance and reduce harmonic vibrations. These innovations not only enhance engine dynamics but also contribute to improved durability and longevity of LS powerplants.

The trend towards hybrid and electric vehicle technologies has also influenced LS engine flywheel design. Some experimental setups have explored the use of high-inertia flywheels as energy storage devices, capable of capturing and releasing kinetic energy to supplement engine power output. While not yet mainstream in LS applications, this concept demonstrates the ongoing evolution and potential future directions of flywheel technology in engine dynamics.

Market Demand Analysis

The market demand for advanced flywheel designs in LS engine dynamics has been steadily increasing, driven by the automotive industry's push for improved performance, fuel efficiency, and emissions reduction. As vehicle manufacturers strive to meet stringent regulatory standards while satisfying consumer expectations for power and responsiveness, the role of flywheels in engine dynamics has gained significant attention.

In the performance automotive sector, there is a growing demand for lightweight flywheels that can enhance engine acceleration and responsiveness. This trend is particularly evident in sports cars and high-performance vehicles, where every fraction of a second in acceleration can make a difference. The market for aftermarket performance flywheels has seen substantial growth, with enthusiasts and racers seeking to optimize their LS-powered vehicles.

Conversely, in the commercial and heavy-duty vehicle segment, there is an increasing focus on flywheels that can improve fuel efficiency and reduce emissions. Fleet operators and truck manufacturers are looking for flywheel designs that can effectively manage engine load fluctuations and contribute to overall powertrain efficiency. This demand is driven by the need to reduce operating costs and comply with tightening emissions regulations.

The automotive industry's shift towards hybridization and electrification has also created new opportunities for flywheel technology. Hybrid vehicles often utilize flywheels as part of their energy recovery systems, storing kinetic energy during braking and releasing it during acceleration. This application has opened up a new market segment for advanced flywheel designs that can efficiently capture and release energy.

In the industrial sector, there is a growing interest in flywheel energy storage systems for power management and grid stabilization. While not directly related to LS engine dynamics, this trend demonstrates the broader market potential for innovative flywheel technologies across various applications.

The global market for engine components, including flywheels, is projected to grow significantly in the coming years. This growth is attributed to the increasing production of vehicles worldwide, particularly in emerging markets, and the continuous technological advancements in engine design.

However, the market demand for advanced flywheel designs is not without challenges. The push for electric vehicles in some regions may impact the long-term growth prospects for traditional engine components. Additionally, the complexity and cost associated with high-performance flywheel designs can limit their adoption in mass-market vehicles.

Despite these challenges, the overall market trend indicates a strong demand for innovative flywheel solutions that can contribute to improved engine dynamics, efficiency, and performance across various vehicle categories. This demand is likely to drive continued research and development in flywheel technology for LS engines and beyond.

In the performance automotive sector, there is a growing demand for lightweight flywheels that can enhance engine acceleration and responsiveness. This trend is particularly evident in sports cars and high-performance vehicles, where every fraction of a second in acceleration can make a difference. The market for aftermarket performance flywheels has seen substantial growth, with enthusiasts and racers seeking to optimize their LS-powered vehicles.

Conversely, in the commercial and heavy-duty vehicle segment, there is an increasing focus on flywheels that can improve fuel efficiency and reduce emissions. Fleet operators and truck manufacturers are looking for flywheel designs that can effectively manage engine load fluctuations and contribute to overall powertrain efficiency. This demand is driven by the need to reduce operating costs and comply with tightening emissions regulations.

The automotive industry's shift towards hybridization and electrification has also created new opportunities for flywheel technology. Hybrid vehicles often utilize flywheels as part of their energy recovery systems, storing kinetic energy during braking and releasing it during acceleration. This application has opened up a new market segment for advanced flywheel designs that can efficiently capture and release energy.

In the industrial sector, there is a growing interest in flywheel energy storage systems for power management and grid stabilization. While not directly related to LS engine dynamics, this trend demonstrates the broader market potential for innovative flywheel technologies across various applications.

The global market for engine components, including flywheels, is projected to grow significantly in the coming years. This growth is attributed to the increasing production of vehicles worldwide, particularly in emerging markets, and the continuous technological advancements in engine design.

However, the market demand for advanced flywheel designs is not without challenges. The push for electric vehicles in some regions may impact the long-term growth prospects for traditional engine components. Additionally, the complexity and cost associated with high-performance flywheel designs can limit their adoption in mass-market vehicles.

Despite these challenges, the overall market trend indicates a strong demand for innovative flywheel solutions that can contribute to improved engine dynamics, efficiency, and performance across various vehicle categories. This demand is likely to drive continued research and development in flywheel technology for LS engines and beyond.

