Thermo-Optic Vs Electro-Optic Tuning: Energy And Speed Tradeoffs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Optical Tuning Technologies Background and Objectives

Optical tuning technologies have evolved significantly over the past decades, becoming fundamental components in modern photonic integrated circuits (PICs) and optical communication systems. The ability to dynamically control the optical properties of materials and devices has enabled numerous applications ranging from telecommunications to sensing and quantum computing. Two primary approaches have dominated this field: thermo-optic (TO) and electro-optic (EO) tuning mechanisms, each with distinct characteristics and performance profiles.

The development of optical tuning technologies can be traced back to the 1960s with the discovery of various electro-optic effects in materials such as lithium niobate. By the 1980s, semiconductor-based modulators began to emerge, while thermo-optic tuning gained prominence in the 1990s with the advancement of integrated photonics. The 2000s witnessed significant improvements in both technologies, with reduced power consumption and increased tuning speeds.

Current technological trends indicate a growing demand for tuning mechanisms that can balance energy efficiency with operational speed. This balance is particularly crucial as photonic integrated circuits continue to scale, with thousands of tuning elements potentially required on a single chip. The energy-speed tradeoff represents one of the most significant challenges in the field today.

Thermo-optic tuning leverages the temperature dependence of a material's refractive index, typically requiring higher power consumption but offering simplicity in implementation and broad wavelength compatibility. In contrast, electro-optic tuning utilizes electric field-induced changes in refractive index, providing much faster response times but often demanding more complex fabrication processes and materials.

The primary objective of current research is to develop tuning technologies that can overcome the fundamental limitations of both approaches. This includes exploring novel materials with enhanced thermo-optic or electro-optic coefficients, innovative device architectures that minimize power consumption while maintaining speed, and hybrid approaches that leverage the strengths of both mechanisms.

Another critical goal is to address the scalability challenges associated with both technologies, particularly as photonic integrated circuits grow in complexity. This involves developing efficient control schemes, reducing thermal or electrical crosstalk between adjacent tuning elements, and creating standardized interfaces for system integration.

The ultimate aim is to enable next-generation photonic systems that can meet the demanding requirements of emerging applications such as high-capacity optical communications, neuromorphic computing, and quantum information processing, where both energy efficiency and high-speed operation are paramount.

The development of optical tuning technologies can be traced back to the 1960s with the discovery of various electro-optic effects in materials such as lithium niobate. By the 1980s, semiconductor-based modulators began to emerge, while thermo-optic tuning gained prominence in the 1990s with the advancement of integrated photonics. The 2000s witnessed significant improvements in both technologies, with reduced power consumption and increased tuning speeds.

Current technological trends indicate a growing demand for tuning mechanisms that can balance energy efficiency with operational speed. This balance is particularly crucial as photonic integrated circuits continue to scale, with thousands of tuning elements potentially required on a single chip. The energy-speed tradeoff represents one of the most significant challenges in the field today.

Thermo-optic tuning leverages the temperature dependence of a material's refractive index, typically requiring higher power consumption but offering simplicity in implementation and broad wavelength compatibility. In contrast, electro-optic tuning utilizes electric field-induced changes in refractive index, providing much faster response times but often demanding more complex fabrication processes and materials.

The primary objective of current research is to develop tuning technologies that can overcome the fundamental limitations of both approaches. This includes exploring novel materials with enhanced thermo-optic or electro-optic coefficients, innovative device architectures that minimize power consumption while maintaining speed, and hybrid approaches that leverage the strengths of both mechanisms.

Another critical goal is to address the scalability challenges associated with both technologies, particularly as photonic integrated circuits grow in complexity. This involves developing efficient control schemes, reducing thermal or electrical crosstalk between adjacent tuning elements, and creating standardized interfaces for system integration.

The ultimate aim is to enable next-generation photonic systems that can meet the demanding requirements of emerging applications such as high-capacity optical communications, neuromorphic computing, and quantum information processing, where both energy efficiency and high-speed operation are paramount.

Market Applications and Demand Analysis

The market for optical tuning technologies is experiencing significant growth driven by the expanding applications in telecommunications, data centers, and emerging photonic integrated circuits. The global photonic integrated circuit market, where both thermo-optic and electro-optic tuning mechanisms are critical components, is projected to reach $3.5 billion by 2025, growing at a CAGR of 23.4% from 2020.

