How to Use Accura 25 for Advanced Design Techniques?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview and Design Goals

Accura 25 is a high-performance stereolithography resin developed by 3D Systems, specifically designed for advanced applications in the field of additive manufacturing. This material has gained significant attention in recent years due to its exceptional properties and versatility in creating complex, functional parts with superior accuracy and surface finish.

The evolution of Accura 25 can be traced back to the early days of stereolithography, where the need for materials with enhanced mechanical properties and improved dimensional stability became increasingly apparent. As the additive manufacturing industry progressed, the demand for materials capable of producing parts with higher precision, better surface quality, and increased durability grew exponentially.

Accura 25 represents a significant milestone in this technological journey, offering a unique combination of features that make it particularly suitable for advanced design techniques. Its development was driven by the growing requirements of industries such as aerospace, automotive, and medical devices, where the ability to produce highly accurate, functional prototypes and end-use parts is crucial.

The primary goals of Accura 25 in advanced design techniques are multifaceted. Firstly, it aims to enable the creation of intricate geometries and fine details that were previously challenging or impossible to achieve with traditional manufacturing methods. This capability opens up new possibilities for designers and engineers to optimize part designs for improved performance and functionality.

Secondly, Accura 25 seeks to enhance the overall quality of 3D printed parts by providing excellent surface finish and dimensional accuracy. This is particularly important in applications where aesthetics and precision are critical, such as in the production of consumer products or medical devices.

Another key objective of Accura 25 is to improve the mechanical properties of printed parts, including strength, stiffness, and impact resistance. This allows for the creation of functional prototypes and end-use parts that can withstand real-world conditions and perform reliably in various applications.

Furthermore, Accura 25 aims to streamline the post-processing requirements of 3D printed parts. By minimizing the need for extensive finishing and post-curing, it helps reduce overall production time and costs, making it an attractive option for both prototyping and small-scale production runs.

In the context of advanced design techniques, Accura 25 also targets improved compatibility with various design optimization tools and software. This integration enables designers to fully leverage the material's properties in conjunction with advanced design methodologies such as topology optimization, generative design, and lattice structures.

The evolution of Accura 25 can be traced back to the early days of stereolithography, where the need for materials with enhanced mechanical properties and improved dimensional stability became increasingly apparent. As the additive manufacturing industry progressed, the demand for materials capable of producing parts with higher precision, better surface quality, and increased durability grew exponentially.

Accura 25 represents a significant milestone in this technological journey, offering a unique combination of features that make it particularly suitable for advanced design techniques. Its development was driven by the growing requirements of industries such as aerospace, automotive, and medical devices, where the ability to produce highly accurate, functional prototypes and end-use parts is crucial.

The primary goals of Accura 25 in advanced design techniques are multifaceted. Firstly, it aims to enable the creation of intricate geometries and fine details that were previously challenging or impossible to achieve with traditional manufacturing methods. This capability opens up new possibilities for designers and engineers to optimize part designs for improved performance and functionality.

Secondly, Accura 25 seeks to enhance the overall quality of 3D printed parts by providing excellent surface finish and dimensional accuracy. This is particularly important in applications where aesthetics and precision are critical, such as in the production of consumer products or medical devices.

Another key objective of Accura 25 is to improve the mechanical properties of printed parts, including strength, stiffness, and impact resistance. This allows for the creation of functional prototypes and end-use parts that can withstand real-world conditions and perform reliably in various applications.

Furthermore, Accura 25 aims to streamline the post-processing requirements of 3D printed parts. By minimizing the need for extensive finishing and post-curing, it helps reduce overall production time and costs, making it an attractive option for both prototyping and small-scale production runs.

In the context of advanced design techniques, Accura 25 also targets improved compatibility with various design optimization tools and software. This integration enables designers to fully leverage the material's properties in conjunction with advanced design methodologies such as topology optimization, generative design, and lattice structures.

