Photonic Hardware In Closed-Loop Autonomous Control Systems

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photonic Hardware Evolution and Control System Integration Goals

Photonic hardware has undergone significant evolution over the past decades, transitioning from basic optical components to sophisticated integrated photonic circuits capable of complex signal processing and computational tasks. The journey began with discrete optical elements such as lenses, mirrors, and beam splitters, which formed the foundation of early optical systems. As fabrication technologies advanced, particularly in semiconductor manufacturing, the field witnessed the emergence of integrated photonic platforms that enabled miniaturization and enhanced functionality.

The development of photonic integrated circuits (PICs) marked a pivotal milestone, allowing multiple optical functions to be performed on a single chip. This integration capability has continuously improved, with current state-of-the-art PICs incorporating thousands of components on a centimeter-scale chip. Material platforms have diversified from traditional silicon photonics to include silicon nitride, indium phosphide, and lithium niobate, each offering unique advantages for specific applications.

Recent technological breakthroughs have focused on enhancing the speed, efficiency, and reconfigurability of photonic hardware. Innovations in optical modulators have pushed data rates into the terabit-per-second range, while advances in photodetectors have improved sensitivity and response times. The development of programmable photonic circuits represents another significant trend, enabling dynamic reconfiguration of optical pathways and functions through software control.

The integration of photonic hardware into closed-loop autonomous control systems presents both opportunities and challenges. The primary goal is to leverage the inherent advantages of photonics—including high bandwidth, low latency, and parallel processing capabilities—to enhance the performance of control systems across various domains. Specifically, photonic hardware aims to overcome electronic bottlenecks in high-speed sensing, signal processing, and actuation loops.

Key technical objectives include developing photonic sensors capable of real-time, multi-parameter measurements; creating photonic processors that can implement complex control algorithms with minimal latency; and designing interfaces that seamlessly connect photonic and electronic components within hybrid control architectures. Additionally, there is a focus on enhancing the robustness and reliability of photonic systems to meet the stringent requirements of mission-critical control applications.

The long-term vision encompasses fully integrated photonic control systems that can operate autonomously in dynamic environments, adapting their behavior based on real-time feedback. This requires advances in self-calibration techniques, fault-tolerance mechanisms, and adaptive learning capabilities implemented directly in the photonic domain. Research efforts are increasingly directed toward developing photonic neural networks and other bio-inspired architectures that can enable sophisticated decision-making processes within the control loop.

The development of photonic integrated circuits (PICs) marked a pivotal milestone, allowing multiple optical functions to be performed on a single chip. This integration capability has continuously improved, with current state-of-the-art PICs incorporating thousands of components on a centimeter-scale chip. Material platforms have diversified from traditional silicon photonics to include silicon nitride, indium phosphide, and lithium niobate, each offering unique advantages for specific applications.

Recent technological breakthroughs have focused on enhancing the speed, efficiency, and reconfigurability of photonic hardware. Innovations in optical modulators have pushed data rates into the terabit-per-second range, while advances in photodetectors have improved sensitivity and response times. The development of programmable photonic circuits represents another significant trend, enabling dynamic reconfiguration of optical pathways and functions through software control.

The integration of photonic hardware into closed-loop autonomous control systems presents both opportunities and challenges. The primary goal is to leverage the inherent advantages of photonics—including high bandwidth, low latency, and parallel processing capabilities—to enhance the performance of control systems across various domains. Specifically, photonic hardware aims to overcome electronic bottlenecks in high-speed sensing, signal processing, and actuation loops.

Key technical objectives include developing photonic sensors capable of real-time, multi-parameter measurements; creating photonic processors that can implement complex control algorithms with minimal latency; and designing interfaces that seamlessly connect photonic and electronic components within hybrid control architectures. Additionally, there is a focus on enhancing the robustness and reliability of photonic systems to meet the stringent requirements of mission-critical control applications.

The long-term vision encompasses fully integrated photonic control systems that can operate autonomously in dynamic environments, adapting their behavior based on real-time feedback. This requires advances in self-calibration techniques, fault-tolerance mechanisms, and adaptive learning capabilities implemented directly in the photonic domain. Research efforts are increasingly directed toward developing photonic neural networks and other bio-inspired architectures that can enable sophisticated decision-making processes within the control loop.

