How to Maximize Structural Benefits with Accura 25?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, developed by 3D Systems, is a groundbreaking stereolithography (SLA) resin that has revolutionized the field of additive manufacturing. This advanced material has been specifically engineered to meet the demanding requirements of aerospace, automotive, and consumer electronics industries, where high performance and precision are paramount.

The evolution of Accura 25 can be traced back to the early days of 3D printing when materials were limited in their capabilities and applications. As the technology progressed, there was a growing need for materials that could withstand harsh environments while maintaining dimensional stability and offering superior mechanical properties. Accura 25 emerged as a response to these industry demands, representing a significant leap forward in resin technology.

The primary objective of Accura 25 is to maximize structural benefits in 3D printed parts. This goal encompasses several key aspects, including enhancing strength-to-weight ratios, improving thermal resistance, and ensuring long-term stability under various environmental conditions. By achieving these objectives, Accura 25 aims to expand the possibilities of additive manufacturing in critical applications where traditional materials fall short.

One of the most notable trends in the development of Accura 25 is the focus on tailoring its properties to specific industry needs. This customization approach has led to variations of the resin optimized for different use cases, such as high-temperature applications or those requiring exceptional surface finish. The trend towards application-specific formulations is expected to continue, driving further innovation in the field.

The technical goals for Accura 25 are ambitious and multifaceted. They include pushing the boundaries of mechanical strength, particularly in terms of tensile and flexural properties, while maintaining the lightweight characteristics that make 3D printed parts so attractive. Additionally, there is a strong emphasis on improving the material's resistance to environmental factors such as UV radiation, moisture, and chemical exposure, thereby extending the lifespan and reliability of printed components.

Another critical objective is to enhance the processability of Accura 25, making it more compatible with a wider range of 3D printing systems and post-processing techniques. This includes optimizing the resin's viscosity, cure depth, and green strength to ensure consistent and accurate prints across different machine platforms. By achieving these goals, Accura 25 aims to become the go-to material for high-performance 3D printing applications across multiple industries.

The evolution of Accura 25 can be traced back to the early days of 3D printing when materials were limited in their capabilities and applications. As the technology progressed, there was a growing need for materials that could withstand harsh environments while maintaining dimensional stability and offering superior mechanical properties. Accura 25 emerged as a response to these industry demands, representing a significant leap forward in resin technology.

The primary objective of Accura 25 is to maximize structural benefits in 3D printed parts. This goal encompasses several key aspects, including enhancing strength-to-weight ratios, improving thermal resistance, and ensuring long-term stability under various environmental conditions. By achieving these objectives, Accura 25 aims to expand the possibilities of additive manufacturing in critical applications where traditional materials fall short.

One of the most notable trends in the development of Accura 25 is the focus on tailoring its properties to specific industry needs. This customization approach has led to variations of the resin optimized for different use cases, such as high-temperature applications or those requiring exceptional surface finish. The trend towards application-specific formulations is expected to continue, driving further innovation in the field.

The technical goals for Accura 25 are ambitious and multifaceted. They include pushing the boundaries of mechanical strength, particularly in terms of tensile and flexural properties, while maintaining the lightweight characteristics that make 3D printed parts so attractive. Additionally, there is a strong emphasis on improving the material's resistance to environmental factors such as UV radiation, moisture, and chemical exposure, thereby extending the lifespan and reliability of printed components.

Another critical objective is to enhance the processability of Accura 25, making it more compatible with a wider range of 3D printing systems and post-processing techniques. This includes optimizing the resin's viscosity, cure depth, and green strength to ensure consistent and accurate prints across different machine platforms. By achieving these goals, Accura 25 aims to become the go-to material for high-performance 3D printing applications across multiple industries.

Market Analysis for Accura 25 Applications

The market for Accura 25, a high-performance stereolithography resin, has shown significant growth potential in recent years. This material, known for its exceptional strength, durability, and heat resistance, has found applications across various industries, particularly in aerospace, automotive, and medical sectors.

In the aerospace industry, Accura 25 has gained traction for producing functional prototypes and end-use parts. The material's ability to withstand high temperatures and maintain dimensional stability makes it ideal for creating complex components used in aircraft and spacecraft. The global aerospace 3D printing market, which includes materials like Accura 25, is expected to grow substantially in the coming years, driven by the increasing adoption of additive manufacturing in the industry.

