How to Enhance Detail Precision with Accura 25?

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Technology Overview and Objectives

Accura 25 is a cutting-edge stereolithography (SLA) resin developed by 3D Systems, designed to enhance detail precision in additive manufacturing processes. This advanced material has revolutionized the production of high-resolution parts, particularly in industries requiring intricate designs and fine features.

The technology behind Accura 25 stems from decades of research and development in photopolymer chemistry and 3D printing techniques. Its evolution can be traced back to the early days of stereolithography, with continuous improvements in resin formulations and printing processes leading to the current state-of-the-art material.

The primary objective of Accura 25 is to push the boundaries of detail precision in 3D printing. It aims to achieve superior surface finish, enhanced feature resolution, and improved overall part quality compared to conventional SLA resins. This technology addresses the growing demand for high-fidelity prototypes and functional parts across various industries, including aerospace, automotive, and medical device manufacturing.

One of the key technological trends driving the development of Accura 25 is the increasing miniaturization of components in many industries. As products become smaller and more complex, the need for materials capable of reproducing fine details with high accuracy has become paramount. Accura 25 responds to this trend by offering exceptional resolution and feature definition.

The material's unique formulation allows for precise control over the curing process, resulting in improved layer-to-layer adhesion and reduced internal stresses. This contributes to enhanced structural integrity and dimensional accuracy of printed parts, addressing common challenges in SLA printing such as warping and shrinkage.

Accura 25 also aligns with the industry's focus on sustainability and efficiency. Its optimized curing properties enable faster print speeds and reduced post-processing requirements, leading to increased productivity and reduced material waste. This efficiency not only benefits manufacturers but also contributes to more sustainable production practices.

Looking ahead, the technology goals for Accura 25 include further refinement of its material properties to achieve even higher levels of detail precision. Research efforts are focused on improving the resin's photosensitivity and curing characteristics to enable the production of parts with sub-micron features. Additionally, there is ongoing work to expand the material's compatibility with a broader range of 3D printing systems and post-processing techniques.

The technology behind Accura 25 stems from decades of research and development in photopolymer chemistry and 3D printing techniques. Its evolution can be traced back to the early days of stereolithography, with continuous improvements in resin formulations and printing processes leading to the current state-of-the-art material.

The primary objective of Accura 25 is to push the boundaries of detail precision in 3D printing. It aims to achieve superior surface finish, enhanced feature resolution, and improved overall part quality compared to conventional SLA resins. This technology addresses the growing demand for high-fidelity prototypes and functional parts across various industries, including aerospace, automotive, and medical device manufacturing.

One of the key technological trends driving the development of Accura 25 is the increasing miniaturization of components in many industries. As products become smaller and more complex, the need for materials capable of reproducing fine details with high accuracy has become paramount. Accura 25 responds to this trend by offering exceptional resolution and feature definition.

The material's unique formulation allows for precise control over the curing process, resulting in improved layer-to-layer adhesion and reduced internal stresses. This contributes to enhanced structural integrity and dimensional accuracy of printed parts, addressing common challenges in SLA printing such as warping and shrinkage.

Accura 25 also aligns with the industry's focus on sustainability and efficiency. Its optimized curing properties enable faster print speeds and reduced post-processing requirements, leading to increased productivity and reduced material waste. This efficiency not only benefits manufacturers but also contributes to more sustainable production practices.

Looking ahead, the technology goals for Accura 25 include further refinement of its material properties to achieve even higher levels of detail precision. Research efforts are focused on improving the resin's photosensitivity and curing characteristics to enable the production of parts with sub-micron features. Additionally, there is ongoing work to expand the material's compatibility with a broader range of 3D printing systems and post-processing techniques.

Market Demand for High-Precision 3D Printing

The market demand for high-precision 3D printing has been steadily increasing across various industries, driven by the need for more accurate and detailed prototypes, functional parts, and end-use products. Accura 25, a photopolymer resin used in stereolithography (SLA) 3D printing, has gained significant attention due to its potential to enhance detail precision in printed objects.

In the automotive and aerospace sectors, there is a growing requirement for high-precision components with complex geometries. These industries are increasingly adopting 3D printing for rapid prototyping, tooling, and even production of end-use parts. The ability to produce intricate designs with fine details and smooth surface finishes is crucial for aerodynamic testing, functional prototypes, and lightweight structural components.

