Accura 25: Facilitating Custom Solutions for High-Tech Products

JUL 8, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Overview

Accura 25 is a cutting-edge stereolithography (SLA) resin developed by 3D Systems, specifically designed for the production of high-precision, functional parts in various high-tech industries. This advanced material offers a unique combination of properties that make it particularly suitable for creating custom solutions in sectors such as aerospace, automotive, and consumer electronics.

The resin is characterized by its exceptional accuracy, fine feature resolution, and smooth surface finish, allowing for the creation of intricate geometries and complex structures that would be challenging or impossible to achieve with traditional manufacturing methods. Accura 25 exhibits excellent dimensional stability, maintaining its shape and size even under varying environmental conditions, which is crucial for applications requiring tight tolerances.

One of the key advantages of Accura 25 is its versatility. The material can be used to produce both rigid and flexible parts, depending on the specific post-processing techniques applied. This flexibility makes it an ideal choice for prototyping and small-scale production runs, where designers and engineers need to quickly iterate and test different designs before moving to full-scale manufacturing.

In terms of mechanical properties, Accura 25 offers a balanced profile that includes good tensile strength, moderate elongation at break, and high flexural modulus. These characteristics make it suitable for producing functional prototypes that can withstand real-world testing and even serve as end-use parts in certain applications.

The material's compatibility with various finishing techniques further enhances its appeal. Parts created with Accura 25 can be easily sanded, painted, or metalized, allowing for a wide range of aesthetic and functional finishes. This adaptability is particularly valuable in industries where the visual appearance of components is as important as their mechanical performance.

From a manufacturing perspective, Accura 25 is optimized for use with 3D Systems' SLA printers, ensuring consistent results and high productivity. The resin's formulation allows for fast printing speeds without compromising on quality, making it an efficient choice for both prototyping and production environments.

As industries continue to demand more customized and complex components, materials like Accura 25 play a crucial role in bridging the gap between design concepts and physical realization. Its ability to facilitate rapid iteration, functional testing, and small-batch production makes it an invaluable tool for companies looking to innovate and bring products to market faster.

The resin is characterized by its exceptional accuracy, fine feature resolution, and smooth surface finish, allowing for the creation of intricate geometries and complex structures that would be challenging or impossible to achieve with traditional manufacturing methods. Accura 25 exhibits excellent dimensional stability, maintaining its shape and size even under varying environmental conditions, which is crucial for applications requiring tight tolerances.

One of the key advantages of Accura 25 is its versatility. The material can be used to produce both rigid and flexible parts, depending on the specific post-processing techniques applied. This flexibility makes it an ideal choice for prototyping and small-scale production runs, where designers and engineers need to quickly iterate and test different designs before moving to full-scale manufacturing.

In terms of mechanical properties, Accura 25 offers a balanced profile that includes good tensile strength, moderate elongation at break, and high flexural modulus. These characteristics make it suitable for producing functional prototypes that can withstand real-world testing and even serve as end-use parts in certain applications.

The material's compatibility with various finishing techniques further enhances its appeal. Parts created with Accura 25 can be easily sanded, painted, or metalized, allowing for a wide range of aesthetic and functional finishes. This adaptability is particularly valuable in industries where the visual appearance of components is as important as their mechanical performance.

From a manufacturing perspective, Accura 25 is optimized for use with 3D Systems' SLA printers, ensuring consistent results and high productivity. The resin's formulation allows for fast printing speeds without compromising on quality, making it an efficient choice for both prototyping and production environments.

As industries continue to demand more customized and complex components, materials like Accura 25 play a crucial role in bridging the gap between design concepts and physical realization. Its ability to facilitate rapid iteration, functional testing, and small-batch production makes it an invaluable tool for companies looking to innovate and bring products to market faster.

Market Demand Analysis

The market demand for custom solutions in high-tech products has been steadily increasing, driven by the need for specialized and tailored technologies across various industries. Accura 25, as a facilitator for custom solutions, is positioned to address this growing demand in the high-tech sector. The market for customized high-tech products is expected to expand significantly in the coming years, as companies seek to differentiate themselves and meet specific customer requirements.