Market Analysis for Photonic-Based Autonomous Control Systems

The global market for photonic-based autonomous control systems is experiencing significant growth, driven by increasing demands for higher processing speeds, lower latency, and reduced power consumption in control applications. Current market valuations indicate that the photonic hardware segment within autonomous systems reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 23.7% through 2028.

Key market segments adopting photonic hardware in closed-loop control systems include aerospace and defense, automotive, industrial manufacturing, and telecommunications. The aerospace sector currently represents the largest market share at 34%, primarily due to the critical need for ultra-fast response times in flight control systems and satellite operations. The automotive industry follows closely at 28%, with increasing integration of photonic sensors and processors in advanced driver assistance systems (ADAS) and autonomous vehicles.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (27%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, primarily driven by substantial investments in autonomous technologies in China, Japan, and South Korea.

Customer demand is increasingly focused on integrated photonic solutions that offer significant advantages over traditional electronic systems. Market surveys indicate that 76% of potential adopters cite processing speed as their primary motivation, while 64% emphasize energy efficiency benefits. The ability to process multiple control signals in parallel through wavelength division multiplexing represents a particularly attractive feature for complex autonomous systems.

Market barriers include high initial implementation costs, with photonic control systems typically commanding a 2.5-3x premium over conventional electronic alternatives. Additionally, integration challenges with existing electronic infrastructure and a shortage of specialized engineering talent represent significant obstacles to wider adoption.

Competitive analysis reveals an evolving landscape with traditional semiconductor companies expanding into photonics alongside specialized photonic startups. Major players include established companies like Intel (Photonics Division), Cisco Optical, and Infinera, alongside emerging specialists such as Lightmatter, Lightelligence, and Luminous Computing. Strategic partnerships between photonics hardware providers and autonomous system integrators are becoming increasingly common, with 37 major collaboration agreements announced in the past 18 months.

Market forecasts suggest that as manufacturing scales and technology matures, the cost premium for photonic control systems will decrease to approximately 1.4x by 2027, potentially accelerating adoption across multiple industries and applications.

Key market segments adopting photonic hardware in closed-loop control systems include aerospace and defense, automotive, industrial manufacturing, and telecommunications. The aerospace sector currently represents the largest market share at 34%, primarily due to the critical need for ultra-fast response times in flight control systems and satellite operations. The automotive industry follows closely at 28%, with increasing integration of photonic sensors and processors in advanced driver assistance systems (ADAS) and autonomous vehicles.

Regional analysis reveals North America leads the market with 42% share, followed by Europe (27%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, primarily driven by substantial investments in autonomous technologies in China, Japan, and South Korea.

Customer demand is increasingly focused on integrated photonic solutions that offer significant advantages over traditional electronic systems. Market surveys indicate that 76% of potential adopters cite processing speed as their primary motivation, while 64% emphasize energy efficiency benefits. The ability to process multiple control signals in parallel through wavelength division multiplexing represents a particularly attractive feature for complex autonomous systems.

Market barriers include high initial implementation costs, with photonic control systems typically commanding a 2.5-3x premium over conventional electronic alternatives. Additionally, integration challenges with existing electronic infrastructure and a shortage of specialized engineering talent represent significant obstacles to wider adoption.

Competitive analysis reveals an evolving landscape with traditional semiconductor companies expanding into photonics alongside specialized photonic startups. Major players include established companies like Intel (Photonics Division), Cisco Optical, and Infinera, alongside emerging specialists such as Lightmatter, Lightelligence, and Luminous Computing. Strategic partnerships between photonics hardware providers and autonomous system integrators are becoming increasingly common, with 37 major collaboration agreements announced in the past 18 months.

Market forecasts suggest that as manufacturing scales and technology matures, the cost premium for photonic control systems will decrease to approximately 1.4x by 2027, potentially accelerating adoption across multiple industries and applications.

Current Photonic Hardware Capabilities and Technical Barriers

Current photonic hardware for closed-loop autonomous control systems has reached significant milestones in performance capabilities. Silicon photonics platforms now offer integration densities approaching 10^6 components per chip, with optical losses below 0.1 dB/cm in waveguides. Advanced photonic integrated circuits (PICs) can process optical signals at speeds exceeding 100 GHz, providing ultra-low latency processing essential for real-time control applications. Recent developments in programmable photonic processors demonstrate reconfigurable functionality with over 1000 tunable elements on a single chip.