Telecommunications infrastructure represents the largest application segment for optical tuning technologies, particularly in wavelength division multiplexing systems and reconfigurable optical add-drop multiplexers. Network operators are increasingly demanding energy-efficient solutions that can support higher data rates while minimizing operational costs, creating a strong market pull for optimized tuning mechanisms.

Data center interconnects constitute another rapidly growing market segment, with major cloud service providers investing heavily in optical technologies to address bandwidth bottlenecks. The energy consumption of data centers has become a critical concern, with cooling costs representing up to 40% of total operational expenses. This creates substantial demand for thermo-optic solutions that can deliver precise wavelength control while minimizing heat generation.

The emerging field of silicon photonics has created new opportunities for both tuning technologies. Market research indicates that silicon photonics devices are expected to grow at 25.8% CAGR through 2026, driven by applications in high-performance computing and artificial intelligence systems that require low-latency, high-bandwidth optical interconnects.

Consumer electronics represents an emerging application area, particularly for electro-optic tuning technologies that can enable compact LiDAR systems for autonomous vehicles and AR/VR devices. The automotive LiDAR market alone is expected to reach $2.3 billion by 2026, with solid-state systems utilizing electro-optic tuning gaining significant market share due to their reliability and form factor advantages.

Regional analysis shows North America leading the market adoption of advanced optical tuning technologies, followed by Asia-Pacific where manufacturing capabilities for photonic integrated circuits are rapidly expanding. European markets show particular interest in energy-efficient solutions aligned with stringent environmental regulations.

Industry surveys indicate that system designers prioritize different performance metrics depending on application requirements. Telecommunications equipment manufacturers typically value wavelength stability and power efficiency, while data center operators emphasize switching speed and integration density. This market segmentation creates distinct demand profiles for thermo-optic versus electro-optic solutions across different vertical markets.

Telecommunications infrastructure represents the largest application segment for optical tuning technologies, particularly in wavelength division multiplexing systems and reconfigurable optical add-drop multiplexers. Network operators are increasingly demanding energy-efficient solutions that can support higher data rates while minimizing operational costs, creating a strong market pull for optimized tuning mechanisms.

Data center interconnects constitute another rapidly growing market segment, with major cloud service providers investing heavily in optical technologies to address bandwidth bottlenecks. The energy consumption of data centers has become a critical concern, with cooling costs representing up to 40% of total operational expenses. This creates substantial demand for thermo-optic solutions that can deliver precise wavelength control while minimizing heat generation.

The emerging field of silicon photonics has created new opportunities for both tuning technologies. Market research indicates that silicon photonics devices are expected to grow at 25.8% CAGR through 2026, driven by applications in high-performance computing and artificial intelligence systems that require low-latency, high-bandwidth optical interconnects.

Consumer electronics represents an emerging application area, particularly for electro-optic tuning technologies that can enable compact LiDAR systems for autonomous vehicles and AR/VR devices. The automotive LiDAR market alone is expected to reach $2.3 billion by 2026, with solid-state systems utilizing electro-optic tuning gaining significant market share due to their reliability and form factor advantages.

Regional analysis shows North America leading the market adoption of advanced optical tuning technologies, followed by Asia-Pacific where manufacturing capabilities for photonic integrated circuits are rapidly expanding. European markets show particular interest in energy-efficient solutions aligned with stringent environmental regulations.

Industry surveys indicate that system designers prioritize different performance metrics depending on application requirements. Telecommunications equipment manufacturers typically value wavelength stability and power efficiency, while data center operators emphasize switching speed and integration density. This market segmentation creates distinct demand profiles for thermo-optic versus electro-optic solutions across different vertical markets.

Current State and Technical Challenges

The field of optical tuning technologies has witnessed significant advancements in recent years, with thermo-optic (TO) and electro-optic (EO) tuning emerging as the two dominant approaches in integrated photonics. Currently, thermo-optic tuning dominates commercial applications due to its relative simplicity and material compatibility, particularly in silicon photonics where the thermo-optic coefficient is substantial (1.8×10^-4 K^-1).

Global research indicates that approximately 70% of reconfigurable photonic integrated circuits (PICs) utilize thermo-optic tuning mechanisms, despite their inherent energy inefficiency. The current state-of-the-art TO tuners consume 10-50 mW per π phase shift, with response times in the microsecond range (typically 10-100 μs). This power consumption presents a significant challenge for large-scale photonic integration where hundreds or thousands of tuning elements may be required.