The medical and dental fields have also shown a substantial demand for high-precision 3D printing. Custom prosthetics, dental implants, and surgical guides require exceptional accuracy and detail to ensure proper fit and functionality. The use of materials like Accura 25 in these applications can lead to improved patient outcomes and more efficient medical procedures.

Consumer electronics manufacturers are another significant market segment seeking enhanced detail precision in 3D printing. As devices become smaller and more complex, the need for precise prototypes and molds with intricate features has increased. High-resolution 3D printing enables faster design iterations and more accurate representation of final products during the development phase.

The jewelry and luxury goods industry has embraced high-precision 3D printing for creating detailed molds and prototypes. The ability to produce intricate patterns, textures, and fine details is essential for maintaining the high standards expected in this sector. Accura 25 and similar materials offer the potential to achieve the level of precision required for these applications.

In the field of scientific research and education, there is a growing demand for accurate 3D-printed models of complex molecular structures, archaeological artifacts, and anatomical models. These applications require materials and printing techniques that can faithfully reproduce minute details and maintain dimensional accuracy.

As the adoption of 3D printing continues to expand across industries, the market for high-precision materials and technologies is expected to grow significantly. Manufacturers and researchers are constantly seeking ways to push the boundaries of detail precision, making materials like Accura 25 increasingly valuable in the evolving landscape of additive manufacturing.

In the automotive and aerospace sectors, there is a growing requirement for high-precision components with complex geometries. These industries are increasingly adopting 3D printing for rapid prototyping, tooling, and even production of end-use parts. The ability to produce intricate designs with fine details and smooth surface finishes is crucial for aerodynamic testing, functional prototypes, and lightweight structural components.

The medical and dental fields have also shown a substantial demand for high-precision 3D printing. Custom prosthetics, dental implants, and surgical guides require exceptional accuracy and detail to ensure proper fit and functionality. The use of materials like Accura 25 in these applications can lead to improved patient outcomes and more efficient medical procedures.

Consumer electronics manufacturers are another significant market segment seeking enhanced detail precision in 3D printing. As devices become smaller and more complex, the need for precise prototypes and molds with intricate features has increased. High-resolution 3D printing enables faster design iterations and more accurate representation of final products during the development phase.

The jewelry and luxury goods industry has embraced high-precision 3D printing for creating detailed molds and prototypes. The ability to produce intricate patterns, textures, and fine details is essential for maintaining the high standards expected in this sector. Accura 25 and similar materials offer the potential to achieve the level of precision required for these applications.

In the field of scientific research and education, there is a growing demand for accurate 3D-printed models of complex molecular structures, archaeological artifacts, and anatomical models. These applications require materials and printing techniques that can faithfully reproduce minute details and maintain dimensional accuracy.

As the adoption of 3D printing continues to expand across industries, the market for high-precision materials and technologies is expected to grow significantly. Manufacturers and researchers are constantly seeking ways to push the boundaries of detail precision, making materials like Accura 25 increasingly valuable in the evolving landscape of additive manufacturing.

Current Limitations in Detail Precision

Accura 25, a widely used resin in stereolithography (SLA) 3D printing, has been instrumental in producing high-resolution parts. However, it faces several limitations in achieving optimal detail precision. One of the primary constraints is the minimum feature size that can be reliably produced. While Accura 25 can theoretically achieve features as small as 0.1mm, practical limitations often result in a minimum feature size of around 0.3-0.5mm, depending on the specific geometry and printing parameters.

The resolution of the laser used in the SLA process also impacts detail precision. Current systems typically have a laser spot size of about 100-150 microns, which limits the ability to create extremely fine details. This becomes particularly challenging when attempting to produce intricate structures or textures on the surface of printed parts.

Another significant limitation is the occurrence of "stepping" or layer lines. The layer thickness in SLA printing with Accura 25 is typically around 50-100 microns. While this is relatively thin compared to other 3D printing technologies, it can still result in visible layer lines on curved or angled surfaces, compromising the overall surface smoothness and detail precision.

The shrinkage and warping of parts during the curing process present additional challenges. Accura 25, like many photopolymer resins, undergoes volumetric shrinkage as it cures. This shrinkage can lead to dimensional inaccuracies and distortions, particularly in larger parts or those with thin, unsupported sections. The effect is more pronounced in areas with sudden changes in cross-sectional area.

Support structures, while necessary for many designs, can also impact detail precision. The points where supports attach to the part can leave small marks or imperfections on the surface, which may require post-processing to remove. In some cases, the presence of supports can limit the achievable detail in certain areas of the print.

