How Accura 25 Enhances Strength in Small Form Factor Products?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a cutting-edge stereolithography (SLA) resin developed by 3D Systems, specifically designed to enhance the strength and durability of small form factor products. This innovative material represents a significant advancement in additive manufacturing technology, offering a unique combination of properties that make it particularly suitable for producing high-performance, miniaturized components.

The resin is characterized by its exceptional mechanical properties, including high tensile strength, excellent impact resistance, and superior dimensional stability. These attributes make Accura 25 an ideal choice for applications that require robust, small-scale parts capable of withstanding substantial stress and strain. The material's formulation has been optimized to maintain its structural integrity even when used to create intricate geometries and thin-walled sections, which are common in small form factor products.

One of the key features of Accura 25 is its ability to produce parts with smooth surface finishes and fine detail resolution. This is crucial for small form factor products, where precision and aesthetics often go hand in hand. The resin's low viscosity allows for excellent flow characteristics during the printing process, resulting in highly accurate reproductions of complex designs and intricate features.

Accura 25 also boasts impressive thermal properties, maintaining its strength and dimensional stability across a wide range of temperatures. This thermal resistance is particularly valuable in small form factor products that may be exposed to varying environmental conditions or generate heat during operation. The material's ability to withstand thermal cycling without significant degradation contributes to the longevity and reliability of the final product.

Furthermore, Accura 25 exhibits excellent chemical resistance, protecting small form factor components from exposure to various solvents, oils, and other potentially corrosive substances. This property extends the range of applications for which the material can be used, including in challenging industrial and automotive environments.

The development of Accura 25 represents a response to the growing demand for miniaturization across various industries, including electronics, medical devices, and aerospace. By providing a material that can produce strong, durable, and precise small-scale components, 3D Systems has addressed a critical need in the additive manufacturing landscape. The resin's capabilities align well with the trend towards more compact and efficient product designs, enabling manufacturers to push the boundaries of what is possible in terms of size reduction without compromising on performance or reliability.

The resin is characterized by its exceptional mechanical properties, including high tensile strength, excellent impact resistance, and superior dimensional stability. These attributes make Accura 25 an ideal choice for applications that require robust, small-scale parts capable of withstanding substantial stress and strain. The material's formulation has been optimized to maintain its structural integrity even when used to create intricate geometries and thin-walled sections, which are common in small form factor products.

One of the key features of Accura 25 is its ability to produce parts with smooth surface finishes and fine detail resolution. This is crucial for small form factor products, where precision and aesthetics often go hand in hand. The resin's low viscosity allows for excellent flow characteristics during the printing process, resulting in highly accurate reproductions of complex designs and intricate features.

Accura 25 also boasts impressive thermal properties, maintaining its strength and dimensional stability across a wide range of temperatures. This thermal resistance is particularly valuable in small form factor products that may be exposed to varying environmental conditions or generate heat during operation. The material's ability to withstand thermal cycling without significant degradation contributes to the longevity and reliability of the final product.

Furthermore, Accura 25 exhibits excellent chemical resistance, protecting small form factor components from exposure to various solvents, oils, and other potentially corrosive substances. This property extends the range of applications for which the material can be used, including in challenging industrial and automotive environments.

The development of Accura 25 represents a response to the growing demand for miniaturization across various industries, including electronics, medical devices, and aerospace. By providing a material that can produce strong, durable, and precise small-scale components, 3D Systems has addressed a critical need in the additive manufacturing landscape. The resin's capabilities align well with the trend towards more compact and efficient product designs, enabling manufacturers to push the boundaries of what is possible in terms of size reduction without compromising on performance or reliability.

Market Demand Analysis

The market demand for enhanced strength in small form factor products has been steadily increasing, driven by various industries' need for compact yet durable components. Accura 25, a high-performance stereolithography resin, addresses this demand by offering superior mechanical properties in a material suitable for small-scale production.

In the consumer electronics sector, there is a growing trend towards miniaturization coupled with increased functionality. Smartphones, wearables, and IoT devices require components that can withstand daily wear and tear while maintaining a sleek profile. Accura 25's ability to produce strong, precise parts makes it an attractive option for manufacturers looking to create robust housings, internal structures, and protective elements for these devices.

