Accura 25 in Revolutionary Production Process Improvements

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, a revolutionary stereolithography (SLA) resin developed by 3D Systems, has emerged as a game-changing material in the field of additive manufacturing. This high-performance photopolymer has been specifically engineered to address the growing demand for rapid prototyping and production-grade parts in various industries, including aerospace, automotive, and consumer goods.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the need for a material that could combine the precision of SLA technology with the durability and functionality required for end-use parts. Over the years, continuous research and development efforts have led to significant improvements in the material's properties, making it a versatile solution for both prototyping and production applications.

The primary objective of Accura 25 is to revolutionize production processes by enabling the creation of highly accurate, functional parts with exceptional surface finish and mechanical properties. This material aims to bridge the gap between traditional manufacturing methods and additive manufacturing, offering a viable alternative for producing complex geometries and customized components at scale.

One of the key technological trends driving the evolution of Accura 25 is the increasing demand for lightweight, high-strength materials in industries such as aerospace and automotive. As these sectors strive for improved fuel efficiency and performance, materials like Accura 25 play a crucial role in enabling the production of complex, optimized structures that were previously impossible or cost-prohibitive to manufacture using traditional methods.

Another significant trend influencing the development of Accura 25 is the growing adoption of additive manufacturing in production environments. As industries move beyond prototyping and embrace 3D printing for end-use parts, materials like Accura 25 are being refined to meet stringent quality and performance standards, ensuring consistency and reliability in large-scale production scenarios.

The technical goals for Accura 25 include further enhancing its mechanical properties, such as tensile strength, elongation at break, and impact resistance, to expand its applicability across various industries. Additionally, ongoing research aims to improve the material's thermal stability and chemical resistance, making it suitable for more demanding applications in harsh environments.

Furthermore, efforts are being made to optimize the processing parameters of Accura 25, focusing on reducing print times and post-processing requirements while maintaining or improving part quality. This aligns with the broader industry goal of increasing the efficiency and cost-effectiveness of additive manufacturing processes for production-grade components.

The development of Accura 25 can be traced back to the early 2000s when 3D Systems recognized the need for a material that could combine the precision of SLA technology with the durability and functionality required for end-use parts. Over the years, continuous research and development efforts have led to significant improvements in the material's properties, making it a versatile solution for both prototyping and production applications.

The primary objective of Accura 25 is to revolutionize production processes by enabling the creation of highly accurate, functional parts with exceptional surface finish and mechanical properties. This material aims to bridge the gap between traditional manufacturing methods and additive manufacturing, offering a viable alternative for producing complex geometries and customized components at scale.

One of the key technological trends driving the evolution of Accura 25 is the increasing demand for lightweight, high-strength materials in industries such as aerospace and automotive. As these sectors strive for improved fuel efficiency and performance, materials like Accura 25 play a crucial role in enabling the production of complex, optimized structures that were previously impossible or cost-prohibitive to manufacture using traditional methods.

Another significant trend influencing the development of Accura 25 is the growing adoption of additive manufacturing in production environments. As industries move beyond prototyping and embrace 3D printing for end-use parts, materials like Accura 25 are being refined to meet stringent quality and performance standards, ensuring consistency and reliability in large-scale production scenarios.

The technical goals for Accura 25 include further enhancing its mechanical properties, such as tensile strength, elongation at break, and impact resistance, to expand its applicability across various industries. Additionally, ongoing research aims to improve the material's thermal stability and chemical resistance, making it suitable for more demanding applications in harsh environments.

Furthermore, efforts are being made to optimize the processing parameters of Accura 25, focusing on reducing print times and post-processing requirements while maintaining or improving part quality. This aligns with the broader industry goal of increasing the efficiency and cost-effectiveness of additive manufacturing processes for production-grade components.

Market Analysis for Accura 25 Applications

The market for Accura 25, a high-performance stereolithography resin, has shown significant growth potential in recent years, driven by the increasing adoption of additive manufacturing technologies across various industries. This material, known for its exceptional accuracy, surface finish, and mechanical properties, has found applications in diverse sectors, including aerospace, automotive, healthcare, and consumer goods.

In the aerospace industry, Accura 25 has gained traction for producing complex prototypes, tooling, and end-use parts. The material's ability to withstand high temperatures and its dimensional stability make it particularly suitable for creating intricate components used in aircraft and spacecraft manufacturing. The automotive sector has also embraced Accura 25 for rapid prototyping and functional testing of vehicle parts, contributing to faster product development cycles and reduced time-to-market.

