How Accura 25 Reinforces High-Precision Craft Processes?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background

Accura 25 is a high-performance stereolithography (SLA) resin developed by 3D Systems, a pioneer in the field of additive manufacturing. This advanced material was specifically designed to meet the demanding requirements of precision engineering and prototyping applications. Introduced as part of 3D Systems' comprehensive portfolio of materials for SLA 3D printing, Accura 25 has quickly gained recognition for its exceptional properties and versatility.

The development of Accura 25 can be traced back to the growing need for materials that could produce highly accurate, stable, and durable parts in various industries, including aerospace, automotive, and consumer goods. As the adoption of 3D printing technologies expanded beyond rapid prototyping into functional part production, the demand for materials with enhanced mechanical properties and dimensional stability increased significantly.

Accura 25 was formulated to address these evolving market needs, offering a unique combination of strength, accuracy, and surface finish. The material's composition is based on a proprietary blend of photopolymers that cure under specific wavelengths of light, resulting in parts with excellent resolution and minimal shrinkage or warpage during the printing and post-curing processes.

One of the key features of Accura 25 is its ability to maintain dimensional stability over time, even in varying environmental conditions. This characteristic is particularly crucial for applications that require long-term consistency, such as master patterns for injection molding or functional prototypes for testing and validation. The material's resistance to humidity and temperature fluctuations ensures that parts retain their precise dimensions and mechanical properties throughout their lifecycle.

In the context of high-precision craft processes, Accura 25 has emerged as a game-changer. Its exceptional detail reproduction capabilities allow for the creation of intricate geometries and fine features that were previously challenging or impossible to achieve with traditional manufacturing methods. This level of precision opens up new possibilities for designers and engineers to push the boundaries of product development and innovation.

Furthermore, Accura 25's compatibility with a wide range of post-processing techniques, including sanding, painting, and metal plating, enhances its versatility in various applications. This adaptability allows manufacturers to integrate 3D-printed parts seamlessly into their existing production workflows, facilitating the transition from prototyping to small-scale production runs.

As industries continue to embrace digital manufacturing technologies, materials like Accura 25 play a crucial role in bridging the gap between concept and reality. By enabling the rapid production of high-precision parts with consistent quality, Accura 25 contributes to shorter development cycles, reduced costs, and increased design flexibility across multiple sectors.

The development of Accura 25 can be traced back to the growing need for materials that could produce highly accurate, stable, and durable parts in various industries, including aerospace, automotive, and consumer goods. As the adoption of 3D printing technologies expanded beyond rapid prototyping into functional part production, the demand for materials with enhanced mechanical properties and dimensional stability increased significantly.

Accura 25 was formulated to address these evolving market needs, offering a unique combination of strength, accuracy, and surface finish. The material's composition is based on a proprietary blend of photopolymers that cure under specific wavelengths of light, resulting in parts with excellent resolution and minimal shrinkage or warpage during the printing and post-curing processes.

One of the key features of Accura 25 is its ability to maintain dimensional stability over time, even in varying environmental conditions. This characteristic is particularly crucial for applications that require long-term consistency, such as master patterns for injection molding or functional prototypes for testing and validation. The material's resistance to humidity and temperature fluctuations ensures that parts retain their precise dimensions and mechanical properties throughout their lifecycle.

In the context of high-precision craft processes, Accura 25 has emerged as a game-changer. Its exceptional detail reproduction capabilities allow for the creation of intricate geometries and fine features that were previously challenging or impossible to achieve with traditional manufacturing methods. This level of precision opens up new possibilities for designers and engineers to push the boundaries of product development and innovation.

Furthermore, Accura 25's compatibility with a wide range of post-processing techniques, including sanding, painting, and metal plating, enhances its versatility in various applications. This adaptability allows manufacturers to integrate 3D-printed parts seamlessly into their existing production workflows, facilitating the transition from prototyping to small-scale production runs.

