Accura 25’s Influence in Breakthrough Industrial Designs

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, a groundbreaking material in the field of industrial design, has emerged as a pivotal innovation in the realm of stereolithography (SLA) 3D printing. Developed by 3D Systems, this high-performance resin has revolutionized the way designers and engineers approach prototyping and manufacturing processes. The primary objective behind the creation of Accura 25 was to address the limitations of traditional materials used in SLA printing, particularly in terms of durability, accuracy, and versatility.

The evolution of Accura 25 can be traced back to the early 2000s when the demand for more robust and precise 3D printing materials began to surge. As industries such as automotive, aerospace, and consumer electronics sought to accelerate their product development cycles, the need for a material that could withstand rigorous testing and simulate end-use parts became increasingly apparent. Accura 25 was conceived as a solution to these challenges, aiming to bridge the gap between prototype and production-grade materials.

One of the key technological trends that influenced the development of Accura 25 was the growing emphasis on functional prototyping. Design teams across various sectors required materials that could not only accurately represent the aesthetics of their products but also mimic the mechanical properties of the final production materials. This shift in focus from purely visual prototypes to functional ones drove the research and development efforts behind Accura 25.

The material's composition was carefully engineered to achieve a balance between strength, flexibility, and thermal resistance. These properties were crucial for enabling designers to create prototypes that could undergo real-world testing scenarios, such as fit checks, assembly trials, and even limited functional testing. The ability to produce parts with fine details and smooth surface finishes further enhanced Accura 25's appeal in the industrial design community.

As the adoption of additive manufacturing technologies continued to expand, Accura 25 played a significant role in pushing the boundaries of what was possible with 3D printed prototypes. Its impact extended beyond mere visual representation, allowing designers to iterate more rapidly and make informed decisions earlier in the product development process. This acceleration of the design cycle has been particularly valuable in industries where time-to-market is a critical factor.

The ongoing refinement of Accura 25 has been driven by continuous feedback from users across various industries. This iterative improvement process has led to enhancements in the material's performance characteristics, such as improved dimensional stability and reduced moisture sensitivity. These advancements have further solidified Accura 25's position as a go-to material for breakthrough industrial designs, enabling innovators to push the boundaries of form and function in their creations.

The evolution of Accura 25 can be traced back to the early 2000s when the demand for more robust and precise 3D printing materials began to surge. As industries such as automotive, aerospace, and consumer electronics sought to accelerate their product development cycles, the need for a material that could withstand rigorous testing and simulate end-use parts became increasingly apparent. Accura 25 was conceived as a solution to these challenges, aiming to bridge the gap between prototype and production-grade materials.

One of the key technological trends that influenced the development of Accura 25 was the growing emphasis on functional prototyping. Design teams across various sectors required materials that could not only accurately represent the aesthetics of their products but also mimic the mechanical properties of the final production materials. This shift in focus from purely visual prototypes to functional ones drove the research and development efforts behind Accura 25.

The material's composition was carefully engineered to achieve a balance between strength, flexibility, and thermal resistance. These properties were crucial for enabling designers to create prototypes that could undergo real-world testing scenarios, such as fit checks, assembly trials, and even limited functional testing. The ability to produce parts with fine details and smooth surface finishes further enhanced Accura 25's appeal in the industrial design community.

As the adoption of additive manufacturing technologies continued to expand, Accura 25 played a significant role in pushing the boundaries of what was possible with 3D printed prototypes. Its impact extended beyond mere visual representation, allowing designers to iterate more rapidly and make informed decisions earlier in the product development process. This acceleration of the design cycle has been particularly valuable in industries where time-to-market is a critical factor.

The ongoing refinement of Accura 25 has been driven by continuous feedback from users across various industries. This iterative improvement process has led to enhancements in the material's performance characteristics, such as improved dimensional stability and reduced moisture sensitivity. These advancements have further solidified Accura 25's position as a go-to material for breakthrough industrial designs, enabling innovators to push the boundaries of form and function in their creations.

Market Demand Analysis for Accura 25

The market demand for Accura 25 in breakthrough industrial designs has been steadily increasing due to its unique properties and versatile applications. This advanced stereolithography resin, developed by 3D Systems, has gained significant traction in various industries, particularly in automotive, aerospace, and consumer electronics sectors.

In the automotive industry, Accura 25 has become a preferred material for rapid prototyping and functional testing of complex parts. Its high resolution and smooth surface finish make it ideal for creating detailed models of interior components, aerodynamic parts, and under-hood applications. The automotive market's shift towards electric vehicles and lightweight designs has further boosted the demand for Accura 25, as it allows for quick iteration and validation of innovative concepts.