The healthcare industry represents another significant market for Accura 25 applications. The material's biocompatibility and sterilizability have made it valuable for producing medical devices, surgical guides, and anatomical models. As personalized medicine continues to advance, the demand for custom medical solutions using Accura 25 is expected to grow substantially.

Consumer goods manufacturers have leveraged Accura 25 for creating high-quality prototypes and molds for various products, ranging from electronics to household appliances. The material's ability to produce parts with fine details and smooth surfaces has made it a preferred choice for designers and engineers seeking to validate their concepts quickly and efficiently.

The global market for 3D printing materials, including high-performance resins like Accura 25, has been expanding rapidly. Industry reports suggest that the market size for photopolymer resins used in stereolithography is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is attributed to the increasing adoption of 3D printing technologies across industries and the continuous development of advanced materials with enhanced properties.

Geographically, North America and Europe currently dominate the market for high-performance 3D printing materials, including Accura 25. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid industrialization and increasing investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

As the demand for more sustainable manufacturing processes grows, there is an emerging trend towards the development of eco-friendly alternatives to traditional resins. This presents both a challenge and an opportunity for Accura 25 and similar materials to evolve and meet the changing market requirements. Manufacturers are increasingly focusing on developing bio-based and recyclable resins that maintain the high performance characteristics of materials like Accura 25 while reducing environmental impact.

In the aerospace industry, Accura 25 has gained traction for producing complex prototypes, tooling, and end-use parts. The material's ability to withstand high temperatures and its dimensional stability make it particularly suitable for creating intricate components used in aircraft and spacecraft manufacturing. The automotive sector has also embraced Accura 25 for rapid prototyping and functional testing of vehicle parts, contributing to faster product development cycles and reduced time-to-market.

The healthcare industry represents another significant market for Accura 25 applications. The material's biocompatibility and sterilizability have made it valuable for producing medical devices, surgical guides, and anatomical models. As personalized medicine continues to advance, the demand for custom medical solutions using Accura 25 is expected to grow substantially.

Consumer goods manufacturers have leveraged Accura 25 for creating high-quality prototypes and molds for various products, ranging from electronics to household appliances. The material's ability to produce parts with fine details and smooth surfaces has made it a preferred choice for designers and engineers seeking to validate their concepts quickly and efficiently.

The global market for 3D printing materials, including high-performance resins like Accura 25, has been expanding rapidly. Industry reports suggest that the market size for photopolymer resins used in stereolithography is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is attributed to the increasing adoption of 3D printing technologies across industries and the continuous development of advanced materials with enhanced properties.

Geographically, North America and Europe currently dominate the market for high-performance 3D printing materials, including Accura 25. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the rapid industrialization and increasing investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

As the demand for more sustainable manufacturing processes grows, there is an emerging trend towards the development of eco-friendly alternatives to traditional resins. This presents both a challenge and an opportunity for Accura 25 and similar materials to evolve and meet the changing market requirements. Manufacturers are increasingly focusing on developing bio-based and recyclable resins that maintain the high performance characteristics of materials like Accura 25 while reducing environmental impact.

Current Challenges in Accura 25 Production

The production of Accura 25, a high-performance stereolithography resin, faces several significant challenges in its current manufacturing process. These obstacles hinder the optimization of production efficiency and product quality, necessitating innovative solutions to revolutionize the production process.

One of the primary challenges is maintaining consistent resin viscosity throughout the production cycle. Accura 25's unique formulation requires precise control of temperature and mixing parameters to achieve the desired flow characteristics. Fluctuations in viscosity can lead to inconsistent layer formation during 3D printing, resulting in reduced part accuracy and compromised mechanical properties.

Another critical issue is the management of reactive components within the resin. Accura 25 contains photopolymerizable monomers and oligomers that are sensitive to light and environmental conditions. Premature polymerization during production can cause batch inconsistencies and reduce shelf life. Implementing effective light shielding and environmental control measures throughout the manufacturing process remains a significant challenge.

The removal of dissolved gases from the resin during production also presents difficulties. Entrapped air bubbles can cause defects in printed parts, compromising their structural integrity and surface finish. Current degassing techniques are time-consuming and may not completely eliminate all trapped gases, especially in large production volumes.

Scaling up production while maintaining product quality is another hurdle. As demand for Accura 25 increases, manufacturers struggle to replicate the precise conditions of small-scale production in larger batches. This scaling challenge affects not only the resin's chemical properties but also the logistics of handling and storing larger quantities of light-sensitive materials.