The viscosity of Accura 25 resin can affect the ability to achieve fine details, particularly in small channels or holes. Higher viscosity can make it difficult for the resin to fully penetrate and cure in tight spaces, potentially leading to incomplete feature formation or trapped uncured resin.

Lastly, the post-processing steps required for parts printed with Accura 25 can impact final detail precision. Cleaning processes to remove uncured resin, if not performed carefully, can potentially damage fine features. Additionally, the post-curing process, while necessary for achieving optimal mechanical properties, can sometimes lead to further shrinkage or warping, affecting the final dimensional accuracy and detail preservation of the printed part.

The resolution of the laser used in the SLA process also impacts detail precision. Current systems typically have a laser spot size of about 100-150 microns, which limits the ability to create extremely fine details. This becomes particularly challenging when attempting to produce intricate structures or textures on the surface of printed parts.

Another significant limitation is the occurrence of "stepping" or layer lines. The layer thickness in SLA printing with Accura 25 is typically around 50-100 microns. While this is relatively thin compared to other 3D printing technologies, it can still result in visible layer lines on curved or angled surfaces, compromising the overall surface smoothness and detail precision.

The shrinkage and warping of parts during the curing process present additional challenges. Accura 25, like many photopolymer resins, undergoes volumetric shrinkage as it cures. This shrinkage can lead to dimensional inaccuracies and distortions, particularly in larger parts or those with thin, unsupported sections. The effect is more pronounced in areas with sudden changes in cross-sectional area.

Support structures, while necessary for many designs, can also impact detail precision. The points where supports attach to the part can leave small marks or imperfections on the surface, which may require post-processing to remove. In some cases, the presence of supports can limit the achievable detail in certain areas of the print.

The viscosity of Accura 25 resin can affect the ability to achieve fine details, particularly in small channels or holes. Higher viscosity can make it difficult for the resin to fully penetrate and cure in tight spaces, potentially leading to incomplete feature formation or trapped uncured resin.

Lastly, the post-processing steps required for parts printed with Accura 25 can impact final detail precision. Cleaning processes to remove uncured resin, if not performed carefully, can potentially damage fine features. Additionally, the post-curing process, while necessary for achieving optimal mechanical properties, can sometimes lead to further shrinkage or warping, affecting the final dimensional accuracy and detail preservation of the printed part.

Existing Solutions for Enhancing Detail Precision

01 3D printing precision and detail enhancement

Techniques for improving the precision and detail of 3D printed objects, particularly in the context of stereolithography. This includes methods for optimizing laser focus, resin formulations, and post-processing techniques to achieve higher resolution and finer details in printed parts.- 3D printing precision and detail enhancement: Techniques for improving the precision and detail of 3D printed objects, particularly in the context of Accura 25 material. This includes optimizing printing parameters, post-processing methods, and material formulation to achieve higher resolution and finer details in the final printed parts.

- Image processing for enhanced detail rendering: Advanced image processing algorithms and techniques to improve the rendering of fine details in digital images and 3D models. These methods can be applied to enhance the visual quality and accuracy of 3D printed objects, including those made with Accura 25 material.

- Material composition and properties optimization: Research and development focused on optimizing the composition and properties of 3D printing materials, such as Accura 25, to enhance their ability to reproduce fine details and maintain precision during the printing process. This includes studying the rheological properties and curing behavior of the material.

- Calibration and alignment techniques for precision printing: Methods and systems for calibrating and aligning 3D printers to ensure high precision and accuracy in reproducing fine details. This includes software algorithms, hardware adjustments, and calibration procedures specifically designed for materials like Accura 25.

- Post-processing methods for detail enhancement: Techniques for post-processing 3D printed objects to enhance their surface finish, detail resolution, and overall quality. This may include chemical treatments, mechanical finishing, or thermal processes specifically tailored for Accura 25 and similar materials to improve the final product's precision and detail.

