Thermosyphon Reboilers: Circulation Limits, Pressure Drop And Heat Flux Constraints

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermosyphon Reboiler Technology Evolution and Objectives

Thermosyphon reboilers have evolved significantly since their introduction in the early 20th century as critical components in distillation and separation processes. Initially designed with simple vertical tube configurations, these systems relied on natural circulation principles established by thermodynamic pioneers like Clausius and Rankine. The fundamental operating principle—utilizing density differences between heated and cooled fluids to create natural circulation—has remained unchanged, though implementation has grown increasingly sophisticated.

The 1950s-1970s marked a pivotal era when thermosyphon technology transitioned from empirical design to scientific engineering. Researchers like Fair and Kern developed the first comprehensive mathematical models describing circulation patterns and heat transfer coefficients. These early models, while groundbreaking, often failed to accurately predict circulation limits under varying process conditions, leading to conservative designs with significant safety margins.

By the 1980s, computational fluid dynamics (CFD) began transforming thermosyphon design, enabling more precise modeling of two-phase flow regimes. This period saw the introduction of enhanced tube geometries—including finned tubes and structured surfaces—that dramatically improved heat transfer efficiency while addressing fouling concerns prevalent in earlier designs.

The 1990s-2000s witnessed integration of advanced materials science, with corrosion-resistant alloys and specialized coatings extending equipment lifespan in aggressive process environments. Simultaneously, instrumentation advances enabled real-time monitoring of circulation patterns and heat flux distribution, allowing operators to optimize performance within safe operating envelopes.

Current technological objectives focus on several critical areas. First, developing more accurate predictive models for circulation limits under transient conditions remains paramount, as existing models often fail during startup, shutdown, or process disturbances. Second, optimizing pressure drop characteristics across the thermosyphon loop to maximize circulation rates without excessive pumping energy represents a key efficiency goal.

Third, establishing precise heat flux constraints for modern tube materials and geometries is essential, as traditional design limits often prove overly conservative for advanced materials. Fourth, integrating thermosyphon technology with renewable energy sources and waste heat recovery systems presents opportunities for significant energy efficiency improvements across process industries.

Finally, miniaturization and modularization of thermosyphon reboilers aims to expand their application beyond traditional large-scale petrochemical processes into emerging fields like biofuels, pharmaceuticals, and specialized chemical manufacturing, where process flexibility and smaller production volumes predominate.

The 1950s-1970s marked a pivotal era when thermosyphon technology transitioned from empirical design to scientific engineering. Researchers like Fair and Kern developed the first comprehensive mathematical models describing circulation patterns and heat transfer coefficients. These early models, while groundbreaking, often failed to accurately predict circulation limits under varying process conditions, leading to conservative designs with significant safety margins.

By the 1980s, computational fluid dynamics (CFD) began transforming thermosyphon design, enabling more precise modeling of two-phase flow regimes. This period saw the introduction of enhanced tube geometries—including finned tubes and structured surfaces—that dramatically improved heat transfer efficiency while addressing fouling concerns prevalent in earlier designs.

The 1990s-2000s witnessed integration of advanced materials science, with corrosion-resistant alloys and specialized coatings extending equipment lifespan in aggressive process environments. Simultaneously, instrumentation advances enabled real-time monitoring of circulation patterns and heat flux distribution, allowing operators to optimize performance within safe operating envelopes.

Current technological objectives focus on several critical areas. First, developing more accurate predictive models for circulation limits under transient conditions remains paramount, as existing models often fail during startup, shutdown, or process disturbances. Second, optimizing pressure drop characteristics across the thermosyphon loop to maximize circulation rates without excessive pumping energy represents a key efficiency goal.

Third, establishing precise heat flux constraints for modern tube materials and geometries is essential, as traditional design limits often prove overly conservative for advanced materials. Fourth, integrating thermosyphon technology with renewable energy sources and waste heat recovery systems presents opportunities for significant energy efficiency improvements across process industries.

Finally, miniaturization and modularization of thermosyphon reboilers aims to expand their application beyond traditional large-scale petrochemical processes into emerging fields like biofuels, pharmaceuticals, and specialized chemical manufacturing, where process flexibility and smaller production volumes predominate.

