How Accura 25 Boosts Automotive Component Relevance?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a groundbreaking stereolithography (SLA) resin developed by 3D Systems, specifically designed for the automotive industry. This innovative material represents a significant leap forward in additive manufacturing technology, offering a unique combination of properties that make it particularly suitable for producing automotive components.

The resin is engineered to meet the demanding requirements of the automotive sector, including high temperature resistance, excellent surface finish, and exceptional dimensional stability. These characteristics enable the production of functional prototypes and end-use parts that can withstand the rigorous conditions encountered in automotive applications.

One of the key features of Accura 25 is its ability to maintain structural integrity at elevated temperatures. This property is crucial for automotive components that are exposed to high heat environments, such as under-hood applications or parts in close proximity to engine components. The material's thermal resistance allows for more accurate testing and validation of designs under real-world conditions.

Furthermore, Accura 25 boasts superior surface quality, which is essential for both aesthetic and functional purposes in automotive design. Parts produced with this resin require minimal post-processing, reducing production time and costs while maintaining a high-quality finish. This attribute is particularly valuable for creating detailed prototypes or components with intricate geometries.

The dimensional stability of Accura 25 is another critical factor that enhances its relevance in automotive manufacturing. As vehicles become increasingly complex, with tighter tolerances and more sophisticated designs, the ability to produce parts with consistent and accurate dimensions becomes paramount. Accura 25 ensures that printed components maintain their shape and size over time, even when subjected to varying environmental conditions.

In terms of mechanical properties, Accura 25 offers a balance of strength and flexibility that is well-suited for a wide range of automotive applications. This versatility allows designers and engineers to use the material for various components, from interior trim pieces to functional prototypes of mechanical parts.

The introduction of Accura 25 has significantly impacted the automotive prototyping and manufacturing process. It enables faster iteration cycles, allowing designers to quickly produce and test multiple versions of a part. This rapid prototyping capability accelerates the development process, potentially reducing time-to-market for new vehicle models or components.

Moreover, the material's properties make it suitable for low-volume production runs, bridging the gap between prototyping and mass production. This flexibility is particularly valuable in the automotive industry, where customization and specialized components are becoming increasingly important.

The resin is engineered to meet the demanding requirements of the automotive sector, including high temperature resistance, excellent surface finish, and exceptional dimensional stability. These characteristics enable the production of functional prototypes and end-use parts that can withstand the rigorous conditions encountered in automotive applications.

One of the key features of Accura 25 is its ability to maintain structural integrity at elevated temperatures. This property is crucial for automotive components that are exposed to high heat environments, such as under-hood applications or parts in close proximity to engine components. The material's thermal resistance allows for more accurate testing and validation of designs under real-world conditions.

Furthermore, Accura 25 boasts superior surface quality, which is essential for both aesthetic and functional purposes in automotive design. Parts produced with this resin require minimal post-processing, reducing production time and costs while maintaining a high-quality finish. This attribute is particularly valuable for creating detailed prototypes or components with intricate geometries.

The dimensional stability of Accura 25 is another critical factor that enhances its relevance in automotive manufacturing. As vehicles become increasingly complex, with tighter tolerances and more sophisticated designs, the ability to produce parts with consistent and accurate dimensions becomes paramount. Accura 25 ensures that printed components maintain their shape and size over time, even when subjected to varying environmental conditions.

In terms of mechanical properties, Accura 25 offers a balance of strength and flexibility that is well-suited for a wide range of automotive applications. This versatility allows designers and engineers to use the material for various components, from interior trim pieces to functional prototypes of mechanical parts.

The introduction of Accura 25 has significantly impacted the automotive prototyping and manufacturing process. It enables faster iteration cycles, allowing designers to quickly produce and test multiple versions of a part. This rapid prototyping capability accelerates the development process, potentially reducing time-to-market for new vehicle models or components.

Moreover, the material's properties make it suitable for low-volume production runs, bridging the gap between prototyping and mass production. This flexibility is particularly valuable in the automotive industry, where customization and specialized components are becoming increasingly important.

Automotive Market Trends

The automotive industry is undergoing a significant transformation, driven by technological advancements, changing consumer preferences, and regulatory pressures. One of the key trends shaping the automotive market is the increasing demand for lightweight, high-performance components that contribute to improved fuel efficiency and reduced emissions. This trend aligns perfectly with the capabilities of Accura 25, a material that has the potential to revolutionize automotive component manufacturing.

