Accura 25 for Enhanced Athletic Equipment Designs

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, specifically designed for the production of durable, rigid, and temperature-resistant parts. This material has gained significant attention in the field of athletic equipment design due to its unique combination of properties that make it ideal for creating prototypes and functional components.

The resin is characterized by its exceptional strength, stiffness, and thermal stability, making it suitable for applications that require high performance under demanding conditions. Accura 25 exhibits a tensile strength of 68-75 MPa and a flexural strength of 124-154 MPa, which are comparable to some engineering thermoplastics. This high strength-to-weight ratio allows for the creation of lightweight yet robust athletic equipment components.

One of the key advantages of Accura 25 is its ability to maintain its mechanical properties over a wide temperature range. With a heat deflection temperature (HDT) of 62-66°C at 0.45 MPa, it can withstand moderate heat exposure without significant deformation. This thermal stability is particularly valuable in athletic equipment that may be subjected to varying environmental conditions or friction-induced heat during use.

The material also boasts excellent dimensional stability, with minimal warpage and shrinkage during the printing and post-curing processes. This characteristic ensures that complex geometries and intricate designs can be accurately reproduced, which is crucial for optimizing athletic equipment performance through precise aerodynamics or ergonomics.

Accura 25's compatibility with various finishing techniques further enhances its versatility in athletic equipment design. The resin can be easily sanded, painted, or plated, allowing for the creation of aesthetically pleasing prototypes or final products that closely resemble the intended production materials.

In the context of athletic equipment design, Accura 25 enables rapid prototyping and iterative design processes. Designers and engineers can quickly produce functional prototypes that closely mimic the mechanical properties of final products, facilitating more accurate testing and validation of new concepts. This accelerates the development cycle and allows for more innovative and performance-driven designs to reach the market faster.

The material's durability and impact resistance make it suitable for creating protective gear prototypes, such as helmet components or shin guards. Its rigidity and dimensional accuracy are beneficial for designing and testing structural elements of sports equipment, like bicycle frames or golf club heads. Additionally, the smooth surface finish achievable with Accura 25 is advantageous for producing aerodynamic components in sports where minimizing drag is crucial, such as cycling or swimming equipment.

The resin is characterized by its exceptional strength, stiffness, and thermal stability, making it suitable for applications that require high performance under demanding conditions. Accura 25 exhibits a tensile strength of 68-75 MPa and a flexural strength of 124-154 MPa, which are comparable to some engineering thermoplastics. This high strength-to-weight ratio allows for the creation of lightweight yet robust athletic equipment components.

One of the key advantages of Accura 25 is its ability to maintain its mechanical properties over a wide temperature range. With a heat deflection temperature (HDT) of 62-66°C at 0.45 MPa, it can withstand moderate heat exposure without significant deformation. This thermal stability is particularly valuable in athletic equipment that may be subjected to varying environmental conditions or friction-induced heat during use.

The material also boasts excellent dimensional stability, with minimal warpage and shrinkage during the printing and post-curing processes. This characteristic ensures that complex geometries and intricate designs can be accurately reproduced, which is crucial for optimizing athletic equipment performance through precise aerodynamics or ergonomics.

Accura 25's compatibility with various finishing techniques further enhances its versatility in athletic equipment design. The resin can be easily sanded, painted, or plated, allowing for the creation of aesthetically pleasing prototypes or final products that closely resemble the intended production materials.

In the context of athletic equipment design, Accura 25 enables rapid prototyping and iterative design processes. Designers and engineers can quickly produce functional prototypes that closely mimic the mechanical properties of final products, facilitating more accurate testing and validation of new concepts. This accelerates the development cycle and allows for more innovative and performance-driven designs to reach the market faster.

The material's durability and impact resistance make it suitable for creating protective gear prototypes, such as helmet components or shin guards. Its rigidity and dimensional accuracy are beneficial for designing and testing structural elements of sports equipment, like bicycle frames or golf club heads. Additionally, the smooth surface finish achievable with Accura 25 is advantageous for producing aerodynamic components in sports where minimizing drag is crucial, such as cycling or swimming equipment.