Market Demand for Advanced Design Solutions

The market demand for advanced design solutions has been steadily increasing across various industries, driven by the need for more efficient, innovative, and cost-effective product development processes. Accura 25, a high-performance stereolithography resin, has emerged as a key enabler for advanced design techniques in rapid prototyping and additive manufacturing.

In the automotive sector, there is a growing demand for lightweight components and complex geometries to improve fuel efficiency and performance. Accura 25's ability to produce high-resolution, durable parts with excellent surface finish makes it ideal for creating functional prototypes and end-use parts in automotive applications. This has led to increased adoption of Accura 25 in the design and testing phases of vehicle development.

The aerospace industry has also shown significant interest in advanced design solutions utilizing Accura 25. With its high temperature resistance and dimensional stability, Accura 25 enables the production of intricate components for aircraft and spacecraft. The material's properties allow for the creation of complex internal structures and optimized designs that were previously difficult or impossible to manufacture using traditional methods.

In the consumer electronics market, the demand for sleek, ergonomic designs and miniaturized components has driven the adoption of advanced design techniques. Accura 25's ability to produce small, precise parts with fine details makes it valuable for prototyping and testing new product designs. This has resulted in faster product development cycles and improved time-to-market for electronic devices.

The medical device industry has also recognized the potential of Accura 25 for advanced design solutions. The material's biocompatibility and ability to produce anatomically accurate models have led to its use in surgical planning, custom implant design, and medical training applications. This has created new opportunities for personalized healthcare solutions and improved patient outcomes.

The industrial equipment sector has seen a rise in demand for customized and optimized components. Accura 25's versatility in producing functional prototypes and end-use parts has enabled manufacturers to iterate designs quickly and create more efficient machinery. This has resulted in improved performance, reduced material waste, and lower production costs across various industrial applications.

As sustainability becomes increasingly important, there is a growing market demand for design solutions that minimize material usage and optimize product lifecycles. Accura 25's ability to create complex, lightweight structures aligns well with this trend, allowing designers to reduce material consumption without compromising on performance or durability.

The education and research sectors have also contributed to the market demand for advanced design solutions using Accura 25. Universities and research institutions are utilizing the material to explore new design possibilities, conduct material studies, and develop innovative manufacturing techniques. This has led to a growing body of knowledge and expertise in advanced design techniques, further driving market demand across industries.

In the automotive sector, there is a growing demand for lightweight components and complex geometries to improve fuel efficiency and performance. Accura 25's ability to produce high-resolution, durable parts with excellent surface finish makes it ideal for creating functional prototypes and end-use parts in automotive applications. This has led to increased adoption of Accura 25 in the design and testing phases of vehicle development.

The aerospace industry has also shown significant interest in advanced design solutions utilizing Accura 25. With its high temperature resistance and dimensional stability, Accura 25 enables the production of intricate components for aircraft and spacecraft. The material's properties allow for the creation of complex internal structures and optimized designs that were previously difficult or impossible to manufacture using traditional methods.

In the consumer electronics market, the demand for sleek, ergonomic designs and miniaturized components has driven the adoption of advanced design techniques. Accura 25's ability to produce small, precise parts with fine details makes it valuable for prototyping and testing new product designs. This has resulted in faster product development cycles and improved time-to-market for electronic devices.

The medical device industry has also recognized the potential of Accura 25 for advanced design solutions. The material's biocompatibility and ability to produce anatomically accurate models have led to its use in surgical planning, custom implant design, and medical training applications. This has created new opportunities for personalized healthcare solutions and improved patient outcomes.

The industrial equipment sector has seen a rise in demand for customized and optimized components. Accura 25's versatility in producing functional prototypes and end-use parts has enabled manufacturers to iterate designs quickly and create more efficient machinery. This has resulted in improved performance, reduced material waste, and lower production costs across various industrial applications.

As sustainability becomes increasingly important, there is a growing market demand for design solutions that minimize material usage and optimize product lifecycles. Accura 25's ability to create complex, lightweight structures aligns well with this trend, allowing designers to reduce material consumption without compromising on performance or durability.

