Accura 25: Key Factors in Next-Level Jewelry Crafting

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 represents a significant advancement in the field of jewelry crafting materials, specifically designed for the production of high-precision, intricate patterns and delicate structures. This innovative material, developed by 3D Systems, has emerged as a game-changer in the jewelry industry, offering unprecedented levels of detail and accuracy in the creation of complex designs.

The evolution of jewelry crafting techniques has been closely tied to technological advancements in materials science and manufacturing processes. Traditional methods, while still valued for their artisanal qualities, often face limitations in terms of precision and reproducibility. The introduction of Accura 25 marks a pivotal moment in this technological progression, addressing many of the challenges faced by contemporary jewelers and designers.

Accura 25 is a photopolymer resin specifically formulated for use in stereolithography (SLA) 3D printing systems. Its unique composition allows for the creation of exceptionally smooth surfaces and fine details, making it ideal for producing jewelry patterns, molds, and even direct casting applications. The material's high resolution capabilities enable the realization of designs that were previously difficult or impossible to achieve through conventional methods.

The primary objective of researching Accura 25 is to explore its full potential in revolutionizing jewelry crafting processes. This includes investigating its material properties, optimizing printing parameters, and developing new design methodologies that leverage its unique characteristics. By understanding the key factors that contribute to its performance, researchers and industry professionals aim to push the boundaries of what is possible in jewelry design and production.

One of the critical areas of focus is the material's ability to capture and reproduce intricate details. This aspect is particularly crucial in jewelry making, where the finest textures and most delicate patterns can significantly enhance the aesthetic value of a piece. Researchers are examining how Accura 25's molecular structure and curing properties contribute to its exceptional resolution and surface finish.

Another important objective is to assess the material's compatibility with various post-processing techniques commonly used in jewelry manufacturing. This includes studying its behavior during burnout processes for lost wax casting, as well as its interaction with different metal alloys and gemstone setting techniques. The goal is to seamlessly integrate Accura 25 into existing jewelry production workflows while maximizing its benefits.

Furthermore, the research aims to explore the potential for creating novel jewelry designs that were previously impractical or impossible. By understanding the material's strengths and limitations, designers can develop new approaches to jewelry creation that fully exploit Accura 25's capabilities, potentially leading to innovative styles and forms in the jewelry industry.

The evolution of jewelry crafting techniques has been closely tied to technological advancements in materials science and manufacturing processes. Traditional methods, while still valued for their artisanal qualities, often face limitations in terms of precision and reproducibility. The introduction of Accura 25 marks a pivotal moment in this technological progression, addressing many of the challenges faced by contemporary jewelers and designers.

Accura 25 is a photopolymer resin specifically formulated for use in stereolithography (SLA) 3D printing systems. Its unique composition allows for the creation of exceptionally smooth surfaces and fine details, making it ideal for producing jewelry patterns, molds, and even direct casting applications. The material's high resolution capabilities enable the realization of designs that were previously difficult or impossible to achieve through conventional methods.

The primary objective of researching Accura 25 is to explore its full potential in revolutionizing jewelry crafting processes. This includes investigating its material properties, optimizing printing parameters, and developing new design methodologies that leverage its unique characteristics. By understanding the key factors that contribute to its performance, researchers and industry professionals aim to push the boundaries of what is possible in jewelry design and production.

One of the critical areas of focus is the material's ability to capture and reproduce intricate details. This aspect is particularly crucial in jewelry making, where the finest textures and most delicate patterns can significantly enhance the aesthetic value of a piece. Researchers are examining how Accura 25's molecular structure and curing properties contribute to its exceptional resolution and surface finish.

Another important objective is to assess the material's compatibility with various post-processing techniques commonly used in jewelry manufacturing. This includes studying its behavior during burnout processes for lost wax casting, as well as its interaction with different metal alloys and gemstone setting techniques. The goal is to seamlessly integrate Accura 25 into existing jewelry production workflows while maximizing its benefits.

Furthermore, the research aims to explore the potential for creating novel jewelry designs that were previously impractical or impossible. By understanding the material's strengths and limitations, designers can develop new approaches to jewelry creation that fully exploit Accura 25's capabilities, potentially leading to innovative styles and forms in the jewelry industry.