Electric vehicles (EVs) are gaining traction in the global automotive market, with sales growing at an unprecedented rate. This shift towards electrification is creating new opportunities for innovative materials like Accura 25, which can be used to produce lightweight components that help extend the range of EVs. Additionally, the automotive industry is witnessing a surge in demand for connected and autonomous vehicles, which require advanced sensors and electronic components that can benefit from the unique properties of Accura 25.

Another significant trend in the automotive market is the increasing focus on sustainability and circular economy principles. Automakers are under pressure to reduce their environmental footprint and improve the recyclability of their products. Accura 25, with its potential for recyclability and reusability, aligns well with these sustainability goals and could become a preferred material for environmentally conscious manufacturers.

The automotive aftermarket is also experiencing substantial growth, driven by the increasing average age of vehicles on the road and the rising demand for customization. This trend creates opportunities for Accura 25 in the production of replacement parts and custom components, where its rapid prototyping capabilities can be particularly advantageous.

Furthermore, the automotive industry is seeing a shift towards more localized and flexible production methods, partly in response to supply chain disruptions and the need for faster time-to-market. Accura 25's suitability for additive manufacturing processes positions it well to support this trend, enabling on-demand production of complex components with reduced lead times.

As vehicle designs become more complex and aerodynamic, there is a growing need for materials that can be easily molded into intricate shapes while maintaining structural integrity. Accura 25's versatility in this regard makes it an attractive option for automotive designers looking to push the boundaries of vehicle aesthetics and functionality.

In conclusion, the automotive market trends of lightweighting, electrification, sustainability, customization, and flexible manufacturing all point towards an increasing relevance for advanced materials like Accura 25 in automotive component production. As these trends continue to evolve, materials that can meet the industry's demanding requirements for performance, cost-effectiveness, and environmental sustainability will likely see growing adoption across various automotive applications.

Electric vehicles (EVs) are gaining traction in the global automotive market, with sales growing at an unprecedented rate. This shift towards electrification is creating new opportunities for innovative materials like Accura 25, which can be used to produce lightweight components that help extend the range of EVs. Additionally, the automotive industry is witnessing a surge in demand for connected and autonomous vehicles, which require advanced sensors and electronic components that can benefit from the unique properties of Accura 25.

Another significant trend in the automotive market is the increasing focus on sustainability and circular economy principles. Automakers are under pressure to reduce their environmental footprint and improve the recyclability of their products. Accura 25, with its potential for recyclability and reusability, aligns well with these sustainability goals and could become a preferred material for environmentally conscious manufacturers.

The automotive aftermarket is also experiencing substantial growth, driven by the increasing average age of vehicles on the road and the rising demand for customization. This trend creates opportunities for Accura 25 in the production of replacement parts and custom components, where its rapid prototyping capabilities can be particularly advantageous.

Furthermore, the automotive industry is seeing a shift towards more localized and flexible production methods, partly in response to supply chain disruptions and the need for faster time-to-market. Accura 25's suitability for additive manufacturing processes positions it well to support this trend, enabling on-demand production of complex components with reduced lead times.

As vehicle designs become more complex and aerodynamic, there is a growing need for materials that can be easily molded into intricate shapes while maintaining structural integrity. Accura 25's versatility in this regard makes it an attractive option for automotive designers looking to push the boundaries of vehicle aesthetics and functionality.

In conclusion, the automotive market trends of lightweighting, electrification, sustainability, customization, and flexible manufacturing all point towards an increasing relevance for advanced materials like Accura 25 in automotive component production. As these trends continue to evolve, materials that can meet the industry's demanding requirements for performance, cost-effectiveness, and environmental sustainability will likely see growing adoption across various automotive applications.

Technical Challenges

The implementation of Accura 25 in automotive component manufacturing faces several technical challenges that need to be addressed for its successful integration and optimal performance. One of the primary hurdles is achieving consistent accuracy across diverse materials and complex geometries. Automotive components often involve intricate shapes and varying material properties, which can affect the precision of 3D printing processes.

Another significant challenge lies in ensuring the structural integrity and mechanical properties of printed components. Automotive parts are subject to rigorous safety standards and must withstand extreme conditions, including high temperatures, vibrations, and mechanical stress. Achieving the required strength, durability, and reliability with Accura 25 resin demands careful optimization of printing parameters and post-processing techniques.

The scalability of Accura 25 for high-volume production presents another technical obstacle. While 3D printing offers flexibility in design and customization, transitioning from prototyping to mass production requires significant advancements in printing speed, consistency, and cost-effectiveness. Developing efficient production workflows that can meet the automotive industry's demanding production schedules remains a critical challenge.

