Accura 25 for Cutting-Edge Commercial Applications

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a high-performance stereolithography resin developed by 3D Systems, specifically designed for use in their SLA (Stereolithography) 3D printing systems. This advanced material has gained significant attention in the additive manufacturing industry due to its exceptional properties and versatile applications in cutting-edge commercial sectors.

The resin is characterized by its outstanding clarity, durability, and dimensional stability, making it an ideal choice for producing transparent parts with high accuracy and fine detail. Accura 25 exhibits excellent resistance to humidity and moisture absorption, ensuring that printed parts maintain their structural integrity and optical properties over time. This feature is particularly valuable in industries where long-term performance and reliability are critical.

One of the key advantages of Accura 25 is its ability to produce parts with smooth surfaces and minimal post-processing requirements. The material's low viscosity allows for easy flow and self-leveling during the printing process, resulting in high-quality finishes straight off the printer. This characteristic significantly reduces the time and effort required for post-processing, making it an efficient choice for commercial applications where rapid prototyping and production are essential.

In terms of mechanical properties, Accura 25 offers a balanced combination of strength and flexibility. The material demonstrates good impact resistance and elongation at break, allowing for the creation of functional prototypes and end-use parts that can withstand real-world stresses. Its thermal properties also make it suitable for applications involving moderate heat exposure, expanding its potential use cases across various industries.

The optical clarity of Accura 25 is one of its standout features, with a refractive index similar to that of glass. This property makes it an excellent choice for applications in the automotive, aerospace, and consumer electronics industries, where transparent components are often required for visual inspection, light transmission, or aesthetic purposes. The material's ability to maintain clarity even in thick sections opens up new possibilities for complex optical designs and innovative product development.

From a manufacturing perspective, Accura 25 offers good processability and compatibility with 3D Systems' SLA printers. Its formulation allows for fast printing speeds and high resolution, enabling the production of intricate geometries and fine details that are challenging to achieve with traditional manufacturing methods. This capability is particularly valuable in industries such as medical device manufacturing, where precise, customized components are often needed.

As the demand for advanced materials in additive manufacturing continues to grow, Accura 25 positions itself as a versatile solution for a wide range of commercial applications. Its unique combination of optical clarity, mechanical strength, and ease of use makes it a compelling choice for businesses looking to leverage the benefits of 3D printing technology in their product development and manufacturing processes.

The resin is characterized by its outstanding clarity, durability, and dimensional stability, making it an ideal choice for producing transparent parts with high accuracy and fine detail. Accura 25 exhibits excellent resistance to humidity and moisture absorption, ensuring that printed parts maintain their structural integrity and optical properties over time. This feature is particularly valuable in industries where long-term performance and reliability are critical.

One of the key advantages of Accura 25 is its ability to produce parts with smooth surfaces and minimal post-processing requirements. The material's low viscosity allows for easy flow and self-leveling during the printing process, resulting in high-quality finishes straight off the printer. This characteristic significantly reduces the time and effort required for post-processing, making it an efficient choice for commercial applications where rapid prototyping and production are essential.

In terms of mechanical properties, Accura 25 offers a balanced combination of strength and flexibility. The material demonstrates good impact resistance and elongation at break, allowing for the creation of functional prototypes and end-use parts that can withstand real-world stresses. Its thermal properties also make it suitable for applications involving moderate heat exposure, expanding its potential use cases across various industries.

The optical clarity of Accura 25 is one of its standout features, with a refractive index similar to that of glass. This property makes it an excellent choice for applications in the automotive, aerospace, and consumer electronics industries, where transparent components are often required for visual inspection, light transmission, or aesthetic purposes. The material's ability to maintain clarity even in thick sections opens up new possibilities for complex optical designs and innovative product development.

From a manufacturing perspective, Accura 25 offers good processability and compatibility with 3D Systems' SLA printers. Its formulation allows for fast printing speeds and high resolution, enabling the production of intricate geometries and fine details that are challenging to achieve with traditional manufacturing methods. This capability is particularly valuable in industries such as medical device manufacturing, where precise, customized components are often needed.

