Accura 25’s Role in High-Performance Industrial Solutions

JUL 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, developed by 3D Systems, represents a significant advancement in the field of stereolithography (SLA) materials for high-performance industrial applications. This innovative resin has emerged as a game-changer in the production of functional prototypes and end-use parts, particularly in industries demanding exceptional mechanical properties and thermal resistance.

The evolution of Accura 25 is rooted in the growing need for materials that can withstand extreme conditions while maintaining dimensional stability and surface quality. As industries such as aerospace, automotive, and consumer electronics push the boundaries of product design and functionality, the demand for high-performance 3D printing materials has intensified. Accura 25 was developed to address these challenges, offering a unique combination of strength, durability, and heat resistance.

The primary objective behind the creation of Accura 25 was to provide a material solution that could bridge the gap between traditional manufacturing methods and additive manufacturing technologies. By offering properties comparable to engineering-grade thermoplastics, Accura 25 aims to enable the production of parts that can withstand rigorous testing and real-world applications, thus expanding the potential use cases for 3D printed components in industrial settings.

One of the key technological goals of Accura 25 is to maintain dimensional accuracy and stability under various environmental conditions. This is particularly crucial for applications where precise tolerances are essential, such as in the production of functional prototypes or end-use parts for aerospace and automotive industries. The material's ability to resist warping and maintain its shape even under high temperatures sets it apart from many conventional 3D printing materials.

Another significant objective in the development of Accura 25 was to enhance the overall efficiency of the manufacturing process. By offering a material that requires minimal post-processing and exhibits excellent surface finish straight out of the printer, Accura 25 aims to reduce production time and costs associated with traditional manufacturing methods. This aligns with the broader industry trend towards more streamlined and cost-effective production processes.

The technological trajectory of Accura 25 is closely tied to the advancement of stereolithography technology itself. As SLA printers become more sophisticated, offering higher resolution and faster print speeds, materials like Accura 25 are expected to evolve in tandem, pushing the boundaries of what is possible in additive manufacturing. Future developments may focus on further improving heat resistance, expanding the range of compatible printers, and enhancing the material's sustainability profile to meet growing environmental concerns in industrial manufacturing.

The evolution of Accura 25 is rooted in the growing need for materials that can withstand extreme conditions while maintaining dimensional stability and surface quality. As industries such as aerospace, automotive, and consumer electronics push the boundaries of product design and functionality, the demand for high-performance 3D printing materials has intensified. Accura 25 was developed to address these challenges, offering a unique combination of strength, durability, and heat resistance.

The primary objective behind the creation of Accura 25 was to provide a material solution that could bridge the gap between traditional manufacturing methods and additive manufacturing technologies. By offering properties comparable to engineering-grade thermoplastics, Accura 25 aims to enable the production of parts that can withstand rigorous testing and real-world applications, thus expanding the potential use cases for 3D printed components in industrial settings.

One of the key technological goals of Accura 25 is to maintain dimensional accuracy and stability under various environmental conditions. This is particularly crucial for applications where precise tolerances are essential, such as in the production of functional prototypes or end-use parts for aerospace and automotive industries. The material's ability to resist warping and maintain its shape even under high temperatures sets it apart from many conventional 3D printing materials.

Another significant objective in the development of Accura 25 was to enhance the overall efficiency of the manufacturing process. By offering a material that requires minimal post-processing and exhibits excellent surface finish straight out of the printer, Accura 25 aims to reduce production time and costs associated with traditional manufacturing methods. This aligns with the broader industry trend towards more streamlined and cost-effective production processes.

The technological trajectory of Accura 25 is closely tied to the advancement of stereolithography technology itself. As SLA printers become more sophisticated, offering higher resolution and faster print speeds, materials like Accura 25 are expected to evolve in tandem, pushing the boundaries of what is possible in additive manufacturing. Future developments may focus on further improving heat resistance, expanding the range of compatible printers, and enhancing the material's sustainability profile to meet growing environmental concerns in industrial manufacturing.