Despite these advances, several technical barriers limit widespread adoption in autonomous control systems. Power consumption remains a critical challenge, with current thermo-optic phase shifters requiring 10-50 mW per element, creating thermal management issues in densely integrated systems. This power requirement significantly constrains deployment in power-limited autonomous platforms like drones or satellites.

Temperature sensitivity presents another major obstacle, as most photonic devices exhibit performance drift of approximately 10 pm/°C in resonant wavelength, necessitating active temperature stabilization systems that add complexity and power overhead. This sensitivity particularly impacts closed-loop control applications requiring consistent performance across varying environmental conditions.

Integration challenges between electronic and photonic components create significant barriers. Current hybrid integration approaches introduce coupling losses of 1-3 dB per interface and increase packaging complexity. The absence of standardized interfaces between electronic control systems and photonic hardware further complicates system design and increases development costs.

Manufacturing scalability remains problematic, with current fabrication processes showing yield issues for complex photonic circuits. Typical yields for advanced PICs with over 100 components can fall below 70%, increasing production costs and limiting commercial viability. Additionally, process variations cause performance inconsistencies between nominally identical devices, complicating calibration for precise control applications.

Nonlinear effects in optical materials create signal distortion at high optical powers, limiting dynamic range in sensing and control applications. Current systems typically operate with optical power budgets below 10 mW to avoid these effects, restricting signal-to-noise ratios in challenging environments.

The lack of robust, field-deployable packaging solutions represents a final significant barrier. Laboratory demonstrations often utilize bulky equipment incompatible with real-world autonomous systems. Current packaging approaches struggle to maintain optical alignment under vibration and shock conditions typical in mobile platforms, with misalignment-induced losses exceeding 3 dB under moderate mechanical stress.

Despite these advances, several technical barriers limit widespread adoption in autonomous control systems. Power consumption remains a critical challenge, with current thermo-optic phase shifters requiring 10-50 mW per element, creating thermal management issues in densely integrated systems. This power requirement significantly constrains deployment in power-limited autonomous platforms like drones or satellites.

Temperature sensitivity presents another major obstacle, as most photonic devices exhibit performance drift of approximately 10 pm/°C in resonant wavelength, necessitating active temperature stabilization systems that add complexity and power overhead. This sensitivity particularly impacts closed-loop control applications requiring consistent performance across varying environmental conditions.

Integration challenges between electronic and photonic components create significant barriers. Current hybrid integration approaches introduce coupling losses of 1-3 dB per interface and increase packaging complexity. The absence of standardized interfaces between electronic control systems and photonic hardware further complicates system design and increases development costs.

Manufacturing scalability remains problematic, with current fabrication processes showing yield issues for complex photonic circuits. Typical yields for advanced PICs with over 100 components can fall below 70%, increasing production costs and limiting commercial viability. Additionally, process variations cause performance inconsistencies between nominally identical devices, complicating calibration for precise control applications.

Nonlinear effects in optical materials create signal distortion at high optical powers, limiting dynamic range in sensing and control applications. Current systems typically operate with optical power budgets below 10 mW to avoid these effects, restricting signal-to-noise ratios in challenging environments.

The lack of robust, field-deployable packaging solutions represents a final significant barrier. Laboratory demonstrations often utilize bulky equipment incompatible with real-world autonomous systems. Current packaging approaches struggle to maintain optical alignment under vibration and shock conditions typical in mobile platforms, with misalignment-induced losses exceeding 3 dB under moderate mechanical stress.

Current Photonic Hardware Implementation in Closed-Loop Systems

01 Optical switching and modulation technologies

Photonic hardware systems utilize various optical switching and modulation technologies to control light signals. These technologies enable high-speed data transmission and processing in optical networks. Advanced modulation techniques allow for efficient encoding of information onto light waves, while optical switches provide the ability to route optical signals without conversion to electrical form, significantly reducing latency and power consumption in data processing applications.- Optical switching and modulation technologies: Photonic hardware systems utilize various optical switching and modulation technologies to control light signals. These technologies enable high-speed data transmission and processing in optical networks. Advanced modulation techniques allow for efficient encoding of information onto light waves, while optical switches provide the ability to route optical signals without conversion to electrical form, significantly reducing latency and power consumption in data processing applications.

