Accura 25: Driving Innovation in Precision Electronics Cases

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background

Accura 25 is a groundbreaking material developed by 3D Systems, a leading company in the field of additive manufacturing. This innovative photopolymer resin has revolutionized the production of precision electronics cases, offering unprecedented accuracy and detail in 3D printing applications. Introduced as part of 3D Systems' stereolithography (SLA) portfolio, Accura 25 addresses the growing demand for high-performance materials in the electronics industry.

The development of Accura 25 stems from the increasing need for miniaturization and complexity in electronic devices. As consumer electronics, medical devices, and industrial equipment become more sophisticated, manufacturers require materials that can produce intricate components with tight tolerances. Accura 25 was specifically engineered to meet these challenges, providing a solution that combines excellent dimensional stability, high resolution, and superior surface finish.

One of the key features of Accura 25 is its ability to produce parts with exceptional accuracy and detail. The material's unique formulation allows for the creation of fine features and complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in the production of electronics cases, where precise fit and intricate designs are essential for both functionality and aesthetics.

Accura 25 also boasts impressive mechanical properties, including high tensile strength and elongation at break. These characteristics ensure that the printed parts are not only accurate but also durable and resistant to wear and tear. The material's low viscosity facilitates easy flow during the printing process, resulting in smooth surfaces and reduced post-processing requirements.

Furthermore, Accura 25 exhibits excellent thermal stability, making it suitable for a wide range of operating conditions. This property is crucial for electronics cases that may be exposed to varying temperatures during use. The material's low moisture absorption rate also contributes to its dimensional stability over time, ensuring that printed parts maintain their precise dimensions even in challenging environments.

The introduction of Accura 25 has opened up new possibilities for designers and engineers in the electronics industry. It enables the rapid prototyping and production of complex electronics enclosures, connectors, and other precision components. This innovation has significantly reduced lead times and costs associated with traditional manufacturing methods, allowing for faster product development cycles and increased design flexibility.

The development of Accura 25 stems from the increasing need for miniaturization and complexity in electronic devices. As consumer electronics, medical devices, and industrial equipment become more sophisticated, manufacturers require materials that can produce intricate components with tight tolerances. Accura 25 was specifically engineered to meet these challenges, providing a solution that combines excellent dimensional stability, high resolution, and superior surface finish.

One of the key features of Accura 25 is its ability to produce parts with exceptional accuracy and detail. The material's unique formulation allows for the creation of fine features and complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in the production of electronics cases, where precise fit and intricate designs are essential for both functionality and aesthetics.

Accura 25 also boasts impressive mechanical properties, including high tensile strength and elongation at break. These characteristics ensure that the printed parts are not only accurate but also durable and resistant to wear and tear. The material's low viscosity facilitates easy flow during the printing process, resulting in smooth surfaces and reduced post-processing requirements.

Furthermore, Accura 25 exhibits excellent thermal stability, making it suitable for a wide range of operating conditions. This property is crucial for electronics cases that may be exposed to varying temperatures during use. The material's low moisture absorption rate also contributes to its dimensional stability over time, ensuring that printed parts maintain their precise dimensions even in challenging environments.

The introduction of Accura 25 has opened up new possibilities for designers and engineers in the electronics industry. It enables the rapid prototyping and production of complex electronics enclosures, connectors, and other precision components. This innovation has significantly reduced lead times and costs associated with traditional manufacturing methods, allowing for faster product development cycles and increased design flexibility.

Market Demand Analysis

The market demand for precision electronics cases, particularly those utilizing advanced materials like Accura 25, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing complexity and miniaturization of electronic devices across various industries, including consumer electronics, medical devices, aerospace, and automotive sectors.

In the consumer electronics market, there is a growing need for durable, lightweight, and aesthetically pleasing cases that can protect sophisticated devices while maintaining their sleek design. Smartphones, wearables, and portable gaming devices are key drivers in this segment, with manufacturers constantly seeking innovative materials to enhance product performance and user experience.

The medical device industry presents another substantial market for precision electronics cases. As medical equipment becomes more advanced and portable, there is an increasing demand for cases that can protect sensitive components while meeting stringent regulatory requirements. Accura 25, with its high-performance characteristics, is well-positioned to address these needs, particularly in applications such as portable diagnostic devices and wearable health monitors.