Industrial Applications and Market Demand Analysis

Thermosyphon reboilers have established themselves as critical components across numerous process industries due to their reliability, energy efficiency, and low maintenance requirements. The global market for heat exchangers, including thermosyphon reboilers, was valued at approximately $16.5 billion in 2022 and is projected to grow at a CAGR of 6.2% through 2030, driven primarily by expanding industrial applications and increasing energy efficiency requirements.

The petroleum refining industry represents the largest application segment for thermosyphon reboilers, accounting for roughly 35% of the total market share. These devices are extensively utilized in distillation columns, fractionation units, and various separation processes where precise temperature control and reliable heat transfer are paramount. The industry's continuous push toward process optimization and energy conservation has intensified demand for thermosyphon systems that can operate at higher efficiency levels while managing circulation limits effectively.

Chemical processing follows as the second-largest application sector, where thermosyphon reboilers play vital roles in reactions requiring controlled heating, evaporation processes, and solvent recovery systems. The pharmaceutical industry has also emerged as a rapidly growing market segment, with increasing requirements for high-purity processing and stringent temperature control in various production stages.

Market analysis reveals a significant shift toward custom-engineered thermosyphon solutions that address specific process requirements while optimizing for circulation limits and pressure drop constraints. This trend is particularly evident in high-value chemical manufacturing, where process efficiency directly impacts product quality and production economics. Manufacturers are increasingly willing to invest in advanced thermosyphon designs that minimize fouling, reduce pressure drops, and maximize heat flux without exceeding circulation limits.

Geographically, North America and Europe currently dominate the thermosyphon reboiler market, collectively accounting for approximately 60% of global installations. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate due to rapid industrialization and expansion of refining and petrochemical capacities. These emerging markets are creating substantial demand for both standard and specialized thermosyphon reboiler technologies.

Energy efficiency regulations and sustainability initiatives are further driving market demand for optimized thermosyphon designs. With industrial energy consumption under increasing scrutiny, process engineers are prioritizing reboiler systems that minimize utility consumption while maintaining operational reliability. This has accelerated research into enhanced heat transfer surfaces, improved circulation patterns, and more precise modeling of thermosyphon behavior under various operating conditions.

The petroleum refining industry represents the largest application segment for thermosyphon reboilers, accounting for roughly 35% of the total market share. These devices are extensively utilized in distillation columns, fractionation units, and various separation processes where precise temperature control and reliable heat transfer are paramount. The industry's continuous push toward process optimization and energy conservation has intensified demand for thermosyphon systems that can operate at higher efficiency levels while managing circulation limits effectively.

Chemical processing follows as the second-largest application sector, where thermosyphon reboilers play vital roles in reactions requiring controlled heating, evaporation processes, and solvent recovery systems. The pharmaceutical industry has also emerged as a rapidly growing market segment, with increasing requirements for high-purity processing and stringent temperature control in various production stages.

Market analysis reveals a significant shift toward custom-engineered thermosyphon solutions that address specific process requirements while optimizing for circulation limits and pressure drop constraints. This trend is particularly evident in high-value chemical manufacturing, where process efficiency directly impacts product quality and production economics. Manufacturers are increasingly willing to invest in advanced thermosyphon designs that minimize fouling, reduce pressure drops, and maximize heat flux without exceeding circulation limits.

Geographically, North America and Europe currently dominate the thermosyphon reboiler market, collectively accounting for approximately 60% of global installations. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate due to rapid industrialization and expansion of refining and petrochemical capacities. These emerging markets are creating substantial demand for both standard and specialized thermosyphon reboiler technologies.

Energy efficiency regulations and sustainability initiatives are further driving market demand for optimized thermosyphon designs. With industrial energy consumption under increasing scrutiny, process engineers are prioritizing reboiler systems that minimize utility consumption while maintaining operational reliability. This has accelerated research into enhanced heat transfer surfaces, improved circulation patterns, and more precise modeling of thermosyphon behavior under various operating conditions.

Current Limitations and Technical Challenges

Thermosyphon reboilers face several significant technical challenges that limit their operational efficiency and applicability. The primary limitation revolves around circulation constraints, which directly impact the system's heat transfer capabilities. When the driving force for natural circulation becomes insufficient, the flow rate decreases dramatically, leading to potential dry-out conditions and thermal inefficiencies. This circulation limitation is particularly pronounced in systems with high viscosity fluids or when operating at low temperature differentials.