Electro-optic tuning, conversely, offers superior switching speeds in the nanosecond to picosecond range, representing a 3-5 order of magnitude improvement over TO tuning. However, EO tuning faces substantial challenges in silicon-based platforms due to silicon's weak electro-optic properties. Alternative materials such as lithium niobate, barium titanate, and various polymers demonstrate stronger EO effects but present integration difficulties with established CMOS fabrication processes.

The geographical distribution of research expertise shows concentration in North America (particularly Silicon Valley and Boston), Europe (especially the Netherlands and Germany), and East Asia (Japan, South Korea, and increasingly China). Each region has developed specialized approaches, with European institutions focusing on hybrid material integration, Asian research emphasizing manufacturing scalability, and North American efforts directed toward novel material platforms.

A critical technical challenge lies in the fundamental energy-speed tradeoff between these technologies. While TO tuning consumes more power but is easier to implement, EO tuning requires specialized materials but offers dramatically faster operation. This dichotomy has created a technological barrier for applications requiring both energy efficiency and high-speed operation.

Thermal crosstalk represents another significant challenge for TO tuning in densely integrated circuits, limiting the proximity of tuning elements and consequently the overall integration density. Current isolation techniques using trenches or suspended structures add complexity to fabrication processes and can compromise structural integrity.

Material stability presents challenges for both approaches, with TO tuning suffering from drift due to environmental temperature fluctuations, while EO materials often face long-term reliability issues, particularly under high electric fields or elevated temperatures. These stability concerns directly impact the commercial viability of both technologies for telecommunications and data center applications where 25+ year lifespans are expected.

Global research indicates that approximately 70% of reconfigurable photonic integrated circuits (PICs) utilize thermo-optic tuning mechanisms, despite their inherent energy inefficiency. The current state-of-the-art TO tuners consume 10-50 mW per π phase shift, with response times in the microsecond range (typically 10-100 μs). This power consumption presents a significant challenge for large-scale photonic integration where hundreds or thousands of tuning elements may be required.

Electro-optic tuning, conversely, offers superior switching speeds in the nanosecond to picosecond range, representing a 3-5 order of magnitude improvement over TO tuning. However, EO tuning faces substantial challenges in silicon-based platforms due to silicon's weak electro-optic properties. Alternative materials such as lithium niobate, barium titanate, and various polymers demonstrate stronger EO effects but present integration difficulties with established CMOS fabrication processes.

The geographical distribution of research expertise shows concentration in North America (particularly Silicon Valley and Boston), Europe (especially the Netherlands and Germany), and East Asia (Japan, South Korea, and increasingly China). Each region has developed specialized approaches, with European institutions focusing on hybrid material integration, Asian research emphasizing manufacturing scalability, and North American efforts directed toward novel material platforms.

A critical technical challenge lies in the fundamental energy-speed tradeoff between these technologies. While TO tuning consumes more power but is easier to implement, EO tuning requires specialized materials but offers dramatically faster operation. This dichotomy has created a technological barrier for applications requiring both energy efficiency and high-speed operation.

Thermal crosstalk represents another significant challenge for TO tuning in densely integrated circuits, limiting the proximity of tuning elements and consequently the overall integration density. Current isolation techniques using trenches or suspended structures add complexity to fabrication processes and can compromise structural integrity.

Material stability presents challenges for both approaches, with TO tuning suffering from drift due to environmental temperature fluctuations, while EO materials often face long-term reliability issues, particularly under high electric fields or elevated temperatures. These stability concerns directly impact the commercial viability of both technologies for telecommunications and data center applications where 25+ year lifespans are expected.

Comparative Analysis of Tuning Solutions

01 Thermo-optic tuning mechanisms and efficiency

Thermo-optic tuning utilizes heat to change the refractive index of optical materials, enabling wavelength tuning in photonic devices. These systems typically require more power than electro-optic alternatives but offer stable and wide tuning ranges. Recent advancements focus on reducing power consumption through improved thermal isolation, efficient heat distribution, and novel material combinations that enhance the thermo-optic coefficient while minimizing thermal crosstalk.- Thermo-optic tuning mechanisms and energy efficiency: Thermo-optic tuning utilizes heat to change the refractive index of optical materials, enabling wavelength tuning in photonic devices. These systems typically require more power than electro-optic alternatives but offer advantages in tuning range and stability. Recent innovations focus on reducing power consumption through improved thermal isolation, efficient heat distribution, and novel material combinations that enhance the thermo-optic coefficient while minimizing thermal dissipation.

