Screw conveying mechanism of screwdriver for connecting screws and screwdriver for connecting screws

A technology for conveying mechanisms and connecting screws, which can be applied to screwdrivers, wrenches, metal processing equipment, etc., and can solve problems such as increased operating load of driving operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Embodiments of the present invention will be described with reference to the drawings.

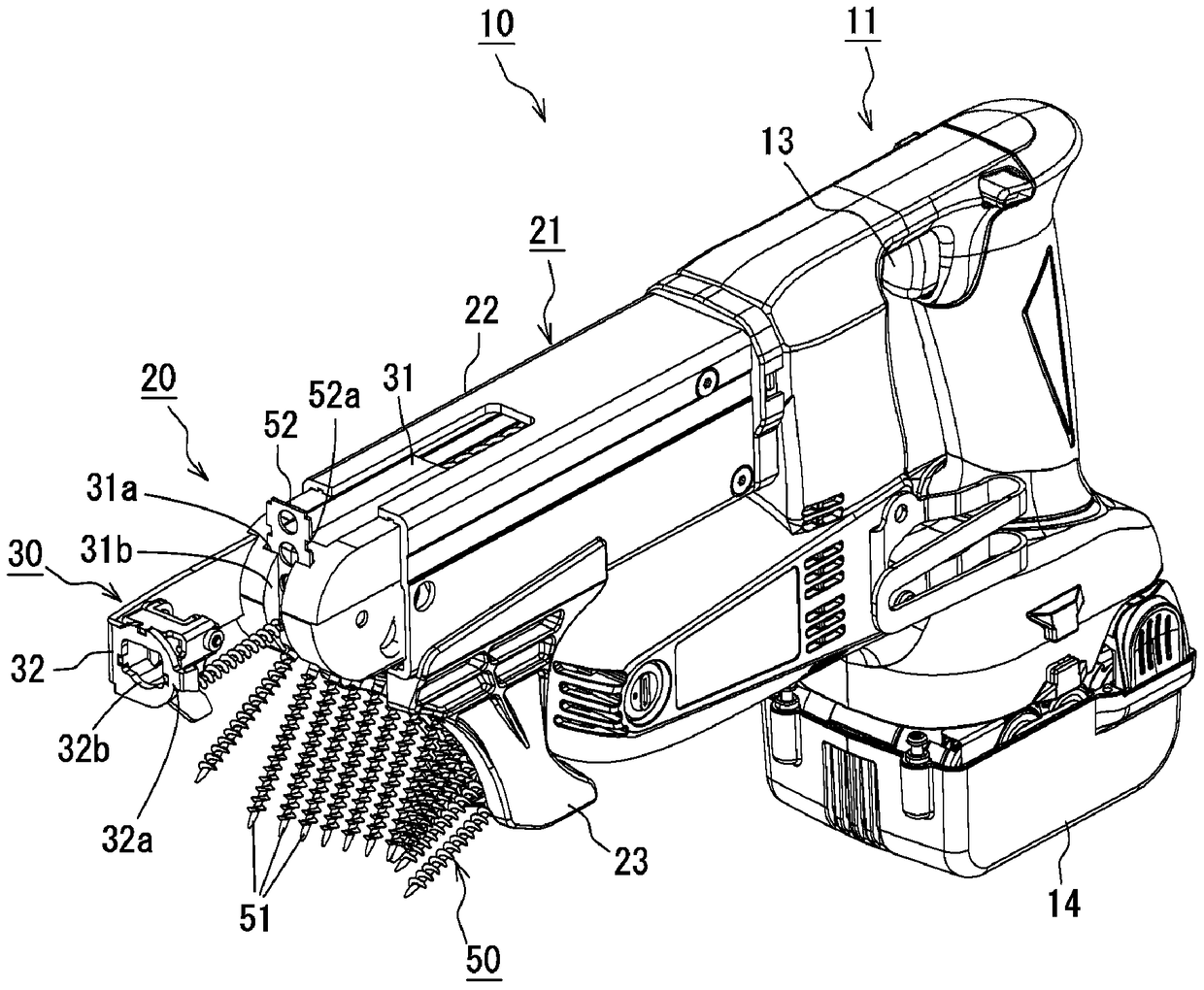