Pressure drop constraints represent another critical challenge in thermosyphon reboiler design. The total pressure drop across the system must be carefully balanced against the available hydrostatic head to maintain proper circulation. Excessive pressure drops in the heating tubes, return lines, or process connections can disrupt the delicate equilibrium required for effective operation. Industry data indicates that pressure drop issues account for approximately 30% of thermosyphon reboiler performance problems in chemical processing applications.

Heat flux constraints further complicate thermosyphon reboiler operations. When heat flux exceeds critical thresholds, film boiling can occur, creating an insulating vapor layer that severely reduces heat transfer efficiency. This phenomenon, known as departure from nucleate boiling (DNB), represents a fundamental limitation that restricts the maximum achievable heat transfer rates. Current designs typically operate with safety margins that limit heat flux to 60-70% of theoretical maximums to avoid these detrimental conditions.

Geometric constraints also present significant challenges. The vertical height requirement for thermosyphon reboilers can be prohibitive in space-limited installations. Additionally, the need for specific tube configurations to optimize flow patterns often conflicts with manufacturing capabilities and cost considerations. These physical constraints frequently force engineers to compromise between theoretical performance and practical implementation.

Material limitations further restrict thermosyphon technology advancement. The combination of high temperatures, potential corrosive environments, and thermal cycling creates demanding conditions for materials. Current metallurgical solutions often represent compromises between thermal conductivity, corrosion resistance, and mechanical strength, limiting overall system performance and longevity.

Control and stability issues present ongoing challenges, particularly during startup, shutdown, and load-change operations. The inherent lag in natural circulation systems makes rapid response to changing process conditions difficult, potentially leading to instabilities and reduced operational flexibility. This limitation becomes particularly problematic in processes requiring precise temperature control or frequent operational adjustments.

Pressure drop constraints represent another critical challenge in thermosyphon reboiler design. The total pressure drop across the system must be carefully balanced against the available hydrostatic head to maintain proper circulation. Excessive pressure drops in the heating tubes, return lines, or process connections can disrupt the delicate equilibrium required for effective operation. Industry data indicates that pressure drop issues account for approximately 30% of thermosyphon reboiler performance problems in chemical processing applications.

Heat flux constraints further complicate thermosyphon reboiler operations. When heat flux exceeds critical thresholds, film boiling can occur, creating an insulating vapor layer that severely reduces heat transfer efficiency. This phenomenon, known as departure from nucleate boiling (DNB), represents a fundamental limitation that restricts the maximum achievable heat transfer rates. Current designs typically operate with safety margins that limit heat flux to 60-70% of theoretical maximums to avoid these detrimental conditions.

Geometric constraints also present significant challenges. The vertical height requirement for thermosyphon reboilers can be prohibitive in space-limited installations. Additionally, the need for specific tube configurations to optimize flow patterns often conflicts with manufacturing capabilities and cost considerations. These physical constraints frequently force engineers to compromise between theoretical performance and practical implementation.

Material limitations further restrict thermosyphon technology advancement. The combination of high temperatures, potential corrosive environments, and thermal cycling creates demanding conditions for materials. Current metallurgical solutions often represent compromises between thermal conductivity, corrosion resistance, and mechanical strength, limiting overall system performance and longevity.

Control and stability issues present ongoing challenges, particularly during startup, shutdown, and load-change operations. The inherent lag in natural circulation systems makes rapid response to changing process conditions difficult, potentially leading to instabilities and reduced operational flexibility. This limitation becomes particularly problematic in processes requiring precise temperature control or frequent operational adjustments.

Circulation Rate Optimization Methodologies

01 Circulation limits in thermosyphon reboilers

Thermosyphon reboilers have specific circulation limits that affect their performance. These limits are determined by factors such as the height of the liquid column, the density difference between the vapor and liquid phases, and the flow resistance in the circulation loop. Understanding these limits is crucial for designing efficient thermosyphon systems that avoid stagnation or flow instabilities. Proper design considerations include optimizing the reboiler height, diameter ratios, and inlet/outlet configurations to ensure stable natural circulation.- Circulation limits and flow dynamics in thermosyphon reboilers: Thermosyphon reboilers have specific circulation limits that affect their performance. These limits are determined by factors such as fluid properties, geometry, and operating conditions. Proper understanding of circulation patterns helps prevent stagnation and ensures efficient heat transfer. The flow dynamics within thermosyphon systems are governed by natural convection principles, where density differences drive the circulation without external pumping. Optimizing these circulation patterns is essential for maintaining stable operation and preventing operational issues like vapor locking.