Flywheel Design Challenges

Flywheel design in LS engine dynamics presents several significant challenges that engineers must address to optimize engine performance and efficiency. One of the primary challenges is balancing the trade-off between rotational inertia and engine responsiveness. A heavier flywheel provides more inertia, which can help smooth out power delivery and reduce engine vibration. However, it also increases the engine's rotational mass, potentially reducing acceleration and overall responsiveness.

Material selection is another critical challenge in flywheel design. Engineers must choose materials that can withstand the high rotational speeds and temperatures encountered in LS engines while maintaining structural integrity. Traditional cast iron flywheels are robust but heavy, while lightweight alternatives like aluminum or composite materials offer reduced weight but may have durability concerns or higher production costs.

The interface between the flywheel and the crankshaft presents additional design challenges. Ensuring a secure and precise fit is crucial to prevent misalignment, which can lead to vibration, premature wear, and potential failure. Engineers must also consider the flywheel's role in heat dissipation, as it can absorb and dissipate heat generated during clutch engagement in manual transmission applications.

Balancing the flywheel is a complex task that directly impacts engine smoothness and longevity. Improper balancing can lead to vibrations, increased wear on bearings and other components, and reduced engine efficiency. The challenge lies in achieving precise balance while accounting for manufacturing tolerances and potential material inconsistencies.

For high-performance LS engine applications, designers must also consider the flywheel's impact on redline and over-rev protection. The flywheel's design can influence the engine's ability to reach higher RPMs safely, and engineers must carefully calculate the stress limits to prevent catastrophic failure at extreme speeds.

Noise, vibration, and harshness (NVH) considerations add another layer of complexity to flywheel design. The flywheel plays a crucial role in dampening torsional vibrations from the crankshaft, and its design must be optimized to reduce engine noise and improve overall driving comfort without compromising performance.

Lastly, manufacturability and cost-effectiveness pose significant challenges. Designers must develop flywheel designs that can be produced efficiently and economically while meeting all performance and safety requirements. This often involves balancing advanced materials and manufacturing techniques with practical production constraints.

Material selection is another critical challenge in flywheel design. Engineers must choose materials that can withstand the high rotational speeds and temperatures encountered in LS engines while maintaining structural integrity. Traditional cast iron flywheels are robust but heavy, while lightweight alternatives like aluminum or composite materials offer reduced weight but may have durability concerns or higher production costs.

The interface between the flywheel and the crankshaft presents additional design challenges. Ensuring a secure and precise fit is crucial to prevent misalignment, which can lead to vibration, premature wear, and potential failure. Engineers must also consider the flywheel's role in heat dissipation, as it can absorb and dissipate heat generated during clutch engagement in manual transmission applications.

Balancing the flywheel is a complex task that directly impacts engine smoothness and longevity. Improper balancing can lead to vibrations, increased wear on bearings and other components, and reduced engine efficiency. The challenge lies in achieving precise balance while accounting for manufacturing tolerances and potential material inconsistencies.

For high-performance LS engine applications, designers must also consider the flywheel's impact on redline and over-rev protection. The flywheel's design can influence the engine's ability to reach higher RPMs safely, and engineers must carefully calculate the stress limits to prevent catastrophic failure at extreme speeds.

Noise, vibration, and harshness (NVH) considerations add another layer of complexity to flywheel design. The flywheel plays a crucial role in dampening torsional vibrations from the crankshaft, and its design must be optimized to reduce engine noise and improve overall driving comfort without compromising performance.

Lastly, manufacturability and cost-effectiveness pose significant challenges. Designers must develop flywheel designs that can be produced efficiently and economically while meeting all performance and safety requirements. This often involves balancing advanced materials and manufacturing techniques with practical production constraints.

Current Flywheel Solutions

01 Flywheel design and configuration

Various designs and configurations of flywheels are used in engine dynamics to improve energy storage and power delivery. These include innovations in flywheel shape, material composition, and integration with other engine components to optimize performance and efficiency.- Flywheel design and configuration: Various designs and configurations of flywheels are used in engine dynamics to improve energy storage and power delivery. These designs may include different materials, shapes, and sizes to optimize performance and efficiency. Some configurations focus on reducing weight while maintaining inertia, while others aim to enhance durability and longevity.

- Flywheel energy storage systems: Flywheel energy storage systems are utilized to capture and store kinetic energy in engine applications. These systems can help improve fuel efficiency, reduce emissions, and provide additional power during acceleration. Advanced designs may incorporate regenerative braking and hybrid power systems to maximize energy recovery and utilization.