The aerospace sector has also shown a growing interest in Accura 25 for its ability to produce precise, lightweight parts with excellent dimensional stability. This material is increasingly used in the production of intricate components for aircraft interiors, as well as for creating prototypes of turbine blades and other critical parts. The aerospace industry's focus on fuel efficiency and performance optimization has led to a surge in demand for materials that can facilitate rapid design iterations and testing.

Consumer electronics manufacturers have embraced Accura 25 for its capacity to create high-quality prototypes of sleek, modern designs. The material's ability to replicate fine details and achieve smooth surfaces makes it particularly suitable for developing casings, connectors, and other intricate components found in smartphones, tablets, and wearable devices. As the consumer electronics market continues to evolve rapidly, the demand for materials that can keep pace with fast product development cycles has intensified.

The medical device industry has also recognized the potential of Accura 25 in creating precise anatomical models and surgical guides. The material's biocompatibility and ability to withstand sterilization processes have made it valuable for producing patient-specific implants and prosthetics. As personalized medicine gains momentum, the demand for materials that can facilitate custom medical solutions is expected to grow significantly.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is driven by the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new applications for advanced materials like Accura 25.

The demand for Accura 25 is also influenced by the broader trend towards sustainable manufacturing practices. As companies seek to reduce waste and improve resource efficiency, the use of additive manufacturing materials that enable precise, on-demand production is becoming more prevalent. Accura 25's ability to produce high-quality parts with minimal material waste aligns well with these sustainability goals, further driving its market demand.

In the automotive industry, Accura 25 has become a preferred material for rapid prototyping and functional testing of complex parts. Its high resolution and smooth surface finish make it ideal for creating detailed models of interior components, aerodynamic parts, and under-hood applications. The automotive market's shift towards electric vehicles and lightweight designs has further boosted the demand for Accura 25, as it allows for quick iteration and validation of innovative concepts.

The aerospace sector has also shown a growing interest in Accura 25 for its ability to produce precise, lightweight parts with excellent dimensional stability. This material is increasingly used in the production of intricate components for aircraft interiors, as well as for creating prototypes of turbine blades and other critical parts. The aerospace industry's focus on fuel efficiency and performance optimization has led to a surge in demand for materials that can facilitate rapid design iterations and testing.

Consumer electronics manufacturers have embraced Accura 25 for its capacity to create high-quality prototypes of sleek, modern designs. The material's ability to replicate fine details and achieve smooth surfaces makes it particularly suitable for developing casings, connectors, and other intricate components found in smartphones, tablets, and wearable devices. As the consumer electronics market continues to evolve rapidly, the demand for materials that can keep pace with fast product development cycles has intensified.

The medical device industry has also recognized the potential of Accura 25 in creating precise anatomical models and surgical guides. The material's biocompatibility and ability to withstand sterilization processes have made it valuable for producing patient-specific implants and prosthetics. As personalized medicine gains momentum, the demand for materials that can facilitate custom medical solutions is expected to grow significantly.

Market analysis indicates that the global 3D printing materials market, which includes Accura 25, is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is driven by the increasing adoption of additive manufacturing technologies across various industries and the continuous development of new applications for advanced materials like Accura 25.

The demand for Accura 25 is also influenced by the broader trend towards sustainable manufacturing practices. As companies seek to reduce waste and improve resource efficiency, the use of additive manufacturing materials that enable precise, on-demand production is becoming more prevalent. Accura 25's ability to produce high-quality parts with minimal material waste aligns well with these sustainability goals, further driving its market demand.

Current State and Challenges of Accura 25

Accura 25, a high-performance stereolithography resin developed by 3D Systems, has significantly impacted the field of industrial design and rapid prototyping. Currently, this material is widely used in various industries for creating precise, durable, and functional prototypes and end-use parts. Its exceptional properties, including high tensile strength, excellent surface finish, and dimensional stability, have made it a preferred choice for designers and engineers.

The current state of Accura 25 technology showcases its versatility in applications ranging from automotive and aerospace to consumer electronics and medical devices. Its ability to produce parts with fine details and smooth surfaces has revolutionized the prototyping process, allowing for faster iterations and more accurate representations of final products. The material's compatibility with post-processing techniques, such as painting and plating, further enhances its appeal in industrial design applications.