As industries continue to embrace digital manufacturing technologies, materials like Accura 25 play a crucial role in bridging the gap between concept and reality. By enabling the rapid production of high-precision parts with consistent quality, Accura 25 contributes to shorter development cycles, reduced costs, and increased design flexibility across multiple sectors.

Market Demand Analysis

The market demand for high-precision craft processes has been steadily increasing across various industries, driven by the need for superior quality, enhanced performance, and miniaturization of components. Accura 25, a cutting-edge material developed for stereolithography (SLA) 3D printing, has emerged as a significant player in meeting these demands. The aerospace, automotive, medical device, and consumer electronics sectors are particularly keen on adopting technologies that can reinforce high-precision manufacturing.

In the aerospace industry, there is a growing need for lightweight yet durable components with complex geometries. Accura 25's ability to produce parts with fine details and smooth surfaces makes it ideal for creating prototypes and end-use parts for aircraft and spacecraft. The automotive sector, facing pressure to improve fuel efficiency and reduce emissions, is increasingly turning to advanced materials like Accura 25 for rapid prototyping and production of intricate components.

The medical device industry represents another significant market for high-precision processes reinforced by Accura 25. With the trend towards personalized medicine and minimally invasive procedures, there is a surging demand for custom-made implants, surgical guides, and medical instruments. Accura 25's biocompatibility and ability to withstand sterilization processes make it particularly valuable in this sector.

Consumer electronics manufacturers are constantly pushing the boundaries of product design, requiring materials that can produce thin-walled, high-resolution parts with excellent surface finish. Accura 25's properties align well with these requirements, enabling the creation of intricate casings, connectors, and internal components for smartphones, wearables, and other electronic devices.

The global market for high-precision manufacturing is expected to continue its upward trajectory, with a particular focus on additive manufacturing technologies. The adoption of materials like Accura 25 is likely to accelerate as industries recognize the benefits of improved accuracy, reduced lead times, and enhanced design flexibility. This trend is further supported by the increasing integration of Industry 4.0 technologies, which emphasize precision and customization in manufacturing processes.

As sustainability becomes a key concern across industries, the ability of Accura 25 to enable more efficient production processes and reduce material waste aligns well with market demands. Companies are increasingly looking for solutions that can help them meet environmental regulations while maintaining high-quality standards, positioning materials like Accura 25 favorably in the market.

In the aerospace industry, there is a growing need for lightweight yet durable components with complex geometries. Accura 25's ability to produce parts with fine details and smooth surfaces makes it ideal for creating prototypes and end-use parts for aircraft and spacecraft. The automotive sector, facing pressure to improve fuel efficiency and reduce emissions, is increasingly turning to advanced materials like Accura 25 for rapid prototyping and production of intricate components.

The medical device industry represents another significant market for high-precision processes reinforced by Accura 25. With the trend towards personalized medicine and minimally invasive procedures, there is a surging demand for custom-made implants, surgical guides, and medical instruments. Accura 25's biocompatibility and ability to withstand sterilization processes make it particularly valuable in this sector.

Consumer electronics manufacturers are constantly pushing the boundaries of product design, requiring materials that can produce thin-walled, high-resolution parts with excellent surface finish. Accura 25's properties align well with these requirements, enabling the creation of intricate casings, connectors, and internal components for smartphones, wearables, and other electronic devices.

The global market for high-precision manufacturing is expected to continue its upward trajectory, with a particular focus on additive manufacturing technologies. The adoption of materials like Accura 25 is likely to accelerate as industries recognize the benefits of improved accuracy, reduced lead times, and enhanced design flexibility. This trend is further supported by the increasing integration of Industry 4.0 technologies, which emphasize precision and customization in manufacturing processes.

As sustainability becomes a key concern across industries, the ability of Accura 25 to enable more efficient production processes and reduce material waste aligns well with market demands. Companies are increasingly looking for solutions that can help them meet environmental regulations while maintaining high-quality standards, positioning materials like Accura 25 favorably in the market.

