How to Integrate Accura 25 into Sustainable Practices?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Sustainability Goals

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, designed for use in additive manufacturing processes. This material has gained significant attention in the industry due to its exceptional mechanical properties and versatility. As the manufacturing sector increasingly focuses on sustainability, integrating Accura 25 into sustainable practices has become a crucial objective.

The evolution of Accura 25 can be traced back to the early developments in SLA technology. Over the years, continuous improvements in resin formulations have led to the creation of this advanced material, which offers a unique combination of strength, durability, and precision. The technology behind Accura 25 represents a significant milestone in the additive manufacturing industry, pushing the boundaries of what is possible in terms of part quality and performance.

In the context of sustainability, the integration of Accura 25 into manufacturing processes aligns with several key environmental goals. Firstly, the material's high performance and durability contribute to the production of long-lasting parts, potentially reducing the need for frequent replacements and minimizing waste. Additionally, the precision offered by Accura 25 allows for the creation of complex geometries that can optimize material usage and enhance product efficiency.

The sustainability goals associated with Accura 25 integration extend beyond the material itself. By leveraging this advanced resin in additive manufacturing processes, companies can potentially reduce energy consumption and material waste compared to traditional manufacturing methods. The ability to produce parts on-demand also aligns with lean manufacturing principles, minimizing inventory and associated storage costs.

Furthermore, the integration of Accura 25 into sustainable practices involves exploring its potential for recycling and reuse. While thermoset resins like Accura 25 have traditionally been challenging to recycle, ongoing research and development efforts are focused on finding innovative solutions to this problem. The goal is to create a closed-loop system where used Accura 25 parts can be effectively recycled or repurposed, further enhancing the material's sustainability profile.

As industries strive to meet increasingly stringent environmental regulations and consumer demands for sustainable products, the role of materials like Accura 25 becomes increasingly important. The technical objectives for integrating this material into sustainable practices include optimizing its use to minimize waste, developing more energy-efficient manufacturing processes, and exploring novel applications that can leverage its unique properties to create more sustainable products and solutions.

The evolution of Accura 25 can be traced back to the early developments in SLA technology. Over the years, continuous improvements in resin formulations have led to the creation of this advanced material, which offers a unique combination of strength, durability, and precision. The technology behind Accura 25 represents a significant milestone in the additive manufacturing industry, pushing the boundaries of what is possible in terms of part quality and performance.

In the context of sustainability, the integration of Accura 25 into manufacturing processes aligns with several key environmental goals. Firstly, the material's high performance and durability contribute to the production of long-lasting parts, potentially reducing the need for frequent replacements and minimizing waste. Additionally, the precision offered by Accura 25 allows for the creation of complex geometries that can optimize material usage and enhance product efficiency.

The sustainability goals associated with Accura 25 integration extend beyond the material itself. By leveraging this advanced resin in additive manufacturing processes, companies can potentially reduce energy consumption and material waste compared to traditional manufacturing methods. The ability to produce parts on-demand also aligns with lean manufacturing principles, minimizing inventory and associated storage costs.

Furthermore, the integration of Accura 25 into sustainable practices involves exploring its potential for recycling and reuse. While thermoset resins like Accura 25 have traditionally been challenging to recycle, ongoing research and development efforts are focused on finding innovative solutions to this problem. The goal is to create a closed-loop system where used Accura 25 parts can be effectively recycled or repurposed, further enhancing the material's sustainability profile.

As industries strive to meet increasingly stringent environmental regulations and consumer demands for sustainable products, the role of materials like Accura 25 becomes increasingly important. The technical objectives for integrating this material into sustainable practices include optimizing its use to minimize waste, developing more energy-efficient manufacturing processes, and exploring novel applications that can leverage its unique properties to create more sustainable products and solutions.

Market Demand for Sustainable 3D Printing Materials

The market demand for sustainable 3D printing materials has been experiencing significant growth in recent years, driven by increasing environmental awareness and the push for more eco-friendly manufacturing processes. Accura 25, a high-performance stereolithography resin, has garnered attention for its potential integration into sustainable practices within the 3D printing industry.

The global 3D printing materials market is projected to expand rapidly, with sustainability becoming a key factor in material selection. Companies across various sectors, including automotive, aerospace, healthcare, and consumer goods, are actively seeking sustainable alternatives to traditional 3D printing materials. This shift is primarily motivated by the need to reduce carbon footprints, comply with stricter environmental regulations, and meet consumer demands for greener products.