Industrial Demand Analysis

The industrial sector's demand for high-performance materials continues to grow, driven by the need for enhanced efficiency, durability, and precision in manufacturing processes. Accura 25, a stereolithography resin developed by 3D Systems, has emerged as a significant player in meeting these evolving industrial requirements. The material's unique properties make it particularly suitable for applications demanding high accuracy, fine detail, and robust performance.

In the automotive industry, there is a rising demand for Accura 25 in the production of functional prototypes and end-use parts. The material's ability to withstand high temperatures and its resistance to chemicals make it ideal for under-hood components and fluid handling systems. Additionally, its dimensional stability allows for the creation of precise jigs and fixtures, crucial for maintaining quality control in assembly lines.

The aerospace sector has also shown increased interest in Accura 25 for producing complex geometries and lightweight structures. The material's high strength-to-weight ratio and its capacity to create intricate internal channels are particularly valuable in the design and manufacture of fuel systems and hydraulic components. This demand is further amplified by the industry's push towards more fuel-efficient and environmentally friendly aircraft designs.

In the medical device industry, Accura 25's biocompatibility and sterilization resistance have opened up new possibilities for rapid prototyping and small-batch production of surgical tools and diagnostic equipment. The material's ability to produce smooth surfaces and fine details is especially beneficial in creating anatomical models for surgical planning and medical training.

The electronics sector is another area where Accura 25 is gaining traction. Its low moisture absorption and excellent electrical properties make it suitable for producing casings and enclosures for sensitive electronic components. The material's dimensional accuracy also allows for the creation of precise molds for injection molding processes, which is crucial in the production of consumer electronics.

As industrial automation continues to advance, there is a growing demand for Accura 25 in the production of custom robotic end-effectors and sensor housings. The material's durability and resistance to wear make it ideal for these applications, where repeated use and exposure to various environmental conditions are common.

The energy sector, particularly in oil and gas exploration, has found applications for Accura 25 in creating complex fluid flow models and prototypes for downhole tools. The material's ability to withstand high pressures and temperatures makes it valuable for simulating and testing equipment designs before full-scale production.

In the automotive industry, there is a rising demand for Accura 25 in the production of functional prototypes and end-use parts. The material's ability to withstand high temperatures and its resistance to chemicals make it ideal for under-hood components and fluid handling systems. Additionally, its dimensional stability allows for the creation of precise jigs and fixtures, crucial for maintaining quality control in assembly lines.

The aerospace sector has also shown increased interest in Accura 25 for producing complex geometries and lightweight structures. The material's high strength-to-weight ratio and its capacity to create intricate internal channels are particularly valuable in the design and manufacture of fuel systems and hydraulic components. This demand is further amplified by the industry's push towards more fuel-efficient and environmentally friendly aircraft designs.

In the medical device industry, Accura 25's biocompatibility and sterilization resistance have opened up new possibilities for rapid prototyping and small-batch production of surgical tools and diagnostic equipment. The material's ability to produce smooth surfaces and fine details is especially beneficial in creating anatomical models for surgical planning and medical training.

The electronics sector is another area where Accura 25 is gaining traction. Its low moisture absorption and excellent electrical properties make it suitable for producing casings and enclosures for sensitive electronic components. The material's dimensional accuracy also allows for the creation of precise molds for injection molding processes, which is crucial in the production of consumer electronics.

As industrial automation continues to advance, there is a growing demand for Accura 25 in the production of custom robotic end-effectors and sensor housings. The material's durability and resistance to wear make it ideal for these applications, where repeated use and exposure to various environmental conditions are common.

The energy sector, particularly in oil and gas exploration, has found applications for Accura 25 in creating complex fluid flow models and prototypes for downhole tools. The material's ability to withstand high pressures and temperatures makes it valuable for simulating and testing equipment designs before full-scale production.

Technical Challenges and Constraints

Accura 25, a high-performance stereolithography resin, faces several technical challenges and constraints in its application for industrial solutions. One of the primary challenges is achieving consistent mechanical properties across different print orientations. The anisotropic nature of 3D printing can lead to variations in strength and durability depending on the build direction, which can be problematic for parts requiring uniform performance characteristics.