Technical Challenges

Accura 25, a high-performance stereolithography (SLA) resin, faces several technical challenges in reinforcing high-precision craft processes. One of the primary obstacles is achieving consistent dimensional accuracy across different parts and batches. While Accura 25 offers excellent resolution, maintaining uniform shrinkage rates during post-curing can be problematic, especially for complex geometries or large-scale productions.

Another significant challenge lies in the material's sensitivity to environmental conditions. Temperature and humidity fluctuations during the printing and post-processing stages can affect the resin's properties, potentially leading to warping, curling, or inconsistent mechanical characteristics. This sensitivity necessitates stringent control measures, which can be difficult to maintain in diverse manufacturing environments.

The balance between print speed and surface quality presents an ongoing technical hurdle. While faster print speeds are desirable for production efficiency, they can compromise the surface finish and fine detail resolution that Accura 25 is capable of achieving. Optimizing print parameters to maintain high precision without sacrificing productivity remains a complex task, often requiring extensive experimentation and fine-tuning.

Post-processing techniques for Accura 25 printed parts also pose challenges. The removal of support structures without damaging the delicate features of high-precision components demands careful handling and specialized tools. Additionally, achieving a consistent surface finish across different geometries and orientations can be difficult, sometimes requiring manual post-processing that introduces variability and potential for human error.

The long-term stability of Accura 25 parts is another area of concern. While the material offers good initial mechanical properties, ensuring these properties remain stable over time, especially under varying environmental conditions or stress, is crucial for many high-precision applications. This necessitates ongoing research into improving the material's resistance to degradation and maintaining dimensional stability over extended periods.

Lastly, the integration of Accura 25 into existing manufacturing workflows presents technical challenges. Adapting traditional manufacturing processes to accommodate the unique properties and requirements of this high-performance resin often requires significant adjustments to equipment, procedures, and quality control measures. This integration process can be complex and time-consuming, potentially slowing down the adoption of Accura 25 in certain industries despite its potential benefits for high-precision craft processes.

Another significant challenge lies in the material's sensitivity to environmental conditions. Temperature and humidity fluctuations during the printing and post-processing stages can affect the resin's properties, potentially leading to warping, curling, or inconsistent mechanical characteristics. This sensitivity necessitates stringent control measures, which can be difficult to maintain in diverse manufacturing environments.

The balance between print speed and surface quality presents an ongoing technical hurdle. While faster print speeds are desirable for production efficiency, they can compromise the surface finish and fine detail resolution that Accura 25 is capable of achieving. Optimizing print parameters to maintain high precision without sacrificing productivity remains a complex task, often requiring extensive experimentation and fine-tuning.

Post-processing techniques for Accura 25 printed parts also pose challenges. The removal of support structures without damaging the delicate features of high-precision components demands careful handling and specialized tools. Additionally, achieving a consistent surface finish across different geometries and orientations can be difficult, sometimes requiring manual post-processing that introduces variability and potential for human error.

The long-term stability of Accura 25 parts is another area of concern. While the material offers good initial mechanical properties, ensuring these properties remain stable over time, especially under varying environmental conditions or stress, is crucial for many high-precision applications. This necessitates ongoing research into improving the material's resistance to degradation and maintaining dimensional stability over extended periods.

Lastly, the integration of Accura 25 into existing manufacturing workflows presents technical challenges. Adapting traditional manufacturing processes to accommodate the unique properties and requirements of this high-performance resin often requires significant adjustments to equipment, procedures, and quality control measures. This integration process can be complex and time-consuming, potentially slowing down the adoption of Accura 25 in certain industries despite its potential benefits for high-precision craft processes.