Accura 25's potential for sustainable integration lies in its unique properties and performance characteristics. The material offers excellent clarity, high resolution, and durability, making it suitable for a wide range of applications. Its ability to produce functional prototypes and end-use parts with minimal post-processing reduces waste and energy consumption, aligning with sustainable manufacturing goals.

The demand for sustainable 3D printing materials like Accura 25 is particularly strong in industries where product lifecycle and environmental impact are critical considerations. For instance, the automotive sector is increasingly utilizing sustainable 3D printing materials for prototyping and production of lightweight components, contributing to improved fuel efficiency and reduced emissions.

In the healthcare industry, there is a growing interest in biocompatible and sustainable materials for medical device manufacturing and customized implants. Accura 25's potential in this sector could drive its adoption in sustainable medical applications, addressing both environmental concerns and patient safety requirements.

The construction industry is another significant market for sustainable 3D printing materials. As large-scale 3D printing in construction gains traction, the demand for eco-friendly materials that can reduce waste and energy consumption in building processes is rising. Accura 25's durability and precision make it a promising candidate for sustainable architectural applications.

Consumer goods manufacturers are also showing increased interest in sustainable 3D printing materials, responding to consumer preferences for environmentally responsible products. The ability to create complex geometries and customize designs using materials like Accura 25 opens up new possibilities for sustainable product development and manufacturing.

As the market for sustainable 3D printing materials continues to evolve, the integration of Accura 25 into sustainable practices is likely to be influenced by factors such as material recyclability, energy efficiency in production and use, and overall lifecycle assessment. The development of closed-loop systems for material recovery and reuse could further enhance the sustainability profile of Accura 25 and similar materials.

The global 3D printing materials market is projected to expand rapidly, with sustainability becoming a key factor in material selection. Companies across various sectors, including automotive, aerospace, healthcare, and consumer goods, are actively seeking sustainable alternatives to traditional 3D printing materials. This shift is primarily motivated by the need to reduce carbon footprints, comply with stricter environmental regulations, and meet consumer demands for greener products.

Accura 25's potential for sustainable integration lies in its unique properties and performance characteristics. The material offers excellent clarity, high resolution, and durability, making it suitable for a wide range of applications. Its ability to produce functional prototypes and end-use parts with minimal post-processing reduces waste and energy consumption, aligning with sustainable manufacturing goals.

The demand for sustainable 3D printing materials like Accura 25 is particularly strong in industries where product lifecycle and environmental impact are critical considerations. For instance, the automotive sector is increasingly utilizing sustainable 3D printing materials for prototyping and production of lightweight components, contributing to improved fuel efficiency and reduced emissions.

In the healthcare industry, there is a growing interest in biocompatible and sustainable materials for medical device manufacturing and customized implants. Accura 25's potential in this sector could drive its adoption in sustainable medical applications, addressing both environmental concerns and patient safety requirements.

The construction industry is another significant market for sustainable 3D printing materials. As large-scale 3D printing in construction gains traction, the demand for eco-friendly materials that can reduce waste and energy consumption in building processes is rising. Accura 25's durability and precision make it a promising candidate for sustainable architectural applications.

Consumer goods manufacturers are also showing increased interest in sustainable 3D printing materials, responding to consumer preferences for environmentally responsible products. The ability to create complex geometries and customize designs using materials like Accura 25 opens up new possibilities for sustainable product development and manufacturing.

As the market for sustainable 3D printing materials continues to evolve, the integration of Accura 25 into sustainable practices is likely to be influenced by factors such as material recyclability, energy efficiency in production and use, and overall lifecycle assessment. The development of closed-loop systems for material recovery and reuse could further enhance the sustainability profile of Accura 25 and similar materials.

Current Challenges in Sustainable 3D Printing

The integration of sustainable practices into 3D printing technology faces several significant challenges, particularly when considering the incorporation of materials like Accura 25. One of the primary obstacles is the environmental impact of the materials used in the printing process. Many 3D printing materials, including some resins, are derived from non-renewable resources and can be difficult to recycle or biodegrade. This poses a substantial hurdle in achieving true sustainability in the manufacturing process.

Energy consumption during the 3D printing process is another major concern. The high-powered lasers and heating elements required for many 3D printing techniques consume significant amounts of electricity, often derived from non-renewable sources. This energy-intensive nature of 3D printing conflicts with sustainable practices that aim to reduce carbon footprints and overall energy usage.