- Flywheel balancing and vibration control: Techniques for balancing flywheels and controlling vibrations are crucial for engine dynamics. This includes methods for reducing harmonic vibrations, minimizing imbalance, and improving overall engine stability. Advanced balancing techniques may involve dynamic balancing, active vibration control, and the use of specialized materials to dampen unwanted oscillations.

- Flywheel integration with transmission systems: The integration of flywheels with transmission systems plays a significant role in engine dynamics. This includes designs for clutch mechanisms, dual-mass flywheels, and continuously variable transmissions (CVTs) that utilize flywheel technology. These integrations aim to improve power transfer, reduce driveline vibrations, and enhance overall vehicle performance.

- Flywheel-based engine starting systems: Flywheel-based engine starting systems utilize the stored kinetic energy in the flywheel to initiate engine rotation. These systems can provide faster and more efficient engine starts, reduce wear on traditional starting components, and improve cold-start performance. Some designs incorporate advanced materials and energy recovery mechanisms to enhance starting reliability and reduce energy consumption.

02 Vibration damping and balancing

Techniques for reducing vibrations and improving engine balance through flywheel design. This includes the use of specialized materials, damping mechanisms, and balanced weight distribution to minimize unwanted oscillations and enhance overall engine stability.Expand Specific Solutions03 Energy recovery and storage systems

Innovative flywheel-based systems for recovering and storing kinetic energy in engines. These systems capture energy during deceleration or braking and store it in the flywheel for later use, improving overall engine efficiency and performance.Expand Specific Solutions04 Flywheel-integrated transmission systems

Advanced transmission systems that incorporate flywheels to enhance power transfer and improve gear shifting. These designs aim to optimize the interaction between the flywheel and transmission components for smoother operation and increased efficiency.Expand Specific Solutions05 Flywheel control and monitoring

Systems and methods for precise control and monitoring of flywheel dynamics in engines. This includes electronic control units, sensors, and algorithms that manage flywheel speed, energy storage, and power output to optimize engine performance under various operating conditions.Expand Specific Solutions

Key LS Engine Manufacturers

The flywheel design in LS engine dynamics represents a mature technology within the automotive industry, with the market in a consolidation phase. Major players like General Motors, Ford, and Toyota have established strong positions, leveraging their extensive R&D capabilities and manufacturing expertise. The global market size for automotive flywheels is substantial, driven by the widespread use of LS engines in various vehicle segments. Companies such as Aisin KK, Schaeffler Technologies, and Valeo Otomotiv have also made significant contributions to flywheel technology advancements, focusing on performance optimization and weight reduction. As the industry moves towards electrification, traditional flywheel designs are evolving, with companies like Honda and Nissan exploring hybrid and electric powertrain applications.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed an advanced flywheel system for LS engines that incorporates their patented pendulum-type absorber technology. This design features a set of pendulum masses integrated into the flywheel structure, which oscillate to counteract torsional vibrations across a wide range of engine speeds[13]. The flywheel also utilizes a dual-mass configuration with optimized spring rates and friction elements to further enhance vibration damping. Schaeffler's design incorporates lightweight materials such as high-strength aluminum alloys and advanced steel compositions to reduce overall mass[14]. The company has also implemented a specialized coating on the flywheel's friction surface to improve wear resistance and clutch engagement characteristics[15].

Strengths: Exceptional vibration damping across a wide RPM range, reduced weight, and improved NVH characteristics. Weaknesses: Higher production costs and increased complexity compared to traditional flywheel designs.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a high-performance flywheel design for LS engines that focuses on weight reduction and improved engine response. Their design utilizes a hybrid construction method, combining a lightweight aluminum core with a steel outer ring for optimal strength and inertia characteristics[10]. The flywheel incorporates a series of strategically placed holes and slots to further reduce mass while maintaining structural integrity. Honda's design also features an integrated dual-mass damper system to minimize torsional vibrations and improve NVH performance[11]. The company has implemented a proprietary surface treatment on the flywheel's friction surface to enhance durability and clutch engagement smoothness[12].

Strengths: Excellent weight reduction, improved engine responsiveness, and effective vibration damping. Weaknesses: Potential higher manufacturing costs and complexity in production.