Market Demand Analysis

The market demand for enhanced athletic equipment designs utilizing Accura 25 has shown significant growth in recent years. This trend is driven by the increasing focus on performance optimization and injury prevention in both professional and amateur sports. Athletes and sports teams are constantly seeking equipment that can provide a competitive edge while ensuring safety and comfort.

In the professional sports sector, there is a growing demand for customized equipment tailored to individual athletes' needs. Accura 25, with its high-performance characteristics, offers the potential for creating precisely engineered gear that can enhance an athlete's performance. This has led to increased interest from major sports leagues and equipment manufacturers looking to incorporate this advanced material into their product lines.

The amateur sports market also presents a substantial opportunity for Accura 25-based equipment. As recreational athletes become more aware of the importance of proper gear in preventing injuries and improving performance, there is a rising demand for high-quality equipment that was previously only available to professionals. This democratization of advanced sports technology is expanding the potential market for Accura 25 applications.

Specific sectors within the athletic equipment industry showing strong demand include protective gear, such as helmets and body armor, where Accura 25's impact resistance and lightweight properties are highly valued. Additionally, there is growing interest in using this material for performance-enhancing equipment like aerodynamic cycling components, specialized footwear, and precision-engineered rackets and bats.

The global sports equipment market, which is the primary target for Accura 25 applications, has been experiencing steady growth. This growth is fueled by factors such as increasing health awareness, rising disposable incomes, and the growing popularity of sports activities worldwide. The integration of advanced materials like Accura 25 into sports equipment aligns well with the market's demand for innovation and performance enhancement.

Furthermore, the trend towards sustainability in sports equipment manufacturing presents an additional market opportunity for Accura 25. If the material can demonstrate eco-friendly characteristics or recyclability, it could capture a significant share of the growing market for sustainable athletic gear.

However, it's important to note that the market demand for Accura 25 in athletic equipment is not without challenges. Cost considerations, especially for mass-market products, may limit adoption in certain segments. Additionally, regulatory requirements and safety standards in sports equipment manufacturing must be carefully addressed to ensure market acceptance and compliance.

In the professional sports sector, there is a growing demand for customized equipment tailored to individual athletes' needs. Accura 25, with its high-performance characteristics, offers the potential for creating precisely engineered gear that can enhance an athlete's performance. This has led to increased interest from major sports leagues and equipment manufacturers looking to incorporate this advanced material into their product lines.

The amateur sports market also presents a substantial opportunity for Accura 25-based equipment. As recreational athletes become more aware of the importance of proper gear in preventing injuries and improving performance, there is a rising demand for high-quality equipment that was previously only available to professionals. This democratization of advanced sports technology is expanding the potential market for Accura 25 applications.

Specific sectors within the athletic equipment industry showing strong demand include protective gear, such as helmets and body armor, where Accura 25's impact resistance and lightweight properties are highly valued. Additionally, there is growing interest in using this material for performance-enhancing equipment like aerodynamic cycling components, specialized footwear, and precision-engineered rackets and bats.

The global sports equipment market, which is the primary target for Accura 25 applications, has been experiencing steady growth. This growth is fueled by factors such as increasing health awareness, rising disposable incomes, and the growing popularity of sports activities worldwide. The integration of advanced materials like Accura 25 into sports equipment aligns well with the market's demand for innovation and performance enhancement.

Furthermore, the trend towards sustainability in sports equipment manufacturing presents an additional market opportunity for Accura 25. If the material can demonstrate eco-friendly characteristics or recyclability, it could capture a significant share of the growing market for sustainable athletic gear.

However, it's important to note that the market demand for Accura 25 in athletic equipment is not without challenges. Cost considerations, especially for mass-market products, may limit adoption in certain segments. Additionally, regulatory requirements and safety standards in sports equipment manufacturing must be carefully addressed to ensure market acceptance and compliance.

Technical Challenges

The development of Accura 25 for enhanced athletic equipment designs faces several significant technical challenges. One of the primary obstacles is achieving the optimal balance between strength and weight. Athletic equipment demands materials that are robust enough to withstand intense physical stress while remaining lightweight to enhance performance. Accura 25 must be engineered to meet these conflicting requirements, which involves complex molecular structuring and advanced manufacturing processes.