In the aerospace and defense industries, there is a strong demand for customized components that can withstand extreme conditions while maintaining high performance. Accura 25's capabilities in producing durable, heat-resistant parts make it particularly attractive for these sectors. The automotive industry also shows substantial interest in custom solutions, especially for prototyping and small-scale production of specialized parts for electric and autonomous vehicles.

The medical device industry represents another key market for Accura 25's custom solutions. With the increasing trend towards personalized medicine, there is a growing need for tailored medical devices and implants. Accura 25's ability to produce biocompatible parts with complex geometries positions it well to serve this market segment.

In the consumer electronics sector, the demand for custom solutions is driven by the need for rapid prototyping and small batch production of innovative devices. Companies are constantly seeking ways to bring unique products to market faster, and Accura 25's capabilities align well with these requirements.

The industrial equipment and machinery market also shows significant potential for custom solutions. As manufacturers strive for greater efficiency and productivity, there is an increasing demand for specialized tools and components that can optimize production processes. Accura 25's ability to produce functional prototypes and end-use parts makes it valuable for this sector.

The overall market trend indicates a shift towards more agile and flexible manufacturing processes, which aligns well with Accura 25's capabilities. Companies are increasingly looking for solutions that can help them reduce time-to-market, minimize inventory costs, and respond quickly to changing customer demands. This trend is expected to continue, driving further growth in the market for custom high-tech solutions.

As sustainability becomes a key focus across industries, there is also a growing demand for custom solutions that can help reduce waste and improve energy efficiency. Accura 25's potential for producing optimized designs with minimal material usage could be particularly appealing in this context.

In the aerospace and defense industries, there is a strong demand for customized components that can withstand extreme conditions while maintaining high performance. Accura 25's capabilities in producing durable, heat-resistant parts make it particularly attractive for these sectors. The automotive industry also shows substantial interest in custom solutions, especially for prototyping and small-scale production of specialized parts for electric and autonomous vehicles.

The medical device industry represents another key market for Accura 25's custom solutions. With the increasing trend towards personalized medicine, there is a growing need for tailored medical devices and implants. Accura 25's ability to produce biocompatible parts with complex geometries positions it well to serve this market segment.

In the consumer electronics sector, the demand for custom solutions is driven by the need for rapid prototyping and small batch production of innovative devices. Companies are constantly seeking ways to bring unique products to market faster, and Accura 25's capabilities align well with these requirements.

The industrial equipment and machinery market also shows significant potential for custom solutions. As manufacturers strive for greater efficiency and productivity, there is an increasing demand for specialized tools and components that can optimize production processes. Accura 25's ability to produce functional prototypes and end-use parts makes it valuable for this sector.

The overall market trend indicates a shift towards more agile and flexible manufacturing processes, which aligns well with Accura 25's capabilities. Companies are increasingly looking for solutions that can help them reduce time-to-market, minimize inventory costs, and respond quickly to changing customer demands. This trend is expected to continue, driving further growth in the market for custom high-tech solutions.

As sustainability becomes a key focus across industries, there is also a growing demand for custom solutions that can help reduce waste and improve energy efficiency. Accura 25's potential for producing optimized designs with minimal material usage could be particularly appealing in this context.

Technical Challenges

The development of Accura 25 for custom solutions in high-tech products faces several significant technical challenges. One of the primary obstacles is achieving precise control over the material properties during the manufacturing process. The intricate nature of high-tech products demands exceptional accuracy in material composition and structure, which can be difficult to maintain consistently across different production batches.

Another major challenge lies in the scalability of the Accura 25 technology. While it shows promise in laboratory settings and small-scale applications, adapting it for large-scale industrial production presents numerous hurdles. These include maintaining quality standards, optimizing production speed, and ensuring cost-effectiveness when scaling up.

The integration of Accura 25 with existing manufacturing processes and equipment poses additional technical difficulties. Many high-tech product manufacturers have established production lines that may require significant modifications to accommodate this new material technology. This integration challenge extends to ensuring compatibility with various post-processing techniques commonly used in high-tech product fabrication.