- Pressure drop considerations in thermosyphon design: Pressure drop is a critical parameter in thermosyphon reboiler design that affects circulation rates and overall efficiency. The total pressure drop includes contributions from friction, elevation changes, and acceleration effects. Designers must carefully balance the available driving force (thermosyphon head) against these pressure losses to ensure adequate circulation. Excessive pressure drop can lead to reduced flow rates and potential operational instabilities, while insufficient pressure drop may result in inadequate control of the circulation process. Optimizing pipe diameters, minimizing flow restrictions, and proper layout design are key strategies for managing pressure drop.

- Heat flux optimization and thermal performance: Heat flux management is crucial for thermosyphon reboiler performance and longevity. Excessive heat flux can lead to film boiling, reduced heat transfer efficiency, and potential tube damage. The critical heat flux varies with operating pressure, fluid properties, and geometry. Optimizing heat flux distribution across the heat transfer surface helps prevent localized overheating and ensures uniform vaporization. Advanced heat transfer enhancement techniques, such as modified tube surfaces or optimized flow patterns, can improve thermal performance while maintaining safe operating conditions.

- Innovative thermosyphon reboiler designs and configurations: Novel thermosyphon reboiler designs address traditional limitations through innovative configurations. These include vertical versus horizontal orientations, multi-pass arrangements, and hybrid systems that combine thermosyphon principles with other heat transfer mechanisms. Some designs incorporate special features to enhance circulation, reduce fouling, or improve turndown ratios. Advanced configurations may include integrated vapor-liquid separation, enhanced heat transfer surfaces, or specialized flow distribution systems to optimize performance across varying operating conditions.

- Control systems and operational stability for thermosyphon reboilers: Maintaining operational stability in thermosyphon reboilers requires sophisticated control systems that monitor and adjust key parameters. These systems help manage variations in heat input, process fluid composition, and operating conditions to prevent instabilities like flow oscillations or vapor locking. Instrumentation for level control, temperature monitoring, and pressure measurement provides essential feedback for control algorithms. Advanced control strategies may incorporate predictive models to anticipate changes in operating conditions and make proactive adjustments, ensuring continuous stable operation even during process transitions.

02 Pressure drop management in thermosyphon systems

Managing pressure drop is essential for efficient thermosyphon reboiler operation. The pressure drop across the system affects the driving force for natural circulation and must be carefully balanced with the available thermosyphonic head. Key factors influencing pressure drop include pipe diameter, flow path configuration, fitting losses, and two-phase flow characteristics. Innovative designs incorporate features to minimize pressure drop while maintaining adequate heat transfer, such as optimized tube arrangements, reduced flow restrictions, and strategic placement of inlet/outlet connections.Expand Specific Solutions03 Heat flux optimization techniques

Heat flux optimization in thermosyphon reboilers involves balancing the heat transfer rate with system stability. Excessive heat flux can lead to film boiling, reduced heat transfer efficiency, or even tube damage, while insufficient heat flux may result in inadequate vaporization. Advanced designs incorporate variable heat flux distribution, enhanced heat transfer surfaces, and optimized tube arrangements to maximize performance while preventing localized overheating. Consideration of fluid properties, operating pressure, and flow patterns is essential for determining the optimal heat flux range.Expand Specific Solutions04 Two-phase flow dynamics and stability

Two-phase flow dynamics significantly impact thermosyphon reboiler performance. The transition between different flow regimes (bubbly, slug, churn, annular) affects both heat transfer efficiency and circulation stability. Design considerations include proper sizing of return lines, strategic placement of vapor-liquid separation zones, and implementation of flow stabilizers to prevent oscillations or flow reversals. Understanding the relationship between vapor generation rate, liquid holdup, and flow pattern is crucial for predicting system behavior across varying operating conditions.Expand Specific Solutions05 Advanced thermosyphon reboiler designs and enhancements

Advanced thermosyphon reboiler designs incorporate innovative features to overcome traditional limitations. These include hybrid systems combining natural and forced circulation, enhanced surface geometries for improved heat transfer, and intelligent control systems for optimizing performance across varying process conditions. Novel approaches such as multi-pass configurations, integrated vapor-liquid separators, and specialized tube inserts help extend operating ranges and improve efficiency. Materials selection and fabrication techniques also play important roles in enhancing thermal performance and extending equipment lifespan.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