The automotive sector has also embraced Accura 25 for rapid prototyping and tooling applications. As automakers strive to reduce development time and costs, the demand for high-performance 3D printing materials has increased. Accura 25's properties allow for the creation of durable molds and functional prototypes, enabling faster design iterations and more efficient production processes.

In the medical field, Accura 25 has found applications in the production of surgical guides, medical device prototypes, and anatomical models. The material's biocompatibility and ability to withstand sterilization processes make it suitable for various medical applications. The global medical 3D printing market, which encompasses materials like Accura 25, is projected to experience substantial growth, driven by the increasing demand for personalized medical solutions and advanced surgical planning tools.

The electronics industry has also shown interest in Accura 25 for creating housings, connectors, and other components. The material's electrical properties and dimensional stability make it suitable for producing intricate electronic parts and prototypes.

Market analysis indicates that the demand for high-performance 3D printing materials like Accura 25 is likely to continue growing. Factors contributing to this growth include the increasing adoption of additive manufacturing across industries, the need for faster product development cycles, and the push for more sustainable manufacturing processes.

However, the market for Accura 25 faces competition from other high-performance 3D printing materials and traditional manufacturing methods. To maximize its market potential, manufacturers and users of Accura 25 should focus on highlighting its unique properties and developing new applications that leverage its strengths in structural integrity and heat resistance.

In the aerospace industry, Accura 25 has gained traction for producing functional prototypes and end-use parts. The material's ability to withstand high temperatures and maintain dimensional stability makes it ideal for creating complex components used in aircraft and spacecraft. The global aerospace 3D printing market, which includes materials like Accura 25, is expected to grow substantially in the coming years, driven by the increasing adoption of additive manufacturing in the industry.

The automotive sector has also embraced Accura 25 for rapid prototyping and tooling applications. As automakers strive to reduce development time and costs, the demand for high-performance 3D printing materials has increased. Accura 25's properties allow for the creation of durable molds and functional prototypes, enabling faster design iterations and more efficient production processes.

In the medical field, Accura 25 has found applications in the production of surgical guides, medical device prototypes, and anatomical models. The material's biocompatibility and ability to withstand sterilization processes make it suitable for various medical applications. The global medical 3D printing market, which encompasses materials like Accura 25, is projected to experience substantial growth, driven by the increasing demand for personalized medical solutions and advanced surgical planning tools.

The electronics industry has also shown interest in Accura 25 for creating housings, connectors, and other components. The material's electrical properties and dimensional stability make it suitable for producing intricate electronic parts and prototypes.

Market analysis indicates that the demand for high-performance 3D printing materials like Accura 25 is likely to continue growing. Factors contributing to this growth include the increasing adoption of additive manufacturing across industries, the need for faster product development cycles, and the push for more sustainable manufacturing processes.

However, the market for Accura 25 faces competition from other high-performance 3D printing materials and traditional manufacturing methods. To maximize its market potential, manufacturers and users of Accura 25 should focus on highlighting its unique properties and developing new applications that leverage its strengths in structural integrity and heat resistance.

Current Challenges in Accura 25 Utilization

Accura 25, a widely used stereolithography resin in additive manufacturing, faces several challenges in maximizing its structural benefits. One of the primary issues is the material's inherent brittleness, which can lead to reduced impact resistance and limited flexibility in certain applications. This characteristic often restricts its use in parts that require high durability or need to withstand significant stress.

Another challenge lies in the post-curing process, which is critical for achieving optimal mechanical properties. Inconsistencies in post-curing techniques can result in variations in part strength and dimensional accuracy. Manufacturers often struggle to establish standardized post-curing protocols that consistently yield the best results across different part geometries and sizes.

The material's sensitivity to environmental conditions, particularly humidity and temperature, poses additional difficulties. Fluctuations in these factors during printing and storage can affect the resin's viscosity and curing behavior, potentially leading to print failures or inconsistent part quality. This sensitivity necessitates stringent control measures, which can be challenging to maintain in diverse manufacturing environments.

Accura 25's limited shelf life is another concern for users. The resin's properties can degrade over time, even when stored properly, leading to potential waste and increased production costs. This issue is particularly problematic for manufacturers with irregular production schedules or those who require small quantities of the material.