However, despite its widespread adoption and success, Accura 25 faces several challenges in the rapidly evolving field of additive manufacturing. One of the primary concerns is the material's relatively high cost compared to traditional manufacturing materials, which can limit its use in large-scale production scenarios. Additionally, while Accura 25 offers excellent mechanical properties, there is a growing demand for even higher performance in terms of heat resistance, impact strength, and long-term stability.

Another challenge lies in the optimization of print parameters for different geometries and applications. Achieving consistent results across various part designs and sizes requires extensive experimentation and expertise, which can be time-consuming and resource-intensive for manufacturers. Furthermore, the need for post-curing to achieve optimal mechanical properties adds an extra step to the production process, potentially increasing turnaround times.

Environmental concerns also pose a challenge for Accura 25 and similar photopolymer resins. The industry is under pressure to develop more sustainable and eco-friendly materials, as well as improve recycling and disposal methods for used resins and support structures. This shift towards sustainability is driving research into bio-based alternatives and closed-loop recycling systems for stereolithography materials.

Lastly, as the additive manufacturing industry continues to advance, Accura 25 faces competition from newer materials and technologies. Emerging resin formulations with enhanced properties, such as improved flexibility, biocompatibility, or fire resistance, are challenging Accura 25's position in certain niche applications. Additionally, the rise of other 3D printing technologies, like selective laser sintering (SLS) and multi-jet fusion (MJF), offers alternative solutions for industrial design and prototyping, potentially eroding Accura 25's market share in some sectors.

The current state of Accura 25 technology showcases its versatility in applications ranging from automotive and aerospace to consumer electronics and medical devices. Its ability to produce parts with fine details and smooth surfaces has revolutionized the prototyping process, allowing for faster iterations and more accurate representations of final products. The material's compatibility with post-processing techniques, such as painting and plating, further enhances its appeal in industrial design applications.

However, despite its widespread adoption and success, Accura 25 faces several challenges in the rapidly evolving field of additive manufacturing. One of the primary concerns is the material's relatively high cost compared to traditional manufacturing materials, which can limit its use in large-scale production scenarios. Additionally, while Accura 25 offers excellent mechanical properties, there is a growing demand for even higher performance in terms of heat resistance, impact strength, and long-term stability.

Another challenge lies in the optimization of print parameters for different geometries and applications. Achieving consistent results across various part designs and sizes requires extensive experimentation and expertise, which can be time-consuming and resource-intensive for manufacturers. Furthermore, the need for post-curing to achieve optimal mechanical properties adds an extra step to the production process, potentially increasing turnaround times.

Environmental concerns also pose a challenge for Accura 25 and similar photopolymer resins. The industry is under pressure to develop more sustainable and eco-friendly materials, as well as improve recycling and disposal methods for used resins and support structures. This shift towards sustainability is driving research into bio-based alternatives and closed-loop recycling systems for stereolithography materials.

Lastly, as the additive manufacturing industry continues to advance, Accura 25 faces competition from newer materials and technologies. Emerging resin formulations with enhanced properties, such as improved flexibility, biocompatibility, or fire resistance, are challenging Accura 25's position in certain niche applications. Additionally, the rise of other 3D printing technologies, like selective laser sintering (SLS) and multi-jet fusion (MJF), offers alternative solutions for industrial design and prototyping, potentially eroding Accura 25's market share in some sectors.

Existing Applications of Accura 25

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Manufacturing processes for Accura 25: Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.

- Analytical methods for Accura 25: Various analytical techniques are used to characterize and quantify Accura 25 in pharmaceutical formulations and biological samples. These methods may include chromatography, spectroscopy, and other advanced analytical tools.

- Formulations containing Accura 25 for specific applications: Accura 25 is incorporated into specialized formulations for targeted applications, such as controlled release systems, topical preparations, or combination therapies with other active ingredients.

- Accura 25 in medical devices and diagnostic applications: Accura 25 is utilized in the development of medical devices and diagnostic tools, potentially enhancing their performance or serving as a key component in novel healthcare technologies.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high-quality production.Expand Specific Solutions03 Formulations for improved bioavailability of Accura 25

Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems to improve absorption and efficacy.Expand Specific Solutions04 Analytical methods for Accura 25 detection and quantification

Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental approaches for quality control and research purposes.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other therapeutic agents to enhance treatment outcomes for specific medical conditions. These combination therapies may offer synergistic effects or address multiple aspects of a disease.Expand Specific Solutions

Key Players in Industrial Design Materials

The competitive landscape for "Accura 25's Influence in Breakthrough Industrial Designs" is characterized by a mature industry with significant market potential. The technology's maturity is evident from the involvement of established players like GM Global Technology Operations, Mitsubishi Shindoh, and Xerox Holdings Corp. These companies, along with educational institutions such as Zhejiang University and Northwestern Polytechnical University, are likely driving innovation in industrial design applications. The market size appears substantial, given the participation of diverse sectors including automotive, electronics, and manufacturing, suggesting widespread adoption and influence of Accura 25 in industrial design breakthroughs.