Material durability and long-term performance stability are also areas of concern. High-tech products often operate in demanding environments, and the Accura 25 material must demonstrate consistent performance over extended periods. This necessitates extensive testing and validation processes to guarantee reliability under various conditions, which can be time-consuming and resource-intensive.

Furthermore, the customization aspect of Accura 25 presents its own set of technical challenges. Developing a flexible manufacturing process that can easily adapt to different product specifications while maintaining high precision and quality is a complex task. It requires advanced control systems and potentially new manufacturing methodologies to achieve the desired level of customization without compromising efficiency or quality.

Lastly, there are challenges related to the characterization and quality control of Accura 25 products. Developing robust, non-destructive testing methods to assess the material properties and product quality in real-time during manufacturing is crucial. This involves creating new sensing technologies and data analysis techniques capable of detecting subtle variations in material properties that could affect product performance.

Another major challenge lies in the scalability of the Accura 25 technology. While it shows promise in laboratory settings and small-scale applications, adapting it for large-scale industrial production presents numerous hurdles. These include maintaining quality standards, optimizing production speed, and ensuring cost-effectiveness when scaling up.

The integration of Accura 25 with existing manufacturing processes and equipment poses additional technical difficulties. Many high-tech product manufacturers have established production lines that may require significant modifications to accommodate this new material technology. This integration challenge extends to ensuring compatibility with various post-processing techniques commonly used in high-tech product fabrication.

Material durability and long-term performance stability are also areas of concern. High-tech products often operate in demanding environments, and the Accura 25 material must demonstrate consistent performance over extended periods. This necessitates extensive testing and validation processes to guarantee reliability under various conditions, which can be time-consuming and resource-intensive.

Furthermore, the customization aspect of Accura 25 presents its own set of technical challenges. Developing a flexible manufacturing process that can easily adapt to different product specifications while maintaining high precision and quality is a complex task. It requires advanced control systems and potentially new manufacturing methodologies to achieve the desired level of customization without compromising efficiency or quality.

Lastly, there are challenges related to the characterization and quality control of Accura 25 products. Developing robust, non-destructive testing methods to assess the material properties and product quality in real-time during manufacturing is crucial. This involves creating new sensing technologies and data analysis techniques capable of detecting subtle variations in material properties that could affect product performance.

Current Accura 25 Apps

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems.

- Analytical methods for Accura 25 detection and quantification: Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may include chromatographic, spectroscopic, or other instrumental techniques for quality control and research purposes.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other active ingredients to create synergistic therapeutic effects. These combinations may target specific diseases or conditions, potentially improving treatment outcomes.

02 Manufacturing processes for Accura 25

Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification steps, and quality control measures to ensure consistent product quality.Expand Specific Solutions03 Analytical methods for Accura 25

Various analytical techniques are used to characterize and quantify Accura 25 in pharmaceutical formulations and biological samples. These methods may include chromatography, spectroscopy, and other advanced analytical tools.Expand Specific Solutions04 Formulation strategies for Accura 25

Different formulation approaches are used to incorporate Accura 25 into various dosage forms, such as tablets, capsules, or injectable solutions. These strategies aim to improve bioavailability, stability, and patient compliance.Expand Specific Solutions05 Applications of Accura 25 in medical devices

Accura 25 is utilized in the development of medical devices and diagnostic tools. Its properties may contribute to improved performance or functionality in these applications.Expand Specific Solutions

Key Industry Players

The research on Accura 25 for high-tech product customization is in an emerging stage, with a growing market as industries seek more tailored solutions. The technology's maturity varies across companies, with established players like IBM, Alibaba, and Sony likely having more advanced capabilities. Smaller firms like Zazzle and B9Creations are innovating in niche areas of customization. The competitive landscape is diverse, spanning tech giants, manufacturing specialists, and startups, indicating significant potential for growth and innovation in this field.

International Business Machines Corp.