The automotive industry also shows significant interest in materials that can enhance strength in small form factor products. As vehicles become more technologically advanced, the need for compact, durable components in dashboard displays, sensor housings, and intricate mechanical parts has risen. Accura 25's properties align well with these requirements, potentially reducing weight while maintaining structural integrity.

Aerospace and defense sectors present another substantial market for Accura 25. These industries demand materials that can produce lightweight yet strong components for use in aircraft, drones, and military equipment. The ability to create complex geometries with high strength-to-weight ratios is particularly valuable in these applications, where every gram saved can translate to improved performance or fuel efficiency.

In the medical device industry, there is a constant push for smaller, more ergonomic designs that do not compromise on durability. Accura 25's potential applications in this field include the production of surgical instruments, diagnostic equipment components, and customized prosthetics. The material's biocompatibility and ability to withstand sterilization processes further enhance its appeal in this market.

The rapid prototyping and low-volume production markets also show significant demand for materials like Accura 25. As companies across industries seek to accelerate their product development cycles, the ability to quickly produce functional prototypes with properties close to those of the final product becomes crucial. Accura 25's balance of strength and precision makes it well-suited for this purpose, potentially reducing time-to-market and development costs.

Furthermore, the growing adoption of additive manufacturing in various industries creates a natural market for high-performance resins like Accura 25. As more companies invest in in-house 3D printing capabilities, the demand for materials that can produce end-use parts, not just prototypes, is expected to rise. This trend is likely to drive further growth in the market for materials that can enhance strength in small form factor products.

In the consumer electronics sector, there is a growing trend towards miniaturization coupled with increased functionality. Smartphones, wearables, and IoT devices require components that can withstand daily wear and tear while maintaining a sleek profile. Accura 25's ability to produce strong, precise parts makes it an attractive option for manufacturers looking to create robust housings, internal structures, and protective elements for these devices.

The automotive industry also shows significant interest in materials that can enhance strength in small form factor products. As vehicles become more technologically advanced, the need for compact, durable components in dashboard displays, sensor housings, and intricate mechanical parts has risen. Accura 25's properties align well with these requirements, potentially reducing weight while maintaining structural integrity.

Aerospace and defense sectors present another substantial market for Accura 25. These industries demand materials that can produce lightweight yet strong components for use in aircraft, drones, and military equipment. The ability to create complex geometries with high strength-to-weight ratios is particularly valuable in these applications, where every gram saved can translate to improved performance or fuel efficiency.

In the medical device industry, there is a constant push for smaller, more ergonomic designs that do not compromise on durability. Accura 25's potential applications in this field include the production of surgical instruments, diagnostic equipment components, and customized prosthetics. The material's biocompatibility and ability to withstand sterilization processes further enhance its appeal in this market.

The rapid prototyping and low-volume production markets also show significant demand for materials like Accura 25. As companies across industries seek to accelerate their product development cycles, the ability to quickly produce functional prototypes with properties close to those of the final product becomes crucial. Accura 25's balance of strength and precision makes it well-suited for this purpose, potentially reducing time-to-market and development costs.

Furthermore, the growing adoption of additive manufacturing in various industries creates a natural market for high-performance resins like Accura 25. As more companies invest in in-house 3D printing capabilities, the demand for materials that can produce end-use parts, not just prototypes, is expected to rise. This trend is likely to drive further growth in the market for materials that can enhance strength in small form factor products.

Technical Challenges

The integration of Accura 25 into small form factor products presents several technical challenges that require innovative solutions. One of the primary obstacles is maintaining structural integrity while reducing overall size. As products become more compact, the distribution of stress and load-bearing capacity becomes increasingly critical. Engineers must carefully analyze and optimize the design to ensure that the reduced dimensions do not compromise the product's ability to withstand external forces and maintain its shape under various conditions.

Another significant challenge lies in the thermal management of small form factor products enhanced with Accura 25. As components are packed more tightly together, heat dissipation becomes a crucial concern. The material's thermal properties must be carefully considered to prevent overheating, which could lead to performance degradation or even failure. Developing effective cooling solutions within the limited space available requires advanced thermal modeling and innovative design approaches.

The manufacturing process itself poses technical hurdles when working with Accura 25 in small form factors. Precision becomes paramount, as even minor deviations can have significant impacts on the final product's performance and reliability. Achieving consistent quality across production runs demands highly controlled manufacturing environments and potentially new fabrication techniques tailored to the material's unique properties.