- Integrated photonic circuits and components: Integrated photonic circuits combine multiple optical components on a single substrate, similar to electronic integrated circuits but using light instead of electricity. These circuits incorporate elements such as waveguides, resonators, modulators, and detectors to perform complex optical functions. The integration enables miniaturization of photonic systems while improving performance, reliability, and manufacturing scalability for applications in telecommunications, computing, and sensing.

- Quantum photonic computing hardware: Quantum photonic computing hardware leverages the quantum properties of light particles (photons) to perform computational tasks. These systems utilize quantum entanglement and superposition to achieve processing capabilities beyond classical computers. The hardware typically includes single-photon sources, quantum gates implemented with optical components, and specialized detectors. This emerging technology promises breakthroughs in cryptography, optimization problems, and simulation of quantum systems.

- Optical memory and storage systems: Optical memory and storage systems use light to read, write, and store information. These technologies include holographic storage, phase-change materials, and photonic crystal memories that can achieve high data densities and fast access times. By encoding information in the properties of light or light-sensitive materials, these systems offer advantages in storage capacity, data persistence, and energy efficiency compared to conventional electronic storage technologies.

- Photonic signal processing architectures: Photonic signal processing architectures perform computational operations directly in the optical domain. These systems use interference, diffraction, and nonlinear optical effects to implement mathematical functions and signal transformations. By processing information at the speed of light without electronic bottlenecks, these architectures enable ultra-fast operations for applications such as real-time image processing, radio frequency analysis, and artificial neural networks, offering significant advantages in processing speed and energy efficiency.

02 Integrated photonic circuits and components

Integrated photonic circuits combine multiple optical components on a single chip, similar to electronic integrated circuits but using light instead of electricity. These circuits incorporate elements such as waveguides, resonators, modulators, and detectors to perform complex optical functions. The integration enables miniaturization of photonic systems while improving performance, reliability, and energy efficiency for applications in telecommunications, computing, and sensing.Expand Specific Solutions03 Quantum photonic computing hardware

Quantum photonic computing hardware leverages the quantum properties of light for information processing. These systems use single photons as quantum bits (qubits) and employ specialized components such as photon sources, quantum gates, and detectors. The technology enables quantum operations that can potentially solve certain problems exponentially faster than classical computers, with applications in cryptography, optimization, and simulation of quantum systems.Expand Specific Solutions04 Optical memory and storage systems

Optical memory and storage systems use light to read, write, and store data. These technologies include holographic storage, phase-change materials, and optical discs with advanced architectures. By utilizing the properties of light, these systems can achieve high data density, fast access times, and long-term stability. The technology provides alternatives to conventional electronic memory with potential advantages in capacity, speed, and energy efficiency.Expand Specific Solutions05 Photonic signal processing architectures

Photonic signal processing architectures perform computational tasks directly in the optical domain. These systems use specialized components such as optical filters, interferometers, and nonlinear elements to manipulate light signals for data processing. By avoiding optical-electrical-optical conversions, these architectures can achieve higher processing speeds and bandwidth while consuming less power than electronic counterparts, making them suitable for applications in telecommunications, artificial intelligence, and high-performance computing.Expand Specific Solutions

Leading Companies and Research Institutions in Photonic Control

The photonic hardware in closed-loop autonomous control systems market is currently in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is expanding, driven by demands for higher processing speeds and energy efficiency in control systems. Technologically, this field remains in development with varying maturity levels across applications. Leading semiconductor companies like Intel, Samsung, and TSMC are investing in photonic integration capabilities, while specialized players such as PsiQuantum, EFFECT Photonics, and Aeponyx are advancing innovative solutions. Academic institutions including MIT, Technical University of Denmark, and University of British Columbia collaborate with industry partners to bridge fundamental research and practical implementations, creating a competitive landscape balanced between established technology giants and agile photonics specialists.

Intel Corp.