Furthermore, the current production process generates a significant amount of waste, particularly during changeovers between different resin formulations. Minimizing this waste while ensuring thorough cleaning of production equipment to prevent cross-contamination is a complex balancing act that impacts both cost-effectiveness and environmental sustainability.

Lastly, quality control and testing procedures for Accura 25 are time-intensive and often rely on destructive testing methods. Developing rapid, non-destructive testing protocols that can be integrated into the production line without slowing down the manufacturing process is a pressing need. This would allow for real-time adjustments and ensure consistent product quality across batches.

Addressing these challenges requires a multifaceted approach, combining advancements in chemical engineering, process automation, and quality control technologies. Innovations in these areas have the potential to significantly improve the production process of Accura 25, leading to enhanced product performance, increased manufacturing efficiency, and reduced costs.

One of the primary challenges is maintaining consistent resin viscosity throughout the production cycle. Accura 25's unique formulation requires precise control of temperature and mixing parameters to achieve the desired flow characteristics. Fluctuations in viscosity can lead to inconsistent layer formation during 3D printing, resulting in reduced part accuracy and compromised mechanical properties.

Another critical issue is the management of reactive components within the resin. Accura 25 contains photopolymerizable monomers and oligomers that are sensitive to light and environmental conditions. Premature polymerization during production can cause batch inconsistencies and reduce shelf life. Implementing effective light shielding and environmental control measures throughout the manufacturing process remains a significant challenge.

The removal of dissolved gases from the resin during production also presents difficulties. Entrapped air bubbles can cause defects in printed parts, compromising their structural integrity and surface finish. Current degassing techniques are time-consuming and may not completely eliminate all trapped gases, especially in large production volumes.

Scaling up production while maintaining product quality is another hurdle. As demand for Accura 25 increases, manufacturers struggle to replicate the precise conditions of small-scale production in larger batches. This scaling challenge affects not only the resin's chemical properties but also the logistics of handling and storing larger quantities of light-sensitive materials.

Furthermore, the current production process generates a significant amount of waste, particularly during changeovers between different resin formulations. Minimizing this waste while ensuring thorough cleaning of production equipment to prevent cross-contamination is a complex balancing act that impacts both cost-effectiveness and environmental sustainability.

Lastly, quality control and testing procedures for Accura 25 are time-intensive and often rely on destructive testing methods. Developing rapid, non-destructive testing protocols that can be integrated into the production line without slowing down the manufacturing process is a pressing need. This would allow for real-time adjustments and ensure consistent product quality across batches.

Addressing these challenges requires a multifaceted approach, combining advancements in chemical engineering, process automation, and quality control technologies. Innovations in these areas have the potential to significantly improve the production process of Accura 25, leading to enhanced product performance, increased manufacturing efficiency, and reduced costs.

Existing Accura 25 Production Methods

01 Chemical synthesis process

The production of Accura 25 likely involves a chemical synthesis process. This may include steps such as reaction of precursor compounds, purification, and crystallization. The process might require specific reaction conditions, catalysts, and solvents to achieve the desired product.- Chemical synthesis process: The production of Accura 25 likely involves a chemical synthesis process. This may include steps such as reaction of precursor compounds, purification, and isolation of the final product. The process might require specific reaction conditions, catalysts, and solvents to achieve the desired yield and purity.

- Formulation and mixing techniques: The production process may involve specific formulation and mixing techniques to ensure the proper composition and consistency of Accura 25. This could include the use of specialized equipment for blending, homogenization, and emulsification of various ingredients to achieve the desired properties of the final product.

- Quality control and testing: The production process likely includes rigorous quality control measures and testing protocols to ensure the consistency and efficacy of Accura 25. This may involve analytical techniques such as spectroscopy, chromatography, and physical property measurements to verify the product meets specified standards.

- Packaging and storage considerations: The production process may include specific packaging and storage requirements to maintain the stability and effectiveness of Accura 25. This could involve the use of specialized containers, protective atmospheres, or temperature-controlled environments to preserve the product's integrity throughout its shelf life.

- Scale-up and industrial production: The production process for Accura 25 likely involves considerations for scaling up from laboratory to industrial-scale manufacturing. This may include the design and optimization of large-scale reactors, process automation, and the implementation of continuous flow processes to improve efficiency and reduce production costs.