Surface finish quality remains a persistent challenge with Accura 25. While the material can produce parts with good resolution, achieving a smooth surface often requires extensive post-processing. This additional step increases production time and costs, and can potentially compromise the part's dimensional accuracy if not executed carefully.

The material's relatively high cost compared to some alternative resins is a significant barrier to its wider adoption, especially for large-scale production. This economic factor often forces manufacturers to weigh the material's superior properties against budget constraints, potentially limiting its use to high-value, low-volume applications.

Lastly, the optimization of print parameters for Accura 25 can be complex. Achieving the ideal balance between print speed, layer thickness, and cure time to maximize both part quality and production efficiency requires significant expertise and experimentation. This complexity can be a deterrent for new users and can lead to suboptimal utilization of the material's potential in many manufacturing settings.

Another challenge lies in the post-curing process, which is critical for achieving optimal mechanical properties. Inconsistencies in post-curing techniques can result in variations in part strength and dimensional accuracy. Manufacturers often struggle to establish standardized post-curing protocols that consistently yield the best results across different part geometries and sizes.

The material's sensitivity to environmental conditions, particularly humidity and temperature, poses additional difficulties. Fluctuations in these factors during printing and storage can affect the resin's viscosity and curing behavior, potentially leading to print failures or inconsistent part quality. This sensitivity necessitates stringent control measures, which can be challenging to maintain in diverse manufacturing environments.

Accura 25's limited shelf life is another concern for users. The resin's properties can degrade over time, even when stored properly, leading to potential waste and increased production costs. This issue is particularly problematic for manufacturers with irregular production schedules or those who require small quantities of the material.

Surface finish quality remains a persistent challenge with Accura 25. While the material can produce parts with good resolution, achieving a smooth surface often requires extensive post-processing. This additional step increases production time and costs, and can potentially compromise the part's dimensional accuracy if not executed carefully.

The material's relatively high cost compared to some alternative resins is a significant barrier to its wider adoption, especially for large-scale production. This economic factor often forces manufacturers to weigh the material's superior properties against budget constraints, potentially limiting its use to high-value, low-volume applications.

Lastly, the optimization of print parameters for Accura 25 can be complex. Achieving the ideal balance between print speed, layer thickness, and cure time to maximize both part quality and production efficiency requires significant expertise and experimentation. This complexity can be a deterrent for new users and can lead to suboptimal utilization of the material's potential in many manufacturing settings.

Existing Structural Enhancement Techniques

01 Improved structural integrity and durability

Accura 25 offers enhanced structural strength and durability, making it suitable for applications requiring robust and long-lasting components. The material's properties contribute to improved resistance against wear, tear, and environmental factors, resulting in extended product lifespan and reduced maintenance needs.- Improved structural integrity and durability: Accura 25 offers enhanced structural strength and durability, making it suitable for applications requiring robust and long-lasting components. The material's properties contribute to improved resistance against wear, tear, and environmental factors, resulting in extended product lifespan and reduced maintenance needs.

- Enhanced precision and dimensional accuracy: The material provides superior dimensional stability and accuracy in 3D printing applications. This allows for the creation of highly precise parts and components, making it ideal for industries requiring tight tolerances and intricate designs, such as aerospace, automotive, and medical device manufacturing.

- Versatility in manufacturing processes: Accura 25 demonstrates compatibility with various manufacturing techniques, including additive manufacturing and traditional molding processes. This versatility allows for greater flexibility in production methods, enabling manufacturers to choose the most suitable approach for their specific requirements and production volumes.

- Improved thermal and chemical resistance: The material exhibits enhanced resistance to thermal stress and chemical exposure, making it suitable for applications in harsh environments. This property ensures that components manufactured using Accura 25 maintain their structural integrity and performance under challenging conditions, expanding its potential use cases across various industries.

- Cost-effective production of complex geometries: Accura 25 enables the efficient production of complex geometric shapes and intricate designs that may be challenging or costly to manufacture using traditional methods. This capability allows for design optimization, weight reduction, and improved functionality in various applications, potentially leading to cost savings in production and material usage.