02 Image processing for enhanced detail rendering

Advanced image processing algorithms and techniques to improve the rendering of fine details in digital images and 3D models. This includes methods for edge detection, texture mapping, and anti-aliasing to enhance the visual quality and accuracy of displayed or printed objects.Expand Specific Solutions03 Precision measurement and calibration in manufacturing

Methods and systems for precise measurement and calibration in manufacturing processes, particularly for ensuring accuracy in the production of detailed components. This includes techniques for dimensional analysis, surface finish evaluation, and quality control in high-precision manufacturing.Expand Specific Solutions04 High-resolution display technologies

Development of high-resolution display technologies capable of rendering fine details with high precision. This includes advancements in pixel density, color accuracy, and refresh rates to improve the visual representation of detailed images and models.Expand Specific Solutions05 Data management for detailed 3D models

Efficient data management and processing techniques for handling large, detailed 3D models. This includes methods for data compression, level-of-detail rendering, and optimized storage solutions to manage complex 3D data sets while maintaining high precision and detail.Expand Specific Solutions

Key Players in High-Precision 3D Printing

The competitive landscape for enhancing detail precision with Accura 25 is characterized by a mature market with significant technological advancements. The industry is in a growth phase, with major players like NVIDIA, Apple, and Samsung Electronics driving innovation. The market size is substantial, given the widespread application of precision enhancement technologies across various sectors. Technologically, companies such as Semiconductor Manufacturing International and Nanya Technology are at the forefront, developing cutting-edge solutions. The involvement of research institutions like Xi'an Jiaotong University and the Institute of Automation Chinese Academy of Sciences indicates ongoing advancements in the field.

Institute of Optics and Electronics, Chinese Academy of Sciences

Technical Solution: The Institute of Optics and Electronics (IOE) at the Chinese Academy of Sciences approaches the enhancement of detail precision with Accura 25 through a combination of advanced optical engineering and computational imaging techniques. Their solution focuses on developing novel adaptive optics systems that can correct for atmospheric turbulence and other distortions in real-time, significantly improving image resolution and detail retention in astronomical and remote sensing applications[13]. IOE also employs phase retrieval algorithms and wavefront sensing technologies to optimize image quality and recover fine details that might be lost due to optical aberrations. In the realm of microscopy, they have developed super-resolution techniques that break the diffraction limit, allowing for imaging of structures at the nanoscale with unprecedented detail[14]. Additionally, IOE incorporates machine learning algorithms to enhance image processing pipelines, enabling more effective noise reduction and feature extraction in complex imaging scenarios[15].

Strengths: Cutting-edge research in optics and photonics, interdisciplinary approach combining hardware and software solutions, and expertise in extreme imaging conditions. Weaknesses: Potential challenges in commercialization and adaptation for consumer-grade applications.

NVIDIA Corp.

Technical Solution: NVIDIA's approach to enhancing detail precision with Accura 25 leverages their expertise in GPU technology and AI. They utilize advanced deep learning algorithms and tensor core acceleration to improve image quality and detail retention. Their solution incorporates real-time super-resolution techniques, allowing for upscaling of lower resolution images to higher resolutions while preserving and enhancing fine details. This is achieved through a combination of convolutional neural networks and proprietary AI models trained on vast datasets of high-quality images[1][3]. NVIDIA's implementation also includes adaptive sharpening filters and noise reduction algorithms to further refine the output, resulting in crisp, clear images with improved detail precision across various lighting conditions and scene complexities[5].

Strengths: Powerful GPU acceleration, extensive AI expertise, and large-scale dataset utilization for training. Weaknesses: High computational requirements and potential dependency on specific NVIDIA hardware for optimal performance.

Core Innovations in Accura 25 Technology

Opponent Color Detail Enhancement for Saturated Colors

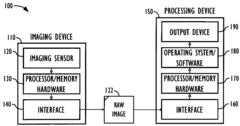

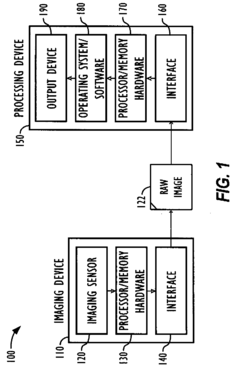

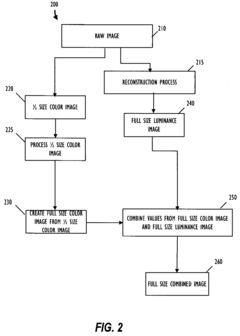

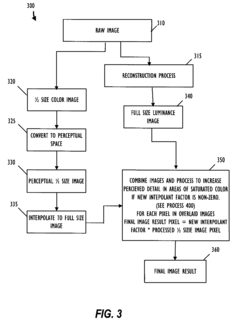

PatentActiveUS20100165149A1

Innovation

- The method involves processing RAW images by utilizing opponent color channels, specifically Green as the opponent channel for Red and Blue, and applying an interpolant factor based on saturation levels and noise values to increase detail in saturated areas, while avoiding excessive noise and artifacts.