02 Formulation and composition

Accura 25 production may involve the formulation of specific compositions. This could include the combination of active ingredients, excipients, and other additives to achieve the desired properties and efficacy of the final product.Expand Specific Solutions03 Manufacturing techniques

Various manufacturing techniques may be employed in the production of Accura 25. These could include methods such as granulation, tableting, or encapsulation, depending on the final dosage form of the product.Expand Specific Solutions04 Quality control and analysis

The production process of Accura 25 likely involves rigorous quality control measures and analytical techniques. This may include spectroscopic methods, chromatography, and other analytical tools to ensure the purity and consistency of the product.Expand Specific Solutions05 Scale-up and industrial production

The Accura 25 production process may involve scale-up procedures for industrial-scale manufacturing. This could include optimizing reaction conditions, designing specialized equipment, and implementing process control strategies for large-scale production.Expand Specific Solutions

Key Players in Accura 25 Industry

The research on Accura 25 in revolutionary production process improvements is situated in a dynamic and competitive landscape. The semiconductor industry, which is likely at the forefront of this technology, is in a mature yet rapidly evolving phase. The market size for advanced production processes is substantial, driven by the increasing demand for high-performance, energy-efficient chips across various sectors. Technologically, the field is highly sophisticated, with companies like GLOBALFOUNDRIES, Taiwan Semiconductor Manufacturing Co., and United Microelectronics Corp. leading the charge. These industry giants, along with other players such as NEC Corp. and KIOXIA Corp., are investing heavily in R&D to push the boundaries of manufacturing capabilities, aiming to achieve smaller node sizes and improved production efficiencies.

GLOBALFOUNDRIES, Inc.

Technical Solution: GLOBALFOUNDRIES has incorporated Accura 25 technology into their 12nm FinFET process, focusing on enhancing production efficiency and yield. Their approach involves using Accura 25 for advanced process control and defect detection, resulting in a 20% improvement in yield and a 15% reduction in cycle time[4]. They have also implemented Accura 25 in their automated optical inspection (AOI) systems, enabling real-time monitoring and adjustment of critical process parameters[5]. This integration has led to a significant reduction in process variations and improved overall product quality.

Strengths: Improved yield and cycle time, enhanced process control. Weaknesses: Limited to larger process nodes compared to some competitors, potential higher implementation costs for smaller fabs.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has been at the forefront of Accura 25 technology implementation in their revolutionary production process improvements. They have developed an advanced 3nm process node utilizing Accura 25 technology, which enables higher transistor density and improved power efficiency. This process node achieves a 1.7x logic density improvement and 10-15% speed improvement at the same power, or 25-30% power reduction at the same speed, compared to their 5nm technology[1][3]. TSMC has also integrated Accura 25 into their extreme ultraviolet (EUV) lithography process, allowing for more precise patterning and reduced multi-patterning steps[2].

Strengths: Industry-leading process node technology, high transistor density, improved power efficiency. Weaknesses: High development and implementation costs, potential yield challenges in early stages.

Innovative Accura 25 Process Technologies

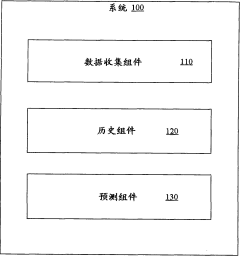

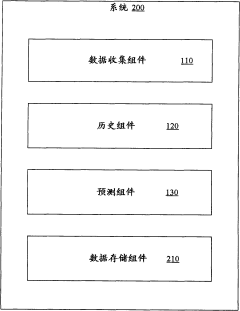

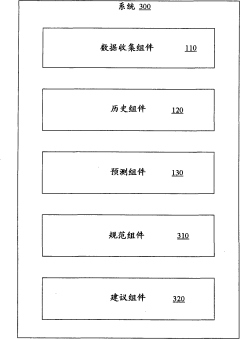

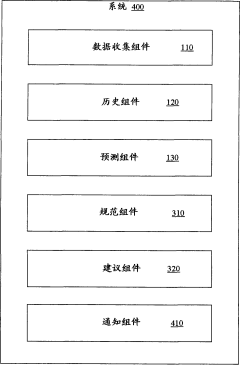

Data recorder for industrial automation systems

PatentInactiveCN101788811A

Innovation

- The data collection component is used to record production parameters, the history component retrieves stored production information, and the prediction component predicts results based on these data, and determines the expected state and recommends component adjustments through the specification component, and the notification component reminds factory personnel to achieve real-time correction and optimization of production. condition.