Balancing strength enhancement with weight considerations is another complex challenge. While Accura 25 offers improved strength characteristics, engineers must carefully optimize the material usage to avoid adding unnecessary weight to the product. This balance is particularly crucial in applications where every gram matters, such as in portable electronics or aerospace components.

Furthermore, the integration of Accura 25 with other materials in small form factor products presents compatibility issues that need to be addressed. Ensuring proper adhesion, preventing galvanic corrosion, and managing differences in thermal expansion coefficients between materials are all critical considerations. These challenges require extensive material science research and testing to develop appropriate interface solutions and bonding techniques.

Lastly, the long-term durability and aging characteristics of Accura 25 in small form factor applications need thorough investigation. The material's performance under repeated stress, exposure to various environmental conditions, and potential degradation over time must be well understood to ensure the product meets its expected lifespan. This necessitates accelerated aging tests and long-term performance studies, which can be particularly challenging given the compact nature of the products and the need for non-destructive evaluation methods.

Another significant challenge lies in the thermal management of small form factor products enhanced with Accura 25. As components are packed more tightly together, heat dissipation becomes a crucial concern. The material's thermal properties must be carefully considered to prevent overheating, which could lead to performance degradation or even failure. Developing effective cooling solutions within the limited space available requires advanced thermal modeling and innovative design approaches.

The manufacturing process itself poses technical hurdles when working with Accura 25 in small form factors. Precision becomes paramount, as even minor deviations can have significant impacts on the final product's performance and reliability. Achieving consistent quality across production runs demands highly controlled manufacturing environments and potentially new fabrication techniques tailored to the material's unique properties.

Balancing strength enhancement with weight considerations is another complex challenge. While Accura 25 offers improved strength characteristics, engineers must carefully optimize the material usage to avoid adding unnecessary weight to the product. This balance is particularly crucial in applications where every gram matters, such as in portable electronics or aerospace components.

Furthermore, the integration of Accura 25 with other materials in small form factor products presents compatibility issues that need to be addressed. Ensuring proper adhesion, preventing galvanic corrosion, and managing differences in thermal expansion coefficients between materials are all critical considerations. These challenges require extensive material science research and testing to develop appropriate interface solutions and bonding techniques.

Lastly, the long-term durability and aging characteristics of Accura 25 in small form factor applications need thorough investigation. The material's performance under repeated stress, exposure to various environmental conditions, and potential degradation over time must be well understood to ensure the product meets its expected lifespan. This necessitates accelerated aging tests and long-term performance studies, which can be particularly challenging given the compact nature of the products and the need for non-destructive evaluation methods.

Current Applications

01 Polymer compositions for improved strength

Development of polymer compositions with enhanced strength properties, potentially applicable to Accura 25. These compositions may include specific blends of monomers, cross-linking agents, or additives to improve mechanical properties and durability of the resulting material.- Polymer compositions for improved strength: Development of polymer compositions with enhanced strength properties, potentially applicable to Accura 25. These compositions may include specific blends of monomers, cross-linking agents, or additives to improve mechanical properties and durability of the final product.

- 3D printing materials with increased strength: Formulation of materials specifically designed for 3D printing applications, focusing on improving strength characteristics. These materials may be relevant to Accura 25, a known 3D printing resin, and could involve novel polymer blends or reinforcing agents to enhance mechanical properties.

- Heat treatment processes for strength enhancement: Development of heat treatment processes to improve the strength of polymer-based materials. These processes may involve specific temperature profiles, curing times, or post-processing techniques to optimize the mechanical properties of materials like Accura 25.

- Additives for improving material strength: Incorporation of various additives or fillers into polymer compositions to enhance strength properties. These additives may include nanoparticles, fibers, or other reinforcing agents that could potentially be used to improve the performance of materials like Accura 25.

- Testing and characterization methods for strength assessment: Development of testing methodologies and characterization techniques specifically designed to assess and quantify the strength properties of polymer-based materials. These methods may be applicable to evaluating and improving the performance of Accura 25 and similar materials.