As the demand for advanced materials in additive manufacturing continues to grow, Accura 25 positions itself as a versatile solution for a wide range of commercial applications. Its unique combination of optical clarity, mechanical strength, and ease of use makes it a compelling choice for businesses looking to leverage the benefits of 3D printing technology in their product development and manufacturing processes.

Market Demand Analysis

The market demand for Accura 25, a high-performance stereolithography resin, has been steadily growing in cutting-edge commercial applications. This advanced material is particularly sought after in industries requiring precise, durable, and high-quality 3D printed parts, such as aerospace, automotive, and medical device manufacturing.

In the aerospace sector, there is an increasing need for lightweight yet robust components that can withstand extreme conditions. Accura 25's unique properties, including its high heat deflection temperature and excellent dimensional stability, make it an ideal choice for prototyping and producing functional parts for aircraft and spacecraft. The global aerospace 3D printing market is expected to expand significantly in the coming years, driving demand for advanced materials like Accura 25.

The automotive industry is another key driver of market demand for Accura 25. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are turning to advanced 3D printing materials for rapid prototyping and small-scale production of complex parts. Accura 25's ability to produce smooth, accurate, and durable components aligns well with the industry's requirements for both aesthetic and functional applications.

In the medical device sector, the demand for customized and patient-specific solutions is fueling the adoption of 3D printing technologies. Accura 25's biocompatibility and ability to produce intricate, high-resolution parts make it particularly valuable for creating surgical guides, anatomical models, and even certain implantable devices. The growing trend towards personalized medicine is expected to further boost the demand for materials like Accura 25 in this sector.

The electronics industry is also showing increased interest in Accura 25 for applications such as rapid prototyping of casings, connectors, and other components. The material's electrical properties and dimensional accuracy make it suitable for creating functional prototypes and low-volume production parts in this fast-paced sector.

As additive manufacturing continues to evolve from a prototyping technology to a viable production method, the demand for high-performance materials like Accura 25 is expected to grow across various industries. The global 3D printing materials market is projected to expand at a compound annual growth rate of over 20% in the next five years, with photopolymers like Accura 25 playing a significant role in this growth.

The increasing adoption of Industry 4.0 principles and the push towards more agile and localized manufacturing are also contributing to the rising demand for advanced 3D printing materials. Accura 25's versatility and performance characteristics position it well to meet the needs of companies looking to implement flexible and responsive production systems.

In the aerospace sector, there is an increasing need for lightweight yet robust components that can withstand extreme conditions. Accura 25's unique properties, including its high heat deflection temperature and excellent dimensional stability, make it an ideal choice for prototyping and producing functional parts for aircraft and spacecraft. The global aerospace 3D printing market is expected to expand significantly in the coming years, driving demand for advanced materials like Accura 25.

The automotive industry is another key driver of market demand for Accura 25. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are turning to advanced 3D printing materials for rapid prototyping and small-scale production of complex parts. Accura 25's ability to produce smooth, accurate, and durable components aligns well with the industry's requirements for both aesthetic and functional applications.

In the medical device sector, the demand for customized and patient-specific solutions is fueling the adoption of 3D printing technologies. Accura 25's biocompatibility and ability to produce intricate, high-resolution parts make it particularly valuable for creating surgical guides, anatomical models, and even certain implantable devices. The growing trend towards personalized medicine is expected to further boost the demand for materials like Accura 25 in this sector.

The electronics industry is also showing increased interest in Accura 25 for applications such as rapid prototyping of casings, connectors, and other components. The material's electrical properties and dimensional accuracy make it suitable for creating functional prototypes and low-volume production parts in this fast-paced sector.

As additive manufacturing continues to evolve from a prototyping technology to a viable production method, the demand for high-performance materials like Accura 25 is expected to grow across various industries. The global 3D printing materials market is projected to expand at a compound annual growth rate of over 20% in the next five years, with photopolymers like Accura 25 playing a significant role in this growth.