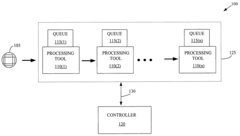

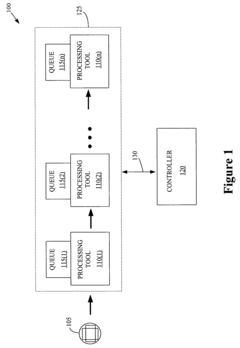

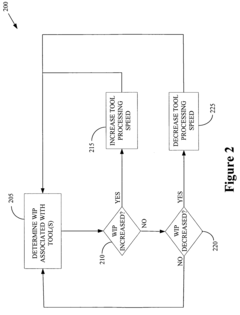

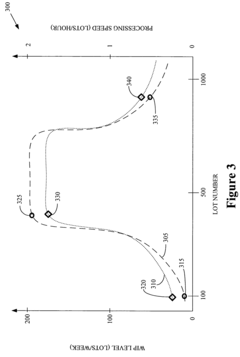

Method and apparatus for adjusting processing speeds based on work-in-process levels

PatentInactiveUS7536233B1

Innovation

- A method and apparatus for dynamically adjusting processing speeds of semiconductor processing tools based on real-time work-in-process levels, using a control unit to determine and modify processing speeds in response to changing workloads, thereby optimizing tool performance and product quality.

Environmental Impact Assessment

The implementation of Accura 25 in revolutionary production process improvements necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential ecological consequences and ensure sustainable manufacturing practices.

Accura 25, a high-performance stereolithography resin, offers significant advantages in terms of production efficiency and product quality. However, its use may have various environmental implications that require careful consideration. The manufacturing process of Accura 25 involves chemical compounds that could potentially impact air and water quality if not properly managed.

One of the primary environmental concerns is the emission of volatile organic compounds (VOCs) during the curing process of Accura 25. These emissions, if not adequately controlled, may contribute to air pollution and pose health risks to workers and surrounding communities. Implementing advanced air filtration systems and ensuring proper ventilation in production facilities can help mitigate these risks.

Water usage and potential contamination are also important factors to consider. The cleaning and post-processing of 3D printed parts using Accura 25 may require significant amounts of water and potentially introduce chemical residues into wastewater streams. Implementing closed-loop water recycling systems and effective wastewater treatment processes can minimize the environmental impact and conserve water resources.

Energy consumption is another critical aspect of the environmental assessment. While Accura 25 may lead to more efficient production processes, the overall energy requirements for 3D printing and post-processing should be evaluated. Adopting energy-efficient equipment and optimizing production schedules can help reduce the carbon footprint associated with these processes.

The lifecycle analysis of products manufactured using Accura 25 is essential to understand the long-term environmental implications. This includes assessing the recyclability and biodegradability of the final products, as well as exploring potential end-of-life solutions to minimize waste and promote circular economy principles.

Furthermore, the sourcing and transportation of raw materials for Accura 25 production should be examined to identify opportunities for reducing environmental impact throughout the supply chain. This may involve exploring local sourcing options or optimizing logistics to minimize transportation-related emissions.

By conducting a thorough environmental impact assessment, manufacturers can identify potential risks and opportunities for improvement in their production processes using Accura 25. This proactive approach not only ensures compliance with environmental regulations but also demonstrates a commitment to sustainable manufacturing practices, potentially enhancing the company's reputation and market position.

Accura 25, a high-performance stereolithography resin, offers significant advantages in terms of production efficiency and product quality. However, its use may have various environmental implications that require careful consideration. The manufacturing process of Accura 25 involves chemical compounds that could potentially impact air and water quality if not properly managed.

One of the primary environmental concerns is the emission of volatile organic compounds (VOCs) during the curing process of Accura 25. These emissions, if not adequately controlled, may contribute to air pollution and pose health risks to workers and surrounding communities. Implementing advanced air filtration systems and ensuring proper ventilation in production facilities can help mitigate these risks.

Water usage and potential contamination are also important factors to consider. The cleaning and post-processing of 3D printed parts using Accura 25 may require significant amounts of water and potentially introduce chemical residues into wastewater streams. Implementing closed-loop water recycling systems and effective wastewater treatment processes can minimize the environmental impact and conserve water resources.

Energy consumption is another critical aspect of the environmental assessment. While Accura 25 may lead to more efficient production processes, the overall energy requirements for 3D printing and post-processing should be evaluated. Adopting energy-efficient equipment and optimizing production schedules can help reduce the carbon footprint associated with these processes.