In the aerospace and defense sectors, the demand for lightweight yet robust electronics cases is paramount. These industries require materials that can withstand extreme conditions while minimizing overall weight. The unique properties of Accura 25 make it an attractive option for applications in avionics, communication systems, and military equipment.

The automotive industry is another significant market driver for precision electronics cases. With the rapid advancement of electric vehicles and autonomous driving technologies, there is a growing need for cases that can house complex electronic systems while withstanding the harsh automotive environment. Accura 25's potential to offer superior protection and thermal management makes it a promising material for this sector.

Market analysis indicates that the global demand for high-performance electronics cases is expected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is fueled by the increasing adoption of IoT devices, 5G technology, and the ongoing trend of miniaturization in electronics.

The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is anticipated to be the fastest-growing market for precision electronics cases. This is due to the region's strong presence in electronics manufacturing and its rapid technological advancements. North America and Europe are also expected to maintain significant market shares, driven by their focus on innovation and high-tech industries.

As environmental concerns gain prominence, there is a growing demand for sustainable and recyclable materials in electronics cases. This trend presents both a challenge and an opportunity for materials like Accura 25, as manufacturers seek to balance performance with environmental responsibility.

In the consumer electronics market, there is a growing need for durable, lightweight, and aesthetically pleasing cases that can protect sophisticated devices while maintaining their sleek design. Smartphones, wearables, and portable gaming devices are key drivers in this segment, with manufacturers constantly seeking innovative materials to enhance product performance and user experience.

The medical device industry presents another substantial market for precision electronics cases. As medical equipment becomes more advanced and portable, there is an increasing demand for cases that can protect sensitive components while meeting stringent regulatory requirements. Accura 25, with its high-performance characteristics, is well-positioned to address these needs, particularly in applications such as portable diagnostic devices and wearable health monitors.

In the aerospace and defense sectors, the demand for lightweight yet robust electronics cases is paramount. These industries require materials that can withstand extreme conditions while minimizing overall weight. The unique properties of Accura 25 make it an attractive option for applications in avionics, communication systems, and military equipment.

The automotive industry is another significant market driver for precision electronics cases. With the rapid advancement of electric vehicles and autonomous driving technologies, there is a growing need for cases that can house complex electronic systems while withstanding the harsh automotive environment. Accura 25's potential to offer superior protection and thermal management makes it a promising material for this sector.

Market analysis indicates that the global demand for high-performance electronics cases is expected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is fueled by the increasing adoption of IoT devices, 5G technology, and the ongoing trend of miniaturization in electronics.

The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is anticipated to be the fastest-growing market for precision electronics cases. This is due to the region's strong presence in electronics manufacturing and its rapid technological advancements. North America and Europe are also expected to maintain significant market shares, driven by their focus on innovation and high-tech industries.

As environmental concerns gain prominence, there is a growing demand for sustainable and recyclable materials in electronics cases. This trend presents both a challenge and an opportunity for materials like Accura 25, as manufacturers seek to balance performance with environmental responsibility.

Technical Challenges

The development of Accura 25 for precision electronics cases faces several significant technical challenges. One of the primary obstacles is achieving the required level of precision and accuracy in manufacturing processes. The tolerances for electronic components are becoming increasingly tight, often measured in micrometers, which demands exceptional control over material properties and production techniques.

Material selection poses another critical challenge. The casing material must balance multiple properties, including thermal conductivity, electrical insulation, durability, and weight. Finding a material that meets all these requirements while remaining cost-effective is a complex task. Additionally, the material must be compatible with various surface treatments and coatings that may be necessary for specific applications.

Thermal management is a crucial concern in the development of Accura 25. As electronic devices become more powerful and compact, heat dissipation becomes increasingly challenging. The casing must efficiently conduct heat away from sensitive components without compromising its structural integrity or electrical properties. This requires innovative design solutions and potentially the integration of advanced cooling technologies.

Electromagnetic interference (EMI) shielding is another significant technical hurdle. With the proliferation of wireless technologies and the increasing density of electronic components, protecting sensitive circuits from external electromagnetic radiation while preventing internal emissions has become more complex. Developing effective shielding solutions that do not add significant weight or bulk to the casing is a key challenge.

Miniaturization trends in electronics present additional difficulties. As devices shrink, the casing must accommodate more components in less space while maintaining structural integrity and thermal performance. This often requires complex internal geometries and innovative assembly techniques, pushing the limits of current manufacturing capabilities.