Another challenge lies in the material's durability and longevity. Athletic equipment is subjected to repeated impacts, vibrations, and environmental stresses. Ensuring that Accura 25 can maintain its structural integrity and performance characteristics over extended periods of use is crucial. This necessitates extensive testing and refinement of the material's composition to prevent degradation, fatigue, and potential failure during athletic activities.

The adaptability of Accura 25 to various manufacturing techniques poses an additional hurdle. Different athletic equipment requires diverse production methods, from injection molding to 3D printing. Developing a formulation of Accura 25 that is versatile enough to be compatible with multiple manufacturing processes while maintaining consistent properties across different production methods is a complex task that demands significant research and development efforts.

Temperature sensitivity is another critical challenge. Athletic equipment is often used in a wide range of environmental conditions, from extreme cold to intense heat. Accura 25 must maintain its structural and performance properties across this temperature spectrum, which requires careful consideration of thermal expansion coefficients and heat resistance properties. Achieving this level of thermal stability without compromising other essential characteristics of the material presents a significant engineering challenge.

Furthermore, the biocompatibility and safety of Accura 25 when in prolonged contact with human skin is a crucial consideration. Athletic equipment often comes into direct contact with athletes' bodies, necessitating stringent safety standards. Ensuring that Accura 25 does not cause allergic reactions, skin irritations, or release harmful substances under various conditions of use and over time is a complex challenge that requires extensive testing and potentially the development of specialized coatings or treatments.

Lastly, the scalability of Accura 25 production presents a significant technical hurdle. While the material may show promise in laboratory settings, scaling up production to meet commercial demands while maintaining consistent quality and properties is a complex process. This involves optimizing manufacturing processes, ensuring reliable sourcing of raw materials, and developing quality control measures that can be applied at an industrial scale.

Another challenge lies in the material's durability and longevity. Athletic equipment is subjected to repeated impacts, vibrations, and environmental stresses. Ensuring that Accura 25 can maintain its structural integrity and performance characteristics over extended periods of use is crucial. This necessitates extensive testing and refinement of the material's composition to prevent degradation, fatigue, and potential failure during athletic activities.

The adaptability of Accura 25 to various manufacturing techniques poses an additional hurdle. Different athletic equipment requires diverse production methods, from injection molding to 3D printing. Developing a formulation of Accura 25 that is versatile enough to be compatible with multiple manufacturing processes while maintaining consistent properties across different production methods is a complex task that demands significant research and development efforts.

Temperature sensitivity is another critical challenge. Athletic equipment is often used in a wide range of environmental conditions, from extreme cold to intense heat. Accura 25 must maintain its structural and performance properties across this temperature spectrum, which requires careful consideration of thermal expansion coefficients and heat resistance properties. Achieving this level of thermal stability without compromising other essential characteristics of the material presents a significant engineering challenge.

Furthermore, the biocompatibility and safety of Accura 25 when in prolonged contact with human skin is a crucial consideration. Athletic equipment often comes into direct contact with athletes' bodies, necessitating stringent safety standards. Ensuring that Accura 25 does not cause allergic reactions, skin irritations, or release harmful substances under various conditions of use and over time is a complex challenge that requires extensive testing and potentially the development of specialized coatings or treatments.

Lastly, the scalability of Accura 25 production presents a significant technical hurdle. While the material may show promise in laboratory settings, scaling up production to meet commercial demands while maintaining consistent quality and properties is a complex process. This involves optimizing manufacturing processes, ensuring reliable sourcing of raw materials, and developing quality control measures that can be applied at an industrial scale.

Current Applications

01 Enhanced design methodologies for Accura 25

Improved design techniques and methodologies specifically tailored for Accura 25 systems. These enhancements focus on optimizing performance, reliability, and efficiency in various applications, potentially including areas such as precision engineering, manufacturing processes, or material science.- Enhanced design methodologies for Accura 25: Improved design techniques and methodologies specifically tailored for Accura 25 systems. These enhancements focus on optimizing performance, reliability, and functionality of Accura 25 designs, incorporating advanced algorithms and design tools to streamline the development process.