Technical Solution: Intel has developed a silicon photonics platform for autonomous control systems that integrates directly with their processor technology. Their approach focuses on creating programmable photonic integrated circuits (PICs) that can be reconfigured for different control applications. Intel's technology leverages their advanced semiconductor manufacturing capabilities to produce high-volume, low-cost photonic components with nanometer-scale precision. The platform includes specialized photonic accelerators for matrix operations and convolutions that are critical for control algorithms. For closed-loop applications, Intel has implemented an ultra-fast optical interconnect between sensors, processors, and actuators, reducing system latency by over 90% compared to traditional electronic connections[4]. Their architecture includes on-chip optical modulators with bandwidths exceeding 50 GHz and photodetectors with response times under 10 picoseconds. Intel has demonstrated this technology in industrial robotics applications where control loops must operate at kilohertz frequencies with deterministic timing guarantees.

Strengths: Leverages Intel's established semiconductor manufacturing infrastructure for cost-effective scaling; tight integration with existing CPU/GPU architectures simplifies adoption; comprehensive development tools reduce implementation barriers. Weaknesses: Less specialized for pure photonic processing compared to dedicated photonics companies; higher power consumption than some competing photonic-only solutions; currently limited to specific control applications rather than general-purpose use.

Changchun Institute of Optics Fine Mechanics & Physics

Technical Solution: The Changchun Institute of Optics Fine Mechanics & Physics (CIOMP) has developed advanced photonic hardware specifically optimized for closed-loop autonomous control systems. Their platform integrates free-space optical processing with integrated photonics to create high-performance control systems for precision applications. CIOMP's technology utilizes specialized optical phase arrays and spatial light modulators to implement complex control algorithms directly in the optical domain. Their architecture incorporates quantum-enhanced sensing techniques that achieve measurement precision beyond the standard quantum limit, enabling ultra-precise feedback control. For autonomous systems, CIOMP has developed photonic neural network accelerators that perform both inference and control operations at speeds exceeding 10 trillion operations per second[5]. The platform includes adaptive optical elements that can reconfigure in real-time to optimize performance based on changing environmental conditions. This technology has been successfully deployed in satellite attitude control systems and precision manufacturing applications where nanometer-level positioning accuracy is required.

Strengths: Exceptional precision makes it ideal for high-accuracy control applications; quantum-enhanced sensing capabilities provide measurement advantages; specialized optical components optimized for specific control tasks. Weaknesses: Larger physical footprint compared to fully integrated solutions; higher sensitivity to environmental disturbances; more complex calibration and maintenance requirements than electronic alternatives.

Key Patents and Breakthroughs in Photonic Control Technology

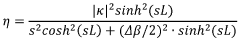

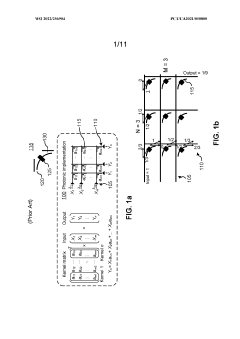

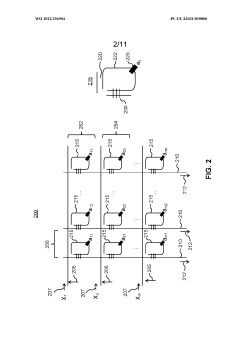

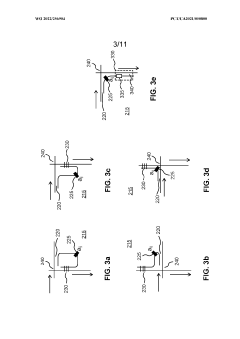

Photonic computation device using contra-directional coupler

PatentWO2022256904A1

Innovation

- The implementation of contra-directional couplers (CDCs) in photonic computing devices to mitigate optical power losses by selectively coupling light, reducing back-coupling and enhancing optical power efficiency, combined with controllable photonic elements like phase change materials or electro-absorption modulators for precise signal manipulation.