Jewelry Market Demand Analysis

The global jewelry market has been experiencing steady growth, driven by increasing disposable incomes, changing consumer preferences, and the rising popularity of luxury goods. In 2020, the market was valued at approximately $230 billion, with projections indicating continued expansion in the coming years. This growth is particularly evident in emerging economies, where a burgeoning middle class is fueling demand for both fine and costume jewelry.

The demand for high-quality, intricately crafted jewelry pieces has been on the rise, especially in the luxury segment. Consumers are increasingly seeking unique, personalized items that showcase exceptional craftsmanship and innovative designs. This trend has led to a growing interest in advanced jewelry manufacturing technologies, such as those offered by Accura 25, which can produce highly detailed and complex pieces with precision.

The bridal jewelry segment remains a significant driver of market demand, accounting for a substantial portion of overall sales. However, there is also a noticeable shift towards self-purchasing, particularly among younger consumers who view jewelry as a form of self-expression and investment. This trend has led to an increased demand for versatile, everyday pieces that can be worn in various settings.

Sustainability and ethical sourcing have become crucial factors influencing consumer purchasing decisions in the jewelry market. There is a growing demand for eco-friendly materials, responsibly sourced gemstones, and transparent supply chains. This shift in consumer preferences presents an opportunity for technologies like Accura 25 to contribute to more sustainable manufacturing processes by reducing material waste and energy consumption.

The online jewelry market has experienced significant growth, accelerated by the COVID-19 pandemic. E-commerce platforms and virtual try-on technologies have made it easier for consumers to purchase jewelry online, expanding the reach of brands and retailers. This digital transformation has also increased the demand for customization options, which can be facilitated by advanced manufacturing technologies.

In terms of regional demand, Asia-Pacific continues to be the fastest-growing market for jewelry, with China and India leading the way. The North American and European markets remain strong, with a focus on high-end, designer pieces. The Middle East is also a significant market, particularly for luxury and bridal jewelry.

The integration of technology in jewelry design and manufacturing, such as 3D printing and computer-aided design (CAD), is becoming increasingly important. This trend aligns well with the capabilities of Accura 25, positioning it as a potentially valuable tool for jewelers looking to enhance their production capabilities and meet evolving consumer demands for intricate, customized pieces.

The demand for high-quality, intricately crafted jewelry pieces has been on the rise, especially in the luxury segment. Consumers are increasingly seeking unique, personalized items that showcase exceptional craftsmanship and innovative designs. This trend has led to a growing interest in advanced jewelry manufacturing technologies, such as those offered by Accura 25, which can produce highly detailed and complex pieces with precision.

The bridal jewelry segment remains a significant driver of market demand, accounting for a substantial portion of overall sales. However, there is also a noticeable shift towards self-purchasing, particularly among younger consumers who view jewelry as a form of self-expression and investment. This trend has led to an increased demand for versatile, everyday pieces that can be worn in various settings.

Sustainability and ethical sourcing have become crucial factors influencing consumer purchasing decisions in the jewelry market. There is a growing demand for eco-friendly materials, responsibly sourced gemstones, and transparent supply chains. This shift in consumer preferences presents an opportunity for technologies like Accura 25 to contribute to more sustainable manufacturing processes by reducing material waste and energy consumption.

The online jewelry market has experienced significant growth, accelerated by the COVID-19 pandemic. E-commerce platforms and virtual try-on technologies have made it easier for consumers to purchase jewelry online, expanding the reach of brands and retailers. This digital transformation has also increased the demand for customization options, which can be facilitated by advanced manufacturing technologies.

In terms of regional demand, Asia-Pacific continues to be the fastest-growing market for jewelry, with China and India leading the way. The North American and European markets remain strong, with a focus on high-end, designer pieces. The Middle East is also a significant market, particularly for luxury and bridal jewelry.

The integration of technology in jewelry design and manufacturing, such as 3D printing and computer-aided design (CAD), is becoming increasingly important. This trend aligns well with the capabilities of Accura 25, positioning it as a potentially valuable tool for jewelers looking to enhance their production capabilities and meet evolving consumer demands for intricate, customized pieces.