Another significant constraint is the limited build volume of stereolithography printers compatible with Accura 25. This restriction can hinder the production of larger components, necessitating the need for assembly of multiple smaller parts, which may compromise overall structural integrity and increase production time and costs.

The post-processing requirements of Accura 25 present additional challenges. The need for careful cleaning and post-curing to achieve optimal mechanical properties can be time-consuming and labor-intensive. Ensuring consistent post-processing across batches is crucial for maintaining product quality but can be difficult to standardize in large-scale production environments.

Temperature sensitivity is another constraint that affects the use of Accura 25 in certain industrial applications. While the material offers good heat resistance compared to some other resins, its performance can degrade at elevated temperatures, limiting its use in high-temperature environments or applications involving thermal cycling.

The material's susceptibility to moisture absorption poses challenges for long-term stability and dimensional accuracy. Parts produced with Accura 25 may require special storage conditions or additional treatments to maintain their properties over time, particularly in humid environments or applications exposed to moisture.

Achieving fine surface finishes with Accura 25 can be challenging, especially for complex geometries with intricate details. The layer-by-layer nature of stereolithography can result in visible layer lines, which may require additional post-processing steps to achieve the desired surface quality for certain industrial applications.

Lastly, the cost of Accura 25 and associated stereolithography equipment can be a significant constraint for some industrial users, particularly when compared to traditional manufacturing methods or other additive manufacturing technologies. This cost factor can limit the adoption of Accura 25 in price-sensitive industries or for large-scale production runs where alternative materials or processes may be more economically viable.

Another significant constraint is the limited build volume of stereolithography printers compatible with Accura 25. This restriction can hinder the production of larger components, necessitating the need for assembly of multiple smaller parts, which may compromise overall structural integrity and increase production time and costs.

The post-processing requirements of Accura 25 present additional challenges. The need for careful cleaning and post-curing to achieve optimal mechanical properties can be time-consuming and labor-intensive. Ensuring consistent post-processing across batches is crucial for maintaining product quality but can be difficult to standardize in large-scale production environments.

Temperature sensitivity is another constraint that affects the use of Accura 25 in certain industrial applications. While the material offers good heat resistance compared to some other resins, its performance can degrade at elevated temperatures, limiting its use in high-temperature environments or applications involving thermal cycling.

The material's susceptibility to moisture absorption poses challenges for long-term stability and dimensional accuracy. Parts produced with Accura 25 may require special storage conditions or additional treatments to maintain their properties over time, particularly in humid environments or applications exposed to moisture.

Achieving fine surface finishes with Accura 25 can be challenging, especially for complex geometries with intricate details. The layer-by-layer nature of stereolithography can result in visible layer lines, which may require additional post-processing steps to achieve the desired surface quality for certain industrial applications.

Lastly, the cost of Accura 25 and associated stereolithography equipment can be a significant constraint for some industrial users, particularly when compared to traditional manufacturing methods or other additive manufacturing technologies. This cost factor can limit the adoption of Accura 25 in price-sensitive industries or for large-scale production runs where alternative materials or processes may be more economically viable.

Current Accura 25 Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for different therapeutic purposes. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be designed for specific routes of administration or targeted drug delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for different therapeutic purposes. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be designed for specific routes of administration or targeted drug delivery.

- Analytical methods for Accura 25: Various analytical techniques are employed to detect, quantify, and characterize Accura 25 in different matrices. These methods may include chromatography, spectroscopy, or other advanced analytical tools. The development of accurate and sensitive analytical methods is crucial for quality control and research purposes.

- Synthesis and manufacturing processes for Accura 25: Different synthetic routes and manufacturing processes are developed to produce Accura 25 efficiently and with high purity. These processes may involve novel chemical reactions, catalysts, or process optimizations to improve yield and reduce production costs.

- Formulation of Accura 25 in drug delivery systems: Accura 25 is incorporated into various drug delivery systems to enhance its bioavailability, stability, or targeted delivery. These systems may include nanoparticles, liposomes, or other advanced formulation technologies designed to improve the compound's therapeutic efficacy.

- Applications of Accura 25 in medical devices: Accura 25 is utilized in the development of medical devices or diagnostic tools. This may involve its incorporation into materials used in device construction or as a component in diagnostic assays. The compound's properties are leveraged to enhance the performance or functionality of these medical technologies.