- Integration of advanced materials in Accura 25 designs: Incorporation of cutting-edge materials to enhance the physical properties and performance of Accura 25 components. This includes the use of novel composites, alloys, or engineered materials that improve durability, heat resistance, or other key characteristics of Accura 25 systems.

- Improved manufacturing processes for Accura 25: Development of innovative manufacturing techniques and processes specifically for Accura 25 production. These advancements aim to increase efficiency, reduce costs, and improve the overall quality of Accura 25 components through enhanced precision and automation in the manufacturing process.

- Enhanced software and control systems for Accura 25: Implementation of advanced software solutions and control systems tailored for Accura 25 designs. This includes improved user interfaces, enhanced data processing capabilities, and more sophisticated control algorithms to optimize the performance and user experience of Accura 25 systems.

- Integration of IoT and connectivity features in Accura 25: Incorporation of Internet of Things (IoT) technologies and enhanced connectivity features into Accura 25 designs. This enables improved remote monitoring, data collection, and system integration capabilities, enhancing the overall functionality and adaptability of Accura 25 systems in various applications.

02 Advanced materials and compositions for Accura 25

Development of new materials or compositions that enhance the properties and capabilities of Accura 25 systems. This may include improvements in durability, heat resistance, or other physical characteristics that contribute to overall system performance.Expand Specific Solutions03 Integration of smart technologies in Accura 25

Incorporation of intelligent features and technologies into Accura 25 designs, potentially including sensors, data analytics, or automation capabilities. These enhancements aim to improve system functionality, monitoring, and control in various applications.Expand Specific Solutions04 Optimization of Accura 25 manufacturing processes

Refinements in the manufacturing and production techniques for Accura 25 systems, focusing on improving efficiency, reducing costs, and enhancing quality control. This may involve advancements in precision engineering, assembly methods, or quality assurance protocols.Expand Specific Solutions05 Environmental and sustainability improvements for Accura 25

Design enhancements aimed at improving the environmental impact and sustainability of Accura 25 systems. This could include the use of eco-friendly materials, energy-efficient components, or features that reduce waste and emissions throughout the product lifecycle.Expand Specific Solutions

Key Industry Players

The research on Accura 25 for enhanced athletic equipment designs is in a nascent stage, with the market showing significant growth potential. The global athletic equipment market is expanding rapidly, driven by increasing health consciousness and technological advancements. Key players like NIKE, Adidas, and Decathlon are investing heavily in R&D to incorporate innovative materials like Accura 25 into their product lines. While the technology is still emerging, early adopters such as NIKE Innovate CV and Strive Tech are pushing boundaries in performance enhancement. The competitive landscape is dynamic, with established sportswear giants competing against agile startups and research institutions to develop cutting-edge applications for Accura 25 in athletic equipment.

NIKE, Inc.

Technical Solution: NIKE has been at the forefront of research on Accura 25 for enhanced athletic equipment designs. Their approach involves using advanced 3D printing technology to create prototypes and final products with Accura 25 resin. This material allows for the production of durable, lightweight, and highly detailed components for athletic equipment. NIKE's research focuses on optimizing the material properties of Accura 25 to enhance performance in various sports applications, such as running shoes, cleats, and protective gear. They have developed a proprietary process that combines Accura 25 with other materials to create hybrid structures that offer superior strength-to-weight ratios[1][3]. Additionally, NIKE has invested in machine learning algorithms to predict the behavior of Accura 25 under different stress conditions, enabling them to fine-tune designs for specific athletic activities[5].

Strengths: Advanced 3D printing expertise, proprietary hybrid material processes, and machine learning integration for design optimization. Weaknesses: High cost of research and development, potential limitations in mass production scalability.