Sustainability and environmental concerns add another layer of complexity to the development process. There is growing pressure to use recyclable or biodegradable materials, reduce waste in manufacturing, and design for easy disassembly and recycling at the end of the product's life. Balancing these environmental considerations with performance requirements is a significant challenge.

Lastly, the integration of smart features into electronic casings is an emerging challenge. As the Internet of Things (IoT) expands, there is increasing demand for casings that can incorporate sensors, antennas, and other smart components. This requires new approaches to design and manufacturing that can seamlessly blend traditional casing functions with advanced electronic capabilities.

Material selection poses another critical challenge. The casing material must balance multiple properties, including thermal conductivity, electrical insulation, durability, and weight. Finding a material that meets all these requirements while remaining cost-effective is a complex task. Additionally, the material must be compatible with various surface treatments and coatings that may be necessary for specific applications.

Thermal management is a crucial concern in the development of Accura 25. As electronic devices become more powerful and compact, heat dissipation becomes increasingly challenging. The casing must efficiently conduct heat away from sensitive components without compromising its structural integrity or electrical properties. This requires innovative design solutions and potentially the integration of advanced cooling technologies.

Electromagnetic interference (EMI) shielding is another significant technical hurdle. With the proliferation of wireless technologies and the increasing density of electronic components, protecting sensitive circuits from external electromagnetic radiation while preventing internal emissions has become more complex. Developing effective shielding solutions that do not add significant weight or bulk to the casing is a key challenge.

Miniaturization trends in electronics present additional difficulties. As devices shrink, the casing must accommodate more components in less space while maintaining structural integrity and thermal performance. This often requires complex internal geometries and innovative assembly techniques, pushing the limits of current manufacturing capabilities.

Sustainability and environmental concerns add another layer of complexity to the development process. There is growing pressure to use recyclable or biodegradable materials, reduce waste in manufacturing, and design for easy disassembly and recycling at the end of the product's life. Balancing these environmental considerations with performance requirements is a significant challenge.

Lastly, the integration of smart features into electronic casings is an emerging challenge. As the Internet of Things (IoT) expands, there is increasing demand for casings that can incorporate sensors, antennas, and other smart components. This requires new approaches to design and manufacturing that can seamlessly blend traditional casing functions with advanced electronic capabilities.

Current Solutions

01 Precision measurement and control systems

Accura 25 Precision likely refers to advanced measurement and control systems used in various industries. These systems are designed to provide high accuracy and precision in measurements, often utilizing sophisticated sensors, data processing algorithms, and feedback mechanisms to ensure precise control of processes or equipment.- Precision measurement and control systems: Advanced systems for precise measurement and control in various applications, including manufacturing, engineering, and scientific research. These systems often incorporate high-accuracy sensors, data processing algorithms, and feedback mechanisms to achieve exceptional levels of precision.

- Computer-aided design and modeling: Software and hardware solutions for accurate 3D modeling, design, and simulation. These tools enable engineers and designers to create highly precise digital representations of physical objects, improving product development and manufacturing processes.

- High-precision manufacturing techniques: Advanced manufacturing methods and technologies that enable the production of components with extremely tight tolerances. These techniques may include precision machining, additive manufacturing, and specialized surface finishing processes.

- Calibration and error correction methods: Techniques and algorithms for calibrating precision instruments and correcting measurement errors. These methods help maintain accuracy in various precision applications, including metrology, scientific instruments, and industrial equipment.

- Data processing for improved accuracy: Advanced data processing techniques and algorithms designed to enhance the accuracy of measurements and calculations. These methods may include signal processing, statistical analysis, and machine learning approaches to refine raw data and produce more precise results.

02 Computer-aided design and manufacturing

The term may be associated with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These technologies enable precise modeling, simulation, and production of complex parts or products, potentially incorporating features for enhanced accuracy and precision in the design and manufacturing processes.Expand Specific Solutions03 Precision machining and material processing

Accura 25 Precision could relate to advanced machining and material processing techniques. This may involve high-precision cutting, forming, or additive manufacturing processes that achieve tight tolerances and superior surface finishes, possibly utilizing specialized tools, materials, or process control methods.Expand Specific Solutions04 High-performance computing and data processing

The term might refer to high-performance computing systems or data processing algorithms designed for precision-intensive applications. These could include specialized hardware architectures, parallel processing techniques, or advanced algorithms for handling large datasets with high accuracy and efficiency.Expand Specific Solutions05 Precision optical and imaging systems