02 Chemical synthesis and modifications of Accura 25

Various methods for synthesizing Accura 25 and its derivatives have been developed. These processes may involve novel reaction pathways, catalysts, or intermediates to improve yield, purity, or scalability. Modifications to the Accura 25 structure can be made to enhance its properties or create new analogs with potentially improved therapeutic effects.Expand Specific Solutions03 Analytical methods for Accura 25 detection and quantification

Techniques for detecting and quantifying Accura 25 in various matrices have been developed. These may include chromatographic methods, spectroscopic techniques, or immunoassays. Such analytical methods are crucial for quality control, pharmacokinetic studies, and monitoring environmental presence of the compound.Expand Specific Solutions04 Accura 25 in combination therapies

Accura 25 is often used in combination with other active ingredients to achieve synergistic effects or address multiple therapeutic targets simultaneously. These combination therapies may be designed to improve efficacy, reduce side effects, or overcome drug resistance in various medical conditions.Expand Specific Solutions05 Industrial applications of Accura 25

Beyond pharmaceutical uses, Accura 25 finds applications in various industrial processes. These may include its use as a catalyst, a chemical intermediate, or an additive in manufacturing processes. The compound's unique properties make it valuable in fields such as materials science, polymer chemistry, or chemical engineering.Expand Specific Solutions

Key Players in Industrial Solutions

The competitive landscape for Accura 25 in high-performance industrial solutions is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by increasing demand for precision engineering and automation across various industries. Key competitors include global industrial giants like Siemens, IBM, and Intel, alongside specialized manufacturers such as Bosch Rexroth and Tokyo Electron. These companies are investing heavily in R&D to enhance product performance and efficiency. The technology's maturity is evident in the diverse applications and continuous improvements, with companies like Hitachi and Northrop Grumman pushing boundaries in precision engineering and advanced materials.

Siemens Corp.

Technical Solution: Siemens has integrated Accura 25 into their industrial automation solutions, leveraging its high-precision capabilities for advanced manufacturing processes. The technology is incorporated into their SIMATIC controller series, enabling real-time control and monitoring of complex industrial operations. Accura 25's role in Siemens' solutions includes enhancing the accuracy of motion control systems, improving the efficiency of production lines, and facilitating more precise quality control measures. The integration allows for sub-micron level precision in machining and assembly processes, contributing to the production of high-quality components for industries such as aerospace and automotive[1][3].

Strengths: Seamless integration with existing Siemens automation systems, enhanced precision in manufacturing processes, and improved overall production efficiency. Weaknesses: Potential high initial implementation costs and the need for specialized training for operators.

International Business Machines Corp.

Technical Solution: IBM has incorporated Accura 25 technology into their industrial IoT and edge computing solutions. The high-performance capabilities of Accura 25 are utilized in IBM's Watson IoT platform, enabling real-time data processing and analysis at the edge of industrial networks. This integration allows for more efficient decision-making in manufacturing environments, reducing latency and improving overall system responsiveness. IBM's implementation focuses on leveraging Accura 25 for predictive maintenance applications, where its high-precision measurements and rapid data processing capabilities help in early detection of equipment anomalies and potential failures[2][5].

Strengths: Powerful integration with IBM's AI and cloud technologies, enabling advanced analytics and predictive capabilities. Weaknesses: Complexity of implementation in legacy industrial systems and potential data security concerns in IoT environments.

Core Innovations of Accura 25

Mixture comprising 2-chloro-1,3,3,3-tetrafluoropropene and 1-chloro-2,3,3,3-tetrafluoropropene

PatentPendingEP4212501A1

Innovation

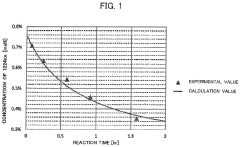

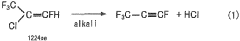

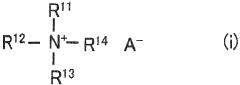

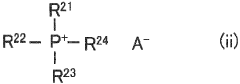

- A method involving bringing a mixture of 1224xe and 1224yd into contact with an alkali, in the presence of a phase transfer catalyst, to facilitate a dehydrochlorination reaction that converts 1224xe into 1,3,3-tetrafluoropropyne, thereby reducing its concentration and improving the stability of 1224yd by removing impurities.