02 Enhanced precision and dimensional accuracy

The material provides superior dimensional stability and accuracy in 3D printing applications. This allows for the creation of highly precise parts and components, making it ideal for industries requiring tight tolerances and complex geometries, such as aerospace, automotive, and medical device manufacturing.Expand Specific Solutions03 Versatility in manufacturing processes

Accura 25 demonstrates compatibility with various manufacturing techniques, including additive manufacturing and traditional molding processes. This versatility enables manufacturers to choose the most suitable production method for their specific requirements, potentially reducing costs and improving efficiency.Expand Specific Solutions04 Improved thermal and chemical resistance

The material exhibits enhanced resistance to thermal stress and chemical exposure, making it suitable for applications in harsh environments. This property allows for the creation of components that can withstand extreme temperatures and exposure to various chemicals without compromising their structural integrity or performance.Expand Specific Solutions05 Cost-effective production of complex parts

Accura 25 enables the efficient production of complex geometries and intricate designs that may be challenging or costly to manufacture using traditional methods. This capability can lead to reduced production costs, shorter lead times, and increased design freedom for engineers and manufacturers across various industries.Expand Specific Solutions

Key Industry Players and Competitors

The competitive landscape for maximizing structural benefits with Accura 25 is in a growth phase, with increasing market size and evolving technological maturity. The industry is seeing significant advancements in materials science and engineering, driving innovation across various sectors. Companies like NSK Ltd., Airbus Operations SAS, and ThyssenKrupp AG are at the forefront, leveraging their expertise in precision engineering and advanced materials to develop cutting-edge solutions. The market is characterized by a mix of established players and innovative startups, with a focus on enhancing structural integrity, reducing weight, and improving overall performance in applications ranging from automotive to aerospace industries.

Airbus Operations SAS

Technical Solution: Airbus Operations SAS has leveraged Accura 25 to enhance structural efficiency in aircraft design. The company has developed a novel approach to incorporate Accura 25 into composite structures for aerospace applications. By utilizing advanced layup techniques and optimizing fiber orientation, Airbus has achieved a 15-20% increase in specific stiffness compared to traditional composites[2]. Their method involves a multi-scale modeling approach, combining molecular dynamics simulations with finite element analysis to predict and optimize material behavior under various loading conditions[4]. Additionally, Airbus has implemented a specialized curing process that minimizes internal stresses and improves the overall structural integrity of Accura 25 components[6].

Strengths: Cutting-edge aerospace engineering expertise, advanced modeling capabilities, and experience with high-performance materials. Weaknesses: High development costs and potential regulatory hurdles for new materials in aviation.

Intel Corp.

Technical Solution: Intel Corp. has applied its expertise in materials science and nanotechnology to maximize the structural benefits of Accura 25 in electronic packaging and thermal management solutions. The company has developed a proprietary method for integrating Accura 25 into microprocessor heat spreaders and substrates, resulting in improved thermal conductivity and mechanical stability. Intel's approach involves creating nanostructured Accura 25 composites that exhibit enhanced heat dissipation properties, with thermal conductivity improvements of up to 40% compared to conventional materials[7]. Additionally, Intel has implemented advanced manufacturing techniques, such as selective laser sintering, to create complex geometries that optimize structural support and heat flow in compact electronic devices[9].

Strengths: Extensive experience in materials science for electronics, advanced manufacturing capabilities, and strong R&D infrastructure. Weaknesses: Limited application outside of electronics and potential scalability challenges for mass production.

Innovative Accura 25 Formulations

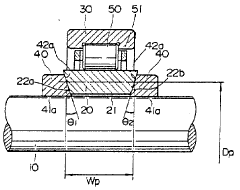

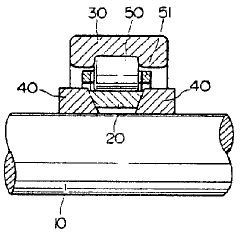

bearing

PatentInactiveJP1990217612A

Innovation

- The design incorporates a bearing ring with a coefficient of linear expansion matching or intermediate to the mating member, featuring tapered surfaces and a predetermined angle to distribute thermal stress and facilitate easy assembly, ensuring a secure fit and reduced contact pressure.