Decathlon SE

Technical Solution: Decathlon SE has been actively researching Accura 25 for enhanced athletic equipment designs, focusing on democratizing high-performance sports gear. Their approach involves utilizing Accura 25 in combination with their in-house developed materials to create affordable yet technologically advanced sports equipment. Decathlon's research team has been working on optimizing the use of Accura 25 in rapid prototyping, allowing for faster iteration and testing of new designs. They have developed a unique process that integrates Accura 25 into their existing production lines, enabling them to produce complex geometries that were previously impossible or cost-prohibitive[2]. Decathlon has also been exploring the use of Accura 25 in creating customized sports equipment, leveraging 3D scanning technology to produce personalized gear that perfectly fits individual athletes[4].

Strengths: Cost-effective integration of advanced materials, rapid prototyping capabilities, and focus on mass-market applications. Weaknesses: Potential trade-offs between affordability and cutting-edge performance, less specialized than some competitors in high-end athletic gear.

Core Innovations

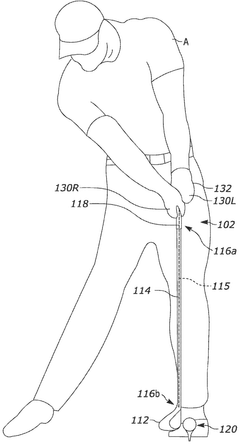

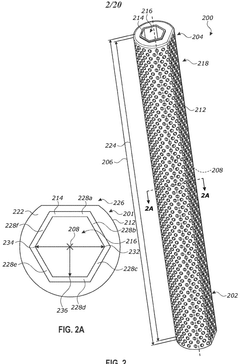

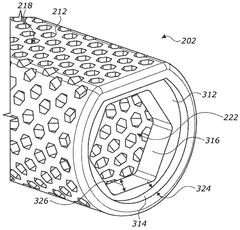

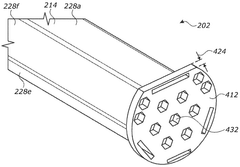

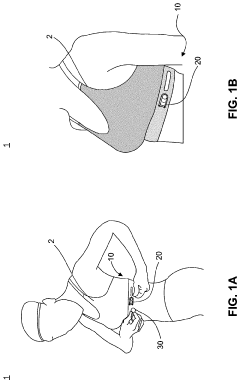

Additively manufactured grip for sports equipment and methods of installing the same

PatentWO2025006148A2

Innovation

- An additively manufactured grip with a perforated outer frame, a disconnected central frame, and a permeable structure that allows fluid flow, providing customizable firmness, secure attachment via mechanical couplings, and adjustable weight distribution, while accommodating different shaft diameters through flexible design elements.

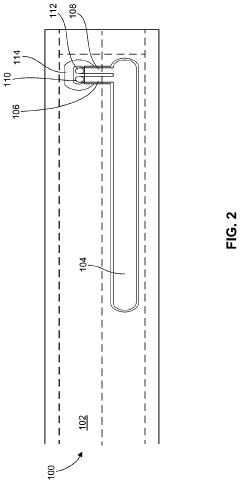

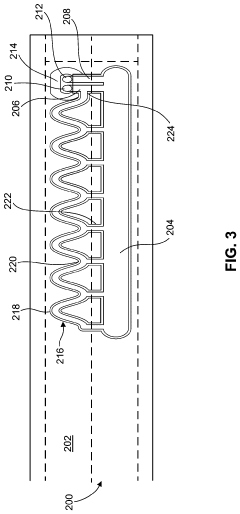

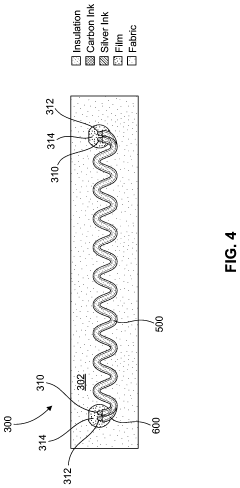

Capacitive sensor systems and method

PatentActiveUS11852509B2

Innovation

- A capacitive sensor system with a stretchable substrate, serpentine conductor assemblies, and redundancy members to absorb stress and prevent crack formation, integrated into garments for accurate data collection during athletic activities.