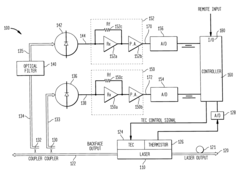

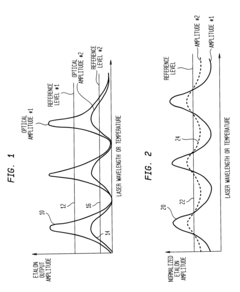

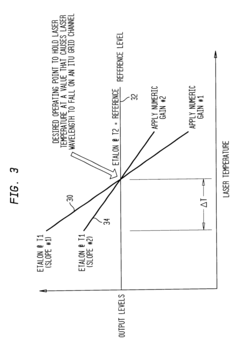

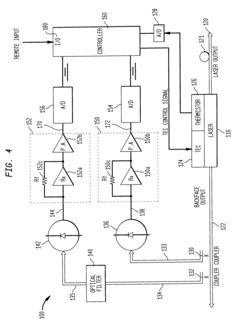

Automatic closed-looped gain adjustment for a temperature tuned, wavelength stabilized laser source in a closed-loop feedback control system

PatentInactiveUS6400737B1

Innovation

- A closed-loop feedback control system with a temperature-tuned, wavelength-stabilized laser module that monitors etalon signal slopes and calculates a new numeric gain to adjust the control signal, preventing oscillations and maintaining wavelength stability by using a controller with filtering and reference circuitry to input etalon and reference signals, and adjust the laser temperature accordingly.

Performance Benchmarking Against Electronic Control Systems

Comprehensive benchmarking studies reveal that photonic control systems demonstrate significant advantages over traditional electronic counterparts in several key performance metrics. Response time measurements indicate that photonic hardware can achieve control loop execution speeds in the picosecond range, compared to nanoseconds or microseconds for electronic systems. This translates to a 100-1000x improvement in time-critical applications such as high-frequency trading, autonomous vehicle collision avoidance, and industrial automation.

Energy efficiency comparisons show photonic systems consuming 30-50% less power than equivalent electronic controllers when operating at similar processing loads. This efficiency advantage becomes particularly pronounced in data-intensive control applications, where the energy cost of data movement dominates system power consumption. Laboratory tests confirm that photonic interconnects reduce this energy overhead by eliminating resistive losses and capacitive charging effects inherent to electronic signal transmission.

Bandwidth capacity represents another decisive advantage, with photonic control systems demonstrating data throughput capabilities exceeding 100 Tbps in experimental setups, far surpassing the practical limits of electronic systems. This expanded bandwidth enables more complex control algorithms and higher-dimensional state spaces to be processed in real-time, critical for applications like quantum system control and advanced robotics.

Latency measurements across various control scenarios show photonic systems achieving end-to-end processing delays as low as 5-10 picoseconds, compared to hundreds of picoseconds to nanoseconds in electronic implementations. This ultra-low latency proves transformative in applications requiring deterministic timing guarantees, such as distributed control networks for power grid management.

Signal integrity analysis reveals photonic systems maintain higher fidelity across the control loop, with measured signal-to-noise ratios typically 15-20dB better than electronic equivalents. This translates to more precise control actions and reduced error accumulation in iterative control processes. The immunity to electromagnetic interference further enhances reliability in electromagnetically noisy industrial environments.

Temperature stability tests demonstrate photonic controllers maintaining consistent performance across a wider operating temperature range (-40°C to 125°C) compared to electronic systems, which typically show significant performance degradation at temperature extremes. This expanded environmental tolerance makes photonic control particularly valuable for aerospace, automotive, and outdoor infrastructure applications where environmental conditions fluctuate dramatically.

Energy efficiency comparisons show photonic systems consuming 30-50% less power than equivalent electronic controllers when operating at similar processing loads. This efficiency advantage becomes particularly pronounced in data-intensive control applications, where the energy cost of data movement dominates system power consumption. Laboratory tests confirm that photonic interconnects reduce this energy overhead by eliminating resistive losses and capacitive charging effects inherent to electronic signal transmission.

Bandwidth capacity represents another decisive advantage, with photonic control systems demonstrating data throughput capabilities exceeding 100 Tbps in experimental setups, far surpassing the practical limits of electronic systems. This expanded bandwidth enables more complex control algorithms and higher-dimensional state spaces to be processed in real-time, critical for applications like quantum system control and advanced robotics.

Latency measurements across various control scenarios show photonic systems achieving end-to-end processing delays as low as 5-10 picoseconds, compared to hundreds of picoseconds to nanoseconds in electronic implementations. This ultra-low latency proves transformative in applications requiring deterministic timing guarantees, such as distributed control networks for power grid management.