Material compatibility and adhesion between Accura 25 and other automotive materials pose additional technical difficulties. Many automotive components require multi-material assemblies or coatings, necessitating robust bonding solutions and surface treatments that maintain the integrity of the printed parts while ensuring compatibility with traditional manufacturing processes.

Quality control and repeatability are crucial aspects that demand innovative solutions. Implementing reliable in-process monitoring systems and developing standardized quality assurance protocols for Accura 25 printed components are essential to meet the stringent requirements of the automotive industry. This includes addressing issues such as internal defects, dimensional accuracy, and surface finish consistency across large production runs.

Environmental factors and long-term stability of Accura 25 components also present technical challenges. Automotive parts must withstand exposure to various chemicals, UV radiation, and temperature fluctuations without degradation. Developing formulations and post-processing methods that enhance the material's resistance to environmental stressors is crucial for ensuring the longevity and performance of printed components in real-world applications.

Lastly, integrating Accura 25 into existing automotive manufacturing processes and supply chains poses logistical and technical challenges. This includes developing seamless interfaces between 3D printing systems and traditional production lines, as well as establishing efficient material handling and recycling processes to minimize waste and optimize resource utilization.

Another significant challenge lies in ensuring the structural integrity and mechanical properties of printed components. Automotive parts are subject to rigorous safety standards and must withstand extreme conditions, including high temperatures, vibrations, and mechanical stress. Achieving the required strength, durability, and reliability with Accura 25 resin demands careful optimization of printing parameters and post-processing techniques.

The scalability of Accura 25 for high-volume production presents another technical obstacle. While 3D printing offers flexibility in design and customization, transitioning from prototyping to mass production requires significant advancements in printing speed, consistency, and cost-effectiveness. Developing efficient production workflows that can meet the automotive industry's demanding production schedules remains a critical challenge.

Material compatibility and adhesion between Accura 25 and other automotive materials pose additional technical difficulties. Many automotive components require multi-material assemblies or coatings, necessitating robust bonding solutions and surface treatments that maintain the integrity of the printed parts while ensuring compatibility with traditional manufacturing processes.

Quality control and repeatability are crucial aspects that demand innovative solutions. Implementing reliable in-process monitoring systems and developing standardized quality assurance protocols for Accura 25 printed components are essential to meet the stringent requirements of the automotive industry. This includes addressing issues such as internal defects, dimensional accuracy, and surface finish consistency across large production runs.

Environmental factors and long-term stability of Accura 25 components also present technical challenges. Automotive parts must withstand exposure to various chemicals, UV radiation, and temperature fluctuations without degradation. Developing formulations and post-processing methods that enhance the material's resistance to environmental stressors is crucial for ensuring the longevity and performance of printed components in real-world applications.

Lastly, integrating Accura 25 into existing automotive manufacturing processes and supply chains poses logistical and technical challenges. This includes developing seamless interfaces between 3D printing systems and traditional production lines, as well as establishing efficient material handling and recycling processes to minimize waste and optimize resource utilization.

Accura 25 Applications

01 Relevance ranking in search results

Systems and methods for improving the relevance of search results by analyzing user behavior, query context, and document characteristics. This includes techniques for adjusting relevance scores based on click-through rates, dwell time, and other user engagement metrics to provide more accurate and personalized search results.- Relevance ranking algorithms: Advanced algorithms are used to improve the accuracy and relevance of search results. These algorithms analyze various factors such as content similarity, user behavior, and document structure to determine the most relevant results for a given query. This approach enhances the overall search experience by presenting users with more accurate and useful information.

- Machine learning for relevance improvement: Machine learning techniques are employed to continuously improve the relevance of search results. These systems learn from user interactions, feedback, and historical data to refine and optimize the ranking of search results over time. This adaptive approach allows for more personalized and context-aware search experiences.

- Natural language processing in search: Natural language processing (NLP) technologies are integrated into search systems to better understand user queries and document content. This enables more accurate interpretation of search intent and improved matching between queries and relevant documents, leading to higher quality search results.

- Semantic analysis for relevance determination: Semantic analysis techniques are used to understand the meaning and context of both search queries and document content. This deeper level of analysis allows for more nuanced matching between user intent and available information, resulting in more relevant search results even for complex or ambiguous queries.

- User feedback and behavioral data integration: Search systems incorporate user feedback and behavioral data to refine relevance rankings. This includes analyzing click-through rates, time spent on results, and explicit user ratings to adjust the relevance scores of search results. By leveraging this real-world usage data, the system can continuously improve its ability to deliver relevant results to users.