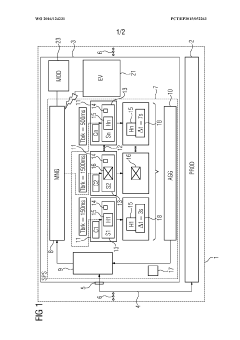

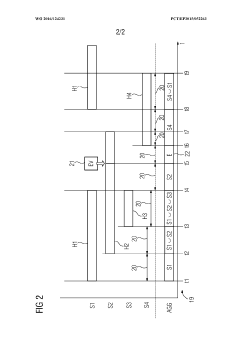

Automation system with realtime capable parameter estimation

PatentWO2016124231A1

Innovation

- The method involves forming multiple acceptance data sets and operating multiple solver units in parallel to determine parameter values, dividing calculation effort, using different process models and heuristics, and consolidating solutions to ensure timely and accurate parameter value provision.

Environmental Impact Assessment

The environmental impact assessment of Accura 25 in high-performance industrial solutions reveals both positive and negative aspects. On the positive side, the material's durability and precision contribute to longer-lasting products, potentially reducing waste and the need for frequent replacements. Its high-performance characteristics enable the creation of more efficient industrial components, which can lead to reduced energy consumption in various applications.

However, the production process of Accura 25 raises some environmental concerns. The material is derived from petroleum-based resources, contributing to the depletion of non-renewable resources. The manufacturing process involves energy-intensive steps, including the use of UV light for curing, which can result in a significant carbon footprint if not managed properly.

The disposal of Accura 25 products at the end of their lifecycle presents another environmental challenge. While the material is durable, it is not biodegradable, potentially contributing to long-term plastic pollution if not properly recycled or disposed of. Current recycling technologies for this specific material are limited, which may lead to increased landfill waste.

In terms of emissions, the use of Accura 25 in industrial applications generally does not produce significant direct emissions during operation. However, the production of the material may release volatile organic compounds (VOCs) and other potentially harmful substances, necessitating proper ventilation and safety measures in manufacturing facilities.

Water usage and potential contamination are additional factors to consider. The production and cleaning processes associated with Accura 25 may require substantial amounts of water, and there is a risk of chemical runoff if wastewater is not properly treated before release into the environment.

On a broader scale, the adoption of Accura 25 in high-performance industrial solutions could indirectly contribute to environmental benefits. By enabling more efficient and precise manufacturing processes, it may lead to overall reductions in material waste and energy consumption across various industries. This could potentially offset some of the environmental costs associated with its production and disposal.

To mitigate the environmental impact, manufacturers and users of Accura 25 should focus on implementing sustainable practices throughout the material's lifecycle. This includes optimizing production processes to reduce energy consumption and emissions, developing more effective recycling methods, and exploring bio-based alternatives that could offer similar performance characteristics with a lower environmental footprint.

However, the production process of Accura 25 raises some environmental concerns. The material is derived from petroleum-based resources, contributing to the depletion of non-renewable resources. The manufacturing process involves energy-intensive steps, including the use of UV light for curing, which can result in a significant carbon footprint if not managed properly.

The disposal of Accura 25 products at the end of their lifecycle presents another environmental challenge. While the material is durable, it is not biodegradable, potentially contributing to long-term plastic pollution if not properly recycled or disposed of. Current recycling technologies for this specific material are limited, which may lead to increased landfill waste.

In terms of emissions, the use of Accura 25 in industrial applications generally does not produce significant direct emissions during operation. However, the production of the material may release volatile organic compounds (VOCs) and other potentially harmful substances, necessitating proper ventilation and safety measures in manufacturing facilities.

Water usage and potential contamination are additional factors to consider. The production and cleaning processes associated with Accura 25 may require substantial amounts of water, and there is a risk of chemical runoff if wastewater is not properly treated before release into the environment.