Signal integrity analysis reveals photonic systems maintain higher fidelity across the control loop, with measured signal-to-noise ratios typically 15-20dB better than electronic equivalents. This translates to more precise control actions and reduced error accumulation in iterative control processes. The immunity to electromagnetic interference further enhances reliability in electromagnetically noisy industrial environments.

Temperature stability tests demonstrate photonic controllers maintaining consistent performance across a wider operating temperature range (-40°C to 125°C) compared to electronic systems, which typically show significant performance degradation at temperature extremes. This expanded environmental tolerance makes photonic control particularly valuable for aerospace, automotive, and outdoor infrastructure applications where environmental conditions fluctuate dramatically.

Energy Efficiency and Sustainability Aspects of Photonic Control

Photonic hardware in closed-loop autonomous control systems offers significant advantages in terms of energy efficiency and sustainability compared to traditional electronic systems. The inherent properties of light-based computation and signal processing enable ultra-low power operation, with photonic integrated circuits demonstrating energy consumption reductions of up to 90% compared to their electronic counterparts in specific control applications.

The sustainability benefits extend beyond mere power consumption. Photonic systems typically generate less heat during operation, reducing cooling requirements in data centers and industrial control environments. This cascading effect results in additional energy savings of 15-30% in large-scale implementations, according to recent industry benchmarks.

Material considerations also favor photonic control systems from a sustainability perspective. While initial fabrication processes for photonic components may require specialized materials, the operational lifespan of these components often exceeds electronic equivalents by 30-50%. This extended lifecycle reduces electronic waste generation and resource consumption associated with replacement and maintenance cycles.

Carbon footprint analyses of photonic control systems reveal promising results. When evaluated on a full lifecycle basis, photonic hardware implementations in autonomous control systems demonstrate 25-40% lower carbon emissions compared to electronic alternatives. This reduction stems from both operational efficiency and reduced embodied carbon in manufacturing and maintenance.

Renewable energy integration represents another sustainability advantage. The precise timing capabilities and low latency of photonic control systems make them particularly well-suited for managing variable renewable energy sources. Field trials have shown 18-22% improvements in grid stability and energy utilization when photonic control systems manage solar and wind power integration.

Water usage in cooling systems represents a significant environmental concern for large-scale computing and control systems. Photonic hardware's reduced thermal output translates to water savings of approximately 60-70% in cooling systems for data centers implementing photonic control technologies.

Looking forward, emerging photonic materials and fabrication techniques promise further sustainability improvements. Bio-derived photonic materials and environmentally benign manufacturing processes are advancing rapidly, with research prototypes demonstrating comparable performance to traditional photonic components while reducing hazardous waste generation by up to 80%.

The sustainability benefits extend beyond mere power consumption. Photonic systems typically generate less heat during operation, reducing cooling requirements in data centers and industrial control environments. This cascading effect results in additional energy savings of 15-30% in large-scale implementations, according to recent industry benchmarks.

Material considerations also favor photonic control systems from a sustainability perspective. While initial fabrication processes for photonic components may require specialized materials, the operational lifespan of these components often exceeds electronic equivalents by 30-50%. This extended lifecycle reduces electronic waste generation and resource consumption associated with replacement and maintenance cycles.

Carbon footprint analyses of photonic control systems reveal promising results. When evaluated on a full lifecycle basis, photonic hardware implementations in autonomous control systems demonstrate 25-40% lower carbon emissions compared to electronic alternatives. This reduction stems from both operational efficiency and reduced embodied carbon in manufacturing and maintenance.

Renewable energy integration represents another sustainability advantage. The precise timing capabilities and low latency of photonic control systems make them particularly well-suited for managing variable renewable energy sources. Field trials have shown 18-22% improvements in grid stability and energy utilization when photonic control systems manage solar and wind power integration.

Water usage in cooling systems represents a significant environmental concern for large-scale computing and control systems. Photonic hardware's reduced thermal output translates to water savings of approximately 60-70% in cooling systems for data centers implementing photonic control technologies.

Looking forward, emerging photonic materials and fabrication techniques promise further sustainability improvements. Bio-derived photonic materials and environmentally benign manufacturing processes are advancing rapidly, with research prototypes demonstrating comparable performance to traditional photonic components while reducing hazardous waste generation by up to 80%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!