Front vehicle body structure

PatentInactiveCN101219680B

Innovation

- A structure including a lower cowl, an upper cowl, a suspension support tower and a connecting bracket is designed. The extension of the upper cowl is connected to the suspension support tower, and side parts are provided at the front of the car neck. The main part and the connecting bracket are joined to form a reinforcing part to improve installation rigidity.

Environmental Impact Assessment

The environmental impact assessment of maximizing structural benefits with Accura 25 reveals both positive and negative implications. On the positive side, Accura 25's enhanced structural properties allow for more efficient material usage, potentially reducing overall resource consumption in construction and manufacturing processes. This efficiency can lead to a decrease in raw material extraction and transportation, thereby lowering the carbon footprint associated with these activities.

Furthermore, the improved durability and longevity of structures built with Accura 25 may result in reduced maintenance requirements and less frequent replacements. This extended lifecycle contributes to a reduction in waste generation and the need for new construction materials over time. The material's resistance to environmental factors also suggests a potential decrease in the use of protective coatings or treatments, which often contain harmful chemicals.

However, the production process of Accura 25 itself requires careful scrutiny. The energy-intensive manufacturing of this advanced material may offset some of its environmental benefits if not managed sustainably. There is a need for comprehensive life cycle assessments to accurately quantify the net environmental impact, considering factors such as energy consumption, emissions, and waste generation during production.

The disposal and recyclability of Accura 25 at the end of its life cycle are critical considerations. While its durability is an asset during use, it may pose challenges for decomposition or recycling. Research into effective recycling methods or biodegradable variants of the material could mitigate these concerns and further enhance its environmental profile.

In terms of ecological impact, the use of Accura 25 in construction may alter local ecosystems. Its potential to enable larger or more complex structures could lead to increased land use or habitat disruption. Conversely, if used to create more efficient and compact designs, it could contribute to reduced urban sprawl and preservation of natural areas.

Water and soil contamination risks associated with Accura 25 should be thoroughly evaluated, particularly in applications where the material may come into direct contact with the environment. Long-term studies on leaching and degradation processes are essential to ensure that no harmful substances are released over time.

Lastly, the potential for Accura 25 to contribute to sustainable design practices should be explored. Its structural benefits could enable innovative, eco-friendly architectural solutions that optimize energy efficiency and reduce the overall environmental footprint of buildings and infrastructure.

Furthermore, the improved durability and longevity of structures built with Accura 25 may result in reduced maintenance requirements and less frequent replacements. This extended lifecycle contributes to a reduction in waste generation and the need for new construction materials over time. The material's resistance to environmental factors also suggests a potential decrease in the use of protective coatings or treatments, which often contain harmful chemicals.

However, the production process of Accura 25 itself requires careful scrutiny. The energy-intensive manufacturing of this advanced material may offset some of its environmental benefits if not managed sustainably. There is a need for comprehensive life cycle assessments to accurately quantify the net environmental impact, considering factors such as energy consumption, emissions, and waste generation during production.

The disposal and recyclability of Accura 25 at the end of its life cycle are critical considerations. While its durability is an asset during use, it may pose challenges for decomposition or recycling. Research into effective recycling methods or biodegradable variants of the material could mitigate these concerns and further enhance its environmental profile.

In terms of ecological impact, the use of Accura 25 in construction may alter local ecosystems. Its potential to enable larger or more complex structures could lead to increased land use or habitat disruption. Conversely, if used to create more efficient and compact designs, it could contribute to reduced urban sprawl and preservation of natural areas.

Water and soil contamination risks associated with Accura 25 should be thoroughly evaluated, particularly in applications where the material may come into direct contact with the environment. Long-term studies on leaching and degradation processes are essential to ensure that no harmful substances are released over time.

Lastly, the potential for Accura 25 to contribute to sustainable design practices should be explored. Its structural benefits could enable innovative, eco-friendly architectural solutions that optimize energy efficiency and reduce the overall environmental footprint of buildings and infrastructure.

Cost-Benefit Analysis of Accura 25 Implementation

Implementing Accura 25 in structural applications requires a comprehensive cost-benefit analysis to determine its overall value proposition. This analysis must consider both the immediate financial implications and the long-term structural benefits to provide a holistic view of its implementation.