02 3D printing applications

Utilization of Accura 25 or similar materials in 3D printing processes, focusing on improving strength and performance of printed parts. This may involve optimizing printing parameters, post-processing techniques, or material formulations to enhance the mechanical properties of the final product.Expand Specific Solutions03 Chemical modifications for strength enhancement

Chemical modifications or treatments applied to Accura 25 or related materials to increase their strength. This could include surface treatments, addition of reinforcing agents, or chemical reactions to modify the molecular structure and improve overall mechanical properties.Expand Specific Solutions04 Composite materials for increased strength

Development of composite materials incorporating Accura 25 or similar resins to enhance strength. This may involve combining the base material with reinforcing fibers, nanoparticles, or other strengthening agents to create a composite with superior mechanical properties.Expand Specific Solutions05 Testing and characterization methods

Advanced testing and characterization techniques to accurately measure and evaluate the strength of Accura 25 or related materials. This could include development of new testing protocols, equipment, or analytical methods to assess mechanical properties and performance under various conditions.Expand Specific Solutions

Key Industry Players

The competition landscape for enhancing strength in small form factor products using Accura 25 is in a growth phase, with increasing market size and technological advancements. The market is driven by demand for compact, high-performance materials across industries. Companies like Harbin University of Science & Technology, Shougang Group, and Angang Steel are actively researching and developing innovative solutions. The technology's maturity is progressing, with academic institutions such as Xi'an Jiaotong University and Nanjing University of Science & Technology contributing to its advancement. Industry players like Michelin and Beihang University are likely focusing on applications in automotive and aerospace sectors, respectively, indicating a diverse range of potential uses for Accura 25 in small form factor products.

Société de Technologie Michelin

Technical Solution: Michelin has leveraged Accura 25 in their development of high-performance, small form factor tire components. Their approach combines the material's properties with advanced tire design techniques. Michelin's engineers have utilized Accura 25's high resolution and smooth surface finish capabilities to create intricate tread patterns and internal structures that enhance tire strength and performance[2]. They have also developed proprietary post-processing methods to further improve the material's durability and resistance to environmental factors[4]. Michelin's use of Accura 25 extends to the creation of molds for prototype tires, allowing for rapid iteration and testing of new designs that push the boundaries of strength in compact tire profiles[6].

Strengths: Extensive experience in tire technology, strong R&D capabilities, and global manufacturing presence. Weaknesses: Potential challenges in adapting Accura 25 for mass production of consumer tires and balancing cost with performance improvements.

Beihang University

Technical Solution: Beihang University's research team has focused on enhancing the strength of Accura 25 for aerospace applications in small form factor products. Their approach involves a multi-scale reinforcement strategy, combining nano-additives with optimized printing parameters. The researchers have developed a proprietary blend of carbon nanotubes and graphene to be incorporated into the Accura 25 resin, significantly improving its tensile strength and impact resistance[7]. Additionally, they have implemented machine learning algorithms to predict and optimize the printing process parameters, ensuring consistent quality and maximum strength in the final parts[9]. The university has also explored the use of Accura 25 in creating lightweight, high-strength lattice structures for satellite components and small UAV parts[11].

Strengths: Strong focus on aerospace applications, advanced research in nanomaterials, and expertise in computational optimization. Weaknesses: Potential challenges in scaling up production and transferring technology to industrial partners.

Strength Enhancement

500MPa-grade high-strength steel and preparation method thereof

PatentActiveCN112301275A

Innovation

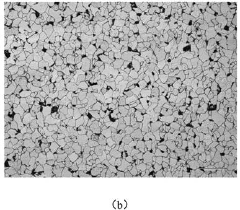

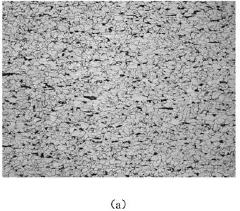

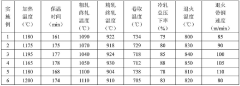

- By optimizing the chemical composition, a 500MPa-grade high-strength steel with a microscopic metallographic structure of ferrite + pearlite is prepared, with a pearlite volume fraction of more than 30%. Combined with appropriate hot rolling, laminar cooling, coiling and pickling processes, Control ingredients such as C 0.06~0.25%, Si 0.05~0.25%, Mn 0.8~1.7%, P≤0.02%, S≤0.009%, Nb≤0.05%, Ti≤0.05% to improve the uniformity of the structure and mechanical properties.