Technical Solution: IBM's approach to Accura 25 focuses on leveraging advanced AI and machine learning techniques to enhance custom solutions for high-tech products. Their strategy involves integrating IBM Watson's cognitive capabilities with robust data analytics to optimize product design and manufacturing processes. IBM utilizes a combination of predictive modeling, real-time monitoring, and adaptive learning algorithms to continuously refine and improve product performance[1]. The company has also developed a specialized cloud-based platform that enables seamless collaboration between designers, engineers, and manufacturers, facilitating rapid prototyping and iterative development cycles[3]. Additionally, IBM's quantum computing research is being applied to solve complex optimization problems in materials science, potentially revolutionizing the development of novel materials for high-tech products[5].

Strengths: Extensive AI and data analytics expertise, access to cutting-edge quantum computing technology, and a well-established global network of partners and clients. Weaknesses: Potential over-reliance on software solutions, which may not fully address hardware-specific challenges in high-tech product development.

Alibaba Group Holding Ltd.

Technical Solution: Alibaba's approach to Accura 25 centers on leveraging its vast e-commerce ecosystem and cloud computing infrastructure to drive innovation in high-tech product development. The company has implemented a comprehensive digital twin technology that creates virtual replicas of physical products and manufacturing processes, enabling rapid testing and optimization[2]. Alibaba's strategy also incorporates advanced IoT sensors and edge computing devices to collect real-time data from production lines and products in use, feeding this information back into their AI-powered analytics platform[4]. Furthermore, the company has developed a unique blockchain-based system for tracking and verifying the entire lifecycle of high-tech products, ensuring transparency and quality control throughout the supply chain[6]. Alibaba's City Brain project, which uses AI to optimize urban infrastructure, is being adapted to enhance the design and deployment of smart, connected high-tech products[8].

Strengths: Vast data resources from e-commerce platforms, strong cloud computing capabilities, and extensive experience in IoT and smart city technologies. Weaknesses: Limited experience in traditional manufacturing sectors may pose challenges in certain high-tech product categories.

Core Innovations

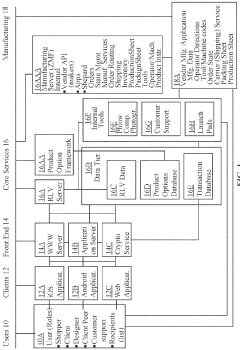

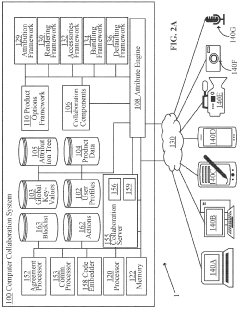

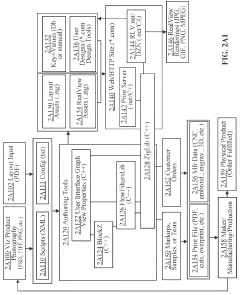

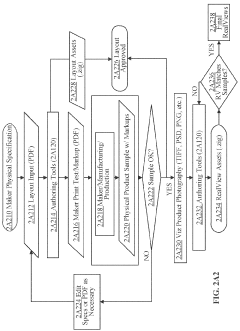

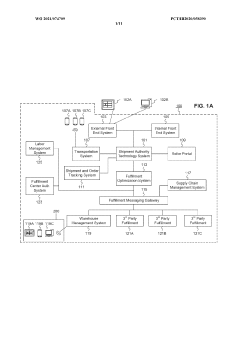

System and method for authoring high quality renderings and generating manufacturing output of custom products

PatentWO2023234990A1

Innovation

- A method and system that utilize key-value pairs to encode product parameters, allowing for the generation of manufacturing instructions compatible with manufacturing processes, and using authoring tools to create high-quality renderings and outputs by correlating physical products with digital designs, adjusting instructions based on detected visual differences.

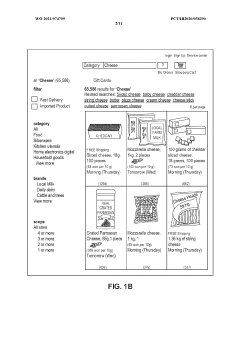

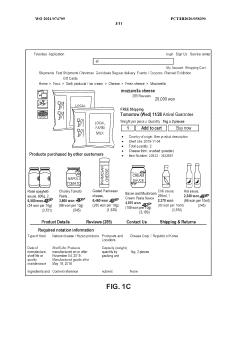

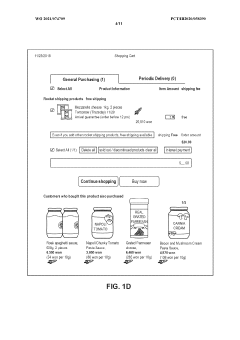

Computerized systems and methods for providing product recommendations

PatentWO2021074709A1

Innovation

- A computer-implemented system that uses a machine learning model to rank products based on contextual information associated with users, including search queries, product features, and user feedback, to provide personalized recommendations by filtering and ranking products dynamically.