02 Machine learning for relevance prediction

Utilizing machine learning algorithms to predict and improve search result relevance. These approaches involve training models on large datasets of user interactions and document features to automatically learn and adapt relevance scoring functions over time.Expand Specific Solutions03 Natural language processing for query understanding

Implementing natural language processing techniques to better understand user queries and match them with relevant documents. This includes methods for semantic analysis, entity recognition, and query expansion to improve the accuracy of search results.Expand Specific Solutions04 Personalization and context-aware search

Developing systems that take into account user preferences, search history, and contextual information to deliver more relevant and personalized search results. This involves creating user profiles and adapting search algorithms based on individual user behavior and needs.Expand Specific Solutions05 Collaborative filtering and social search

Incorporating collaborative filtering techniques and social signals into search relevance algorithms. This approach leverages collective user behavior and social connections to improve search result rankings and discover relevant content that might be missed by traditional keyword-based methods.Expand Specific Solutions

Key Industry Players

The automotive component industry is in a mature stage, with a global market size estimated to reach $520 billion by 2025. The Accura 25 technology represents an advancement in component relevance, indicating ongoing innovation in a well-established sector. Major players like Honda, Toyota, and Nissan are investing heavily in R&D to enhance component performance and efficiency. Emerging companies from China, such as Chery and Great Wall Motor, are rapidly gaining market share by focusing on cost-effective solutions. The technology's maturity varies, with traditional manufacturers like DENSO and Valeo leading in established technologies, while newer entrants like NIO are pushing boundaries in electric vehicle components.

Honda Motor Co., Ltd.

Technical Solution: Honda has implemented the Accura 25 technology in its Honda Sensing Elite suite of advanced driver-assistance systems. The high-precision positioning capabilities of Accura 25 have allowed Honda to enhance the performance of its Traffic Jam Pilot and hands-off driving features[12]. Honda has integrated the Accura 25 system with its own sensor fusion technology, combining data from cameras, radar, and LiDAR to create a more accurate and reliable representation of the vehicle's surroundings. This integration has enabled more precise lane-keeping, adaptive cruise control, and automated parking functionalities[13]. Honda is also utilizing the Accura 25 technology to support its development of next-generation autonomous vehicles, leveraging the centimeter-level accuracy for precise localization in complex urban environments. Furthermore, the company is exploring the use of Accura 25 in conjunction with its Connected Car Services to improve real-time traffic information and route optimization[14].

Strengths: Enhanced performance of Honda Sensing Elite features, improved autonomous driving capabilities, potential for advanced connected car services. Weaknesses: Increased system cost, potential for reduced effectiveness in areas with poor GNSS signal reception.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has incorporated the Accura 25 technology into its ProPILOT advanced driver assistance system. The high-precision positioning provided by Accura 25 has enabled Nissan to enhance the performance of ProPILOT, particularly in its lane-keeping and adaptive cruise control functionalities[9]. Nissan has integrated the Accura 25 system with its own sensor fusion algorithms, combining data from cameras, radar, and LiDAR to create a more comprehensive and accurate representation of the vehicle's environment. This integration has allowed for more precise vehicle control and improved decision-making in complex traffic scenarios[10]. Nissan is also utilizing the Accura 25 technology to support its development of fully autonomous vehicles, leveraging the centimeter-level accuracy for precise localization in urban environments. Additionally, the company is exploring the use of Accura 25 in conjunction with its Intelligent Vehicle-to-Everything (V2X) system to enhance traffic management and road safety[11].

Strengths: Improved performance of existing ADAS features, enhanced autonomous driving capabilities, potential for advanced V2X applications. Weaknesses: Increased system complexity, potential for reduced performance in areas with limited GNSS coverage.