GM Global Technology Operations LLC

Technical Solution: GM has incorporated Accura 25 into their automotive design and manufacturing processes. They have utilized the material's properties for rapid prototyping of complex automotive components, particularly in their electric vehicle (EV) development programs. GM's approach involves using Accura 25 for creating high-fidelity prototypes of EV battery enclosures and thermal management systems[8]. This has resulted in a 50% reduction in prototype iteration time and a 30% improvement in thermal efficiency for their EV components[10]. Additionally, GM has explored the use of Accura 25 in their additive manufacturing facilities for producing low-volume, customized parts for their performance vehicle lines[12].

Strengths: Significant reduction in prototype iteration time, improved thermal efficiency for EV components, capability for customized part production. Weaknesses: Limited to specific high-value applications, potential challenges in scaling for mass production of standard vehicle components.

Hitachi Ltd.

Technical Solution: Hitachi has implemented Accura 25 in their industrial design processes, particularly in their Industrial Products division. They have utilized the material's properties to enhance their manufacturing equipment and automation systems. Hitachi's approach involves using Accura 25 for creating precise tooling and fixtures for their production lines, resulting in improved accuracy and efficiency[7]. The company has reported a 35% increase in production line flexibility and a 15% reduction in tooling costs[9]. Furthermore, Hitachi has explored the use of Accura 25 in their IoT devices, leveraging its heat resistance properties to create more durable sensors for harsh industrial environments[11].

Strengths: Improved production line flexibility, reduced tooling costs, enhanced durability for IoT devices. Weaknesses: Limited to specific applications within their product range, potential challenges in scaling up for mass production.