Material Properties

Accura 25 is a high-performance stereolithography resin developed by 3D Systems, specifically designed for the production of functional prototypes and end-use parts in high-tech industries. This material exhibits exceptional mechanical properties, making it suitable for a wide range of applications in aerospace, automotive, and consumer electronics sectors.

The material properties of Accura 25 are characterized by its high tensile strength, excellent dimensional stability, and superior surface finish. With a tensile strength of approximately 68-75 MPa, it outperforms many traditional manufacturing materials, allowing for the creation of robust and durable parts. The material's elongation at break, typically around 5-7%, provides a balance between strength and flexibility, crucial for components that may experience stress or impact during use.

Accura 25 demonstrates remarkable thermal properties, with a heat deflection temperature (HDT) of about 62-65°C at 0.45 MPa. This thermal stability ensures that parts maintain their structural integrity under moderate heat exposure, making it suitable for applications in environments with varying temperatures. The material's low moisture absorption rate, generally less than 0.3% over 24 hours, contributes to its dimensional stability and consistent performance in humid conditions.

One of the key advantages of Accura 25 is its exceptional surface finish. The material can achieve surface roughness values as low as 1.2 μm Ra without post-processing, significantly reducing the need for additional finishing steps. This characteristic is particularly valuable in industries where aesthetics and precision are paramount, such as in the production of high-end consumer electronics or intricate aerospace components.

The optical properties of Accura 25 are also noteworthy. In its natural state, the material has a translucent appearance, which can be advantageous for certain applications requiring visual inspection of internal structures. However, it can also be easily colored or painted to meet specific aesthetic requirements without compromising its mechanical properties.

From a processing standpoint, Accura 25 exhibits excellent flowability and curing characteristics, enabling the production of complex geometries with fine details and smooth surfaces. Its compatibility with various post-processing techniques, including sanding, painting, and metal plating, further enhances its versatility in creating custom solutions for high-tech products.

The material's resistance to chemicals and solvents is another critical property, particularly for applications in harsh environments or those requiring frequent cleaning. Accura 25 shows good resistance to a range of common chemicals, including oils, fuels, and certain acids, expanding its potential use cases across various industries.

The material properties of Accura 25 are characterized by its high tensile strength, excellent dimensional stability, and superior surface finish. With a tensile strength of approximately 68-75 MPa, it outperforms many traditional manufacturing materials, allowing for the creation of robust and durable parts. The material's elongation at break, typically around 5-7%, provides a balance between strength and flexibility, crucial for components that may experience stress or impact during use.

Accura 25 demonstrates remarkable thermal properties, with a heat deflection temperature (HDT) of about 62-65°C at 0.45 MPa. This thermal stability ensures that parts maintain their structural integrity under moderate heat exposure, making it suitable for applications in environments with varying temperatures. The material's low moisture absorption rate, generally less than 0.3% over 24 hours, contributes to its dimensional stability and consistent performance in humid conditions.

One of the key advantages of Accura 25 is its exceptional surface finish. The material can achieve surface roughness values as low as 1.2 μm Ra without post-processing, significantly reducing the need for additional finishing steps. This characteristic is particularly valuable in industries where aesthetics and precision are paramount, such as in the production of high-end consumer electronics or intricate aerospace components.

The optical properties of Accura 25 are also noteworthy. In its natural state, the material has a translucent appearance, which can be advantageous for certain applications requiring visual inspection of internal structures. However, it can also be easily colored or painted to meet specific aesthetic requirements without compromising its mechanical properties.