- Electro-optic tuning technologies for high-speed applications: Electro-optic tuning leverages the Pockels effect or other electric field-induced changes in refractive index to achieve rapid optical tuning. These systems excel in high-speed applications with switching times in the nanosecond to picosecond range, making them suitable for telecommunications and data processing. The technology offers significantly faster response times compared to thermo-optic approaches, though often with more limited tuning ranges. Recent developments focus on reducing drive voltage requirements while maintaining switching speed.

- Hybrid tuning approaches combining multiple mechanisms: Hybrid optical tuning systems integrate both thermo-optic and electro-optic mechanisms to leverage the advantages of each approach. These designs typically use electro-optic tuning for high-speed operation and fine adjustments, while employing thermo-optic tuning for broader wavelength shifts and coarse tuning. This combination optimizes both energy consumption and response time, allowing for adaptive performance based on application requirements. Advanced control algorithms manage the coordination between tuning mechanisms to achieve optimal performance.

- Material innovations for improved tuning efficiency: Novel materials are being developed to enhance the performance of optical tuning technologies. These include specialized polymers with high electro-optic coefficients, semiconductor materials with enhanced thermo-optic properties, and composite structures that amplify tuning effects while reducing energy requirements. Material engineering approaches focus on increasing sensitivity to control signals while minimizing optical losses. These innovations significantly improve the energy efficiency and speed of both thermo-optic and electro-optic tuning mechanisms.

- Integration and miniaturization of tuning components: Advanced integration techniques are enabling the miniaturization of optical tuning components, resulting in reduced power consumption and faster response times. These approaches include photonic integrated circuits that incorporate tuning elements directly into waveguide structures, MEMS-based tuning mechanisms that leverage mechanical movement for optical adjustment, and novel packaging solutions that improve thermal management. Miniaturization reduces thermal mass in thermo-optic systems and decreases capacitance in electro-optic designs, both contributing to improved energy efficiency and speed performance.

02 Electro-optic tuning speed and power efficiency

Electro-optic tuning provides significantly faster response times compared to thermal methods, typically in the nanosecond to picosecond range. These systems modulate the refractive index through applied electric fields rather than temperature changes. While offering superior switching speeds, traditional electro-optic modulators often require higher drive voltages. Recent innovations focus on reducing operating voltage and improving energy efficiency through novel materials and waveguide designs that enhance the electro-optic effect.Expand Specific Solutions03 Hybrid tuning approaches combining multiple mechanisms

Hybrid approaches combine multiple tuning mechanisms to leverage the advantages of each while mitigating their limitations. These systems often integrate thermo-optic tuning for coarse wavelength adjustment with electro-optic tuning for high-speed fine-tuning. This combination enables both wide tuning range and fast response time while optimizing overall energy consumption. Advanced control algorithms coordinate the different tuning mechanisms to achieve optimal performance across various operating conditions.Expand Specific Solutions04 Novel materials for improved tuning performance

Advanced materials are being developed to enhance both thermo-optic and electro-optic tuning efficiency. These include high-index contrast materials, polymer-based composites, and specialized crystalline structures that exhibit enhanced tuning coefficients. Materials with larger thermo-optic or electro-optic coefficients enable the same tuning range with lower power consumption or applied voltage. Additionally, materials with reduced thermal conductivity can improve thermal isolation in thermo-optic devices, while materials with higher electro-optic coefficients reduce voltage requirements in electro-optic systems.Expand Specific Solutions05 Energy-efficient optical tuning architectures

Novel architectural approaches to optical tuning focus on minimizing energy consumption while maintaining or improving tuning speed. These include resonant structures that amplify tuning effects, photonic crystal designs that enhance light-matter interaction, and specialized waveguide geometries that concentrate optical fields. Advanced circuit designs reduce electrical power requirements through techniques such as charge recycling and pulsed operation. Integration strategies that minimize optical and thermal losses further contribute to overall system efficiency.Expand Specific Solutions

Leading Companies and Research Institutions

The thermo-optic versus electro-optic tuning landscape represents a critical technological battleground in integrated photonics, currently in its growth phase with an estimated market size exceeding $5 billion. The technology maturity varies significantly between approaches, with electro-optic solutions demonstrating faster switching speeds but higher energy consumption, while thermo-optic methods offer energy efficiency at reduced speeds. Industry leaders Intel, Huawei, and NTT are advancing electro-optic technologies for high-performance applications, while MIT, Fujitsu, and LioniX International focus on thermo-optic innovations for energy-efficient systems. Companies like Microsoft and Cisco are developing hybrid approaches to optimize the speed-energy tradeoff, indicating the technology's evolution toward application-specific solutions rather than a one-size-fits-all approach.