The increasing adoption of Industry 4.0 principles and the push towards more agile and localized manufacturing are also contributing to the rising demand for advanced 3D printing materials. Accura 25's versatility and performance characteristics position it well to meet the needs of companies looking to implement flexible and responsive production systems.

Technical Challenges

Accura 25, a high-performance stereolithography resin, faces several technical challenges in its application for cutting-edge commercial uses. One of the primary obstacles is achieving consistent dimensional accuracy across various part geometries and sizes. While Accura 25 offers excellent resolution for small, intricate features, maintaining this precision for larger components or complex structures remains challenging. This inconsistency can lead to issues in fit and function, particularly in industries requiring tight tolerances.

Another significant challenge lies in the material's long-term stability and durability. Although Accura 25 exhibits good initial mechanical properties, its performance under prolonged exposure to environmental factors such as UV light, humidity, and temperature fluctuations needs improvement. This limitation restricts its use in outdoor applications or in environments with harsh conditions, potentially limiting its commercial viability in certain sectors.

The post-processing requirements of Accura 25 present additional technical hurdles. The need for careful cleaning, curing, and finishing to achieve optimal mechanical properties and surface quality can be time-consuming and labor-intensive. This aspect not only impacts production efficiency but also introduces variability in the final product quality, which is critical for commercial applications demanding consistency and reliability.

Furthermore, the biocompatibility of Accura 25 remains a concern for certain medical and consumer product applications. While the material has shown promise in prototyping for these industries, its long-term safety and compatibility with biological systems require further research and validation. This limitation currently restricts its use in direct-contact medical devices or food-related applications.

The material's thermal properties also pose challenges for some cutting-edge applications. Accura 25's relatively low heat deflection temperature limits its use in environments or applications involving elevated temperatures. This characteristic narrows its potential in automotive, aerospace, or industrial sectors where heat resistance is crucial.

Lastly, the balance between the material's optical clarity and its mechanical strength presents a technical dilemma. While Accura 25 offers good transparency, enhancing this property often comes at the cost of reduced mechanical performance. Finding the optimal balance to meet both optical and structural requirements for advanced commercial applications remains a significant challenge, particularly in industries such as automotive lighting or consumer electronics where both aesthetics and functionality are paramount.

Another significant challenge lies in the material's long-term stability and durability. Although Accura 25 exhibits good initial mechanical properties, its performance under prolonged exposure to environmental factors such as UV light, humidity, and temperature fluctuations needs improvement. This limitation restricts its use in outdoor applications or in environments with harsh conditions, potentially limiting its commercial viability in certain sectors.

The post-processing requirements of Accura 25 present additional technical hurdles. The need for careful cleaning, curing, and finishing to achieve optimal mechanical properties and surface quality can be time-consuming and labor-intensive. This aspect not only impacts production efficiency but also introduces variability in the final product quality, which is critical for commercial applications demanding consistency and reliability.

Furthermore, the biocompatibility of Accura 25 remains a concern for certain medical and consumer product applications. While the material has shown promise in prototyping for these industries, its long-term safety and compatibility with biological systems require further research and validation. This limitation currently restricts its use in direct-contact medical devices or food-related applications.

The material's thermal properties also pose challenges for some cutting-edge applications. Accura 25's relatively low heat deflection temperature limits its use in environments or applications involving elevated temperatures. This characteristic narrows its potential in automotive, aerospace, or industrial sectors where heat resistance is crucial.

Lastly, the balance between the material's optical clarity and its mechanical strength presents a technical dilemma. While Accura 25 offers good transparency, enhancing this property often comes at the cost of reduced mechanical performance. Finding the optimal balance to meet both optical and structural requirements for advanced commercial applications remains a significant challenge, particularly in industries such as automotive lighting or consumer electronics where both aesthetics and functionality are paramount.

Current Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems.

- Analytical methods for Accura 25 detection and quantification: Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental techniques for quality control and research purposes.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients for synergistic therapeutic effects. These combinations may target specific diseases or conditions, potentially improving treatment outcomes compared to monotherapy.