Waste generation is a persistent issue in 3D printing, including support structures and failed prints. While some materials can be recycled, many end up in landfills, contributing to environmental degradation. The challenge lies in developing more efficient printing processes and improving material recyclability to minimize waste.

The durability and longevity of 3D printed products also present challenges to sustainability. Some printed items may have shorter lifespans compared to traditionally manufactured counterparts, leading to increased replacement rates and, consequently, more resource consumption and waste generation.

Chemical emissions during the printing process pose both environmental and health concerns. Many resins and plastics used in 3D printing release volatile organic compounds (VOCs) and other potentially harmful substances. Addressing these emissions while maintaining print quality and efficiency is a significant challenge in making 3D printing more sustainable.

Supply chain sustainability is another critical issue. The production and transportation of 3D printing materials often involve complex, global supply chains that can be difficult to monitor and optimize for sustainability. Ensuring ethical sourcing and reducing the carbon footprint of these supply chains remains a challenge.

Lastly, there's a notable lack of standardization in sustainable 3D printing practices. Without clear industry-wide guidelines and metrics for sustainability, it becomes challenging for manufacturers and users to make informed decisions about materials, processes, and equipment that truly align with sustainable goals. Developing and implementing such standards is crucial for the widespread adoption of sustainable 3D printing practices.

Energy consumption during the 3D printing process is another major concern. The high-powered lasers and heating elements required for many 3D printing techniques consume significant amounts of electricity, often derived from non-renewable sources. This energy-intensive nature of 3D printing conflicts with sustainable practices that aim to reduce carbon footprints and overall energy usage.

Waste generation is a persistent issue in 3D printing, including support structures and failed prints. While some materials can be recycled, many end up in landfills, contributing to environmental degradation. The challenge lies in developing more efficient printing processes and improving material recyclability to minimize waste.

The durability and longevity of 3D printed products also present challenges to sustainability. Some printed items may have shorter lifespans compared to traditionally manufactured counterparts, leading to increased replacement rates and, consequently, more resource consumption and waste generation.

Chemical emissions during the printing process pose both environmental and health concerns. Many resins and plastics used in 3D printing release volatile organic compounds (VOCs) and other potentially harmful substances. Addressing these emissions while maintaining print quality and efficiency is a significant challenge in making 3D printing more sustainable.

Supply chain sustainability is another critical issue. The production and transportation of 3D printing materials often involve complex, global supply chains that can be difficult to monitor and optimize for sustainability. Ensuring ethical sourcing and reducing the carbon footprint of these supply chains remains a challenge.

Lastly, there's a notable lack of standardization in sustainable 3D printing practices. Without clear industry-wide guidelines and metrics for sustainability, it becomes challenging for manufacturers and users to make informed decisions about materials, processes, and equipment that truly align with sustainable goals. Developing and implementing such standards is crucial for the widespread adoption of sustainable 3D printing practices.

Existing Sustainable Practices for Accura 25

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for different therapeutic purposes. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be designed for specific routes of administration or targeted drug delivery.

- Analytical methods for Accura 25: Various analytical techniques are employed to detect, quantify, and characterize Accura 25 in different matrices. These methods may include chromatography, spectroscopy, or other advanced analytical tools. The development of accurate and sensitive analytical methods is crucial for quality control and research purposes.

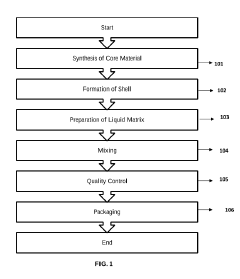

- Synthesis and manufacturing processes for Accura 25: Different synthetic routes and manufacturing processes are developed to produce Accura 25 efficiently and with high purity. These processes may involve novel chemical reactions, catalysts, or process optimizations to improve yield and reduce production costs.

- Formulation of Accura 25 in drug delivery systems: Accura 25 is incorporated into various drug delivery systems to enhance its bioavailability, control release, or target specific tissues. These formulations may include nanoparticles, liposomes, or other advanced drug delivery technologies to improve the compound's therapeutic efficacy.

- Applications of Accura 25 in medical devices: Accura 25 is utilized in the development of medical devices or diagnostic tools. This may involve its incorporation into materials used in device fabrication or its use as a component in diagnostic assays or imaging agents.