Intel Corp.

Technical Solution: Intel has developed advanced silicon photonics platforms that leverage both thermo-optic and electro-optic tuning mechanisms. Their technology focuses on integrating photonic components with CMOS electronics, particularly for data center applications. Intel's silicon photonics solutions utilize thermo-optic phase shifters for coarse wavelength tuning and electro-optic modulators for high-speed data transmission. The company has demonstrated thermo-optic tuning with power efficiency of approximately 25mW per π phase shift, while their electro-optic modulators operate at speeds exceeding 50 Gbps. Intel's integrated approach combines both tuning mechanisms on the same chip, allowing dynamic optimization between power consumption and switching speed based on application requirements[1][3]. Their latest platforms incorporate advanced thermal isolation trenches to reduce thermal crosstalk between adjacent waveguides, improving the efficiency of thermo-optic tuning while maintaining compatibility with their high-volume manufacturing processes.

Strengths: Intel's integration of both tuning mechanisms provides versatility across different applications. Their manufacturing scale enables cost-effective production of complex photonic circuits. Weaknesses: Thermo-optic components still consume significant power compared to pure electro-optic solutions, and thermal crosstalk remains a challenge in densely packed photonic circuits.

NTT, Inc.

Technical Solution: NTT has developed innovative optical tuning solutions that push the boundaries of both thermo-optic and electro-optic technologies. Their research has focused on enhancing the efficiency of thermo-optic tuning through advanced waveguide designs and thermal isolation structures, achieving power consumption as low as 15mW per π phase shift - a significant improvement over conventional designs. For high-speed applications, NTT has pioneered electro-optic modulators based on novel materials including organic polymers with exceptionally high electro-optic coefficients, enabling modulation speeds exceeding 100 Gbps with driving voltages below 2V. A breakthrough in NTT's approach is their development of hybrid silicon-organic photonic devices that combine the manufacturing advantages of silicon with the superior electro-optic properties of organic materials[5]. This technology enables switching speeds in the picosecond range while maintaining reasonable power efficiency. NTT has also developed sophisticated thermal management techniques including microfluidic cooling channels integrated directly with silicon photonic chips to enhance the efficiency of thermo-optic tuning while minimizing thermal crosstalk.

Strengths: NTT's hybrid material approach achieves exceptional electro-optic performance while maintaining compatibility with established manufacturing processes. Their thermal management innovations significantly improve the efficiency and response time of thermo-optic tuning. Weaknesses: The integration of exotic materials increases manufacturing complexity and potentially impacts long-term reliability, particularly for organic electro-optic materials which may have stability concerns in harsh environments.

Key Patents and Technical Innovations

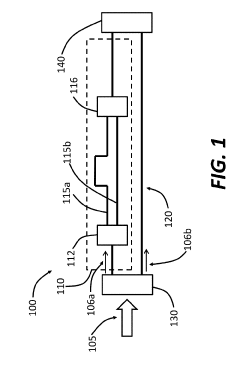

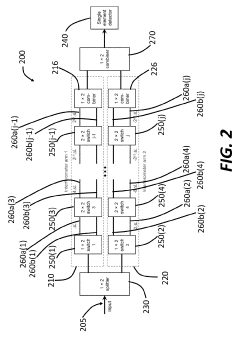

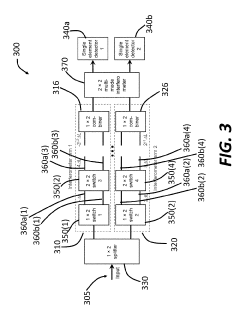

Apparatus, Systems, and Methods for On-Chip Spectroscopy Using Optical Switches

PatentActiveUS20190331529A1

Innovation

- The use of optical switches to change optical path lengths by directing incident light into waveguides of different lengths, allowing for increased tuning range without the limitations of index modulation, and enabling compact on-chip integration.