Accura 25 Technical Challenges

Accura 25, a cutting-edge material in jewelry crafting, presents several technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal resolution and surface finish. While Accura 25 offers excellent detail reproduction, maintaining consistent quality across complex geometries remains difficult. This is particularly evident in intricate filigree work and micro-pavé settings, where even minor imperfections can significantly impact the final product's aesthetics and value.

Another significant challenge lies in the material's post-processing requirements. Accura 25 demands precise curing and finishing techniques to achieve its full potential. The curing process must be carefully controlled to prevent warping or shrinkage, which can compromise the dimensional accuracy of delicate jewelry pieces. Additionally, developing effective polishing methods that enhance the material's inherent luster without compromising its structural integrity poses a considerable technical hurdle.

Durability and long-term stability represent another set of challenges for Accura 25 in jewelry applications. While the material exhibits good strength properties, ensuring its resilience under various environmental conditions and wear patterns typical in jewelry use requires further research and development. This includes improving its resistance to UV degradation, chemical exposure, and mechanical stress, particularly in areas subject to frequent contact or movement, such as ring shanks or bracelet clasps.

Color consistency and customization present yet another technical challenge. Achieving uniform coloration throughout complex shapes and maintaining color stability over time are critical for high-end jewelry production. Furthermore, expanding the color palette while maintaining the material's other desirable properties requires advanced formulation techniques and extensive testing.

Lastly, the integration of Accura 25 with traditional jewelry materials and manufacturing processes poses significant challenges. Developing reliable methods for combining Accura 25 with precious metals, gemstones, and other materials commonly used in jewelry making is crucial for its widespread adoption in the industry. This includes addressing issues related to adhesion, thermal expansion differences, and compatibility with existing setting and finishing techniques.

Overcoming these technical challenges is essential for fully leveraging Accura 25's potential in next-level jewelry crafting. Addressing these issues will not only enhance the material's performance but also open up new possibilities for innovative designs and manufacturing processes in the jewelry industry.

Another significant challenge lies in the material's post-processing requirements. Accura 25 demands precise curing and finishing techniques to achieve its full potential. The curing process must be carefully controlled to prevent warping or shrinkage, which can compromise the dimensional accuracy of delicate jewelry pieces. Additionally, developing effective polishing methods that enhance the material's inherent luster without compromising its structural integrity poses a considerable technical hurdle.

Durability and long-term stability represent another set of challenges for Accura 25 in jewelry applications. While the material exhibits good strength properties, ensuring its resilience under various environmental conditions and wear patterns typical in jewelry use requires further research and development. This includes improving its resistance to UV degradation, chemical exposure, and mechanical stress, particularly in areas subject to frequent contact or movement, such as ring shanks or bracelet clasps.

Color consistency and customization present yet another technical challenge. Achieving uniform coloration throughout complex shapes and maintaining color stability over time are critical for high-end jewelry production. Furthermore, expanding the color palette while maintaining the material's other desirable properties requires advanced formulation techniques and extensive testing.

Lastly, the integration of Accura 25 with traditional jewelry materials and manufacturing processes poses significant challenges. Developing reliable methods for combining Accura 25 with precious metals, gemstones, and other materials commonly used in jewelry making is crucial for its widespread adoption in the industry. This includes addressing issues related to adhesion, thermal expansion differences, and compatibility with existing setting and finishing techniques.

Overcoming these technical challenges is essential for fully leveraging Accura 25's potential in next-level jewelry crafting. Addressing these issues will not only enhance the material's performance but also open up new possibilities for innovative designs and manufacturing processes in the jewelry industry.

Current Accura 25 Implementation

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.

- Analytical methods for Accura 25: Various analytical techniques are employed to characterize and quantify Accura 25 in different matrices. These methods may include chromatography, spectroscopy, and other advanced analytical tools for quality control and research purposes.

- Formulations and delivery systems for Accura 25: Different formulations and delivery systems are developed to improve the bioavailability and efficacy of Accura 25. These may include novel drug delivery technologies, controlled release formulations, and combination products.