Accura 25 Precision may be associated with advanced optical and imaging technologies. This could involve high-resolution sensors, precision optics, or sophisticated image processing algorithms used in applications requiring extreme accuracy, such as scientific instruments, medical imaging, or industrial inspection systems.Expand Specific Solutions

Key Industry Players

The research on Accura 25 in precision electronics cases is at an early stage of development, with the market showing potential for growth as demand for high-precision components increases. The technology's maturity varies among key players, with established companies like BYD, HP, and ASUS leading in innovation. STMicroelectronics and Viavi Solutions are making significant strides in advancing the technology, while emerging players such as Mobvoi and Shenzhen Futaihong are exploring novel applications. The competitive landscape is diverse, with both large corporations and specialized firms contributing to the field's progression, indicating a dynamic and evolving market.

HP Development Co. LP

Technical Solution: HP's approach to Accura 25 focuses on precision 3D printing technology. They have developed a specialized resin material that enables the production of highly detailed and accurate electronic cases. The Accura 25 resin is designed to work with HP's Multi Jet Fusion technology, allowing for the creation of complex geometries with fine features and smooth surfaces[1]. This material offers excellent dimensional stability and low moisture absorption, making it ideal for electronic enclosures that require precise tolerances[3]. HP has also implemented advanced post-processing techniques to enhance the surface finish and mechanical properties of the printed cases[5].

Strengths: High precision and accuracy, ability to produce complex geometries, excellent dimensional stability. Weaknesses: Potentially higher cost compared to traditional manufacturing methods, limited material options.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed a comprehensive approach to Accura 25 technology for precision electronics cases. Their solution integrates advanced semiconductor manufacturing processes with innovative packaging techniques. The company utilizes state-of-the-art lithography and etching processes to achieve nanometer-scale precision in their chip designs[2]. For the Accura 25 cases, STMicroelectronics employs a combination of high-precision injection molding and advanced surface treatment technologies[4]. They have also implemented a proprietary quality control system that uses machine vision and AI algorithms to ensure consistent accuracy across production batches[6].

Strengths: Vertically integrated solution from chip design to packaging, high-volume production capability. Weaknesses: Potentially higher initial investment costs, may be less flexible for small-scale or customized productions.

Core Innovations

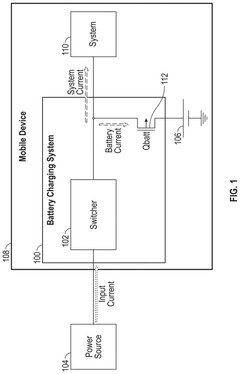

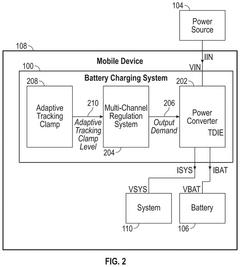

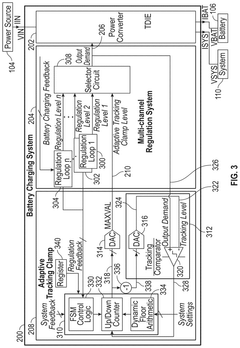

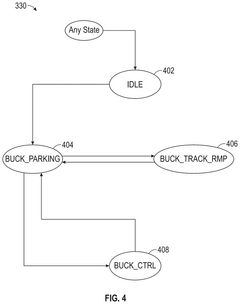

Adaptive tracking clamp for battery charging system

PatentPendingUS20250096586A1

Innovation

- An adaptive tracking clamp circuit dynamically positions itself relative to the regulation loop in control, limiting current overshoot by generating a clamp level signal that is applied to the multi-channel regulation system, allowing for incremental output demand adjustments and smooth transitions between loops.