The education and research sectors have also contributed to the market demand for advanced design solutions using Accura 25. Universities and research institutions are utilizing the material to explore new design possibilities, conduct material studies, and develop innovative manufacturing techniques. This has led to a growing body of knowledge and expertise in advanced design techniques, further driving market demand across industries.

Current Challenges in Advanced Design Techniques

Advanced design techniques face several significant challenges in the current landscape, particularly when considering the use of Accura 25. One of the primary obstacles is the complexity of integrating Accura 25's advanced features into existing design workflows. Many designers struggle to fully leverage the software's capabilities due to its steep learning curve and the need for specialized training.

Another challenge lies in the optimization of computational resources. Accura 25's advanced simulations and analyses often require substantial processing power, which can lead to bottlenecks in the design process. This is especially problematic for smaller firms or individual designers who may not have access to high-performance computing systems.

Interoperability issues also present a significant hurdle. While Accura 25 offers powerful design tools, it may not always seamlessly integrate with other software commonly used in the design process. This can result in data transfer problems, file format incompatibilities, and workflow disruptions, ultimately impacting productivity and design quality.

The rapid pace of technological advancement in the field of design software poses another challenge. Designers must constantly update their skills and knowledge to keep up with new features and methodologies introduced in Accura 25. This continuous learning process can be time-consuming and may temporarily reduce productivity as teams adapt to new tools and techniques.

Cost considerations also play a role in the challenges faced by designers. The advanced features of Accura 25 often come with a premium price tag, which can be prohibitive for smaller organizations or independent designers. This financial barrier may limit access to cutting-edge design techniques for a significant portion of the industry.

Furthermore, the increasing complexity of design projects demands more sophisticated collaboration tools. While Accura 25 offers some collaborative features, coordinating large-scale projects with multiple stakeholders and disciplines remains challenging. Ensuring effective communication and seamless data sharing across diverse teams and software platforms is an ongoing struggle.

Lastly, the growing emphasis on sustainability and environmental considerations in design presents new challenges. Integrating these factors into the design process using Accura 25 requires additional expertise and often more complex analyses. Designers must balance performance, aesthetics, and sustainability, which can be difficult to achieve within the constraints of current software capabilities.

Another challenge lies in the optimization of computational resources. Accura 25's advanced simulations and analyses often require substantial processing power, which can lead to bottlenecks in the design process. This is especially problematic for smaller firms or individual designers who may not have access to high-performance computing systems.

Interoperability issues also present a significant hurdle. While Accura 25 offers powerful design tools, it may not always seamlessly integrate with other software commonly used in the design process. This can result in data transfer problems, file format incompatibilities, and workflow disruptions, ultimately impacting productivity and design quality.

The rapid pace of technological advancement in the field of design software poses another challenge. Designers must constantly update their skills and knowledge to keep up with new features and methodologies introduced in Accura 25. This continuous learning process can be time-consuming and may temporarily reduce productivity as teams adapt to new tools and techniques.

Cost considerations also play a role in the challenges faced by designers. The advanced features of Accura 25 often come with a premium price tag, which can be prohibitive for smaller organizations or independent designers. This financial barrier may limit access to cutting-edge design techniques for a significant portion of the industry.

Furthermore, the increasing complexity of design projects demands more sophisticated collaboration tools. While Accura 25 offers some collaborative features, coordinating large-scale projects with multiple stakeholders and disciplines remains challenging. Ensuring effective communication and seamless data sharing across diverse teams and software platforms is an ongoing struggle.

Lastly, the growing emphasis on sustainability and environmental considerations in design presents new challenges. Integrating these factors into the design process using Accura 25 requires additional expertise and often more complex analyses. Designers must balance performance, aesthetics, and sustainability, which can be difficult to achieve within the constraints of current software capabilities.

Existing Accura 25 Design Techniques

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems.

- Analytical methods for Accura 25 detection and quantification: Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental techniques for quality control and research purposes.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients for synergistic therapeutic effects. These combinations may target multiple pathways or provide enhanced efficacy in treating specific conditions.