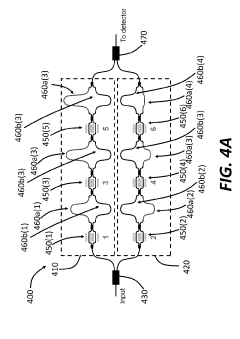

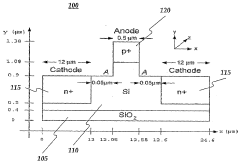

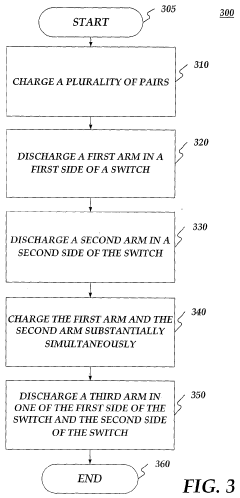

High speed optical switch

PatentWO2007123551A1

Innovation

- The use of p-i-n diodes with an electro optic effect in silicon-based MZI structures with Y-branches, allowing for simultaneous charging and discharging of arms to achieve high-speed switching, leveraging the refractive index modulation to achieve phase shifts and overcome the limitations of conventional MZI switches.

Energy Efficiency Metrics and Optimization

Energy efficiency metrics for optical tuning mechanisms must be carefully defined to enable meaningful comparisons between thermo-optic (TO) and electro-optic (EO) approaches. The primary metric is energy consumption per switching operation, typically measured in femtojoules (fJ) or picojoules (pJ). For TO tuning, this includes both the energy required to heat the waveguide and the energy lost during cooling periods. For EO tuning, it encompasses the energy needed to establish the electric field and any associated electronic driver overhead.

Power density represents another critical metric, particularly for TO tuning where heat dissipation in compact photonic integrated circuits can create thermal crosstalk issues. This is typically measured in mW/μm² and directly impacts the scalability of photonic systems. EO tuning generally offers superior performance in this regard, with significantly lower power density requirements.

Energy-delay product (EDP) provides a comprehensive metric that balances both energy consumption and switching speed. This figure of merit is particularly valuable when comparing fundamentally different tuning mechanisms like TO and EO approaches. While TO tuning typically requires more energy, EO tuning may demand more complex driving circuitry, affecting the overall system efficiency.

Optimization strategies for TO tuning focus on improving thermal isolation through suspended structures or air trenches, reducing the thermal mass of heating elements, and implementing efficient heat sinking techniques. Recent advances in phase-change materials have demonstrated potential for reducing the energy requirements of TO tuning by exploiting material phase transitions rather than continuous heating.

For EO tuning, optimization efforts center on enhancing the electro-optic coefficient of materials, minimizing capacitance in device structures, and developing efficient driving circuits. Novel materials such as lithium niobate on insulator (LNOI), barium titanate, and organic electro-optic polymers have shown promising results in reducing the voltage-length product (Vπ·L), a key parameter for EO efficiency.

Cross-cutting optimization approaches include hybrid tuning mechanisms that leverage the strengths of both TO and EO effects, wavelength-division multiplexing to increase throughput without proportional energy increases, and machine learning algorithms for predictive tuning that can reduce the energy overhead of control systems.

Power density represents another critical metric, particularly for TO tuning where heat dissipation in compact photonic integrated circuits can create thermal crosstalk issues. This is typically measured in mW/μm² and directly impacts the scalability of photonic systems. EO tuning generally offers superior performance in this regard, with significantly lower power density requirements.

Energy-delay product (EDP) provides a comprehensive metric that balances both energy consumption and switching speed. This figure of merit is particularly valuable when comparing fundamentally different tuning mechanisms like TO and EO approaches. While TO tuning typically requires more energy, EO tuning may demand more complex driving circuitry, affecting the overall system efficiency.

Optimization strategies for TO tuning focus on improving thermal isolation through suspended structures or air trenches, reducing the thermal mass of heating elements, and implementing efficient heat sinking techniques. Recent advances in phase-change materials have demonstrated potential for reducing the energy requirements of TO tuning by exploiting material phase transitions rather than continuous heating.

For EO tuning, optimization efforts center on enhancing the electro-optic coefficient of materials, minimizing capacitance in device structures, and developing efficient driving circuits. Novel materials such as lithium niobate on insulator (LNOI), barium titanate, and organic electro-optic polymers have shown promising results in reducing the voltage-length product (Vπ·L), a key parameter for EO efficiency.