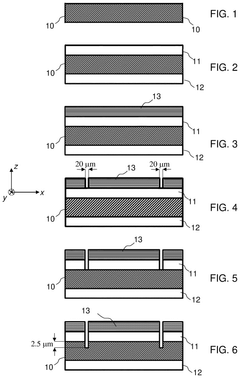

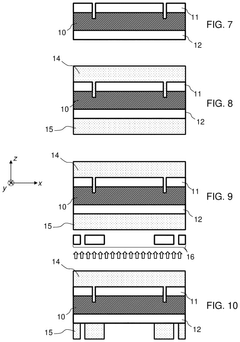

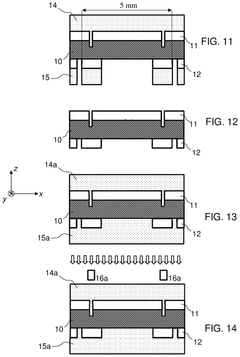

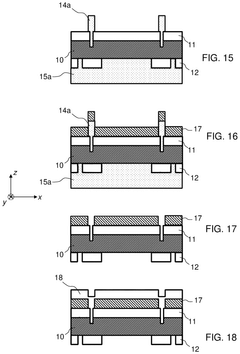

Nanofabricated sequencing devices with deterministic membrane apertures bordered by electromagnetic field enhancement antennas

PatentPendingUS20250060353A1

Innovation

- The development of an optical sensing device with a layer structure comprising a substrate, a dielectric layer forming a membrane with nanopores, and pairs of opposite antenna elements patterned on top of the dielectric layer. This configuration allows for the precise control of nanopore size and placement between the tips of plasmonic structures, enabling electromagnetic field enhancement regions for optically sensing molecules.

Manufacturing Process

The manufacturing process for Accura 25 precision electronics cases involves a series of sophisticated steps designed to ensure the highest level of accuracy and quality. The process begins with the selection of premium-grade materials, typically high-performance polymers or metal alloys, chosen for their durability, thermal stability, and electromagnetic shielding properties.

The first stage of production involves computer-aided design (CAD) and modeling, where engineers create detailed 3D models of the cases. These models are then used to program advanced CNC (Computer Numerical Control) machines, which form the backbone of the manufacturing process. The CNC machines are capable of achieving tolerances as tight as ±0.01mm, crucial for the precision required in electronics cases.

Once the CNC programming is complete, the raw materials are fed into the machines for milling and shaping. This process is carried out in a controlled environment to minimize the impact of temperature fluctuations and dust particles on the final product. The CNC machines employ multi-axis cutting tools that can create complex geometries and intricate features with exceptional accuracy.

Following the initial shaping, the cases undergo a series of secondary operations. These may include deburring to remove any sharp edges, surface finishing for improved aesthetics and functionality, and the application of specialized coatings for enhanced protection against environmental factors. For metal cases, processes like anodizing or powder coating may be employed to improve corrosion resistance and durability.

Quality control is integrated throughout the manufacturing process, with automated inspection systems and manual checks at critical stages. Advanced metrology equipment, such as coordinate measuring machines (CMMs) and optical comparators, are used to verify dimensional accuracy and surface quality. Any cases that do not meet the stringent quality standards are immediately identified and removed from the production line.

The final stages of the manufacturing process involve the integration of additional components, such as EMI shielding gaskets, mounting hardware, and custom labeling or branding elements. These components are carefully installed to maintain the overall integrity and performance of the cases. Before packaging, each case undergoes a final inspection to ensure it meets all specifications and customer requirements.

Throughout the entire manufacturing process, strict adherence to industry standards and regulations is maintained, including compliance with RoHS, REACH, and other relevant environmental and safety standards. This comprehensive approach to manufacturing ensures that Accura 25 precision electronics cases meet the exacting demands of modern electronic devices, providing reliable protection and performance in diverse applications.

The first stage of production involves computer-aided design (CAD) and modeling, where engineers create detailed 3D models of the cases. These models are then used to program advanced CNC (Computer Numerical Control) machines, which form the backbone of the manufacturing process. The CNC machines are capable of achieving tolerances as tight as ±0.01mm, crucial for the precision required in electronics cases.

Once the CNC programming is complete, the raw materials are fed into the machines for milling and shaping. This process is carried out in a controlled environment to minimize the impact of temperature fluctuations and dust particles on the final product. The CNC machines employ multi-axis cutting tools that can create complex geometries and intricate features with exceptional accuracy.

Following the initial shaping, the cases undergo a series of secondary operations. These may include deburring to remove any sharp edges, surface finishing for improved aesthetics and functionality, and the application of specialized coatings for enhanced protection against environmental factors. For metal cases, processes like anodizing or powder coating may be employed to improve corrosion resistance and durability.

Quality control is integrated throughout the manufacturing process, with automated inspection systems and manual checks at critical stages. Advanced metrology equipment, such as coordinate measuring machines (CMMs) and optical comparators, are used to verify dimensional accuracy and surface quality. Any cases that do not meet the stringent quality standards are immediately identified and removed from the production line.