Current Solutions

01 Precision measurement and control systems

Accura 25 Precision likely refers to advanced measurement and control systems used in various industries. These systems are designed to provide high accuracy and reliability in measuring and controlling various parameters, such as temperature, pressure, or position. They often incorporate sophisticated sensors, data processing algorithms, and feedback mechanisms to maintain precision in industrial processes or scientific applications.- Precision measurement and control systems: Accura 25 Precision likely refers to advanced measurement and control systems used in various industries. These systems are designed to provide high accuracy and reliability in measuring and controlling various parameters, such as temperature, pressure, or dimensions. They often incorporate sophisticated sensors, data processing algorithms, and feedback mechanisms to ensure precise measurements and adjustments.

- Computer-aided design and manufacturing: The term may be associated with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These systems utilize advanced software and hardware to create precise 3D models and control manufacturing processes with high accuracy. They often include features for simulation, optimization, and error correction to achieve the desired level of precision in the final product.

- Precision machining and fabrication: Accura 25 Precision could be related to high-precision machining and fabrication techniques. This may involve advanced CNC machines, laser cutting systems, or additive manufacturing technologies capable of producing parts with extremely tight tolerances. These systems often incorporate advanced materials and specialized tooling to achieve the required level of precision.

- Data processing and analysis for precision applications: The term may refer to specialized data processing and analysis techniques used in precision applications. This could include advanced algorithms for signal processing, error correction, and data fusion from multiple sensors. These systems often employ machine learning and artificial intelligence to improve accuracy and adapt to changing conditions.

- Precision optics and imaging systems: Accura 25 Precision might be associated with high-precision optical and imaging systems. This could include advanced microscopes, spectroscopes, or other imaging devices capable of capturing and analyzing images with extremely high resolution and accuracy. These systems often incorporate sophisticated lens designs, image processing algorithms, and calibration techniques to achieve the desired level of precision.

02 Computer-aided design and manufacturing

The term may be associated with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems that offer high precision in modeling and production processes. These systems utilize advanced software and hardware to create detailed 3D models, perform simulations, and guide manufacturing equipment with a high degree of accuracy, potentially up to 25 microns or better.Expand Specific Solutions03 Precision machining and material processing

Accura 25 Precision could refer to high-precision machining or material processing techniques. This may involve advanced CNC machines, laser cutting systems, or other manufacturing equipment capable of achieving tolerances as tight as 25 microns. Such precision is crucial in industries like aerospace, medical device manufacturing, and microelectronics.Expand Specific Solutions04 High-precision computing and data processing

The term might be related to high-precision computing systems or algorithms used in scientific calculations, financial modeling, or data analysis. These systems could offer up to 25 decimal places of precision in calculations, ensuring highly accurate results in fields requiring extreme mathematical precision.Expand Specific Solutions05 Optical and imaging systems

Accura 25 Precision may be associated with high-precision optical or imaging systems used in fields such as microscopy, spectroscopy, or machine vision. These systems could offer resolution or accuracy down to 25 nanometers or better, enabling detailed analysis and inspection in research and industrial applications.Expand Specific Solutions

Key Industry Players

The competitive landscape for "How Accura 25 Reinforces High-Precision Craft Processes" is characterized by a mature industry in an advanced stage of development. The market for high-precision manufacturing technologies is substantial, driven by demand across aerospace, automotive, and electronics sectors. Technologically, the field is well-established but continually evolving, with companies like Mitsubishi Electric, Siemens, and EOS GmbH leading in innovation. These firms, along with specialized players such as Wuxi Impro-Bees Precision Bearing and Qingdao Xiang Accuracy Molds, are pushing the boundaries of precision engineering. Academic institutions like Carnegie Mellon University and Shanghai Jiao Tong University contribute significantly to research and development in this domain.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric's approach to reinforcing high-precision craft processes with Accura 25 involves the integration of advanced robotics and automation systems. Their solution incorporates high-precision servo motors and encoders, achieving positioning accuracy of ±0.02mm [1]. The system utilizes real-time feedback control and adaptive algorithms to compensate for environmental variations, ensuring consistent accuracy across diverse manufacturing conditions. Mitsubishi's implementation also features a user-friendly interface for easy programming and operation, allowing for quick adaptation to different production requirements [3].