- Applications of Accura 25 in various industries: Accura 25 finds applications in diverse industries beyond pharmaceuticals, such as agriculture, materials science, and chemical manufacturing. Its unique properties make it suitable for use in different products and processes across multiple sectors.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.Expand Specific Solutions03 Formulations for improved bioavailability of Accura 25

Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction, or novel drug delivery systems to improve absorption and efficacy.Expand Specific Solutions04 Analytical methods for Accura 25 detection and quantification

Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental techniques for quality control and research purposes.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other active ingredients to create synergistic therapeutic effects. These combinations may target multiple pathways or provide enhanced efficacy in treating specific conditions.Expand Specific Solutions

Key Players in Jewelry Manufacturing

The jewelry crafting industry, particularly in the context of Accura 25 research, is experiencing a dynamic phase of growth and innovation. The market is expanding rapidly, driven by increasing demand for high-precision, customized jewelry pieces. Technological advancements are reshaping the competitive landscape, with companies like EOS GmbH and Element Six Ltd. leading in additive manufacturing and synthetic diamond production, respectively. Established luxury brands such as Hermès Sellier SAS and Louis Vuitton SA are integrating cutting-edge technologies to enhance their craftsmanship. The industry is witnessing a convergence of traditional artisanship and modern manufacturing techniques, with firms like Pandora Jewelry LLC and Titan Company Limited leveraging technology to scale production while maintaining quality. As the market matures, collaboration between technology providers and jewelry manufacturers is becoming crucial for driving innovation and maintaining competitive edge.

EOS GmbH

Technical Solution: EOS, a leader in industrial 3D printing, has applied its expertise to jewelry crafting through Accura 25 research. They have developed specialized metal powders and printing parameters optimized for jewelry production, allowing for intricate designs with minimal support structures[13]. EOS's Direct Metal Laser Sintering (DMLS) technology enables the creation of complex lattice structures and internal cavities, reducing weight while maintaining strength[14]. Their research extends to improving surface finish quality directly from the printer, reducing the need for extensive post-processing. EOS is also exploring multi-material printing capabilities, potentially allowing for the seamless integration of different metals or even gemstones within a single printing process[15].

Strengths: Unparalleled capabilities in complex geometry creation, potential for significant reduction in material waste, and high precision in large-scale production. Weaknesses: High equipment costs and the need for specialized expertise in operation and design for additive manufacturing.

Pandora Jewelry LLC

Technical Solution: Pandora's approach to Accura 25 centers on sustainable and ethical jewelry production. They have developed a proprietary recycling process for precious metals that maintains purity while reducing environmental impact[2]. In crafting, Pandora employs advanced CAD/CAM systems integrated with AI for design optimization, ensuring each piece meets strict quality standards while minimizing material use[4]. Their research extends to innovative stone-setting techniques that enhance durability without compromising aesthetics. Pandora is also exploring bio-based alternatives to traditional plastics used in some jewelry components, aligning with their sustainability goals[6].

Strengths: Strong focus on sustainability, efficient production processes, and consistent quality across large-scale manufacturing. Weaknesses: Limited application in high-end, unique piece creation, and potential challenges in maintaining artisanal appeal in mass-produced items.

Core Innovations in Accura 25

Process for the construction of precious objects and products obtained therewith

PatentWO2006105810A1

Innovation

- An industrial method involving the construction of hollow structures using noble metals or alloys followed by filling with polymer materials or their derivatives to enhance mechanical resistance and hardness, providing a feeling of fullness and reducing metal consumption.

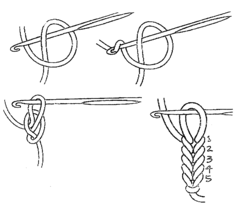

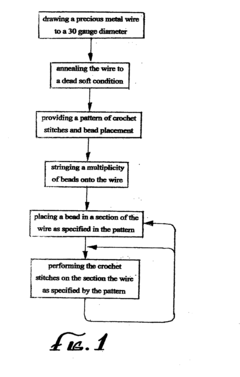

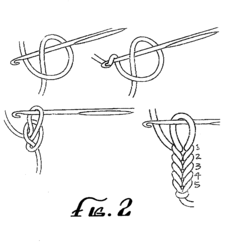

Metal crochet jewelry

PatentInactiveUS20060162164A1

Innovation

- The use of fully annealed 30 gauge precious metal wire, which is made more malleable and less prone to breakage through the annealing process, combined with specific crochet techniques and tools, such as a blunt-nosed needle, to create durable and aesthetically appealing jewelry components that can be mass-produced.