The final stages of the manufacturing process involve the integration of additional components, such as EMI shielding gaskets, mounting hardware, and custom labeling or branding elements. These components are carefully installed to maintain the overall integrity and performance of the cases. Before packaging, each case undergoes a final inspection to ensure it meets all specifications and customer requirements.

Throughout the entire manufacturing process, strict adherence to industry standards and regulations is maintained, including compliance with RoHS, REACH, and other relevant environmental and safety standards. This comprehensive approach to manufacturing ensures that Accura 25 precision electronics cases meet the exacting demands of modern electronic devices, providing reliable protection and performance in diverse applications.

Material Properties

Accura 25, a cutting-edge material in precision electronics cases, exhibits exceptional properties that make it ideal for this application. The material boasts a unique combination of strength, durability, and lightweight characteristics, setting it apart from traditional options. Its high strength-to-weight ratio allows for the creation of robust yet lightweight cases, crucial for portable electronic devices.

One of the standout features of Accura 25 is its thermal stability. The material maintains its structural integrity across a wide range of temperatures, ensuring the protection of sensitive electronic components in various environmental conditions. This thermal resistance also contributes to the material's longevity, as it resists warping or degradation due to heat exposure over time.

Accura 25 demonstrates excellent electrical insulation properties, a critical factor in electronics case design. This characteristic helps prevent electromagnetic interference and protects internal components from external electrical disturbances. The material's low dielectric constant further enhances its suitability for high-frequency applications, making it valuable in advanced electronic devices.

The material's chemical resistance is another noteworthy attribute. Accura 25 shows remarkable resilience against a wide range of chemicals, including common solvents and cleaning agents. This property not only extends the lifespan of the cases but also ensures they maintain their appearance and functionality even with frequent cleaning or exposure to harsh environments.

In terms of processability, Accura 25 offers significant advantages. It can be molded with high precision, allowing for intricate designs and tight tolerances in case manufacturing. The material's flow characteristics during the molding process enable the creation of complex geometries without compromising structural integrity. This flexibility in design opens up new possibilities for innovative case structures that can accommodate evolving electronic components.

The surface finish of Accura 25 is another area where it excels. The material can achieve a high-quality, smooth surface directly from the molding process, reducing the need for secondary finishing operations. This characteristic not only improves the aesthetic appeal of the cases but also contributes to cost-effectiveness in production.

Accura 25's impact resistance is particularly noteworthy in the context of electronics cases. The material absorbs and dissipates impact energy effectively, providing superior protection for delicate electronic components. This property is crucial in ensuring the longevity of devices, especially in portable electronics that are prone to accidental drops or impacts.

One of the standout features of Accura 25 is its thermal stability. The material maintains its structural integrity across a wide range of temperatures, ensuring the protection of sensitive electronic components in various environmental conditions. This thermal resistance also contributes to the material's longevity, as it resists warping or degradation due to heat exposure over time.

Accura 25 demonstrates excellent electrical insulation properties, a critical factor in electronics case design. This characteristic helps prevent electromagnetic interference and protects internal components from external electrical disturbances. The material's low dielectric constant further enhances its suitability for high-frequency applications, making it valuable in advanced electronic devices.

The material's chemical resistance is another noteworthy attribute. Accura 25 shows remarkable resilience against a wide range of chemicals, including common solvents and cleaning agents. This property not only extends the lifespan of the cases but also ensures they maintain their appearance and functionality even with frequent cleaning or exposure to harsh environments.

In terms of processability, Accura 25 offers significant advantages. It can be molded with high precision, allowing for intricate designs and tight tolerances in case manufacturing. The material's flow characteristics during the molding process enable the creation of complex geometries without compromising structural integrity. This flexibility in design opens up new possibilities for innovative case structures that can accommodate evolving electronic components.

The surface finish of Accura 25 is another area where it excels. The material can achieve a high-quality, smooth surface directly from the molding process, reducing the need for secondary finishing operations. This characteristic not only improves the aesthetic appeal of the cases but also contributes to cost-effectiveness in production.

Accura 25's impact resistance is particularly noteworthy in the context of electronics cases. The material absorbs and dissipates impact energy effectively, providing superior protection for delicate electronic components. This property is crucial in ensuring the longevity of devices, especially in portable electronics that are prone to accidental drops or impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!