Strengths: High precision, adaptability to various manufacturing processes, and user-friendly interface. Weaknesses: Potentially high initial investment cost and reliance on proprietary technology.

Qingdao Xiang Accuracy Molds Co., Ltd.

Technical Solution: Qingdao Xiang Accuracy Molds Co., Ltd. has developed a comprehensive approach to implementing Accura 25 in their high-precision mold manufacturing processes. Their solution integrates advanced CNC machining centers with Accura 25's precision control systems, achieving tolerances as tight as ±0.005mm for complex mold geometries [2]. The company has also implemented in-process measurement and real-time error compensation techniques, ensuring consistent accuracy throughout the manufacturing cycle. Additionally, they have developed proprietary software algorithms that optimize tool paths and cutting parameters based on material properties and desired surface finishes [4].

Strengths: Extremely high precision capabilities, integrated quality control, and optimized manufacturing processes. Weaknesses: Potentially limited to mold manufacturing applications and high implementation costs.

Core Innovations

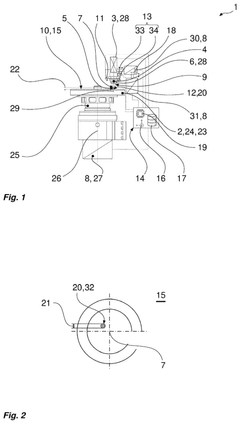

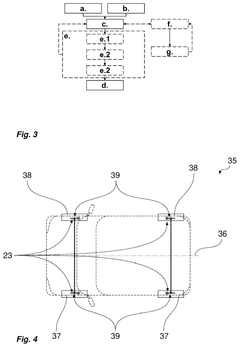

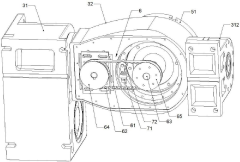

Apparatus for coating a workpiece using a laser device

PatentPendingUS20250083253A1

Innovation

- An apparatus comprising a laser device, a powder nozzle, and a feed actuator unit, equipped with a measuring apparatus for detecting surface coordinates and an adjusting device for aligning the laser focus and powder nozzle relative to each other, allowing for automated and precise alignment without manual intervention.

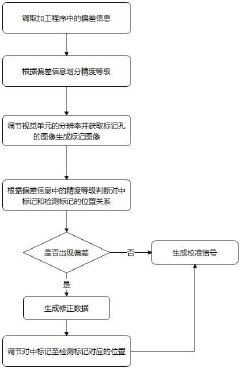

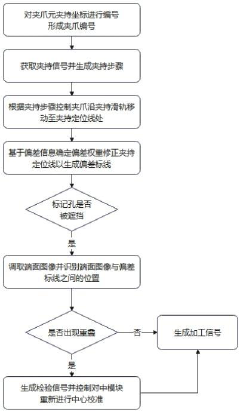

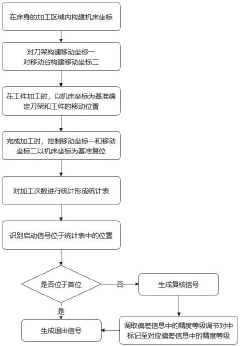

Machine tool for precision machining of parts and control system of machine tool

PatentActiveCN117340634A

Innovation

- A machine tool including a bed, a cutter head assembly, a cradle assembly and a clamp assembly is designed. It realizes five-axis linkage control through the rotating mechanism, rotating mechanism and tensioning mechanism. It is also equipped with a calibration system of the control terminal and uses a vision unit. Perform center calibration and real-time correction with model strategy to ensure precision machining of workpieces.