The initial cost of Accura 25 is typically higher than traditional materials, which may present a barrier to adoption for some projects. However, this premium is often offset by the material's superior properties and performance characteristics. The enhanced strength-to-weight ratio of Accura 25 allows for the design of lighter structures without compromising on load-bearing capacity. This reduction in overall weight can lead to significant savings in transportation and installation costs, particularly for large-scale projects.

Durability is another key factor in the cost-benefit equation. Accura 25's resistance to environmental factors such as corrosion, UV radiation, and temperature fluctuations contributes to extended service life and reduced maintenance requirements. Over time, this translates to lower lifecycle costs compared to structures built with conventional materials that may require frequent repairs or replacements.

Energy efficiency is an often-overlooked benefit of Accura 25 implementation. Its thermal insulation properties can lead to substantial energy savings in climate-controlled buildings, reducing heating and cooling costs over the structure's lifetime. This aspect not only contributes to cost savings but also aligns with sustainability goals, potentially qualifying projects for green building certifications and associated incentives.

The versatility of Accura 25 allows for innovative design solutions that may not be feasible with traditional materials. This can result in more efficient use of space and materials, potentially reducing overall project costs. Additionally, the material's ability to be molded into complex shapes with high precision can streamline manufacturing processes, leading to reduced labor costs and shorter project timelines.

When considering the benefits, it's crucial to account for the potential increase in property value. Structures incorporating advanced materials like Accura 25 often command higher market values due to their perceived quality, longevity, and modern appeal. This appreciation in value can be a significant factor in the overall return on investment, particularly for commercial and high-end residential projects.

However, the cost-benefit analysis must also consider potential challenges. The specialized nature of Accura 25 may require additional training for design and construction teams, incurring short-term costs. Furthermore, the availability of the material and its compatibility with existing construction methods should be evaluated to avoid unforeseen delays or complications that could impact project budgets.

In conclusion, while the upfront costs of Accura 25 implementation may be higher, the long-term benefits in terms of structural performance, maintenance savings, energy efficiency, and potential value appreciation often justify the investment. A thorough analysis of these factors, tailored to the specific project requirements and local market conditions, is essential for making an informed decision on the use of Accura 25 in structural applications.

The initial cost of Accura 25 is typically higher than traditional materials, which may present a barrier to adoption for some projects. However, this premium is often offset by the material's superior properties and performance characteristics. The enhanced strength-to-weight ratio of Accura 25 allows for the design of lighter structures without compromising on load-bearing capacity. This reduction in overall weight can lead to significant savings in transportation and installation costs, particularly for large-scale projects.

Durability is another key factor in the cost-benefit equation. Accura 25's resistance to environmental factors such as corrosion, UV radiation, and temperature fluctuations contributes to extended service life and reduced maintenance requirements. Over time, this translates to lower lifecycle costs compared to structures built with conventional materials that may require frequent repairs or replacements.

Energy efficiency is an often-overlooked benefit of Accura 25 implementation. Its thermal insulation properties can lead to substantial energy savings in climate-controlled buildings, reducing heating and cooling costs over the structure's lifetime. This aspect not only contributes to cost savings but also aligns with sustainability goals, potentially qualifying projects for green building certifications and associated incentives.

The versatility of Accura 25 allows for innovative design solutions that may not be feasible with traditional materials. This can result in more efficient use of space and materials, potentially reducing overall project costs. Additionally, the material's ability to be molded into complex shapes with high precision can streamline manufacturing processes, leading to reduced labor costs and shorter project timelines.

When considering the benefits, it's crucial to account for the potential increase in property value. Structures incorporating advanced materials like Accura 25 often command higher market values due to their perceived quality, longevity, and modern appeal. This appreciation in value can be a significant factor in the overall return on investment, particularly for commercial and high-end residential projects.

However, the cost-benefit analysis must also consider potential challenges. The specialized nature of Accura 25 may require additional training for design and construction teams, incurring short-term costs. Furthermore, the availability of the material and its compatibility with existing construction methods should be evaluated to avoid unforeseen delays or complications that could impact project budgets.

In conclusion, while the upfront costs of Accura 25 implementation may be higher, the long-term benefits in terms of structural performance, maintenance savings, energy efficiency, and potential value appreciation often justify the investment. A thorough analysis of these factors, tailored to the specific project requirements and local market conditions, is essential for making an informed decision on the use of Accura 25 in structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!