Material Sustainability in Jewelry Production

In the realm of jewelry production, material sustainability has become a paramount concern, driven by increasing environmental awareness and consumer demand for ethical products. The use of Accura 25 in jewelry crafting presents a significant opportunity to address these sustainability challenges while maintaining the high quality expected in luxury jewelry.

Accura 25, a photopolymer resin developed for stereolithography 3D printing, offers several advantages in terms of sustainability. Its precision and durability allow for the creation of intricate jewelry designs with minimal material waste, a stark contrast to traditional subtractive manufacturing methods. This efficiency in material use directly contributes to reduced environmental impact and resource conservation.

Furthermore, the adaptability of Accura 25 enables the integration of recycled materials into the jewelry production process. By incorporating recycled precious metals or gemstones into the resin matrix, jewelers can create pieces that blend sustainability with luxury. This approach not only reduces the demand for newly mined materials but also appeals to environmentally conscious consumers.

The longevity of jewelry pieces created with Accura 25 is another key factor in its sustainability profile. The material's resistance to wear and tear ensures that items maintain their appearance and structural integrity over time, reducing the need for frequent replacements and thereby minimizing the overall environmental footprint of jewelry consumption.

In terms of end-of-life considerations, Accura 25 presents both challenges and opportunities. While the material itself is not biodegradable, advancements in recycling technologies for photopolymers are opening new avenues for circular economy practices in jewelry production. Research into methods for breaking down and repurposing used Accura 25 items is ongoing, with promising results that could further enhance the material's sustainability credentials.

The adoption of Accura 25 in jewelry production also facilitates more sustainable manufacturing processes. The precision of 3D printing with this material allows for on-demand production, reducing inventory waste and the energy consumption associated with large-scale manufacturing. Additionally, the ability to create complex geometries with minimal support structures further minimizes material waste during the production process.

As the jewelry industry continues to evolve, the role of materials like Accura 25 in promoting sustainability cannot be overstated. By enabling more efficient use of resources, incorporating recycled materials, and supporting longer-lasting products, Accura 25 is poised to play a crucial role in the next level of sustainable jewelry crafting. The ongoing research and development in this area promise to unlock even greater potential for environmentally friendly luxury jewelry production in the years to come.

Accura 25, a photopolymer resin developed for stereolithography 3D printing, offers several advantages in terms of sustainability. Its precision and durability allow for the creation of intricate jewelry designs with minimal material waste, a stark contrast to traditional subtractive manufacturing methods. This efficiency in material use directly contributes to reduced environmental impact and resource conservation.

Furthermore, the adaptability of Accura 25 enables the integration of recycled materials into the jewelry production process. By incorporating recycled precious metals or gemstones into the resin matrix, jewelers can create pieces that blend sustainability with luxury. This approach not only reduces the demand for newly mined materials but also appeals to environmentally conscious consumers.

The longevity of jewelry pieces created with Accura 25 is another key factor in its sustainability profile. The material's resistance to wear and tear ensures that items maintain their appearance and structural integrity over time, reducing the need for frequent replacements and thereby minimizing the overall environmental footprint of jewelry consumption.

In terms of end-of-life considerations, Accura 25 presents both challenges and opportunities. While the material itself is not biodegradable, advancements in recycling technologies for photopolymers are opening new avenues for circular economy practices in jewelry production. Research into methods for breaking down and repurposing used Accura 25 items is ongoing, with promising results that could further enhance the material's sustainability credentials.

The adoption of Accura 25 in jewelry production also facilitates more sustainable manufacturing processes. The precision of 3D printing with this material allows for on-demand production, reducing inventory waste and the energy consumption associated with large-scale manufacturing. Additionally, the ability to create complex geometries with minimal support structures further minimizes material waste during the production process.

As the jewelry industry continues to evolve, the role of materials like Accura 25 in promoting sustainability cannot be overstated. By enabling more efficient use of resources, incorporating recycled materials, and supporting longer-lasting products, Accura 25 is poised to play a crucial role in the next level of sustainable jewelry crafting. The ongoing research and development in this area promise to unlock even greater potential for environmentally friendly luxury jewelry production in the years to come.