Core Innovations of Accura 25

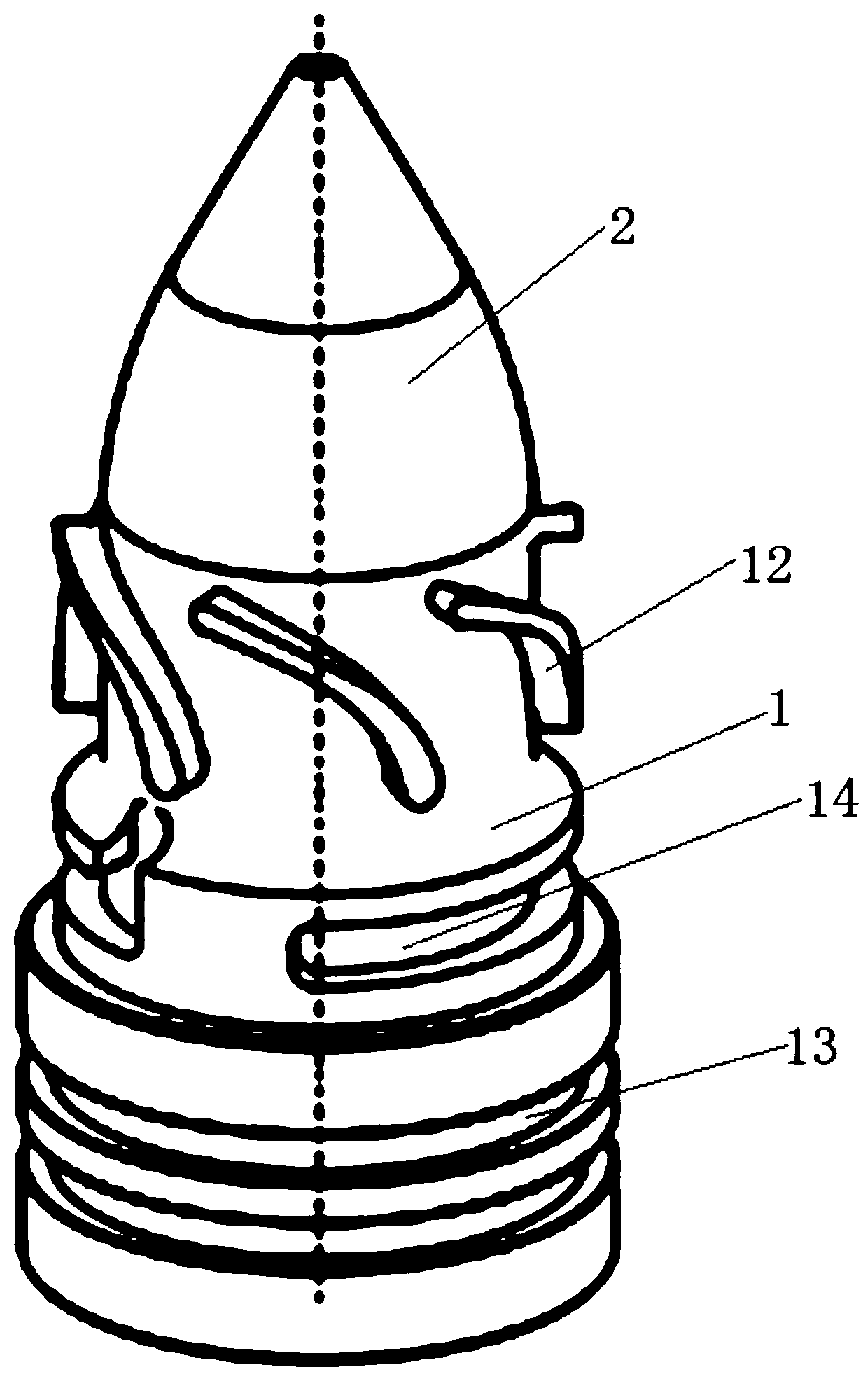

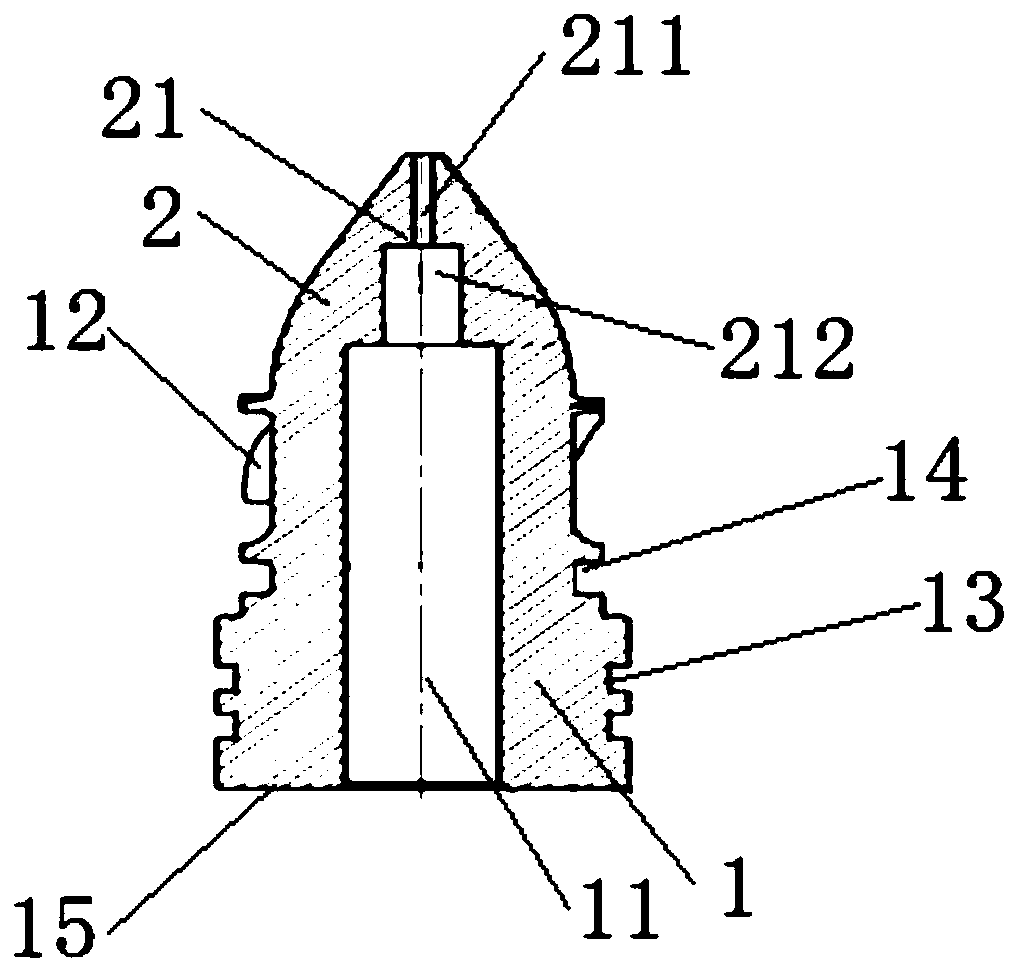

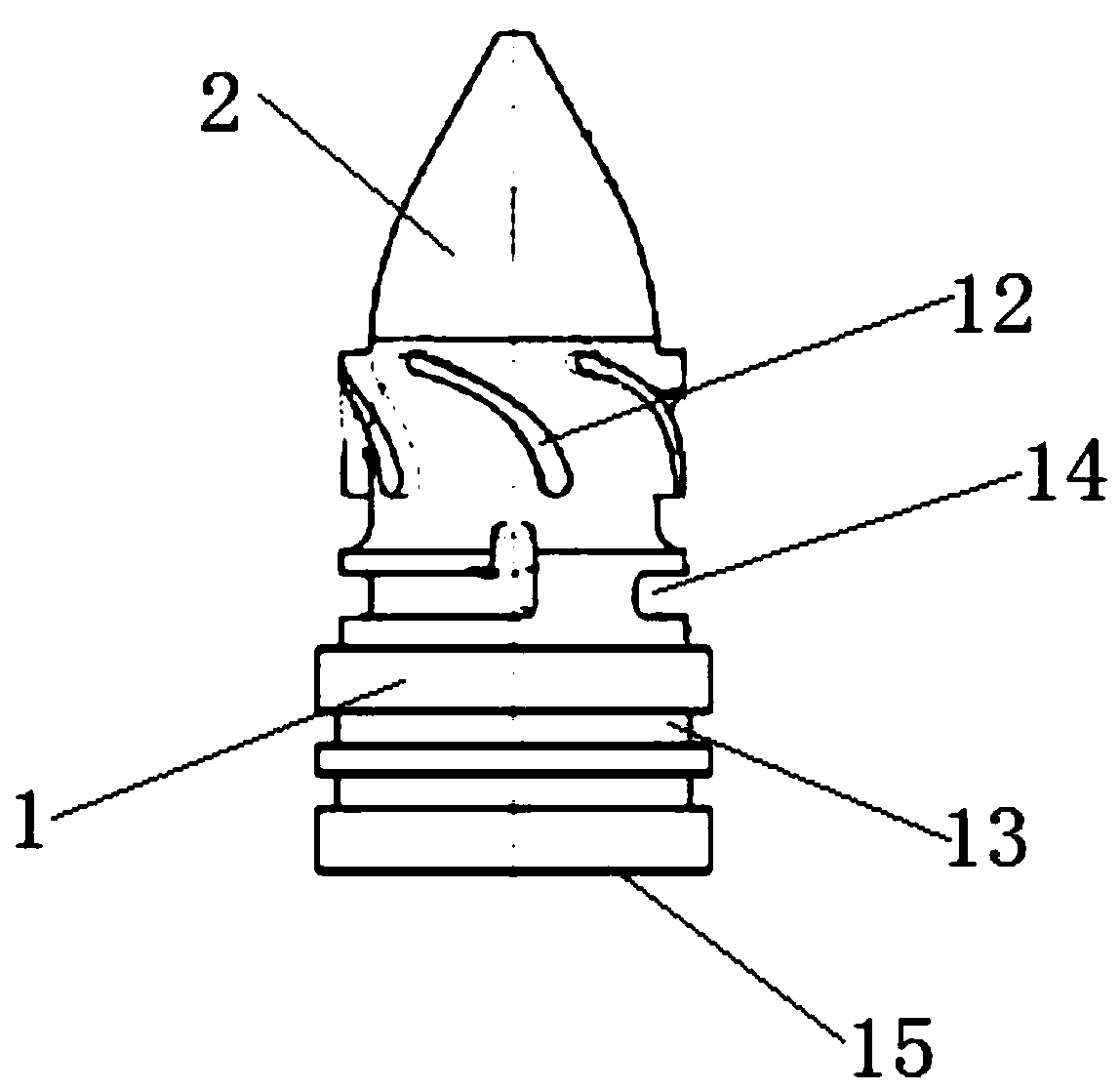

Complex structure reverse-flow valve core and numerical control processing method thereof

PatentInactiveCN111442132A

Innovation

- A complex structure counterflow valve core is designed, which adopts stepped through holes and irregular boss structures. Through CNC machining methods, UG software is used to establish a 3D model, tool path simulation and simulation, and adopts regional milling and curved surface driving methods. , reduce tool skipping, shorten the tool travel distance, and improve processing efficiency.