Dynamic image enhancement method and device using backlight adjustment, and computer apparatus

PatentWO2020078347A1

Innovation

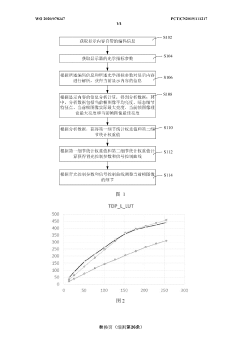

- By obtaining the coding information of the display content and the optical index parameters of the display, the analysis data is obtained through analysis and calculation, the detail statistical weight value and the signal control curve are calculated, and the backlight control parameters are adjusted to adjust the image details to ensure that image details are not sacrificed during backlight adjustment. And enhance the layering and three-dimensionality of the image.

Material Science Advancements for Accura 25

Accura 25, a widely used stereolithography resin, has been a cornerstone in the 3D printing industry for its versatility and reliability. However, as the demand for higher precision and finer details in 3D printed parts continues to grow, material scientists are exploring innovative ways to enhance the capabilities of Accura 25. These advancements are crucial for industries such as aerospace, medical devices, and microfluidics, where intricate designs and tight tolerances are paramount.

One of the primary focuses in material science for Accura 25 is the modification of its molecular structure. Researchers are investigating the incorporation of nanoparticles and novel cross-linking agents to improve the resin's resolution and mechanical properties. These modifications aim to reduce the minimum feature size achievable with Accura 25, potentially pushing the boundaries of detail precision below the current limitations.

Another area of advancement is the development of hybrid formulations that combine Accura 25 with other high-performance materials. By carefully balancing the properties of different components, scientists are creating new resins that maintain the ease of use of Accura 25 while significantly enhancing its detail reproduction capabilities. These hybrid materials show promise in achieving sharper edges, smoother surfaces, and more accurate representation of complex geometries.

Surface chemistry modifications are also being explored to improve the wetting and adhesion properties of Accura 25. By optimizing the interaction between the resin and the laser used in stereolithography, researchers aim to achieve more precise curing patterns and reduce the occurrence of over-curing or under-curing, which can affect detail precision.

Advancements in post-processing techniques specifically tailored for Accura 25 are being developed to complement the material improvements. These include novel cleaning methods that can remove uncured resin from intricate structures without damaging fine details, as well as specialized curing processes that can further enhance the resolution and strength of printed parts.

The integration of computational modeling and machine learning algorithms is playing a crucial role in predicting and optimizing the behavior of modified Accura 25 formulations. These tools allow researchers to simulate the curing process at a molecular level, enabling rapid iteration and development of new material compositions that push the boundaries of detail precision.

As these material science advancements continue to evolve, the future of Accura 25 looks promising for applications requiring ultra-high precision. The ongoing research and development efforts are paving the way for a new generation of stereolithography resins that can meet the ever-increasing demands of industries relying on additive manufacturing for their most challenging applications.

One of the primary focuses in material science for Accura 25 is the modification of its molecular structure. Researchers are investigating the incorporation of nanoparticles and novel cross-linking agents to improve the resin's resolution and mechanical properties. These modifications aim to reduce the minimum feature size achievable with Accura 25, potentially pushing the boundaries of detail precision below the current limitations.

Another area of advancement is the development of hybrid formulations that combine Accura 25 with other high-performance materials. By carefully balancing the properties of different components, scientists are creating new resins that maintain the ease of use of Accura 25 while significantly enhancing its detail reproduction capabilities. These hybrid materials show promise in achieving sharper edges, smoother surfaces, and more accurate representation of complex geometries.

Surface chemistry modifications are also being explored to improve the wetting and adhesion properties of Accura 25. By optimizing the interaction between the resin and the laser used in stereolithography, researchers aim to achieve more precise curing patterns and reduce the occurrence of over-curing or under-curing, which can affect detail precision.

Advancements in post-processing techniques specifically tailored for Accura 25 are being developed to complement the material improvements. These include novel cleaning methods that can remove uncured resin from intricate structures without damaging fine details, as well as specialized curing processes that can further enhance the resolution and strength of printed parts.