02 Chemical synthesis and properties of Accura 25

The synthesis of Accura 25 involves specific chemical processes and reactions. Understanding its chemical properties is crucial for its application in various fields, including pharmaceuticals and materials science.Expand Specific Solutions03 Analytical methods for detecting Accura 25

Various analytical techniques are employed to detect and quantify Accura 25 in different matrices. These methods are essential for quality control, research, and regulatory compliance in industries using this compound.Expand Specific Solutions04 Applications of Accura 25 in material science

Accura 25 finds applications in material science, particularly in the development of advanced materials with specific properties. It may be used in coatings, polymers, or other engineered materials to impart desired characteristics.Expand Specific Solutions05 Biological effects and safety profile of Accura 25

Research on the biological effects and safety profile of Accura 25 is crucial for its use in various applications. Studies may include toxicology assessments, pharmacokinetics, and potential interactions with biological systems.Expand Specific Solutions

Key Players in Advanced Design Software Industry

The advanced design techniques using Accura 25 are in a competitive and evolving landscape. The industry is in a growth phase, with increasing market size driven by demand for precision engineering solutions. The technology's maturity is advancing, with key players like TRUMPF Werkzeugmaschinen and Cadence Design Systems leading innovation. Universities such as Harbin Institute of Technology and South China University of Technology are contributing to research and development. The market is characterized by a mix of established industrial firms and emerging tech companies, indicating a dynamic ecosystem with potential for further technological advancements and market expansion.

NVIDIA Corp.

Technical Solution: NVIDIA has incorporated Accura 25 into their GPU design workflow to enhance the accuracy and efficiency of their chip design process. The company utilizes Accura 25's advanced modeling capabilities to improve the simulation of complex GPU architectures, particularly focusing on power analysis and thermal management[2]. NVIDIA's implementation of Accura 25 allows for more precise estimation of power consumption and heat dissipation in their high-performance GPUs, enabling better optimization of chip layouts and cooling solutions. The technology is also employed in NVIDIA's AI chip design process, where it helps in optimizing the performance and energy efficiency of neural network accelerators[4].

Strengths: Enhanced power and thermal analysis for GPU designs, improved optimization for AI chip architectures. Weaknesses: May require significant computational resources for large-scale GPU simulations, potential complexity in integrating with existing proprietary design tools.

Cadence Design Systems, Inc.

Technical Solution: Cadence Design Systems has integrated Accura 25 into their advanced design techniques, leveraging its capabilities for improved accuracy and performance in electronic design automation (EDA). Their approach involves utilizing Accura 25's advanced modeling and simulation features to enhance the design and verification of complex integrated circuits. The company has implemented Accura 25 in their suite of tools, allowing designers to perform more accurate parasitic extraction, signal integrity analysis, and power integrity simulations[1]. This integration enables designers to address challenges associated with advanced process nodes, such as FinFET and GAA technologies, by providing more precise modeling of physical effects and interconnect parasitics[3].

Strengths: Improved accuracy in parasitic extraction and simulation, better support for advanced process nodes, and enhanced integration with existing EDA tools. Weaknesses: Potential learning curve for designers adapting to new features, and possible increased computational requirements for more complex simulations.

Core Innovations in Accura 25 Technology

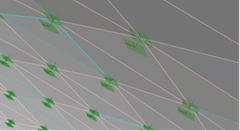

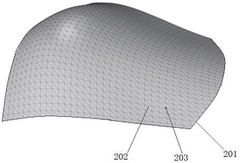

A method and system for rapidly deepening design of special-shaped spatial steel structures based on Grasshopper

PatentPendingCN119760843A

Innovation

- The final steel component linear model is established using the Grasshopper plug-in, and the design is deepened through steps S1 to S5, including establishing a solid model of the rod component, extracting parameters, generating processing drawings and assembly drawings.