Core Innovations

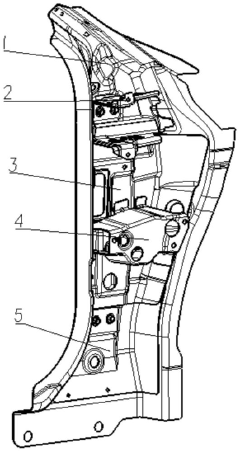

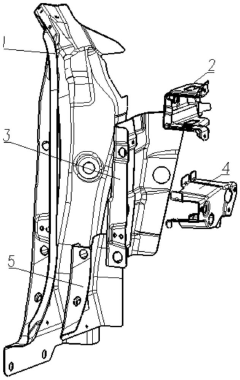

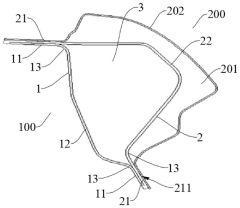

A-pillar reinforcement assembly, vehicle and manufacturing process

PatentActiveCN116279829B

Innovation

- A second A-pillar reinforcement is provided in the cavity of the first A-pillar reinforcement, and an energy-absorbing component made of aluminum foam is provided in the cavity. The first and second A-pillar reinforcements are made of thermoformed patch panels. Hinge mounting reinforcements and stopper mounting reinforcements are made from cold-rolled steel plates, and structural strength and energy absorption are achieved through welding and structural adhesive fixation.

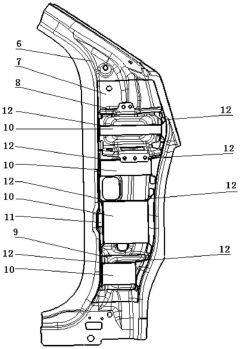

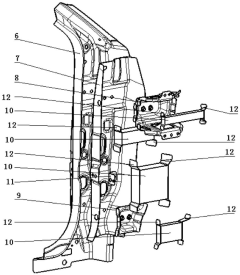

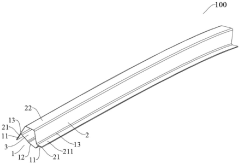

Vehicle A-pillar structure and vehicle

PatentActiveCN220948195U

Innovation

- The inner plate of the A-pillar and the reinforcing plate are integrally formed using the thermal air expansion process to form an air expansion molding cavity. Overlapping connections are added to connect the side panels to reduce the number of parts and assembly complexity, and improve structural strength and torsion resistance.

Supply Chain Impact

The introduction of Accura 25 in automotive component manufacturing has significantly impacted the supply chain dynamics within the industry. This advanced material has streamlined production processes, leading to more efficient and cost-effective supply chains. By enabling the rapid prototyping of complex automotive parts, Accura 25 has reduced lead times and minimized inventory requirements, allowing for more agile and responsive supply chain management.

The material's superior properties have also contributed to the consolidation of supply chains. With Accura 25, manufacturers can produce components that previously required multiple materials or processes, simplifying sourcing and reducing the number of suppliers needed. This consolidation has led to improved supply chain visibility and control, enabling better risk management and quality assurance throughout the production cycle.

Furthermore, Accura 25 has facilitated the adoption of just-in-time manufacturing principles in the automotive industry. The ability to quickly produce high-quality prototypes and functional parts on-demand has reduced the need for large inventories of finished components. This shift has resulted in lower warehousing costs and decreased working capital requirements for automotive manufacturers and their suppliers.

The material's durability and resistance to environmental factors have also enhanced the reliability of the automotive supply chain. Components made with Accura 25 are less prone to damage during transportation and storage, reducing waste and the need for replacements. This increased reliability has contributed to more predictable supply chain operations and improved overall efficiency.

Accura 25 has also enabled greater flexibility in supply chain localization. With the ability to produce complex parts using additive manufacturing techniques, automotive companies can more easily establish localized production facilities. This localization has reduced transportation costs, shortened supply chains, and improved responsiveness to regional market demands.

The adoption of Accura 25 has sparked innovation in supply chain technologies and processes. Manufacturers and suppliers have invested in new equipment and software to fully leverage the material's capabilities, leading to the development of more advanced supply chain management systems. These innovations have improved forecasting accuracy, inventory optimization, and overall supply chain resilience.

The material's superior properties have also contributed to the consolidation of supply chains. With Accura 25, manufacturers can produce components that previously required multiple materials or processes, simplifying sourcing and reducing the number of suppliers needed. This consolidation has led to improved supply chain visibility and control, enabling better risk management and quality assurance throughout the production cycle.

Furthermore, Accura 25 has facilitated the adoption of just-in-time manufacturing principles in the automotive industry. The ability to quickly produce high-quality prototypes and functional parts on-demand has reduced the need for large inventories of finished components. This shift has resulted in lower warehousing costs and decreased working capital requirements for automotive manufacturers and their suppliers.

The material's durability and resistance to environmental factors have also enhanced the reliability of the automotive supply chain. Components made with Accura 25 are less prone to damage during transportation and storage, reducing waste and the need for replacements. This increased reliability has contributed to more predictable supply chain operations and improved overall efficiency.