02 Manufacturing processes for Accura 25

Different methods and processes are employed in the production of Accura 25. These may involve specific synthesis routes, purification techniques, or formulation strategies to ensure the quality and consistency of the final product.Expand Specific Solutions03 Applications of Accura 25 in medical devices

Accura 25 is utilized in various medical devices, potentially due to its specific properties. These applications may include diagnostic tools, drug delivery systems, or other medical equipment where the properties of Accura 25 provide particular benefits.Expand Specific Solutions04 Analytical methods for Accura 25

Various analytical techniques and methods are developed for the detection, quantification, or characterization of Accura 25. These may include spectroscopic, chromatographic, or other instrumental methods to ensure the quality and purity of the compound.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other therapeutic agents for enhanced efficacy in treating certain conditions. These combination therapies may target multiple pathways or provide synergistic effects for improved patient outcomes.Expand Specific Solutions

Key Players in Sustainable 3D Printing Industry

The integration of Accura 25 into sustainable practices is currently in an emerging phase, with the market showing potential for growth as industries increasingly focus on sustainability. The technology's maturity is still developing, with key players like Lovely Professional University, ITK SAS, and Zhejiang University contributing to research and development. State Grid Corp. of China and China Three Gorges University are exploring applications in the energy sector, while companies like EnergyWorks BioPower LLC are investigating its potential in renewable energy. As the technology evolves, collaboration between academic institutions and industry leaders will be crucial for advancing Accura 25's integration into sustainable practices across various sectors.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has implemented Accura 25 in its smart grid initiatives to enhance sustainability. The company utilizes Accura 25's high-precision measurement capabilities to optimize power distribution and reduce transmission losses across its vast network. This integration enables more accurate load forecasting and demand response management, facilitating the integration of renewable energy sources into the grid[5]. State Grid has also deployed Accura 25 in its substation automation systems, improving the efficiency of power transmission and distribution while minimizing equipment failures and downtime[6].

Strengths: Massive scale of operations allows for significant impact on national energy efficiency. Weaknesses: Complexity of integrating new technology across a vast and diverse infrastructure.

Oracle International Corp.

Technical Solution: Oracle has integrated Accura 25 into its sustainable practices through its cloud-based environmental management solutions. The company leverages Accura 25's data processing capabilities to enhance its Oracle Environmental Accounting and Reporting system, providing businesses with more accurate and real-time environmental impact assessments[7]. Oracle has also incorporated Accura 25 into its IoT-based energy management platforms, enabling more precise monitoring and control of energy consumption in data centers and office facilities. This integration supports Oracle's commitment to achieving 100% renewable energy use in its operations[8].

Strengths: Extensive experience in data management and analytics, global reach for implementing solutions. Weaknesses: Indirect impact on sustainability as primarily a technology provider rather than an end-user.

Innovations in Accura 25 Sustainability

Puncture-resistant inflatable objects

PatentPendingIN202411020431A

Innovation

- A composite material comprising a biodegradable liquid matrix and stable gas mixture with nanoparticles that self-seal punctures, utilizing a core-shell structure for rapid sealing and ensuring structural integrity, along with an environmentally friendly design for minimal ecological impact.

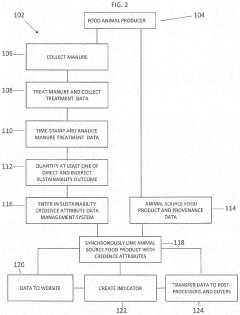

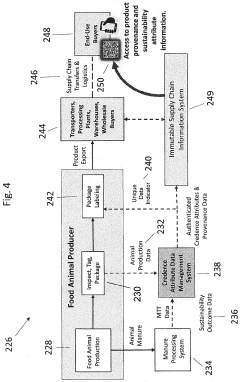

Method for imparting sustainability credance attributes for animal source food products

PatentActiveUS20220309434A1

Innovation

- A method is introduced to quantify and record sustainability outcomes from manure treatment systems, linking these outcomes to animal source food products through a credence attribute data management system, providing traceability across the supply chain via an immutable information system and data indicators on product packaging.

Environmental Impact Assessment of Accura 25

The environmental impact assessment of Accura 25 is a critical component in evaluating its integration into sustainable practices. This assessment encompasses various aspects of the material's lifecycle, from production to disposal, and its effects on ecosystems and human health.