Thermosyphon reboilers technology is currently in a mature development stage, with established applications across petrochemical, energy, and manufacturing sectors. The market size is estimated to be substantial, driven by increasing demand for efficient heat transfer solutions in industrial processes. From a technical maturity perspective, industry leaders have developed sophisticated approaches to address circulation limits, pressure drop, and heat flux constraints. Companies like Saudi Aramco and Sinopec have pioneered advanced thermosyphon designs for large-scale refinery operations, while specialized thermal engineering firms such as J R Thermal LLC offer customized solutions. Academic institutions including Tianjin University and Xi'an Jiaotong University contribute significant research to overcome technical limitations. Equipment manufacturers like Mitsubishi Heavy Industries and The Babcock & Wilcox Co. have incorporated these advancements into commercial offerings, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

J R Thermal LLC

Technical Solution: J R Thermal has developed specialized thermosyphon reboiler technology focused on overcoming circulation limitations in challenging process applications. Their innovative approach incorporates variable-geometry flow channels that automatically adjust to changing process conditions, maintaining optimal circulation rates across a wide range of heat fluxes. The company's research has yielded proprietary surface treatments that enhance nucleate boiling while minimizing the formation of vapor films that can impede circulation. Their thermosyphon systems feature carefully engineered inlet distributors that ensure uniform fluid distribution across the heat transfer surface, preventing localized overheating and premature circulation failure. J R Thermal's technology includes advanced computational models that accurately predict the complex interaction between pressure drop, heat flux, and circulation rate, enabling precise design optimization for specific applications. Their systems incorporate strategic venting arrangements that effectively manage non-condensable gases that can accumulate and disrupt natural circulation patterns.

Strengths: Superior performance in applications with variable process conditions; excellent resistance to fouling; compact design requiring less installation space than conventional alternatives. Weaknesses: Higher engineering and fabrication costs; more complex maintenance procedures; requires more sophisticated process monitoring systems.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed advanced thermosyphon reboiler systems that address circulation limitations through optimized tube bundle configurations. Their technology implements variable baffle spacing and strategic nozzle placement to manage pressure drop across the system while maintaining thermal efficiency. The company's research has yielded proprietary designs that can operate at up to 30% higher heat flux than conventional systems without encountering circulation instabilities. Their approach incorporates computational fluid dynamics (CFD) modeling to predict two-phase flow patterns and identify potential stagnation zones, allowing for preemptive design modifications. Saudi Aramco's thermosyphon reboilers feature specially engineered inlet configurations that promote natural circulation even under varying process conditions, with particular attention to the critical region where vapor generation begins to impede liquid flow.

Strengths: Superior thermal efficiency in high-temperature applications; robust performance in heavy hydrocarbon processing; reduced fouling tendency through optimized flow distribution. Weaknesses: Higher initial capital investment; requires more sophisticated control systems; performance advantages diminish in lower heat flux applications.

Critical Heat Transfer and Pressure Drop Correlations

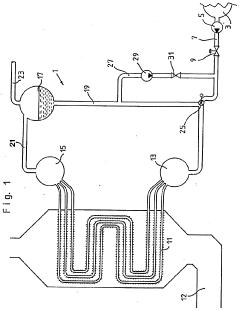

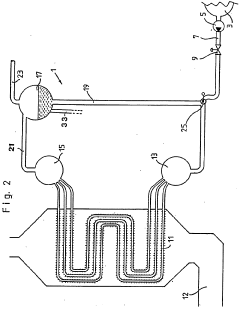

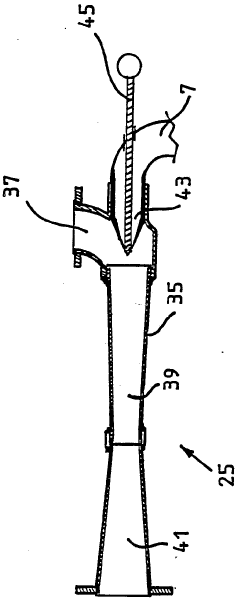

Heat recovery boiler with induced circulation

PatentWO1993023702A1

Innovation

- The implementation of an induced circulation system using an ejector to ensure water circulation in heat recovery boilers, eliminating the need for a circulation pump and allowing for adjustable pressure drop and reduced complexity, with the ejector being capable of maintaining circulation even when the water column height is minimized.