Innovative Flywheel Patents

Acceleration flywheel

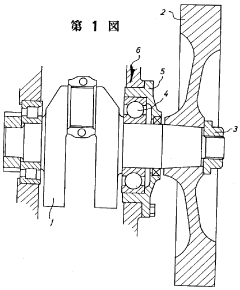

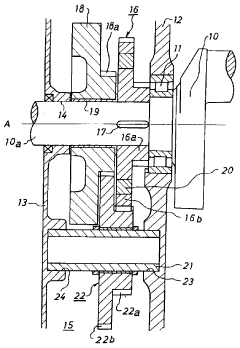

PatentInactiveJP1984017041A

Innovation

- A flywheel design where the flywheel and crankshaft are separately formed, with a gear case incorporating a rubber-like elastic body to absorb twisting forces, allowing for increased speed and compactness by using a gear system with a damper to manage torque variations and prevent gear breakage, while maintaining durability through appropriate gear ratios and a lightweight construction.

Material Science Advancements

Material science advancements have played a crucial role in enhancing the performance and efficiency of flywheel designs in LS engine dynamics. The development of new materials and manufacturing techniques has led to significant improvements in flywheel characteristics, directly impacting engine performance and reliability.

One of the most notable advancements in material science for flywheel design is the introduction of high-strength, lightweight alloys. These materials, such as titanium alloys and advanced steel composites, offer superior strength-to-weight ratios compared to traditional cast iron flywheels. This reduction in mass allows for faster engine response and improved fuel efficiency, as the engine requires less energy to accelerate and decelerate the flywheel.

Composite materials have also emerged as a promising option for flywheel construction. Carbon fiber reinforced polymers (CFRP) and other advanced composites offer exceptional strength and stiffness while maintaining an extremely low weight. These materials allow for the creation of flywheels with higher rotational speeds and energy storage capacities, potentially revolutionizing the way energy is managed within LS engines.

Surface treatment technologies have advanced significantly, enabling the development of more durable and wear-resistant flywheel surfaces. Techniques such as plasma nitriding and diamond-like carbon (DLC) coatings have been applied to flywheel friction surfaces, resulting in improved clutch engagement characteristics and extended component lifespan.

Nanotechnology has also made its way into flywheel design, with nanomaterials being incorporated to enhance specific properties. For example, carbon nanotubes can be used to reinforce traditional materials, improving their strength and heat dissipation capabilities without significantly increasing weight.

Advancements in metallurgy have led to the development of new alloys specifically tailored for flywheel applications. These alloys offer improved thermal stability, reducing the risk of warping or deformation under high-stress conditions. This enhanced stability contributes to more consistent engine performance and improved longevity of the flywheel and related components.

The integration of smart materials into flywheel design is an emerging trend with significant potential. Materials with shape memory or piezoelectric properties could be used to create adaptive flywheels that can adjust their characteristics in real-time based on engine operating conditions, further optimizing performance across various driving scenarios.

These material science advancements have not only improved the performance characteristics of flywheels but have also contributed to increased safety in high-performance applications. The ability to create stronger, more resilient flywheels has reduced the risk of catastrophic failure under extreme conditions, making LS engines safer for both street and racing applications.

One of the most notable advancements in material science for flywheel design is the introduction of high-strength, lightweight alloys. These materials, such as titanium alloys and advanced steel composites, offer superior strength-to-weight ratios compared to traditional cast iron flywheels. This reduction in mass allows for faster engine response and improved fuel efficiency, as the engine requires less energy to accelerate and decelerate the flywheel.

Composite materials have also emerged as a promising option for flywheel construction. Carbon fiber reinforced polymers (CFRP) and other advanced composites offer exceptional strength and stiffness while maintaining an extremely low weight. These materials allow for the creation of flywheels with higher rotational speeds and energy storage capacities, potentially revolutionizing the way energy is managed within LS engines.

Surface treatment technologies have advanced significantly, enabling the development of more durable and wear-resistant flywheel surfaces. Techniques such as plasma nitriding and diamond-like carbon (DLC) coatings have been applied to flywheel friction surfaces, resulting in improved clutch engagement characteristics and extended component lifespan.

Nanotechnology has also made its way into flywheel design, with nanomaterials being incorporated to enhance specific properties. For example, carbon nanotubes can be used to reinforce traditional materials, improving their strength and heat dissipation capabilities without significantly increasing weight.

Advancements in metallurgy have led to the development of new alloys specifically tailored for flywheel applications. These alloys offer improved thermal stability, reducing the risk of warping or deformation under high-stress conditions. This enhanced stability contributes to more consistent engine performance and improved longevity of the flywheel and related components.

The integration of smart materials into flywheel design is an emerging trend with significant potential. Materials with shape memory or piezoelectric properties could be used to create adaptive flywheels that can adjust their characteristics in real-time based on engine operating conditions, further optimizing performance across various driving scenarios.