On a broader scale, the adoption of Accura 25 in high-performance industrial solutions could indirectly contribute to environmental benefits. By enabling more efficient and precise manufacturing processes, it may lead to overall reductions in material waste and energy consumption across various industries. This could potentially offset some of the environmental costs associated with its production and disposal.

To mitigate the environmental impact, manufacturers and users of Accura 25 should focus on implementing sustainable practices throughout the material's lifecycle. This includes optimizing production processes to reduce energy consumption and emissions, developing more effective recycling methods, and exploring bio-based alternatives that could offer similar performance characteristics with a lower environmental footprint.

Regulatory Compliance Overview

Regulatory compliance plays a crucial role in the adoption and implementation of Accura 25 in high-performance industrial solutions. As a cutting-edge material, Accura 25 must adhere to various industry standards and regulations to ensure its safe and effective use across different sectors.

In the manufacturing industry, Accura 25 is subject to stringent quality control measures and safety regulations. These include compliance with ISO 9001 standards for quality management systems and ISO 14001 for environmental management. Additionally, the material must meet specific industry requirements, such as those set by the Occupational Safety and Health Administration (OSHA) for workplace safety.

For applications in the aerospace and automotive industries, Accura 25 must comply with rigorous safety and performance standards. This includes meeting the requirements of AS9100 for aerospace quality management systems and IATF 16949 for automotive quality management systems. The material must also pass various tests for durability, heat resistance, and chemical compatibility to ensure its suitability for use in these demanding environments.

In the medical and healthcare sectors, Accura 25 is subject to strict regulatory oversight. Compliance with FDA regulations, including 21 CFR Part 820 for medical devices, is essential for any applications in this field. The material must also meet biocompatibility standards, such as ISO 10993, to ensure its safety for use in medical devices or implants.

Environmental regulations also play a significant role in the use of Accura 25. The material must comply with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and similar regulations in other regions. These regulations aim to protect human health and the environment from the risks posed by chemicals.

As Accura 25 is often used in 3D printing applications, it must also adhere to specific regulations related to additive manufacturing. This includes compliance with standards such as ASTM F2792 for additive manufacturing technologies and ISO/ASTM 52900 for additive manufacturing terminology.

Ensuring regulatory compliance for Accura 25 requires ongoing monitoring of changing regulations and standards across different industries and regions. Manufacturers and users of the material must stay informed about updates to relevant regulations and adjust their processes accordingly to maintain compliance and maximize the potential of Accura 25 in high-performance industrial solutions.

In the manufacturing industry, Accura 25 is subject to stringent quality control measures and safety regulations. These include compliance with ISO 9001 standards for quality management systems and ISO 14001 for environmental management. Additionally, the material must meet specific industry requirements, such as those set by the Occupational Safety and Health Administration (OSHA) for workplace safety.

For applications in the aerospace and automotive industries, Accura 25 must comply with rigorous safety and performance standards. This includes meeting the requirements of AS9100 for aerospace quality management systems and IATF 16949 for automotive quality management systems. The material must also pass various tests for durability, heat resistance, and chemical compatibility to ensure its suitability for use in these demanding environments.

In the medical and healthcare sectors, Accura 25 is subject to strict regulatory oversight. Compliance with FDA regulations, including 21 CFR Part 820 for medical devices, is essential for any applications in this field. The material must also meet biocompatibility standards, such as ISO 10993, to ensure its safety for use in medical devices or implants.

Environmental regulations also play a significant role in the use of Accura 25. The material must comply with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and similar regulations in other regions. These regulations aim to protect human health and the environment from the risks posed by chemicals.

As Accura 25 is often used in 3D printing applications, it must also adhere to specific regulations related to additive manufacturing. This includes compliance with standards such as ASTM F2792 for additive manufacturing technologies and ISO/ASTM 52900 for additive manufacturing terminology.

Ensuring regulatory compliance for Accura 25 requires ongoing monitoring of changing regulations and standards across different industries and regions. Manufacturers and users of the material must stay informed about updates to relevant regulations and adjust their processes accordingly to maintain compliance and maximize the potential of Accura 25 in high-performance industrial solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!