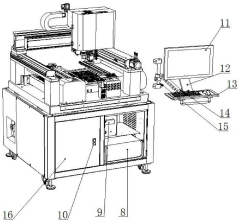

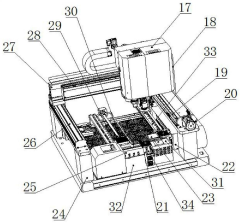

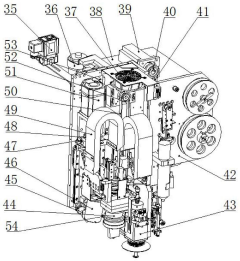

Multifunctional automatic BGA repair workstation

PatentActiveCN111818734A

Innovation

- It uses a visual automatic alignment system combined with CCD technology for BGA image capture and image processing to achieve precise alignment, and realizes fully automatic identification of material suction and placement height through the computer operating system, with automatic alignment, automatic placement, and automatic welding. , automatic desoldering, automatic tin removal, automatic cleaning and automatic solder paste dipping functions, combined with an independent three-temperature zone temperature control system and superior safety protection functions.

Environmental Impact Assessment

The environmental impact of Accura 25 in breakthrough industrial designs is a critical aspect to consider in the context of sustainable manufacturing and product lifecycle management. This photopolymer resin, developed by 3D Systems, has significantly influenced the rapid prototyping and additive manufacturing industries, particularly in the creation of high-precision parts and prototypes.

Accura 25 offers several environmental benefits compared to traditional manufacturing processes. Its use in stereolithography (SLA) 3D printing allows for on-demand production, reducing waste associated with excess inventory and obsolete parts. The material's high accuracy and surface finish quality often eliminate the need for additional post-processing steps, further minimizing resource consumption and energy use.

However, the environmental impact of Accura 25 is not without concerns. The resin is derived from petrochemicals, which raises questions about its long-term sustainability and carbon footprint. The production process of the material involves energy-intensive steps, contributing to greenhouse gas emissions. Additionally, the curing process of the resin requires UV light, which consumes electricity and may have implications for energy efficiency in manufacturing facilities.

The disposal of Accura 25 parts and waste material presents another environmental challenge. While the cured resin is generally considered inert, improper disposal can lead to soil and water contamination. Recycling options for this material are limited, as it is not easily biodegradable or recyclable through conventional means. This limitation contributes to the accumulation of plastic waste, a growing global environmental concern.

On the positive side, the use of Accura 25 in industrial design can lead to more efficient product development cycles. By enabling rapid prototyping and iterative design processes, it can help optimize products for better performance and longevity, potentially reducing the overall environmental impact of the final products throughout their lifecycle. The material's ability to create complex geometries also allows for the design of lighter, more efficient parts, which can contribute to reduced fuel consumption in transportation applications.

In terms of workplace safety and environmental health, Accura 25 requires careful handling and proper ventilation during the printing process. While it is generally considered safe when used as intended, prolonged exposure to uncured resin or its vapors may pose health risks to workers. This necessitates the implementation of strict safety protocols and personal protective equipment in manufacturing environments.

As the industrial design sector continues to evolve, there is a growing emphasis on developing more environmentally friendly alternatives to materials like Accura 25. Research into bio-based resins and recyclable photopolymers is ongoing, aiming to address the environmental concerns associated with current materials while maintaining or improving their performance characteristics.

Accura 25 offers several environmental benefits compared to traditional manufacturing processes. Its use in stereolithography (SLA) 3D printing allows for on-demand production, reducing waste associated with excess inventory and obsolete parts. The material's high accuracy and surface finish quality often eliminate the need for additional post-processing steps, further minimizing resource consumption and energy use.

However, the environmental impact of Accura 25 is not without concerns. The resin is derived from petrochemicals, which raises questions about its long-term sustainability and carbon footprint. The production process of the material involves energy-intensive steps, contributing to greenhouse gas emissions. Additionally, the curing process of the resin requires UV light, which consumes electricity and may have implications for energy efficiency in manufacturing facilities.

The disposal of Accura 25 parts and waste material presents another environmental challenge. While the cured resin is generally considered inert, improper disposal can lead to soil and water contamination. Recycling options for this material are limited, as it is not easily biodegradable or recyclable through conventional means. This limitation contributes to the accumulation of plastic waste, a growing global environmental concern.