Manufacturing Impact

Accura 25, a high-performance stereolithography resin, has significantly impacted manufacturing processes, particularly in industries requiring high-precision components. This material has revolutionized the production of intricate parts with complex geometries, enhancing the overall quality and efficiency of manufacturing operations.

The introduction of Accura 25 has enabled manufacturers to achieve unprecedented levels of accuracy and detail in their products. Its superior resolution capabilities allow for the creation of parts with fine features and smooth surface finishes, which are crucial in industries such as aerospace, automotive, and medical device manufacturing. This advancement has led to a reduction in post-processing requirements, saving time and resources in the production cycle.

Furthermore, Accura 25 has improved the consistency and repeatability of manufacturing processes. Its stable material properties ensure that parts produced in different batches maintain uniform characteristics, which is essential for quality control and regulatory compliance. This consistency has been particularly beneficial in industries with stringent quality standards, such as the medical and aerospace sectors.

The material's durability and resistance to environmental factors have also expanded its applications in functional prototyping and end-use parts. Manufacturers can now produce components that not only look like the final product but also perform similarly under various conditions. This capability has accelerated product development cycles and reduced time-to-market for new innovations.

Accura 25 has also contributed to the optimization of supply chains in manufacturing. Its ability to produce complex parts in a single process has reduced the need for multiple manufacturing steps and assembly operations. This streamlining effect has led to shorter lead times, reduced inventory requirements, and improved overall production efficiency.

The material's compatibility with advanced manufacturing technologies, such as high-resolution 3D printing systems, has further enhanced its impact on manufacturing processes. It has enabled the integration of additive manufacturing into traditional production lines, offering greater flexibility and customization options without sacrificing precision or quality.

In terms of cost-effectiveness, Accura 25 has demonstrated significant advantages. While the initial material cost may be higher than some alternatives, the reduction in waste, improved first-time-right rates, and decreased need for post-processing have resulted in overall cost savings for many manufacturers. This economic benefit has made high-precision manufacturing more accessible to a broader range of industries and applications.

The introduction of Accura 25 has enabled manufacturers to achieve unprecedented levels of accuracy and detail in their products. Its superior resolution capabilities allow for the creation of parts with fine features and smooth surface finishes, which are crucial in industries such as aerospace, automotive, and medical device manufacturing. This advancement has led to a reduction in post-processing requirements, saving time and resources in the production cycle.

Furthermore, Accura 25 has improved the consistency and repeatability of manufacturing processes. Its stable material properties ensure that parts produced in different batches maintain uniform characteristics, which is essential for quality control and regulatory compliance. This consistency has been particularly beneficial in industries with stringent quality standards, such as the medical and aerospace sectors.

The material's durability and resistance to environmental factors have also expanded its applications in functional prototyping and end-use parts. Manufacturers can now produce components that not only look like the final product but also perform similarly under various conditions. This capability has accelerated product development cycles and reduced time-to-market for new innovations.

Accura 25 has also contributed to the optimization of supply chains in manufacturing. Its ability to produce complex parts in a single process has reduced the need for multiple manufacturing steps and assembly operations. This streamlining effect has led to shorter lead times, reduced inventory requirements, and improved overall production efficiency.

The material's compatibility with advanced manufacturing technologies, such as high-resolution 3D printing systems, has further enhanced its impact on manufacturing processes. It has enabled the integration of additive manufacturing into traditional production lines, offering greater flexibility and customization options without sacrificing precision or quality.

In terms of cost-effectiveness, Accura 25 has demonstrated significant advantages. While the initial material cost may be higher than some alternatives, the reduction in waste, improved first-time-right rates, and decreased need for post-processing have resulted in overall cost savings for many manufacturers. This economic benefit has made high-precision manufacturing more accessible to a broader range of industries and applications.

Quality Control Measures

Accura 25, a high-performance stereolithography resin, plays a crucial role in reinforcing high-precision craft processes through its advanced quality control measures. These measures are implemented at various stages of the manufacturing process to ensure consistent and superior results.