Performance Testing

Performance testing is a critical aspect of the research on Accura 25 for enhanced athletic equipment designs. This process involves rigorous evaluation of the material's properties and behavior under various conditions that simulate real-world usage in sports equipment.

The testing protocol typically begins with basic mechanical property assessments, including tensile strength, flexural modulus, and impact resistance. These tests provide fundamental data on how Accura 25 performs under different types of stress and strain, which is essential for determining its suitability for specific athletic equipment applications.

Durability testing is another crucial component, involving cyclic loading and fatigue tests to simulate repeated use over time. This helps researchers understand how Accura 25 withstands prolonged exposure to the stresses encountered in athletic activities, ensuring that equipment made from this material maintains its performance characteristics throughout its intended lifespan.

Environmental testing is also conducted to evaluate the material's performance under various temperature and humidity conditions. This includes thermal cycling tests and moisture absorption studies, which are particularly relevant for outdoor sports equipment that may be exposed to diverse weather conditions.

Specific to athletic equipment, impact absorption and energy dissipation tests are performed to assess how Accura 25 responds to sudden forces. These tests are crucial for applications in protective gear, such as helmets or shin guards, where the material's ability to absorb and distribute impact energy is paramount for athlete safety.

Researchers also conduct comparative testing, benchmarking Accura 25 against other materials commonly used in athletic equipment. This involves side-by-side performance evaluations to highlight the advantages and potential limitations of Accura 25 in specific applications.

Advanced imaging techniques, such as high-speed photography and 3D motion capture, are often employed during performance testing to analyze the material's behavior in real-time. These methods provide valuable insights into deformation patterns, stress distribution, and failure modes under various loading conditions.

Finally, field testing with prototype equipment made from Accura 25 is conducted to validate laboratory findings and assess real-world performance. This involves collaborating with athletes and sports professionals to gather feedback on comfort, functionality, and overall user experience.

The comprehensive performance testing of Accura 25 not only validates its suitability for athletic equipment but also guides design optimizations and identifies potential areas for further material development. This iterative process ensures that the final athletic equipment designs leveraging Accura 25 meet the highest standards of performance, durability, and safety.

The testing protocol typically begins with basic mechanical property assessments, including tensile strength, flexural modulus, and impact resistance. These tests provide fundamental data on how Accura 25 performs under different types of stress and strain, which is essential for determining its suitability for specific athletic equipment applications.

Durability testing is another crucial component, involving cyclic loading and fatigue tests to simulate repeated use over time. This helps researchers understand how Accura 25 withstands prolonged exposure to the stresses encountered in athletic activities, ensuring that equipment made from this material maintains its performance characteristics throughout its intended lifespan.

Environmental testing is also conducted to evaluate the material's performance under various temperature and humidity conditions. This includes thermal cycling tests and moisture absorption studies, which are particularly relevant for outdoor sports equipment that may be exposed to diverse weather conditions.

Specific to athletic equipment, impact absorption and energy dissipation tests are performed to assess how Accura 25 responds to sudden forces. These tests are crucial for applications in protective gear, such as helmets or shin guards, where the material's ability to absorb and distribute impact energy is paramount for athlete safety.

Researchers also conduct comparative testing, benchmarking Accura 25 against other materials commonly used in athletic equipment. This involves side-by-side performance evaluations to highlight the advantages and potential limitations of Accura 25 in specific applications.

Advanced imaging techniques, such as high-speed photography and 3D motion capture, are often employed during performance testing to analyze the material's behavior in real-time. These methods provide valuable insights into deformation patterns, stress distribution, and failure modes under various loading conditions.

Finally, field testing with prototype equipment made from Accura 25 is conducted to validate laboratory findings and assess real-world performance. This involves collaborating with athletes and sports professionals to gather feedback on comfort, functionality, and overall user experience.

The comprehensive performance testing of Accura 25 not only validates its suitability for athletic equipment but also guides design optimizations and identifies potential areas for further material development. This iterative process ensures that the final athletic equipment designs leveraging Accura 25 meet the highest standards of performance, durability, and safety.