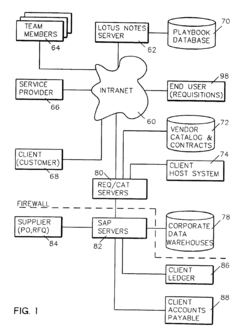

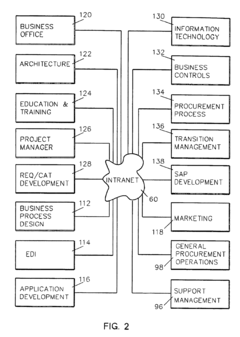

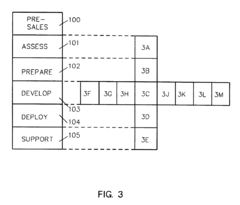

System and method for project designing and developing a procurement and accounts payable system

PatentInactiveUS6714915B1

Innovation

- A system and method that utilizes a server-based database with web-enabled terminals for coordinating and tracking activities, providing templates for project management, training, and quality assurance, integrating all aspects of procurement and accounts payable processes through electronic requisitions and SAP systems.

Integration with Other Design Tools

Accura 25, a powerful design software, offers advanced capabilities that can be further enhanced through integration with other design tools. This integration allows designers to leverage the strengths of multiple platforms, creating a more comprehensive and efficient workflow. One of the primary advantages of integrating Accura 25 with other tools is the ability to seamlessly transfer data and designs between different software environments.

For instance, Accura 25 can be integrated with CAD software such as AutoCAD or SolidWorks. This integration enables designers to import complex 3D models created in these CAD programs directly into Accura 25 for further refinement and analysis. The compatibility between these tools ensures that design integrity is maintained throughout the process, reducing the risk of errors that can occur during manual data transfer.

Another valuable integration is with simulation and analysis tools. By connecting Accura 25 with finite element analysis (FEA) software like ANSYS or Abaqus, designers can perform advanced structural and thermal analyses on their designs. This integration allows for real-time feedback on design performance, enabling iterative improvements without the need to switch between multiple software platforms.

Accura 25 can also be integrated with project management and collaboration tools such as Autodesk BIM 360 or Trimble Connect. This integration facilitates better communication and coordination among team members, allowing for real-time design updates and version control. It streamlines the design process by providing a centralized platform for sharing and reviewing designs, reducing the likelihood of miscommunication and improving overall project efficiency.

Furthermore, integration with rendering and visualization tools like V-Ray or KeyShot can enhance the presentation capabilities of Accura 25. Designers can create photorealistic renderings and animations of their designs, which is particularly useful for client presentations and marketing materials. This integration bridges the gap between technical design and visual communication, allowing for more effective presentation of design concepts.

Lastly, Accura 25 can be integrated with manufacturing and 3D printing software, such as Simplify3D or Cura. This integration enables a seamless transition from design to production, allowing designers to prepare their models for 3D printing or CNC machining directly within the Accura 25 environment. By streamlining this process, designers can reduce the time and potential errors associated with transferring designs between multiple software platforms.

For instance, Accura 25 can be integrated with CAD software such as AutoCAD or SolidWorks. This integration enables designers to import complex 3D models created in these CAD programs directly into Accura 25 for further refinement and analysis. The compatibility between these tools ensures that design integrity is maintained throughout the process, reducing the risk of errors that can occur during manual data transfer.

Another valuable integration is with simulation and analysis tools. By connecting Accura 25 with finite element analysis (FEA) software like ANSYS or Abaqus, designers can perform advanced structural and thermal analyses on their designs. This integration allows for real-time feedback on design performance, enabling iterative improvements without the need to switch between multiple software platforms.

Accura 25 can also be integrated with project management and collaboration tools such as Autodesk BIM 360 or Trimble Connect. This integration facilitates better communication and coordination among team members, allowing for real-time design updates and version control. It streamlines the design process by providing a centralized platform for sharing and reviewing designs, reducing the likelihood of miscommunication and improving overall project efficiency.

Furthermore, integration with rendering and visualization tools like V-Ray or KeyShot can enhance the presentation capabilities of Accura 25. Designers can create photorealistic renderings and animations of their designs, which is particularly useful for client presentations and marketing materials. This integration bridges the gap between technical design and visual communication, allowing for more effective presentation of design concepts.