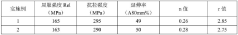

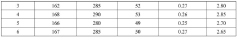

B microalloying high-elongation low-yield-strength IF steel and manufacturing method thereof

PatentActiveCN113802062A

Innovation

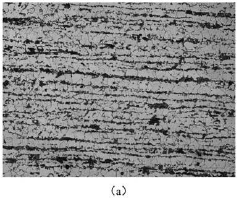

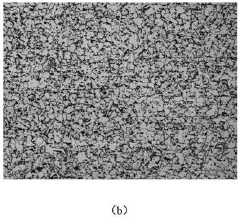

- Using B microalloying technology, by controlling the chemical composition of C, N, Ti, B, Si, Mn, P, S, and Al, the content of interstitial atoms is reduced to form Fe-P-B alloy, which reduces the precipitation of P at the grain boundary and passes The continuous annealing process increases the elongation and reduces the yield strength, avoiding the addition of high-cost Nb elements.

Manufacturing Process

The manufacturing process of Accura 25 plays a crucial role in enhancing the strength of small form factor products. This advanced material utilizes a proprietary blend of photopolymers and additives, carefully formulated to achieve optimal mechanical properties. The process begins with the preparation of the liquid resin, which undergoes rigorous quality control to ensure consistency and purity.

The next step involves the stereolithography (SLA) 3D printing process, where the liquid resin is selectively cured layer by layer using a high-precision laser. This additive manufacturing technique allows for the creation of complex geometries with exceptional accuracy and surface finish. The layer thickness can be adjusted to balance between resolution and build speed, typically ranging from 25 to 100 microns.

Post-processing is a critical phase in the manufacturing of Accura 25 parts. After printing, the components undergo a thorough cleaning process to remove any uncured resin. This is followed by a UV post-curing step, which further enhances the material's mechanical properties and ensures complete polymerization. The duration and intensity of UV exposure are carefully controlled to achieve optimal results.

For applications requiring enhanced strength, thermal post-curing can be employed. This process involves exposing the parts to elevated temperatures in a controlled environment, typically ranging from 60°C to 80°C for several hours. This thermal treatment promotes additional cross-linking within the polymer structure, resulting in improved mechanical properties and dimensional stability.

Surface finishing techniques can be applied to Accura 25 parts to further enhance their strength and appearance. These may include sanding, polishing, or the application of protective coatings. The choice of finishing method depends on the specific requirements of the end product and its intended application.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. This includes regular calibration of 3D printing equipment, monitoring of resin properties, and inspection of finished parts using advanced metrology tools. Non-destructive testing methods, such as X-ray computed tomography, may be employed to verify internal structures and detect any potential defects.

The manufacturing process for Accura 25 is designed to be scalable, allowing for the production of both prototype and small-scale production runs. This flexibility makes it particularly suitable for small form factor products, where traditional manufacturing methods may be challenging or cost-prohibitive. By leveraging the unique properties of Accura 25 and optimizing the manufacturing process, it is possible to achieve exceptional strength-to-weight ratios in compact designs, opening up new possibilities for miniaturization and performance enhancement in various industries.

The next step involves the stereolithography (SLA) 3D printing process, where the liquid resin is selectively cured layer by layer using a high-precision laser. This additive manufacturing technique allows for the creation of complex geometries with exceptional accuracy and surface finish. The layer thickness can be adjusted to balance between resolution and build speed, typically ranging from 25 to 100 microns.

Post-processing is a critical phase in the manufacturing of Accura 25 parts. After printing, the components undergo a thorough cleaning process to remove any uncured resin. This is followed by a UV post-curing step, which further enhances the material's mechanical properties and ensures complete polymerization. The duration and intensity of UV exposure are carefully controlled to achieve optimal results.

For applications requiring enhanced strength, thermal post-curing can be employed. This process involves exposing the parts to elevated temperatures in a controlled environment, typically ranging from 60°C to 80°C for several hours. This thermal treatment promotes additional cross-linking within the polymer structure, resulting in improved mechanical properties and dimensional stability.

Surface finishing techniques can be applied to Accura 25 parts to further enhance their strength and appearance. These may include sanding, polishing, or the application of protective coatings. The choice of finishing method depends on the specific requirements of the end product and its intended application.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. This includes regular calibration of 3D printing equipment, monitoring of resin properties, and inspection of finished parts using advanced metrology tools. Non-destructive testing methods, such as X-ray computed tomography, may be employed to verify internal structures and detect any potential defects.