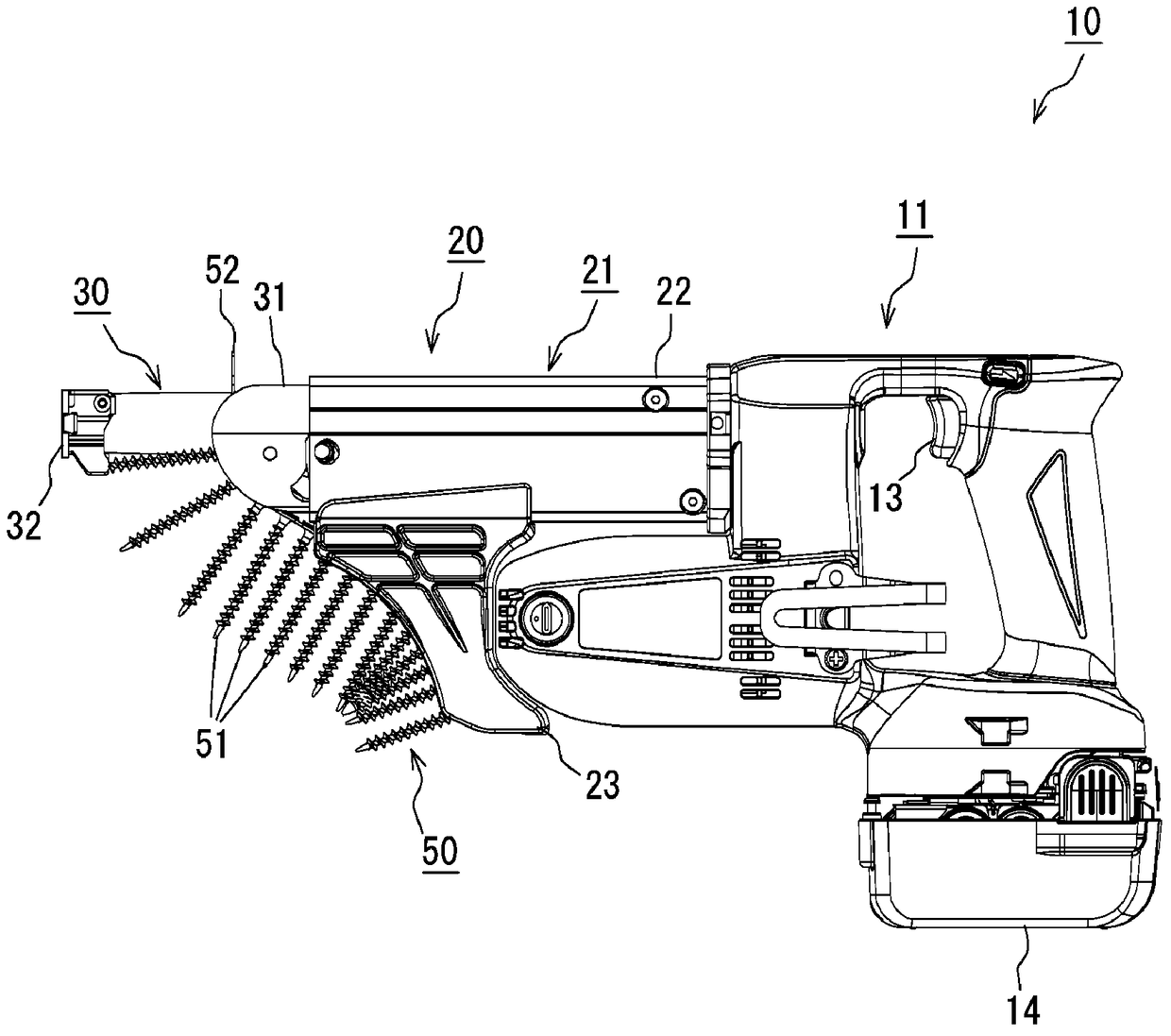

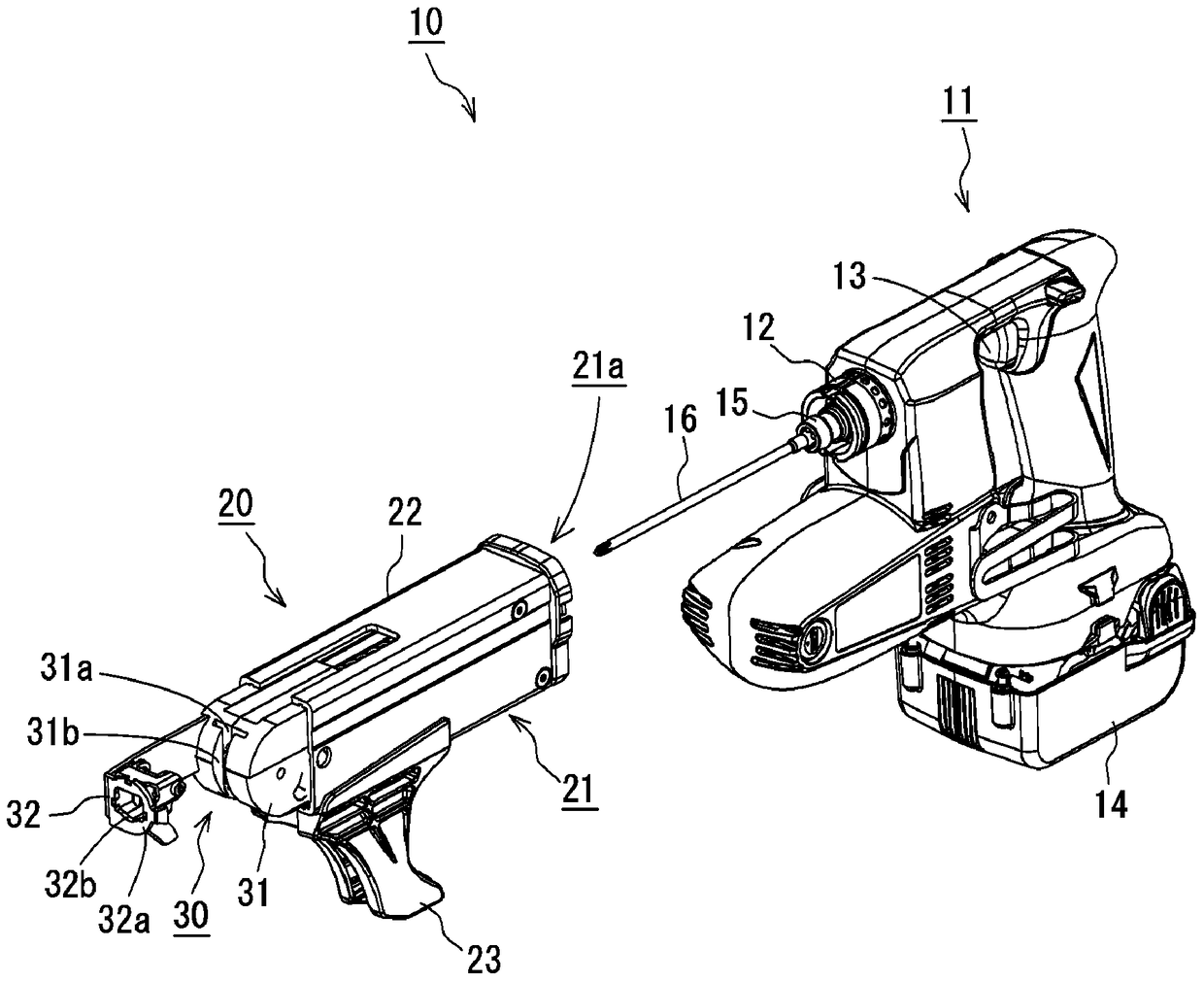

[0085] The screwdriver 10 for connecting screws according to this embodiment uses a connecting screw 50 in which a plurality of screws 51 are connected by a connecting band 52 . Such as Figure 1~3 As shown, the screwdriver 10 includes a tool body 11 and a fastener supply device 20 attached to the tool body 11 . A mounting portion 12 is provided at the front end of the tool body 11 , and the connecting portion 21 a at the rear end of the fastener supply device 20 can be fitted outside the mounting portion 12 , whereby the fastener supply device 20 can be detached from the tool body 11 .

[0086] Such as image 3 As shown, the tool main body 11 includes a bit mounting portion 15 at a front end portion covered by the fastener supply device 20 , and a screwdriver bit 16 is mounted on the bit mounting portion 15 . When the trigger 13 of the tool main body 11 is pulled, a motor (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com