The integration of computational modeling and machine learning algorithms is playing a crucial role in predicting and optimizing the behavior of modified Accura 25 formulations. These tools allow researchers to simulate the curing process at a molecular level, enabling rapid iteration and development of new material compositions that push the boundaries of detail precision.

As these material science advancements continue to evolve, the future of Accura 25 looks promising for applications requiring ultra-high precision. The ongoing research and development efforts are paving the way for a new generation of stereolithography resins that can meet the ever-increasing demands of industries relying on additive manufacturing for their most challenging applications.

Post-Processing Techniques for Improved Detail

Post-processing techniques play a crucial role in enhancing the detail precision of parts manufactured using Accura 25, a widely used stereolithography resin. These techniques are applied after the initial 3D printing process to refine and improve the final product's quality, particularly in terms of surface finish and dimensional accuracy.

One of the primary post-processing methods for Accura 25 parts is careful cleaning and removal of excess resin. This process typically involves using isopropyl alcohol (IPA) or specialized cleaning solutions to dissolve and wash away any uncured resin from the part's surface. Ultrasonic cleaning baths can be employed to ensure thorough cleaning, especially for intricate geometries with hard-to-reach areas.

Following the cleaning process, UV post-curing is essential to fully solidify the part and achieve optimal mechanical properties. This step involves exposing the cleaned part to UV light in a controlled environment, often using dedicated post-curing chambers. The duration and intensity of UV exposure can be fine-tuned based on the part's size and complexity to ensure complete curing without over-exposure, which could lead to brittleness or warping.

Surface finishing techniques can significantly enhance the detail precision of Accura 25 parts. Gentle sanding with progressively finer grit sandpaper can smooth out layer lines and minor imperfections. For more delicate features, micro-abrasive blasting using fine media like glass beads or aluminum oxide can provide a uniform surface finish without compromising intricate details.

Chemical smoothing is another advanced technique that can be applied to Accura 25 parts. This process involves carefully exposing the part's surface to a solvent vapor, which temporarily softens the outer layer, allowing surface tension to smooth out imperfections. However, this method requires precise control to avoid over-smoothing and loss of fine details.

For parts requiring extreme precision, CNC machining can be employed as a post-processing step. This hybrid approach combines the advantages of additive manufacturing with the accuracy of subtractive techniques. Key features or critical dimensions can be machined to tight tolerances, ensuring the highest level of detail precision.

Coating and painting processes can also contribute to improved detail visibility and surface quality. Applying a thin layer of primer followed by carefully airbrushed paint can enhance contrast and highlight fine features. For functional parts, specialized coatings can be applied to improve wear resistance or other surface properties without significantly altering dimensions.

One of the primary post-processing methods for Accura 25 parts is careful cleaning and removal of excess resin. This process typically involves using isopropyl alcohol (IPA) or specialized cleaning solutions to dissolve and wash away any uncured resin from the part's surface. Ultrasonic cleaning baths can be employed to ensure thorough cleaning, especially for intricate geometries with hard-to-reach areas.

Following the cleaning process, UV post-curing is essential to fully solidify the part and achieve optimal mechanical properties. This step involves exposing the cleaned part to UV light in a controlled environment, often using dedicated post-curing chambers. The duration and intensity of UV exposure can be fine-tuned based on the part's size and complexity to ensure complete curing without over-exposure, which could lead to brittleness or warping.

Surface finishing techniques can significantly enhance the detail precision of Accura 25 parts. Gentle sanding with progressively finer grit sandpaper can smooth out layer lines and minor imperfections. For more delicate features, micro-abrasive blasting using fine media like glass beads or aluminum oxide can provide a uniform surface finish without compromising intricate details.

Chemical smoothing is another advanced technique that can be applied to Accura 25 parts. This process involves carefully exposing the part's surface to a solvent vapor, which temporarily softens the outer layer, allowing surface tension to smooth out imperfections. However, this method requires precise control to avoid over-smoothing and loss of fine details.

For parts requiring extreme precision, CNC machining can be employed as a post-processing step. This hybrid approach combines the advantages of additive manufacturing with the accuracy of subtractive techniques. Key features or critical dimensions can be machined to tight tolerances, ensuring the highest level of detail precision.

Coating and painting processes can also contribute to improved detail visibility and surface quality. Applying a thin layer of primer followed by carefully airbrushed paint can enhance contrast and highlight fine features. For functional parts, specialized coatings can be applied to improve wear resistance or other surface properties without significantly altering dimensions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!