Cross-cutting optimization approaches include hybrid tuning mechanisms that leverage the strengths of both TO and EO effects, wavelength-division multiplexing to increase throughput without proportional energy increases, and machine learning algorithms for predictive tuning that can reduce the energy overhead of control systems.

Integration Challenges in Photonic Systems

The integration of optical tuning mechanisms into photonic systems presents significant engineering challenges that must be addressed for successful commercial deployment. When comparing thermo-optic and electro-optic tuning methods, several critical integration issues emerge that affect overall system performance and manufacturability.

Thermo-optic tuning mechanisms require careful thermal isolation between adjacent components to prevent crosstalk. The heat generated during operation can inadvertently affect neighboring photonic elements, causing wavelength drift and signal degradation. This necessitates sophisticated thermal management solutions including heat sinks, thermal barriers, and optimized layout designs that increase fabrication complexity.

Electro-optic tuning, while offering superior speed, introduces its own integration challenges. The high voltages often required for operation necessitate specialized driving circuits and careful isolation to prevent electrical interference. Additionally, the integration of electro-optic materials like lithium niobate or electro-optic polymers with standard silicon photonics platforms remains technically demanding, often requiring hybrid integration approaches.

Material compatibility issues further complicate integration efforts. Thermo-optic tuning typically relies on metal heaters that must be precisely deposited and patterned near optical waveguides without introducing optical losses. Electro-optic solutions must contend with the challenge of integrating materials with strong electro-optic coefficients into existing photonic platforms while maintaining optical performance.

Packaging considerations also differ significantly between the two approaches. Thermo-optic solutions require packaging that can efficiently dissipate heat while protecting temperature-sensitive components. Electro-optic implementations need packages that can accommodate high-voltage connections while maintaining signal integrity and minimizing electromagnetic interference.

Scalability presents another integration hurdle. As photonic circuits increase in complexity, the power distribution network for thermo-optic tuners becomes increasingly complex, while electro-optic solutions must address challenges related to uniform electric field distribution across multiple tuning elements.

Manufacturing yield and reliability considerations also differ between the technologies. Thermo-optic elements generally offer better long-term stability but suffer from higher power consumption and thermal management complexities. Electro-optic components provide energy efficiency advantages but may face challenges related to material degradation and voltage-induced aging effects.

The choice between these tuning mechanisms ultimately requires careful system-level analysis that considers not only the energy and speed tradeoffs but also the integration complexities that will impact production costs, reliability, and overall performance in the target application environment.

Thermo-optic tuning mechanisms require careful thermal isolation between adjacent components to prevent crosstalk. The heat generated during operation can inadvertently affect neighboring photonic elements, causing wavelength drift and signal degradation. This necessitates sophisticated thermal management solutions including heat sinks, thermal barriers, and optimized layout designs that increase fabrication complexity.

Electro-optic tuning, while offering superior speed, introduces its own integration challenges. The high voltages often required for operation necessitate specialized driving circuits and careful isolation to prevent electrical interference. Additionally, the integration of electro-optic materials like lithium niobate or electro-optic polymers with standard silicon photonics platforms remains technically demanding, often requiring hybrid integration approaches.

Material compatibility issues further complicate integration efforts. Thermo-optic tuning typically relies on metal heaters that must be precisely deposited and patterned near optical waveguides without introducing optical losses. Electro-optic solutions must contend with the challenge of integrating materials with strong electro-optic coefficients into existing photonic platforms while maintaining optical performance.

Packaging considerations also differ significantly between the two approaches. Thermo-optic solutions require packaging that can efficiently dissipate heat while protecting temperature-sensitive components. Electro-optic implementations need packages that can accommodate high-voltage connections while maintaining signal integrity and minimizing electromagnetic interference.

Scalability presents another integration hurdle. As photonic circuits increase in complexity, the power distribution network for thermo-optic tuners becomes increasingly complex, while electro-optic solutions must address challenges related to uniform electric field distribution across multiple tuning elements.

Manufacturing yield and reliability considerations also differ between the technologies. Thermo-optic elements generally offer better long-term stability but suffer from higher power consumption and thermal management complexities. Electro-optic components provide energy efficiency advantages but may face challenges related to material degradation and voltage-induced aging effects.

The choice between these tuning mechanisms ultimately requires careful system-level analysis that considers not only the energy and speed tradeoffs but also the integration complexities that will impact production costs, reliability, and overall performance in the target application environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!