Lastly, Accura 25 can be integrated with manufacturing and 3D printing software, such as Simplify3D or Cura. This integration enables a seamless transition from design to production, allowing designers to prepare their models for 3D printing or CNC machining directly within the Accura 25 environment. By streamlining this process, designers can reduce the time and potential errors associated with transferring designs between multiple software platforms.

User Training and Adoption Strategies

Implementing effective user training and adoption strategies is crucial for maximizing the potential of Accura 25 in advanced design techniques. A comprehensive approach should begin with a thorough assessment of the user base, identifying varying skill levels and specific design needs. This information can be used to tailor training programs that address individual requirements and organizational goals.

Developing a multi-tiered training curriculum is essential to accommodate users with different expertise levels. Beginner courses should focus on fundamental software navigation and basic design principles, while intermediate and advanced modules can delve into complex modeling techniques, advanced simulation capabilities, and integration with other design tools. Hands-on workshops and practical exercises should be incorporated to reinforce learning and encourage experimentation with Accura 25's advanced features.

Online learning platforms can be leveraged to provide on-demand access to training materials, video tutorials, and interactive lessons. This approach allows users to learn at their own pace and revisit challenging concepts as needed. Regular webinars and virtual Q&A sessions can supplement these resources, offering real-time support and fostering a community of practice among users.

To drive adoption, it is crucial to demonstrate the tangible benefits of using Accura 25 for advanced design techniques. Case studies showcasing successful projects and measurable improvements in design efficiency and quality can be powerful motivators. Peer-to-peer learning should be encouraged through user groups and forums, where experienced designers can share best practices and innovative applications of the software.

Gamification elements can be introduced to make the learning process more engaging and rewarding. Achievement badges, progress tracking, and friendly competitions can incentivize users to explore advanced features and push the boundaries of their design capabilities. Additionally, a mentorship program pairing experienced Accura 25 users with newcomers can accelerate skill development and foster a culture of continuous learning within the organization.

Regular feedback loops should be established to gather user insights and identify areas for improvement in both the software and training programs. This iterative approach ensures that the adoption strategy remains aligned with evolving user needs and technological advancements. By continuously refining the training and support ecosystem, organizations can maximize the return on investment in Accura 25 and empower their design teams to achieve new levels of innovation and productivity.

Developing a multi-tiered training curriculum is essential to accommodate users with different expertise levels. Beginner courses should focus on fundamental software navigation and basic design principles, while intermediate and advanced modules can delve into complex modeling techniques, advanced simulation capabilities, and integration with other design tools. Hands-on workshops and practical exercises should be incorporated to reinforce learning and encourage experimentation with Accura 25's advanced features.

Online learning platforms can be leveraged to provide on-demand access to training materials, video tutorials, and interactive lessons. This approach allows users to learn at their own pace and revisit challenging concepts as needed. Regular webinars and virtual Q&A sessions can supplement these resources, offering real-time support and fostering a community of practice among users.

To drive adoption, it is crucial to demonstrate the tangible benefits of using Accura 25 for advanced design techniques. Case studies showcasing successful projects and measurable improvements in design efficiency and quality can be powerful motivators. Peer-to-peer learning should be encouraged through user groups and forums, where experienced designers can share best practices and innovative applications of the software.

Gamification elements can be introduced to make the learning process more engaging and rewarding. Achievement badges, progress tracking, and friendly competitions can incentivize users to explore advanced features and push the boundaries of their design capabilities. Additionally, a mentorship program pairing experienced Accura 25 users with newcomers can accelerate skill development and foster a culture of continuous learning within the organization.

Regular feedback loops should be established to gather user insights and identify areas for improvement in both the software and training programs. This iterative approach ensures that the adoption strategy remains aligned with evolving user needs and technological advancements. By continuously refining the training and support ecosystem, organizations can maximize the return on investment in Accura 25 and empower their design teams to achieve new levels of innovation and productivity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!