Heat recovery boiler with induced circulation

PatentInactiveEP0640198A1

Innovation

- The implementation of an induced circulation mechanism using an ejector in heat recovery boilers, allowing for adjustable pressure drop and eliminating the need for a circulation pump, with optional auxiliary pumps for start-up assistance, enabling compact design and improved dynamic behavior.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in the design and operation of thermosyphon reboilers, particularly as industries face increasing pressure to reduce carbon footprints and operational costs. Thermosyphon reboilers, when properly designed and operated within their circulation limits, pressure drop parameters, and heat flux constraints, can offer significant energy advantages over alternative heating systems.

The energy efficiency of thermosyphon reboilers stems primarily from their natural circulation mechanism, which eliminates the need for pumping equipment and the associated energy consumption. This passive operation translates to lower operational costs and reduced maintenance requirements compared to forced circulation systems. However, maximizing this efficiency requires careful consideration of the circulation limits to ensure optimal heat transfer without encountering stagnation or flow instabilities.

Heat recovery opportunities present another dimension of energy efficiency in thermosyphon systems. By integrating these reboilers into comprehensive heat exchange networks, process plants can capture and utilize waste heat that would otherwise be lost. This integration can significantly reduce the overall energy demand of distillation processes, which typically account for 40-70% of energy consumption in chemical processing facilities.

From a sustainability perspective, the reduced energy consumption directly correlates with lower greenhouse gas emissions. Studies indicate that optimized thermosyphon reboilers can achieve 15-30% energy savings compared to conventional forced circulation systems, translating to proportional reductions in carbon dioxide emissions. This makes them increasingly attractive as industries pursue decarbonization targets and face stricter environmental regulations.

Material selection also plays a crucial role in the sustainability profile of thermosyphon reboilers. Corrosion-resistant materials that extend equipment lifespan reduce the environmental impact associated with manufacturing and replacing system components. Additionally, materials with superior heat transfer properties can enhance energy efficiency while potentially reducing the physical footprint of the equipment.

Looking forward, emerging technologies such as advanced surface treatments and enhanced tube geometries offer promising avenues for further improving the energy performance of thermosyphon reboilers. These innovations aim to address the fundamental constraints of heat flux and pressure drop while pushing the boundaries of thermal efficiency. Combined with digital monitoring systems that enable real-time optimization of operating parameters, next-generation thermosyphon reboilers could achieve unprecedented levels of energy efficiency and sustainability.

The energy efficiency of thermosyphon reboilers stems primarily from their natural circulation mechanism, which eliminates the need for pumping equipment and the associated energy consumption. This passive operation translates to lower operational costs and reduced maintenance requirements compared to forced circulation systems. However, maximizing this efficiency requires careful consideration of the circulation limits to ensure optimal heat transfer without encountering stagnation or flow instabilities.

Heat recovery opportunities present another dimension of energy efficiency in thermosyphon systems. By integrating these reboilers into comprehensive heat exchange networks, process plants can capture and utilize waste heat that would otherwise be lost. This integration can significantly reduce the overall energy demand of distillation processes, which typically account for 40-70% of energy consumption in chemical processing facilities.

From a sustainability perspective, the reduced energy consumption directly correlates with lower greenhouse gas emissions. Studies indicate that optimized thermosyphon reboilers can achieve 15-30% energy savings compared to conventional forced circulation systems, translating to proportional reductions in carbon dioxide emissions. This makes them increasingly attractive as industries pursue decarbonization targets and face stricter environmental regulations.

Material selection also plays a crucial role in the sustainability profile of thermosyphon reboilers. Corrosion-resistant materials that extend equipment lifespan reduce the environmental impact associated with manufacturing and replacing system components. Additionally, materials with superior heat transfer properties can enhance energy efficiency while potentially reducing the physical footprint of the equipment.

Looking forward, emerging technologies such as advanced surface treatments and enhanced tube geometries offer promising avenues for further improving the energy performance of thermosyphon reboilers. These innovations aim to address the fundamental constraints of heat flux and pressure drop while pushing the boundaries of thermal efficiency. Combined with digital monitoring systems that enable real-time optimization of operating parameters, next-generation thermosyphon reboilers could achieve unprecedented levels of energy efficiency and sustainability.