Accura 25, a photopolymer resin used in stereolithography 3D printing, offers unique properties that contribute to its growing popularity in manufacturing. However, its environmental footprint requires careful consideration. The production process of Accura 25 involves energy-intensive steps and the use of potentially hazardous chemicals, which can contribute to greenhouse gas emissions and pose risks of environmental contamination if not properly managed.

During its use phase, Accura 25 demonstrates some positive environmental attributes. Its precision in 3D printing allows for the creation of complex geometries with minimal material waste, potentially reducing overall resource consumption compared to traditional manufacturing methods. Additionally, the ability to produce parts on-demand can lead to reduced inventory and associated storage-related environmental impacts.

Post-use, the environmental impact of Accura 25 becomes more challenging. The material is not biodegradable and can persist in the environment for extended periods if improperly disposed of. Recycling options for Accura 25 are currently limited, which can lead to increased landfill waste or incineration, both of which have negative environmental consequences.

Water systems are particularly vulnerable to potential contamination from Accura 25 residues. Uncured resin particles, if released into aquatic environments, can harm marine life and disrupt ecosystems. Therefore, proper handling and disposal protocols are essential to mitigate these risks.

The energy consumption associated with the use of Accura 25 in 3D printing processes also contributes to its environmental impact. While additive manufacturing can be more energy-efficient for small-scale production, the cumulative energy use for large-scale manufacturing with Accura 25 needs to be carefully evaluated against traditional methods to ensure net environmental benefits.

To fully assess the environmental impact of Accura 25, life cycle assessment (LCA) studies are crucial. These studies should consider raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. By quantifying impacts such as carbon footprint, water usage, and toxicity potential, a comprehensive understanding of Accura 25's environmental profile can be developed.

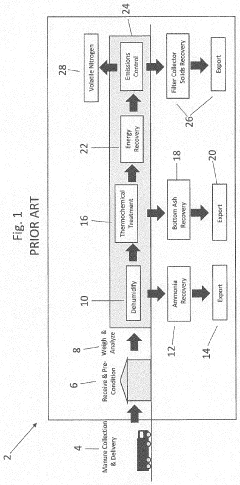

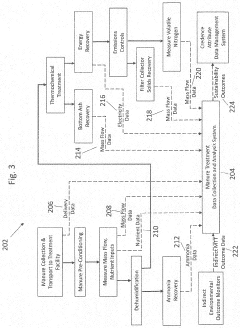

Integrating Accura 25 into sustainable practices requires a holistic approach that addresses its entire lifecycle. This includes optimizing production processes to reduce energy consumption and chemical use, implementing closed-loop systems to minimize waste and maximize material recovery, and developing effective recycling technologies specific to photopolymer resins. Furthermore, exploring bio-based alternatives or additives that enhance the biodegradability of Accura 25 could significantly improve its environmental performance.

Accura 25, a photopolymer resin used in stereolithography 3D printing, offers unique properties that contribute to its growing popularity in manufacturing. However, its environmental footprint requires careful consideration. The production process of Accura 25 involves energy-intensive steps and the use of potentially hazardous chemicals, which can contribute to greenhouse gas emissions and pose risks of environmental contamination if not properly managed.

During its use phase, Accura 25 demonstrates some positive environmental attributes. Its precision in 3D printing allows for the creation of complex geometries with minimal material waste, potentially reducing overall resource consumption compared to traditional manufacturing methods. Additionally, the ability to produce parts on-demand can lead to reduced inventory and associated storage-related environmental impacts.

Post-use, the environmental impact of Accura 25 becomes more challenging. The material is not biodegradable and can persist in the environment for extended periods if improperly disposed of. Recycling options for Accura 25 are currently limited, which can lead to increased landfill waste or incineration, both of which have negative environmental consequences.

Water systems are particularly vulnerable to potential contamination from Accura 25 residues. Uncured resin particles, if released into aquatic environments, can harm marine life and disrupt ecosystems. Therefore, proper handling and disposal protocols are essential to mitigate these risks.

The energy consumption associated with the use of Accura 25 in 3D printing processes also contributes to its environmental impact. While additive manufacturing can be more energy-efficient for small-scale production, the cumulative energy use for large-scale manufacturing with Accura 25 needs to be carefully evaluated against traditional methods to ensure net environmental benefits.

To fully assess the environmental impact of Accura 25, life cycle assessment (LCA) studies are crucial. These studies should consider raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. By quantifying impacts such as carbon footprint, water usage, and toxicity potential, a comprehensive understanding of Accura 25's environmental profile can be developed.