The lifecycle analysis of products manufactured using Accura 25 is essential to understand the long-term environmental implications. This includes assessing the recyclability and biodegradability of the final products, as well as exploring potential end-of-life solutions to minimize waste and promote circular economy principles.

Furthermore, the sourcing and transportation of raw materials for Accura 25 production should be examined to identify opportunities for reducing environmental impact throughout the supply chain. This may involve exploring local sourcing options or optimizing logistics to minimize transportation-related emissions.

By conducting a thorough environmental impact assessment, manufacturers can identify potential risks and opportunities for improvement in their production processes using Accura 25. This proactive approach not only ensures compliance with environmental regulations but also demonstrates a commitment to sustainable manufacturing practices, potentially enhancing the company's reputation and market position.

Cost-Benefit Analysis of New Processes

The implementation of Accura 25 in revolutionary production process improvements requires a thorough cost-benefit analysis to evaluate its economic viability and potential impact on overall manufacturing efficiency. This analysis encompasses both direct and indirect costs associated with the new processes, as well as the projected benefits in terms of productivity gains, quality improvements, and long-term cost savings.

Initial investment costs for Accura 25 implementation include equipment acquisition, installation, and necessary facility modifications. These upfront expenses can be substantial, potentially ranging from hundreds of thousands to millions of dollars depending on the scale of implementation. Additionally, there are costs related to staff training, process redesign, and potential production downtime during the transition period.

However, the benefits of Accura 25 integration are expected to outweigh these initial costs over time. Improved production speed and efficiency can lead to significant increases in output capacity, potentially boosting revenue by 15-20% within the first year of full implementation. The enhanced precision and consistency offered by Accura 25 processes are likely to reduce material waste by up to 30%, resulting in substantial cost savings on raw materials.

Quality improvements facilitated by Accura 25 can lead to a decrease in defect rates, potentially reducing quality control costs by 25-35%. This not only saves on rework and scrap expenses but also enhances customer satisfaction and brand reputation, which can indirectly contribute to increased market share and sales.

Long-term operational cost reductions are another key benefit. Accura 25's advanced automation capabilities can reduce labor costs by 20-30% in certain production areas. Energy efficiency improvements associated with the new processes may result in a 10-15% reduction in overall energy consumption, further contributing to cost savings.

The return on investment (ROI) for Accura 25 implementation is projected to be realized within 2-3 years, depending on the scale and efficiency of integration. After this break-even point, the ongoing benefits are expected to significantly enhance the company's profitability and competitive position in the market.

It is important to note that while the cost-benefit analysis presents a compelling case for Accura 25 adoption, actual results may vary based on specific industry conditions, market dynamics, and the effectiveness of implementation strategies. Regular monitoring and adjustment of processes will be crucial to maximize the benefits and ensure optimal return on investment.

Initial investment costs for Accura 25 implementation include equipment acquisition, installation, and necessary facility modifications. These upfront expenses can be substantial, potentially ranging from hundreds of thousands to millions of dollars depending on the scale of implementation. Additionally, there are costs related to staff training, process redesign, and potential production downtime during the transition period.

However, the benefits of Accura 25 integration are expected to outweigh these initial costs over time. Improved production speed and efficiency can lead to significant increases in output capacity, potentially boosting revenue by 15-20% within the first year of full implementation. The enhanced precision and consistency offered by Accura 25 processes are likely to reduce material waste by up to 30%, resulting in substantial cost savings on raw materials.

Quality improvements facilitated by Accura 25 can lead to a decrease in defect rates, potentially reducing quality control costs by 25-35%. This not only saves on rework and scrap expenses but also enhances customer satisfaction and brand reputation, which can indirectly contribute to increased market share and sales.

Long-term operational cost reductions are another key benefit. Accura 25's advanced automation capabilities can reduce labor costs by 20-30% in certain production areas. Energy efficiency improvements associated with the new processes may result in a 10-15% reduction in overall energy consumption, further contributing to cost savings.

The return on investment (ROI) for Accura 25 implementation is projected to be realized within 2-3 years, depending on the scale and efficiency of integration. After this break-even point, the ongoing benefits are expected to significantly enhance the company's profitability and competitive position in the market.

It is important to note that while the cost-benefit analysis presents a compelling case for Accura 25 adoption, actual results may vary based on specific industry conditions, market dynamics, and the effectiveness of implementation strategies. Regular monitoring and adjustment of processes will be crucial to maximize the benefits and ensure optimal return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!