Accura 25’s Role in Cutting-Edge Creative Processes

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25, a groundbreaking material developed by 3D Systems, has emerged as a pivotal innovation in the realm of stereolithography (SLA) 3D printing. This advanced resin has revolutionized the landscape of additive manufacturing, particularly in industries demanding high-precision prototypes and end-use parts. The evolution of Accura 25 is rooted in the continuous pursuit of enhancing the capabilities of 3D printing technologies to meet the ever-growing demands of various sectors, including aerospace, automotive, and medical device manufacturing.

The primary objective behind the development of Accura 25 was to address the limitations of traditional SLA materials, particularly in terms of durability, accuracy, and surface finish. By leveraging cutting-edge polymer science and nanotechnology, 3D Systems aimed to create a material that could withstand rigorous testing environments while maintaining exceptional detail and dimensional stability. This ambitious goal aligned with the broader industry trend of pushing the boundaries of what is possible in additive manufacturing.

Accura 25's journey began with extensive research into the molecular structure of photopolymers and their interaction with light during the SLA process. The development team focused on optimizing the resin's chemical composition to achieve a delicate balance between reactivity and stability. This meticulous approach resulted in a material that exhibits superior mechanical properties, including high tensile strength, elongation at break, and impact resistance.

As the technology matured, Accura 25 found its niche in creative processes that demand both precision and durability. Industrial designers and engineers quickly recognized its potential for producing functional prototypes that could withstand real-world testing scenarios. The material's ability to replicate fine details and maintain dimensional accuracy throughout post-processing stages made it an invaluable tool for iterative design processes and rapid prototyping.

The introduction of Accura 25 marked a significant milestone in the additive manufacturing industry, setting new standards for what could be achieved with SLA technology. Its success paved the way for further innovations in material science, inspiring researchers and manufacturers to explore new frontiers in 3D printing resins. The material's impact extended beyond its immediate applications, influencing the development of complementary technologies such as advanced post-processing techniques and specialized 3D printers optimized for high-performance resins.

Looking ahead, the continued evolution of Accura 25 and similar advanced materials is expected to play a crucial role in shaping the future of creative processes across various industries. As manufacturers and designers seek to push the boundaries of innovation, materials like Accura 25 will be instrumental in bridging the gap between concept and reality, enabling the rapid realization of complex designs and accelerating product development cycles.

The primary objective behind the development of Accura 25 was to address the limitations of traditional SLA materials, particularly in terms of durability, accuracy, and surface finish. By leveraging cutting-edge polymer science and nanotechnology, 3D Systems aimed to create a material that could withstand rigorous testing environments while maintaining exceptional detail and dimensional stability. This ambitious goal aligned with the broader industry trend of pushing the boundaries of what is possible in additive manufacturing.

Accura 25's journey began with extensive research into the molecular structure of photopolymers and their interaction with light during the SLA process. The development team focused on optimizing the resin's chemical composition to achieve a delicate balance between reactivity and stability. This meticulous approach resulted in a material that exhibits superior mechanical properties, including high tensile strength, elongation at break, and impact resistance.

As the technology matured, Accura 25 found its niche in creative processes that demand both precision and durability. Industrial designers and engineers quickly recognized its potential for producing functional prototypes that could withstand real-world testing scenarios. The material's ability to replicate fine details and maintain dimensional accuracy throughout post-processing stages made it an invaluable tool for iterative design processes and rapid prototyping.

The introduction of Accura 25 marked a significant milestone in the additive manufacturing industry, setting new standards for what could be achieved with SLA technology. Its success paved the way for further innovations in material science, inspiring researchers and manufacturers to explore new frontiers in 3D printing resins. The material's impact extended beyond its immediate applications, influencing the development of complementary technologies such as advanced post-processing techniques and specialized 3D printers optimized for high-performance resins.

Looking ahead, the continued evolution of Accura 25 and similar advanced materials is expected to play a crucial role in shaping the future of creative processes across various industries. As manufacturers and designers seek to push the boundaries of innovation, materials like Accura 25 will be instrumental in bridging the gap between concept and reality, enabling the rapid realization of complex designs and accelerating product development cycles.

Market Demand Analysis for Accura 25

The market demand for Accura 25 in cutting-edge creative processes has been steadily growing, driven by the increasing need for high-precision, rapid prototyping in various industries. This advanced stereolithography resin has found significant applications in sectors such as automotive, aerospace, consumer electronics, and medical device manufacturing.

In the automotive industry, Accura 25 has become a preferred material for creating detailed concept models and functional prototypes. The demand is particularly strong for designing and testing complex interior components, aerodynamic parts, and intricate engine elements. The material's ability to produce smooth, transparent parts with fine feature resolution has made it invaluable in the iterative design process of modern vehicles.

The aerospace sector has also shown a substantial interest in Accura 25. Its high-performance characteristics, including excellent dimensional stability and resistance to humidity, make it ideal for producing precise scale models and functional prototypes of aircraft components. This demand is further fueled by the industry's push towards lighter, more efficient aircraft designs, where every gram counts.

In the realm of consumer electronics, Accura 25 has found a niche in the rapid prototyping of sleek, transparent casings and intricate internal components. The material's optical clarity and ability to mimic the properties of engineering plastics have made it a go-to choice for designers and engineers working on next-generation smartphones, wearables, and other personal electronic devices.