Accura 25 Quality Control Measures

Quality control measures are paramount in ensuring the consistent production of high-quality jewelry using Accura 25 resin. These measures encompass various stages of the manufacturing process, from material handling to final product inspection.

The first critical step in quality control is the proper storage and handling of Accura 25 resin. The material must be kept in a controlled environment with specific temperature and humidity ranges to maintain its optimal properties. Regular checks on storage conditions and expiration dates are essential to prevent the use of degraded materials.

Prior to production, thorough testing of each batch of Accura 25 resin is necessary. This includes viscosity tests, curing time assessments, and sample prints to verify material consistency. Any deviations from established standards must be addressed before proceeding with full-scale production.

During the 3D printing process, continuous monitoring of printing parameters is crucial. This involves real-time tracking of laser power, scanning speed, and layer thickness. Advanced monitoring systems can detect anomalies in the printing process and make automatic adjustments to maintain quality.

Post-printing, a series of quality checks are implemented. These include visual inspections for surface defects, dimensional accuracy measurements using high-precision tools, and non-destructive testing methods such as X-ray or CT scanning to detect internal flaws.

Mechanical properties of the printed jewelry pieces are rigorously tested. This includes strength tests, flexibility assessments, and durability evaluations to ensure the final products meet or exceed industry standards. Samples from each production batch undergo these tests to maintain consistency.

Surface finish quality is a critical aspect of jewelry production. Advanced polishing techniques and specialized equipment are employed to achieve the desired luster and smoothness. Quality control measures in this stage include surface roughness measurements and visual inspections under magnification.

Chemical resistance tests are conducted to ensure the jewelry can withstand exposure to common substances like perfumes, lotions, and cleaning agents. This involves subjecting sample pieces to various chemicals and monitoring for any adverse reactions or degradation.

Lastly, a final comprehensive inspection is performed on each piece before packaging. This includes checks for color consistency, proper assembly of components, and overall aesthetic quality. Any pieces that do not meet the stringent quality standards are rejected and recycled.

Implementing these rigorous quality control measures ensures that jewelry crafted with Accura 25 resin consistently meets the high standards expected in the luxury market, positioning it as a premium material for next-level jewelry crafting.

The first critical step in quality control is the proper storage and handling of Accura 25 resin. The material must be kept in a controlled environment with specific temperature and humidity ranges to maintain its optimal properties. Regular checks on storage conditions and expiration dates are essential to prevent the use of degraded materials.

Prior to production, thorough testing of each batch of Accura 25 resin is necessary. This includes viscosity tests, curing time assessments, and sample prints to verify material consistency. Any deviations from established standards must be addressed before proceeding with full-scale production.

During the 3D printing process, continuous monitoring of printing parameters is crucial. This involves real-time tracking of laser power, scanning speed, and layer thickness. Advanced monitoring systems can detect anomalies in the printing process and make automatic adjustments to maintain quality.

Post-printing, a series of quality checks are implemented. These include visual inspections for surface defects, dimensional accuracy measurements using high-precision tools, and non-destructive testing methods such as X-ray or CT scanning to detect internal flaws.

Mechanical properties of the printed jewelry pieces are rigorously tested. This includes strength tests, flexibility assessments, and durability evaluations to ensure the final products meet or exceed industry standards. Samples from each production batch undergo these tests to maintain consistency.

Surface finish quality is a critical aspect of jewelry production. Advanced polishing techniques and specialized equipment are employed to achieve the desired luster and smoothness. Quality control measures in this stage include surface roughness measurements and visual inspections under magnification.

Chemical resistance tests are conducted to ensure the jewelry can withstand exposure to common substances like perfumes, lotions, and cleaning agents. This involves subjecting sample pieces to various chemicals and monitoring for any adverse reactions or degradation.

Lastly, a final comprehensive inspection is performed on each piece before packaging. This includes checks for color consistency, proper assembly of components, and overall aesthetic quality. Any pieces that do not meet the stringent quality standards are rejected and recycled.

Implementing these rigorous quality control measures ensures that jewelry crafted with Accura 25 resin consistently meets the high standards expected in the luxury market, positioning it as a premium material for next-level jewelry crafting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!