These material science advancements have not only improved the performance characteristics of flywheels but have also contributed to increased safety in high-performance applications. The ability to create stronger, more resilient flywheels has reduced the risk of catastrophic failure under extreme conditions, making LS engines safer for both street and racing applications.

Environmental Impact Assessment

The environmental impact of flywheel design in LS engine dynamics is a critical consideration in the automotive industry's pursuit of sustainable technologies. Flywheels, as energy storage devices, play a significant role in engine performance and efficiency, which directly influences fuel consumption and emissions. The design of flywheels can affect the overall environmental footprint of LS engines in several ways.

Firstly, the weight and material composition of flywheels have implications for vehicle fuel efficiency. Lighter flywheels can contribute to reduced overall vehicle weight, potentially leading to improved fuel economy and lower greenhouse gas emissions. However, the material selection process must balance performance requirements with environmental considerations, as some high-performance materials may have higher environmental costs in production or end-of-life disposal.

The rotational dynamics of flywheels also impact engine efficiency. Optimized flywheel designs can enhance engine smoothness and reduce vibrations, potentially extending engine life and reducing the need for premature replacements. This longevity factor contributes to resource conservation and waste reduction in the long term.

Furthermore, the role of flywheels in energy recovery systems, such as regenerative braking, presents opportunities for environmental benefits. By capturing and storing kinetic energy that would otherwise be lost as heat during braking, flywheels can contribute to improved overall vehicle efficiency, particularly in urban driving conditions with frequent stops and starts.

The manufacturing processes involved in flywheel production also warrant environmental scrutiny. Advanced manufacturing techniques, such as precision machining and balancing, may require significant energy inputs. However, these processes can also lead to flywheels with superior performance characteristics, potentially offsetting the initial environmental costs through improved engine efficiency over the vehicle's lifetime.

Noise pollution is another environmental aspect influenced by flywheel design. Well-designed flywheels can contribute to quieter engine operation, reducing noise pollution in urban environments. This is particularly relevant as cities worldwide implement stricter noise regulations to improve quality of life.

End-of-life considerations for flywheels are also crucial in assessing their overall environmental impact. The recyclability of materials used in flywheel construction, as well as the ease of disassembly and separation of components, can significantly affect the environmental footprint of LS engines at the end of their service life.

In conclusion, the environmental impact assessment of flywheel design in LS engine dynamics reveals a complex interplay of factors. While flywheels offer potential benefits in terms of energy efficiency and performance, their design must be approached holistically, considering the entire lifecycle from material sourcing to end-of-life disposal. As automotive technologies continue to evolve, integrating environmental considerations into flywheel design will be crucial for developing more sustainable LS engine systems.

Firstly, the weight and material composition of flywheels have implications for vehicle fuel efficiency. Lighter flywheels can contribute to reduced overall vehicle weight, potentially leading to improved fuel economy and lower greenhouse gas emissions. However, the material selection process must balance performance requirements with environmental considerations, as some high-performance materials may have higher environmental costs in production or end-of-life disposal.

The rotational dynamics of flywheels also impact engine efficiency. Optimized flywheel designs can enhance engine smoothness and reduce vibrations, potentially extending engine life and reducing the need for premature replacements. This longevity factor contributes to resource conservation and waste reduction in the long term.

Furthermore, the role of flywheels in energy recovery systems, such as regenerative braking, presents opportunities for environmental benefits. By capturing and storing kinetic energy that would otherwise be lost as heat during braking, flywheels can contribute to improved overall vehicle efficiency, particularly in urban driving conditions with frequent stops and starts.

The manufacturing processes involved in flywheel production also warrant environmental scrutiny. Advanced manufacturing techniques, such as precision machining and balancing, may require significant energy inputs. However, these processes can also lead to flywheels with superior performance characteristics, potentially offsetting the initial environmental costs through improved engine efficiency over the vehicle's lifetime.

Noise pollution is another environmental aspect influenced by flywheel design. Well-designed flywheels can contribute to quieter engine operation, reducing noise pollution in urban environments. This is particularly relevant as cities worldwide implement stricter noise regulations to improve quality of life.

End-of-life considerations for flywheels are also crucial in assessing their overall environmental impact. The recyclability of materials used in flywheel construction, as well as the ease of disassembly and separation of components, can significantly affect the environmental footprint of LS engines at the end of their service life.

In conclusion, the environmental impact assessment of flywheel design in LS engine dynamics reveals a complex interplay of factors. While flywheels offer potential benefits in terms of energy efficiency and performance, their design must be approached holistically, considering the entire lifecycle from material sourcing to end-of-life disposal. As automotive technologies continue to evolve, integrating environmental considerations into flywheel design will be crucial for developing more sustainable LS engine systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!