From a processing standpoint, Accura 25 exhibits excellent flowability and curing characteristics, enabling the production of complex geometries with fine details and smooth surfaces. Its compatibility with various post-processing techniques, including sanding, painting, and metal plating, further enhances its versatility in creating custom solutions for high-tech products.

The material's resistance to chemicals and solvents is another critical property, particularly for applications in harsh environments or those requiring frequent cleaning. Accura 25 shows good resistance to a range of common chemicals, including oils, fuels, and certain acids, expanding its potential use cases across various industries.

Sustainability Aspects

Sustainability has become a crucial aspect in the development and implementation of high-tech products, including custom solutions facilitated by Accura 25. This advanced material offers significant potential for enhancing the sustainability of various applications across industries.

One of the primary sustainability benefits of Accura 25 is its ability to enable rapid prototyping and small-scale production. This capability reduces material waste and energy consumption associated with traditional manufacturing processes. By allowing for precise, on-demand production of custom parts, Accura 25 minimizes overproduction and the need for large inventories, further contributing to resource conservation.

The durability and longevity of parts produced using Accura 25 also play a role in sustainability. High-quality, custom-fit components can extend the lifespan of products, reducing the frequency of replacements and the overall environmental impact of product lifecycles. This is particularly relevant in industries such as aerospace and automotive, where component longevity is critical.

Accura 25's versatility in creating complex geometries enables the design of more efficient and lightweight parts. This can lead to improved fuel efficiency in transportation applications or reduced energy consumption in various devices, contributing to long-term sustainability goals.

The material's compatibility with post-processing techniques allows for surface improvements and coatings that can enhance wear resistance and chemical stability. These properties can further extend product lifespans and reduce the need for frequent replacements, aligning with circular economy principles.

From a supply chain perspective, the ability to produce custom parts on-demand using Accura 25 can significantly reduce transportation-related emissions. By enabling localized production, companies can minimize the carbon footprint associated with shipping components across long distances.

However, it is important to consider the end-of-life aspects of Accura 25 products. While the material offers excellent performance characteristics, research into recyclability and biodegradability of used parts is ongoing. Developing effective recycling methods for Accura 25 components will be crucial for closing the loop on sustainability.

As industries continue to prioritize sustainability, the role of materials like Accura 25 in facilitating custom, efficient, and durable solutions becomes increasingly significant. Future developments in this area may focus on improving the material's recyclability, reducing its environmental footprint during production, and exploring bio-based alternatives that maintain similar performance characteristics.

One of the primary sustainability benefits of Accura 25 is its ability to enable rapid prototyping and small-scale production. This capability reduces material waste and energy consumption associated with traditional manufacturing processes. By allowing for precise, on-demand production of custom parts, Accura 25 minimizes overproduction and the need for large inventories, further contributing to resource conservation.

The durability and longevity of parts produced using Accura 25 also play a role in sustainability. High-quality, custom-fit components can extend the lifespan of products, reducing the frequency of replacements and the overall environmental impact of product lifecycles. This is particularly relevant in industries such as aerospace and automotive, where component longevity is critical.

Accura 25's versatility in creating complex geometries enables the design of more efficient and lightweight parts. This can lead to improved fuel efficiency in transportation applications or reduced energy consumption in various devices, contributing to long-term sustainability goals.

The material's compatibility with post-processing techniques allows for surface improvements and coatings that can enhance wear resistance and chemical stability. These properties can further extend product lifespans and reduce the need for frequent replacements, aligning with circular economy principles.

From a supply chain perspective, the ability to produce custom parts on-demand using Accura 25 can significantly reduce transportation-related emissions. By enabling localized production, companies can minimize the carbon footprint associated with shipping components across long distances.

However, it is important to consider the end-of-life aspects of Accura 25 products. While the material offers excellent performance characteristics, research into recyclability and biodegradability of used parts is ongoing. Developing effective recycling methods for Accura 25 components will be crucial for closing the loop on sustainability.

As industries continue to prioritize sustainability, the role of materials like Accura 25 in facilitating custom, efficient, and durable solutions becomes increasingly significant. Future developments in this area may focus on improving the material's recyclability, reducing its environmental footprint during production, and exploring bio-based alternatives that maintain similar performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!