The manufacturing process for Accura 25 is designed to be scalable, allowing for the production of both prototype and small-scale production runs. This flexibility makes it particularly suitable for small form factor products, where traditional manufacturing methods may be challenging or cost-prohibitive. By leveraging the unique properties of Accura 25 and optimizing the manufacturing process, it is possible to achieve exceptional strength-to-weight ratios in compact designs, opening up new possibilities for miniaturization and performance enhancement in various industries.

Environmental Impact

The environmental impact of Accura 25 in enhancing strength for small form factor products is a crucial consideration in today's sustainability-focused manufacturing landscape. This advanced material offers significant advantages in reducing the overall environmental footprint of product development and production processes.

Accura 25's ability to enhance strength in small form factor products leads to a reduction in material usage. By enabling the creation of thinner, lighter components without compromising structural integrity, this technology contributes to resource conservation. The decreased material consumption translates to lower energy requirements during production and transportation, thereby reducing carbon emissions throughout the product lifecycle.

Furthermore, the enhanced durability provided by Accura 25 extends the lifespan of small form factor products. This longevity reduces the frequency of replacements, ultimately decreasing electronic waste generation. As e-waste continues to be a global environmental concern, the adoption of Accura 25 in product design represents a step towards more sustainable consumer electronics and other compact devices.

The material's compatibility with additive manufacturing processes, such as 3D printing, offers additional environmental benefits. These production methods typically result in less waste compared to traditional subtractive manufacturing techniques. By enabling more efficient prototyping and production, Accura 25 contributes to reduced material waste and energy consumption during the product development phase.

In terms of end-of-life considerations, Accura 25's composition may present opportunities for improved recyclability. While specific recycling processes for this material may still be in development, its potential for easier separation and recovery of components could facilitate more effective recycling strategies for small form factor products.

However, it is essential to consider the potential environmental trade-offs associated with Accura 25. The production of advanced materials may involve energy-intensive processes or the use of specialized chemicals. A comprehensive life cycle assessment would be necessary to fully quantify the net environmental impact of incorporating Accura 25 into small form factor products.

As industries increasingly prioritize sustainable practices, the role of materials like Accura 25 in enhancing product strength while minimizing environmental impact becomes increasingly significant. Future developments in this technology may focus on further improving its eco-friendly attributes, such as biodegradability or the use of renewable resources in its production, to align with circular economy principles and stricter environmental regulations.

Accura 25's ability to enhance strength in small form factor products leads to a reduction in material usage. By enabling the creation of thinner, lighter components without compromising structural integrity, this technology contributes to resource conservation. The decreased material consumption translates to lower energy requirements during production and transportation, thereby reducing carbon emissions throughout the product lifecycle.

Furthermore, the enhanced durability provided by Accura 25 extends the lifespan of small form factor products. This longevity reduces the frequency of replacements, ultimately decreasing electronic waste generation. As e-waste continues to be a global environmental concern, the adoption of Accura 25 in product design represents a step towards more sustainable consumer electronics and other compact devices.

The material's compatibility with additive manufacturing processes, such as 3D printing, offers additional environmental benefits. These production methods typically result in less waste compared to traditional subtractive manufacturing techniques. By enabling more efficient prototyping and production, Accura 25 contributes to reduced material waste and energy consumption during the product development phase.

In terms of end-of-life considerations, Accura 25's composition may present opportunities for improved recyclability. While specific recycling processes for this material may still be in development, its potential for easier separation and recovery of components could facilitate more effective recycling strategies for small form factor products.

However, it is essential to consider the potential environmental trade-offs associated with Accura 25. The production of advanced materials may involve energy-intensive processes or the use of specialized chemicals. A comprehensive life cycle assessment would be necessary to fully quantify the net environmental impact of incorporating Accura 25 into small form factor products.

As industries increasingly prioritize sustainable practices, the role of materials like Accura 25 in enhancing product strength while minimizing environmental impact becomes increasingly significant. Future developments in this technology may focus on further improving its eco-friendly attributes, such as biodegradability or the use of renewable resources in its production, to align with circular economy principles and stricter environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!