Integrating Accura 25 into sustainable practices requires a holistic approach that addresses its entire lifecycle. This includes optimizing production processes to reduce energy consumption and chemical use, implementing closed-loop systems to minimize waste and maximize material recovery, and developing effective recycling technologies specific to photopolymer resins. Furthermore, exploring bio-based alternatives or additives that enhance the biodegradability of Accura 25 could significantly improve its environmental performance.

Circular Economy Strategies for Accura 25

Integrating Accura 25 into sustainable practices requires a comprehensive approach that aligns with circular economy principles. This strategy focuses on maximizing resource efficiency, minimizing waste, and extending the lifecycle of materials used in 3D printing processes.

One key aspect of circular economy strategies for Accura 25 is the implementation of closed-loop recycling systems. These systems aim to recover and reprocess used Accura 25 resin, reducing the need for virgin materials and minimizing waste. By establishing efficient collection and recycling processes, companies can significantly reduce their environmental footprint while potentially lowering material costs.

Another important strategy is the optimization of 3D printing processes to minimize material waste. This includes refining design techniques to reduce support structures, implementing advanced slicing algorithms, and utilizing software that optimizes part orientation and nesting. These approaches not only conserve material but also reduce energy consumption during printing.

Extending the lifespan of Accura 25 printed parts is crucial for sustainable practices. This can be achieved through improved design for durability, modular construction techniques, and the development of repair and refurbishment services. By creating products that are easily maintainable and upgradable, companies can reduce the need for frequent replacements and minimize overall material consumption.

The adoption of bio-based or biodegradable alternatives to traditional Accura 25 resin is another promising avenue for sustainability. Research and development efforts are focusing on creating resins with similar performance characteristics but derived from renewable sources or designed to decompose naturally at the end of their lifecycle.

Implementing energy-efficient 3D printing technologies and processes is essential for reducing the carbon footprint associated with Accura 25 usage. This includes the use of low-power lasers, optimized curing processes, and the integration of renewable energy sources in manufacturing facilities.

Collaboration across the value chain is critical for successful circular economy strategies. This involves partnerships between material suppliers, 3D printer manufacturers, end-users, and recycling facilities to create a cohesive ecosystem that supports sustainable practices throughout the lifecycle of Accura 25 products.

Education and training programs play a vital role in promoting sustainable practices. By raising awareness about the importance of circular economy principles and providing practical guidance on sustainable design and manufacturing techniques, companies can foster a culture of sustainability among their workforce and customers.

One key aspect of circular economy strategies for Accura 25 is the implementation of closed-loop recycling systems. These systems aim to recover and reprocess used Accura 25 resin, reducing the need for virgin materials and minimizing waste. By establishing efficient collection and recycling processes, companies can significantly reduce their environmental footprint while potentially lowering material costs.

Another important strategy is the optimization of 3D printing processes to minimize material waste. This includes refining design techniques to reduce support structures, implementing advanced slicing algorithms, and utilizing software that optimizes part orientation and nesting. These approaches not only conserve material but also reduce energy consumption during printing.

Extending the lifespan of Accura 25 printed parts is crucial for sustainable practices. This can be achieved through improved design for durability, modular construction techniques, and the development of repair and refurbishment services. By creating products that are easily maintainable and upgradable, companies can reduce the need for frequent replacements and minimize overall material consumption.

The adoption of bio-based or biodegradable alternatives to traditional Accura 25 resin is another promising avenue for sustainability. Research and development efforts are focusing on creating resins with similar performance characteristics but derived from renewable sources or designed to decompose naturally at the end of their lifecycle.

Implementing energy-efficient 3D printing technologies and processes is essential for reducing the carbon footprint associated with Accura 25 usage. This includes the use of low-power lasers, optimized curing processes, and the integration of renewable energy sources in manufacturing facilities.

Collaboration across the value chain is critical for successful circular economy strategies. This involves partnerships between material suppliers, 3D printer manufacturers, end-users, and recycling facilities to create a cohesive ecosystem that supports sustainable practices throughout the lifecycle of Accura 25 products.

Education and training programs play a vital role in promoting sustainable practices. By raising awareness about the importance of circular economy principles and providing practical guidance on sustainable design and manufacturing techniques, companies can foster a culture of sustainability among their workforce and customers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!