02 Chemical synthesis and manufacturing of Accura 25

Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.Expand Specific Solutions03 Formulations and drug delivery systems for Accura 25

Various formulations and drug delivery systems have been developed for Accura 25, including controlled release formulations, transdermal patches, and nanoparticle-based delivery systems. These approaches aim to improve bioavailability and patient compliance.Expand Specific Solutions04 Analytical methods for detecting and quantifying Accura 25

Analytical techniques have been developed for detecting and quantifying Accura 25 in various matrices, including biological samples and pharmaceutical formulations. These methods may involve chromatography, spectroscopy, or other advanced analytical techniques.Expand Specific Solutions05 Combination therapies involving Accura 25

Accura 25 is used in combination with other therapeutic agents to enhance treatment efficacy for various medical conditions. These combination therapies may target multiple pathways or mechanisms of action to improve patient outcomes.Expand Specific Solutions

Key Industry Players

The research on Accura 25 for cutting-edge commercial applications is in an early development stage, with a growing market potential as industries seek advanced solutions. The technology's maturity varies among key players, with established companies like Google, NVIDIA, and ON Semiconductor likely leading in innovation. Academic institutions such as Tsinghua University and Rensselaer Polytechnic Institute contribute valuable research. Specialized firms like Cyient and Ramona Optics may offer niche expertise. The competitive landscape is diverse, spanning tech giants, research institutions, and specialized companies, indicating a dynamic and evolving field with significant growth opportunities.

Google LLC

Technical Solution: Google's approach to Accura 25 for cutting-edge commercial applications focuses on integrating it with their cloud-based machine learning platforms. They have developed a specialized version of TensorFlow optimized for Accura 25, enabling faster training and inference of complex AI models[1]. Google has also implemented Accura 25 in their custom-designed Tensor Processing Units (TPUs), which are tailored for high-performance machine learning tasks[3]. This integration allows for more efficient processing of large-scale data analytics and AI workloads, particularly in areas such as natural language processing and computer vision[5].

Strengths: Seamless integration with existing cloud infrastructure, optimized for large-scale data processing. Weaknesses: May require significant computational resources, potentially limiting accessibility for smaller businesses.

NVIDIA Corp.

Technical Solution: NVIDIA has leveraged Accura 25 technology in their latest GPU architectures, particularly in their data center and AI-focused products. They have developed custom CUDA libraries that take advantage of Accura 25's precision capabilities, allowing for more efficient deep learning operations[2]. NVIDIA's implementation includes hardware-level support for mixed-precision training, which significantly accelerates AI model training while maintaining accuracy[4]. Additionally, they have introduced Accura 25-optimized versions of popular deep learning frameworks, such as PyTorch and TensorRT, to streamline adoption in various commercial applications[6].

Strengths: Powerful hardware acceleration, wide ecosystem support. Weaknesses: May require specialized hardware, potentially increasing implementation costs.

Core Innovations

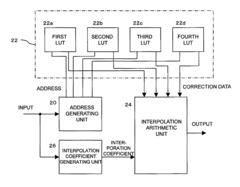

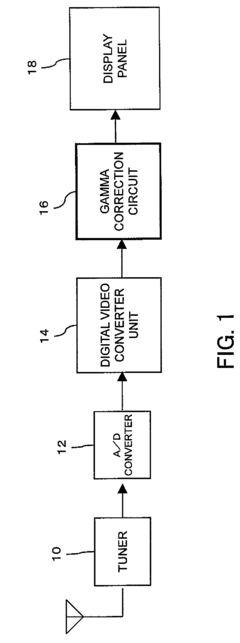

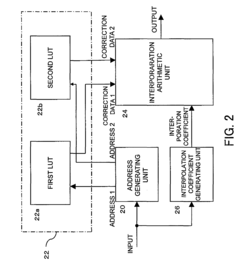

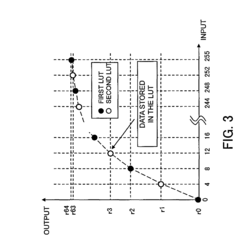

Correction arithmetic circuit

PatentActiveUS8089490B2

Innovation

- A system utilizing multiple one-port split lookup tables and an interpolation arithmetic unit to generate addresses and perform interpolation with lower-order bits, reducing the overall memory area requirement.