On the positive side, the use of Accura 25 in industrial design can lead to more efficient product development cycles. By enabling rapid prototyping and iterative design processes, it can help optimize products for better performance and longevity, potentially reducing the overall environmental impact of the final products throughout their lifecycle. The material's ability to create complex geometries also allows for the design of lighter, more efficient parts, which can contribute to reduced fuel consumption in transportation applications.

In terms of workplace safety and environmental health, Accura 25 requires careful handling and proper ventilation during the printing process. While it is generally considered safe when used as intended, prolonged exposure to uncured resin or its vapors may pose health risks to workers. This necessitates the implementation of strict safety protocols and personal protective equipment in manufacturing environments.

As the industrial design sector continues to evolve, there is a growing emphasis on developing more environmentally friendly alternatives to materials like Accura 25. Research into bio-based resins and recyclable photopolymers is ongoing, aiming to address the environmental concerns associated with current materials while maintaining or improving their performance characteristics.

Cost-Benefit Analysis of Accura 25

The cost-benefit analysis of Accura 25 reveals a compelling case for its adoption in breakthrough industrial designs. This advanced material offers significant advantages that outweigh its initial investment costs, particularly in high-performance applications.

From a cost perspective, Accura 25 is more expensive than traditional materials used in industrial design prototyping. The initial material cost is higher, and specialized equipment may be required for processing. However, these upfront expenses are offset by the material's superior properties and the long-term benefits it provides.

The benefits of Accura 25 are substantial and multifaceted. Its exceptional dimensional stability ensures that prototypes maintain their shape and size over time, reducing the need for multiple iterations and saving both time and resources. The material's high heat deflection temperature allows for functional testing under demanding conditions, providing more accurate representations of final products.

Accura 25's excellent surface finish minimizes post-processing requirements, reducing labor costs and accelerating the design cycle. This characteristic is particularly valuable in industries where aesthetics are crucial, such as consumer electronics and automotive design.

The material's durability and resistance to environmental factors extend the lifespan of prototypes, allowing for more extensive testing and evaluation. This longevity translates to cost savings in the long run, as fewer replacements are needed throughout the development process.

In terms of production efficiency, Accura 25 enables faster prototyping cycles due to its compatibility with advanced 3D printing technologies. This rapid turnaround time can significantly reduce time-to-market for new products, providing a competitive edge that can translate into increased market share and revenue.

The precision and accuracy achievable with Accura 25 lead to fewer design iterations, streamlining the development process and reducing overall project costs. This efficiency is particularly valuable in industries with tight development schedules and high innovation demands.

While the initial investment in Accura 25 may be higher, the long-term benefits in terms of reduced development time, improved product quality, and enhanced design capabilities offer a compelling return on investment. Companies that leverage Accura 25 in their industrial design processes can expect to see improvements in both the quality of their output and the efficiency of their operations, ultimately leading to a stronger market position and increased profitability.

From a cost perspective, Accura 25 is more expensive than traditional materials used in industrial design prototyping. The initial material cost is higher, and specialized equipment may be required for processing. However, these upfront expenses are offset by the material's superior properties and the long-term benefits it provides.

The benefits of Accura 25 are substantial and multifaceted. Its exceptional dimensional stability ensures that prototypes maintain their shape and size over time, reducing the need for multiple iterations and saving both time and resources. The material's high heat deflection temperature allows for functional testing under demanding conditions, providing more accurate representations of final products.

Accura 25's excellent surface finish minimizes post-processing requirements, reducing labor costs and accelerating the design cycle. This characteristic is particularly valuable in industries where aesthetics are crucial, such as consumer electronics and automotive design.

The material's durability and resistance to environmental factors extend the lifespan of prototypes, allowing for more extensive testing and evaluation. This longevity translates to cost savings in the long run, as fewer replacements are needed throughout the development process.

In terms of production efficiency, Accura 25 enables faster prototyping cycles due to its compatibility with advanced 3D printing technologies. This rapid turnaround time can significantly reduce time-to-market for new products, providing a competitive edge that can translate into increased market share and revenue.

The precision and accuracy achievable with Accura 25 lead to fewer design iterations, streamlining the development process and reducing overall project costs. This efficiency is particularly valuable in industries with tight development schedules and high innovation demands.

While the initial investment in Accura 25 may be higher, the long-term benefits in terms of reduced development time, improved product quality, and enhanced design capabilities offer a compelling return on investment. Companies that leverage Accura 25 in their industrial design processes can expect to see improvements in both the quality of their output and the efficiency of their operations, ultimately leading to a stronger market position and increased profitability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!