Sustainability Aspects

Sustainability has become a crucial aspect in the development and production of athletic equipment, including those utilizing Accura 25 material. This high-performance stereolithography resin offers significant advantages in terms of durability and performance, but its environmental impact must be carefully considered.

Accura 25's long-lasting properties contribute to sustainability by reducing the need for frequent replacements of athletic equipment. This durability translates to less waste generation over time, as products maintain their integrity and functionality for extended periods. However, the production process of Accura 25 involves energy-intensive methods and potentially harmful chemicals, which necessitates a thorough examination of its overall environmental footprint.

The recyclability of Accura 25 is an area of ongoing research and development. While the material itself is not biodegradable, efforts are being made to establish effective recycling processes for end-of-life athletic equipment made from this resin. Some manufacturers are exploring closed-loop systems where used products can be collected, processed, and reintegrated into new equipment, minimizing waste and conserving resources.

Energy efficiency in the manufacturing of Accura 25-based athletic equipment is another critical sustainability consideration. Advancements in 3D printing technologies and optimized production processes are helping to reduce energy consumption during fabrication. Additionally, the ability to create complex, lightweight designs with Accura 25 can lead to reduced material usage and improved fuel efficiency in transportation of finished products.

The potential for bio-based alternatives to Accura 25 is an area of growing interest in the athletic equipment industry. Researchers are investigating sustainable sources for resin components that could maintain the high-performance characteristics of Accura 25 while reducing reliance on petroleum-based materials. This shift towards renewable resources could significantly enhance the overall sustainability profile of athletic equipment designs.

Water usage and pollution prevention in the production of Accura 25 and related athletic equipment are also important sustainability aspects. Manufacturers are implementing water-saving technologies and closed-loop water systems to minimize consumption and prevent contamination of local water sources. Furthermore, stringent waste management protocols are being developed to ensure proper handling and disposal of any hazardous byproducts associated with Accura 25 production.

As the athletic equipment industry continues to evolve, the integration of life cycle assessment (LCA) methodologies in product development becomes increasingly important. These assessments provide a comprehensive view of the environmental impact of Accura 25-based products from raw material extraction to end-of-life disposal, enabling manufacturers to make informed decisions and improvements in their sustainability practices.

Accura 25's long-lasting properties contribute to sustainability by reducing the need for frequent replacements of athletic equipment. This durability translates to less waste generation over time, as products maintain their integrity and functionality for extended periods. However, the production process of Accura 25 involves energy-intensive methods and potentially harmful chemicals, which necessitates a thorough examination of its overall environmental footprint.

The recyclability of Accura 25 is an area of ongoing research and development. While the material itself is not biodegradable, efforts are being made to establish effective recycling processes for end-of-life athletic equipment made from this resin. Some manufacturers are exploring closed-loop systems where used products can be collected, processed, and reintegrated into new equipment, minimizing waste and conserving resources.

Energy efficiency in the manufacturing of Accura 25-based athletic equipment is another critical sustainability consideration. Advancements in 3D printing technologies and optimized production processes are helping to reduce energy consumption during fabrication. Additionally, the ability to create complex, lightweight designs with Accura 25 can lead to reduced material usage and improved fuel efficiency in transportation of finished products.

The potential for bio-based alternatives to Accura 25 is an area of growing interest in the athletic equipment industry. Researchers are investigating sustainable sources for resin components that could maintain the high-performance characteristics of Accura 25 while reducing reliance on petroleum-based materials. This shift towards renewable resources could significantly enhance the overall sustainability profile of athletic equipment designs.

Water usage and pollution prevention in the production of Accura 25 and related athletic equipment are also important sustainability aspects. Manufacturers are implementing water-saving technologies and closed-loop water systems to minimize consumption and prevent contamination of local water sources. Furthermore, stringent waste management protocols are being developed to ensure proper handling and disposal of any hazardous byproducts associated with Accura 25 production.

As the athletic equipment industry continues to evolve, the integration of life cycle assessment (LCA) methodologies in product development becomes increasingly important. These assessments provide a comprehensive view of the environmental impact of Accura 25-based products from raw material extraction to end-of-life disposal, enabling manufacturers to make informed decisions and improvements in their sustainability practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!