A system and method for conducting finite element analysis of structures with cutout

PatentInactiveIN1638CHE2014A

Innovation

- A method that involves creating a CAD model of the structure, defining cutout information including shape, dimension, and location, creating a finite element mesh, making finite elements inside the cutout boundary ineffective by assigning zero material properties, and iteratively adjusting cutout parameters until stress values meet predefined limits, thereby streamlining the analysis process.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing Accura 25 in cutting-edge commercial applications. As this advanced material gains traction in various industries, adherence to relevant regulations and standards becomes paramount to ensure safety, quality, and legal compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating materials used in medical devices and food contact applications. For Accura 25 to be utilized in these sectors, it must meet the stringent requirements set forth by the FDA. This includes demonstrating biocompatibility, chemical inertness, and resistance to degradation under intended use conditions.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is another significant consideration for Accura 25 applications. Manufacturers and importers must register substances used in quantities over one tonne per year, providing detailed information on their properties, uses, and potential risks. Compliance with REACH ensures that Accura 25 can be legally marketed and used within the EU.

For aerospace and automotive applications, Accura 25 must meet industry-specific standards. The Federal Aviation Administration (FAA) in the US and the European Union Aviation Safety Agency (EASA) have strict requirements for materials used in aircraft components. Similarly, automotive manufacturers adhere to standards set by organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE).

Environmental regulations also play a significant role in the adoption of Accura 25. The material's recyclability and end-of-life disposal methods must comply with local and international environmental protection laws. This includes adherence to the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous substances in electrical and electronic equipment.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, must be considered when working with Accura 25. This includes proper handling procedures, personal protective equipment requirements, and workplace exposure limits for any potentially hazardous substances used in the material's production or processing.

As Accura 25 finds applications in consumer products, compliance with consumer safety regulations becomes essential. This includes meeting the requirements of the Consumer Product Safety Commission (CPSC) in the US and similar agencies in other countries. Manufacturers must ensure that products made with Accura 25 meet all relevant safety standards and carry appropriate warning labels if necessary.

In conclusion, navigating the complex landscape of regulatory compliance is crucial for the successful implementation of Accura 25 in cutting-edge commercial applications. Companies working with this material must stay informed about relevant regulations across different industries and geographical regions, ensuring that their products meet all necessary standards and legal requirements.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating materials used in medical devices and food contact applications. For Accura 25 to be utilized in these sectors, it must meet the stringent requirements set forth by the FDA. This includes demonstrating biocompatibility, chemical inertness, and resistance to degradation under intended use conditions.

The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is another significant consideration for Accura 25 applications. Manufacturers and importers must register substances used in quantities over one tonne per year, providing detailed information on their properties, uses, and potential risks. Compliance with REACH ensures that Accura 25 can be legally marketed and used within the EU.

For aerospace and automotive applications, Accura 25 must meet industry-specific standards. The Federal Aviation Administration (FAA) in the US and the European Union Aviation Safety Agency (EASA) have strict requirements for materials used in aircraft components. Similarly, automotive manufacturers adhere to standards set by organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE).

Environmental regulations also play a significant role in the adoption of Accura 25. The material's recyclability and end-of-life disposal methods must comply with local and international environmental protection laws. This includes adherence to the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous substances in electrical and electronic equipment.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, must be considered when working with Accura 25. This includes proper handling procedures, personal protective equipment requirements, and workplace exposure limits for any potentially hazardous substances used in the material's production or processing.