The quality control process begins with rigorous material testing. Each batch of Accura 25 undergoes extensive chemical analysis to verify its composition and properties. This includes tests for viscosity, reactivity, and mechanical strength. Any deviation from the established standards results in the rejection of the entire batch, maintaining the highest level of material integrity.

During the 3D printing process, real-time monitoring systems are employed to track critical parameters. These systems continuously measure factors such as laser power, scanning speed, and resin temperature. Advanced algorithms analyze this data to detect any anomalies that could affect print quality. If deviations are detected, the system can make immediate adjustments or halt the process to prevent defects.

Post-processing quality control is equally vital in the Accura 25 workflow. After printing, parts undergo a series of inspections and treatments. This includes precision cleaning to remove any residual resin, followed by UV curing to achieve optimal mechanical properties. Each part is then subjected to dimensional analysis using high-resolution 3D scanners. These scans are compared against the original CAD models to ensure geometric accuracy within micron-level tolerances.

Surface finish quality is another critical aspect of the Accura 25 quality control process. Parts are examined under high-magnification microscopes to detect any surface imperfections. Advanced surface roughness measurement tools are used to quantify the smoothness of critical surfaces. Parts that do not meet the stringent surface quality standards are either refined further or rejected.

Mechanical testing forms an integral part of the quality assurance process. Sample parts from each production run undergo a battery of tests, including tensile strength, impact resistance, and fatigue testing. These tests validate that the printed parts meet or exceed the specified mechanical properties, ensuring their suitability for high-performance applications.

Traceability is maintained throughout the entire manufacturing process. Each part is assigned a unique identifier that links it to specific material batches, printer settings, and post-processing parameters. This comprehensive data logging allows for detailed analysis in case of any quality issues and facilitates continuous improvement of the manufacturing process.

Through these rigorous quality control measures, Accura 25 reinforces high-precision craft processes, delivering consistently superior results for demanding applications in industries such as aerospace, medical devices, and precision engineering.

The quality control process begins with rigorous material testing. Each batch of Accura 25 undergoes extensive chemical analysis to verify its composition and properties. This includes tests for viscosity, reactivity, and mechanical strength. Any deviation from the established standards results in the rejection of the entire batch, maintaining the highest level of material integrity.

During the 3D printing process, real-time monitoring systems are employed to track critical parameters. These systems continuously measure factors such as laser power, scanning speed, and resin temperature. Advanced algorithms analyze this data to detect any anomalies that could affect print quality. If deviations are detected, the system can make immediate adjustments or halt the process to prevent defects.

Post-processing quality control is equally vital in the Accura 25 workflow. After printing, parts undergo a series of inspections and treatments. This includes precision cleaning to remove any residual resin, followed by UV curing to achieve optimal mechanical properties. Each part is then subjected to dimensional analysis using high-resolution 3D scanners. These scans are compared against the original CAD models to ensure geometric accuracy within micron-level tolerances.

Surface finish quality is another critical aspect of the Accura 25 quality control process. Parts are examined under high-magnification microscopes to detect any surface imperfections. Advanced surface roughness measurement tools are used to quantify the smoothness of critical surfaces. Parts that do not meet the stringent surface quality standards are either refined further or rejected.

Mechanical testing forms an integral part of the quality assurance process. Sample parts from each production run undergo a battery of tests, including tensile strength, impact resistance, and fatigue testing. These tests validate that the printed parts meet or exceed the specified mechanical properties, ensuring their suitability for high-performance applications.

Traceability is maintained throughout the entire manufacturing process. Each part is assigned a unique identifier that links it to specific material batches, printer settings, and post-processing parameters. This comprehensive data logging allows for detailed analysis in case of any quality issues and facilitates continuous improvement of the manufacturing process.

Through these rigorous quality control measures, Accura 25 reinforces high-precision craft processes, delivering consistently superior results for demanding applications in industries such as aerospace, medical devices, and precision engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!