Safety Standards and Risk Mitigation Strategies

The operation of thermosyphon reboilers involves inherent risks due to the handling of potentially hazardous fluids at elevated temperatures and pressures. Comprehensive safety standards have been developed by organizations such as the American Society of Mechanical Engineers (ASME), the American Petroleum Institute (API), and the International Organization for Standardization (ISO) to address these concerns. These standards encompass design requirements, material specifications, fabrication procedures, and inspection protocols specifically tailored for pressure vessels and heat exchangers.

Pressure relief systems represent a critical safety component in thermosyphon reboiler installations. These systems must be designed to accommodate various scenarios including fire exposure, loss of circulation, and excessive heat input. The sizing and selection of pressure relief devices must comply with standards such as API RP 520 and 521, which provide guidelines for determining relief requirements and designing appropriate discharge systems.

Operational safety measures for thermosyphon reboilers include continuous monitoring of key parameters such as liquid level, circulation rate, pressure drop, and temperature distribution. Advanced control systems equipped with automated shutdown capabilities can detect abnormal conditions such as stagnation, flow reversal, or excessive pressure drop that might indicate impending circulation failure. Implementation of process hazard analysis (PHA) methodologies, including HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis), helps identify potential failure modes and establish appropriate safeguards.

Material selection represents another crucial aspect of risk mitigation in thermosyphon reboiler design. Consideration must be given to corrosion resistance, thermal cycling capabilities, and mechanical properties at operating temperatures. Regular inspection protocols, including non-destructive testing techniques such as ultrasonic thickness measurement and radiographic examination, help detect deterioration before failure occurs.

Emergency response planning specifically tailored for thermosyphon reboiler incidents forms an essential component of a comprehensive safety management system. This includes procedures for safe shutdown during circulation disruptions, response to tube ruptures, and management of potential releases of process fluids. Training programs for operational personnel should emphasize recognition of early warning signs of circulation problems and appropriate corrective actions.

Risk assessment methodologies specific to thermosyphon systems focus on identifying potential circulation failure mechanisms, including vapor binding, insufficient driving head, and excessive pressure drop. Quantitative risk assessment techniques can help prioritize mitigation measures based on consequence severity and probability of occurrence. Implementation of inherently safer design principles, such as minimizing inventory of hazardous materials and designing for stable circulation across the operating envelope, provides fundamental risk reduction.

Pressure relief systems represent a critical safety component in thermosyphon reboiler installations. These systems must be designed to accommodate various scenarios including fire exposure, loss of circulation, and excessive heat input. The sizing and selection of pressure relief devices must comply with standards such as API RP 520 and 521, which provide guidelines for determining relief requirements and designing appropriate discharge systems.

Operational safety measures for thermosyphon reboilers include continuous monitoring of key parameters such as liquid level, circulation rate, pressure drop, and temperature distribution. Advanced control systems equipped with automated shutdown capabilities can detect abnormal conditions such as stagnation, flow reversal, or excessive pressure drop that might indicate impending circulation failure. Implementation of process hazard analysis (PHA) methodologies, including HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis), helps identify potential failure modes and establish appropriate safeguards.

Material selection represents another crucial aspect of risk mitigation in thermosyphon reboiler design. Consideration must be given to corrosion resistance, thermal cycling capabilities, and mechanical properties at operating temperatures. Regular inspection protocols, including non-destructive testing techniques such as ultrasonic thickness measurement and radiographic examination, help detect deterioration before failure occurs.

Emergency response planning specifically tailored for thermosyphon reboiler incidents forms an essential component of a comprehensive safety management system. This includes procedures for safe shutdown during circulation disruptions, response to tube ruptures, and management of potential releases of process fluids. Training programs for operational personnel should emphasize recognition of early warning signs of circulation problems and appropriate corrective actions.

Risk assessment methodologies specific to thermosyphon systems focus on identifying potential circulation failure mechanisms, including vapor binding, insufficient driving head, and excessive pressure drop. Quantitative risk assessment techniques can help prioritize mitigation measures based on consequence severity and probability of occurrence. Implementation of inherently safer design principles, such as minimizing inventory of hazardous materials and designing for stable circulation across the operating envelope, provides fundamental risk reduction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!