As Accura 25 finds applications in consumer products, compliance with consumer safety regulations becomes essential. This includes meeting the requirements of the Consumer Product Safety Commission (CPSC) in the US and similar agencies in other countries. Manufacturers must ensure that products made with Accura 25 meet all relevant safety standards and carry appropriate warning labels if necessary.

In conclusion, navigating the complex landscape of regulatory compliance is crucial for the successful implementation of Accura 25 in cutting-edge commercial applications. Companies working with this material must stay informed about relevant regulations across different industries and geographical regions, ensuring that their products meet all necessary standards and legal requirements.

Economic Impact

The economic impact of Accura 25 in cutting-edge commercial applications is significant and far-reaching. This advanced material has the potential to revolutionize various industries, leading to substantial cost savings, increased productivity, and new market opportunities.

In the manufacturing sector, Accura 25 enables the production of highly precise and durable components, reducing material waste and improving product quality. This translates to lower production costs and increased competitiveness for businesses adopting this technology. The aerospace industry, in particular, stands to benefit greatly from the use of Accura 25 in creating lightweight yet strong parts, potentially leading to fuel savings and improved aircraft performance.

The medical device industry is another area where Accura 25 can have a profound economic impact. Its biocompatibility and ability to produce intricate designs make it ideal for creating customized implants and prosthetics. This not only improves patient outcomes but also opens up new revenue streams for healthcare providers and medical device manufacturers.

In the automotive sector, Accura 25 can contribute to the development of more efficient and lightweight vehicles. This aligns with the industry's push towards electrification and sustainability, potentially accelerating the adoption of electric vehicles and reducing dependency on fossil fuels. The resulting shift could have significant implications for the global energy economy.

The adoption of Accura 25 in rapid prototyping and small-scale production runs can dramatically reduce time-to-market for new products. This agility in product development can give companies a competitive edge, allowing them to respond quickly to market demands and potentially capture larger market shares.

Furthermore, the use of Accura 25 in additive manufacturing processes can lead to the decentralization of production. This could result in shorter supply chains, reduced transportation costs, and the ability to manufacture on-demand, potentially transforming traditional business models and creating new economic opportunities in local manufacturing hubs.

The economic ripple effects of Accura 25 extend to the job market as well. While it may displace some traditional manufacturing jobs, it is likely to create new roles in advanced manufacturing, materials science, and related fields. This shift could drive demand for upskilling and education in these areas, potentially stimulating growth in the education and training sectors.

In the manufacturing sector, Accura 25 enables the production of highly precise and durable components, reducing material waste and improving product quality. This translates to lower production costs and increased competitiveness for businesses adopting this technology. The aerospace industry, in particular, stands to benefit greatly from the use of Accura 25 in creating lightweight yet strong parts, potentially leading to fuel savings and improved aircraft performance.

The medical device industry is another area where Accura 25 can have a profound economic impact. Its biocompatibility and ability to produce intricate designs make it ideal for creating customized implants and prosthetics. This not only improves patient outcomes but also opens up new revenue streams for healthcare providers and medical device manufacturers.

In the automotive sector, Accura 25 can contribute to the development of more efficient and lightweight vehicles. This aligns with the industry's push towards electrification and sustainability, potentially accelerating the adoption of electric vehicles and reducing dependency on fossil fuels. The resulting shift could have significant implications for the global energy economy.

The adoption of Accura 25 in rapid prototyping and small-scale production runs can dramatically reduce time-to-market for new products. This agility in product development can give companies a competitive edge, allowing them to respond quickly to market demands and potentially capture larger market shares.

Furthermore, the use of Accura 25 in additive manufacturing processes can lead to the decentralization of production. This could result in shorter supply chains, reduced transportation costs, and the ability to manufacture on-demand, potentially transforming traditional business models and creating new economic opportunities in local manufacturing hubs.

The economic ripple effects of Accura 25 extend to the job market as well. While it may displace some traditional manufacturing jobs, it is likely to create new roles in advanced manufacturing, materials science, and related fields. This shift could drive demand for upskilling and education in these areas, potentially stimulating growth in the education and training sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!