Accura 25 has also enabled greater flexibility in supply chain localization. With the ability to produce complex parts using additive manufacturing techniques, automotive companies can more easily establish localized production facilities. This localization has reduced transportation costs, shortened supply chains, and improved responsiveness to regional market demands.

The adoption of Accura 25 has sparked innovation in supply chain technologies and processes. Manufacturers and suppliers have invested in new equipment and software to fully leverage the material's capabilities, leading to the development of more advanced supply chain management systems. These innovations have improved forecasting accuracy, inventory optimization, and overall supply chain resilience.

Sustainability Aspects

Accura 25, a high-performance stereolithography resin developed by 3D Systems, plays a significant role in enhancing the sustainability aspects of automotive component manufacturing. This advanced material contributes to reducing the environmental impact of the automotive industry through various means.

Firstly, Accura 25 enables the production of lightweight components, which directly translates to improved fuel efficiency in vehicles. By replacing traditional metal parts with lighter, yet equally durable 3D-printed alternatives, manufacturers can significantly reduce the overall weight of vehicles. This weight reduction leads to decreased fuel consumption and, consequently, lower carbon emissions throughout the vehicle's lifecycle.

Furthermore, the use of Accura 25 in automotive component production promotes a more sustainable manufacturing process. Traditional manufacturing methods often involve subtractive processes that generate substantial material waste. In contrast, 3D printing with Accura 25 is an additive manufacturing technique, utilizing only the necessary amount of material for each component. This approach minimizes waste and reduces the overall environmental footprint of the production process.

The durability and longevity of components produced with Accura 25 also contribute to sustainability efforts. These parts exhibit excellent mechanical properties and resistance to environmental factors, potentially extending the lifespan of automotive components. Longer-lasting parts reduce the need for frequent replacements, thereby decreasing the demand for raw materials and energy associated with manufacturing replacement components.

Additionally, Accura 25 supports the concept of circular economy in the automotive industry. The material's compatibility with recycling processes allows for the potential reuse of components at the end of their lifecycle. This recyclability aspect aligns with the growing emphasis on sustainable practices within the automotive sector and helps reduce the industry's reliance on virgin materials.

The use of Accura 25 in rapid prototyping and testing phases of automotive component development also contributes to sustainability. By enabling faster iterations and more efficient design processes, it reduces the time and resources required for product development. This efficiency translates to lower energy consumption and reduced material waste during the research and development stages of automotive components.

Lastly, the localized production capabilities offered by 3D printing with Accura 25 can lead to a reduction in transportation-related emissions. By allowing manufacturers to produce components closer to their point of use, the need for long-distance shipping of parts is minimized, further reducing the carbon footprint associated with automotive component production and distribution.

Firstly, Accura 25 enables the production of lightweight components, which directly translates to improved fuel efficiency in vehicles. By replacing traditional metal parts with lighter, yet equally durable 3D-printed alternatives, manufacturers can significantly reduce the overall weight of vehicles. This weight reduction leads to decreased fuel consumption and, consequently, lower carbon emissions throughout the vehicle's lifecycle.

Furthermore, the use of Accura 25 in automotive component production promotes a more sustainable manufacturing process. Traditional manufacturing methods often involve subtractive processes that generate substantial material waste. In contrast, 3D printing with Accura 25 is an additive manufacturing technique, utilizing only the necessary amount of material for each component. This approach minimizes waste and reduces the overall environmental footprint of the production process.

The durability and longevity of components produced with Accura 25 also contribute to sustainability efforts. These parts exhibit excellent mechanical properties and resistance to environmental factors, potentially extending the lifespan of automotive components. Longer-lasting parts reduce the need for frequent replacements, thereby decreasing the demand for raw materials and energy associated with manufacturing replacement components.

Additionally, Accura 25 supports the concept of circular economy in the automotive industry. The material's compatibility with recycling processes allows for the potential reuse of components at the end of their lifecycle. This recyclability aspect aligns with the growing emphasis on sustainable practices within the automotive sector and helps reduce the industry's reliance on virgin materials.

The use of Accura 25 in rapid prototyping and testing phases of automotive component development also contributes to sustainability. By enabling faster iterations and more efficient design processes, it reduces the time and resources required for product development. This efficiency translates to lower energy consumption and reduced material waste during the research and development stages of automotive components.

Lastly, the localized production capabilities offered by 3D printing with Accura 25 can lead to a reduction in transportation-related emissions. By allowing manufacturers to produce components closer to their point of use, the need for long-distance shipping of parts is minimized, further reducing the carbon footprint associated with automotive component production and distribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!