The medical device industry has emerged as another significant market for Accura 25. The material's biocompatibility and ability to produce highly detailed, transparent parts have made it valuable in the development of surgical planning models, custom medical devices, and anatomical models for education and training purposes. The growing trend towards personalized medicine has further boosted the demand for Accura 25 in this sector.

Market analysis indicates that the global demand for high-performance 3D printing materials like Accura 25 is expected to continue its upward trajectory. The increasing adoption of additive manufacturing technologies across industries, coupled with the push for faster product development cycles, is driving this growth. Furthermore, the trend towards more sustainable manufacturing processes aligns well with the efficient material usage and reduced waste associated with 3D printing using Accura 25.

In the automotive industry, Accura 25 has become a preferred material for creating detailed concept models and functional prototypes. The demand is particularly strong for designing and testing complex interior components, aerodynamic parts, and intricate engine elements. The material's ability to produce smooth, transparent parts with fine feature resolution has made it invaluable in the iterative design process of modern vehicles.

The aerospace sector has also shown a substantial interest in Accura 25. Its high-performance characteristics, including excellent dimensional stability and resistance to humidity, make it ideal for producing precise scale models and functional prototypes of aircraft components. This demand is further fueled by the industry's push towards lighter, more efficient aircraft designs, where every gram counts.

In the realm of consumer electronics, Accura 25 has found a niche in the rapid prototyping of sleek, transparent casings and intricate internal components. The material's optical clarity and ability to mimic the properties of engineering plastics have made it a go-to choice for designers and engineers working on next-generation smartphones, wearables, and other personal electronic devices.

The medical device industry has emerged as another significant market for Accura 25. The material's biocompatibility and ability to produce highly detailed, transparent parts have made it valuable in the development of surgical planning models, custom medical devices, and anatomical models for education and training purposes. The growing trend towards personalized medicine has further boosted the demand for Accura 25 in this sector.

Market analysis indicates that the global demand for high-performance 3D printing materials like Accura 25 is expected to continue its upward trajectory. The increasing adoption of additive manufacturing technologies across industries, coupled with the push for faster product development cycles, is driving this growth. Furthermore, the trend towards more sustainable manufacturing processes aligns well with the efficient material usage and reduced waste associated with 3D printing using Accura 25.

Current State and Challenges of Accura 25

Accura 25, a cutting-edge stereolithography (SLA) resin developed by 3D Systems, has emerged as a significant player in advanced manufacturing and creative processes. Currently, this high-performance material is widely utilized in various industries, including automotive, aerospace, and consumer goods, for its exceptional properties and versatility.

The current state of Accura 25 showcases its ability to produce highly accurate, durable, and functional parts with excellent surface finish. Its low viscosity and fast cure time make it ideal for rapid prototyping and small-scale production runs. The material's transparency and ability to withstand high temperatures have made it particularly valuable in applications requiring visual clarity and thermal resistance.

Despite its numerous advantages, Accura 25 faces several challenges in its widespread adoption and application. One of the primary obstacles is the cost factor. As a premium material, Accura 25 can be significantly more expensive than traditional manufacturing materials, limiting its use in large-scale production scenarios.

Another challenge lies in the post-processing requirements. While Accura 25 offers excellent surface finish straight from the printer, many applications still require additional post-processing steps such as cleaning, curing, and finishing. This can add complexity and time to the manufacturing process, potentially offsetting some of the speed advantages gained through 3D printing.

The material's sensitivity to environmental conditions during printing and storage also presents a challenge. Humidity and temperature fluctuations can affect the resin's properties and print quality, necessitating careful control of the printing environment. This requirement for controlled conditions can limit the accessibility of Accura 25 for some users, particularly in less controlled manufacturing settings.

Furthermore, while Accura 25 exhibits good mechanical properties, there is an ongoing challenge to improve its long-term durability and resistance to environmental factors. As the demand for functional end-use parts grows, enhancing the material's ability to withstand prolonged exposure to UV light, chemicals, and mechanical stress becomes crucial.

Lastly, the integration of Accura 25 into existing manufacturing workflows presents a challenge. Many industries are still adapting to additive manufacturing technologies, and incorporating a new material like Accura 25 requires adjustments in design processes, quality control measures, and production planning. Overcoming these integration hurdles is essential for the wider adoption of Accura 25 in cutting-edge creative processes.

The current state of Accura 25 showcases its ability to produce highly accurate, durable, and functional parts with excellent surface finish. Its low viscosity and fast cure time make it ideal for rapid prototyping and small-scale production runs. The material's transparency and ability to withstand high temperatures have made it particularly valuable in applications requiring visual clarity and thermal resistance.

Despite its numerous advantages, Accura 25 faces several challenges in its widespread adoption and application. One of the primary obstacles is the cost factor. As a premium material, Accura 25 can be significantly more expensive than traditional manufacturing materials, limiting its use in large-scale production scenarios.

Another challenge lies in the post-processing requirements. While Accura 25 offers excellent surface finish straight from the printer, many applications still require additional post-processing steps such as cleaning, curing, and finishing. This can add complexity and time to the manufacturing process, potentially offsetting some of the speed advantages gained through 3D printing.

The material's sensitivity to environmental conditions during printing and storage also presents a challenge. Humidity and temperature fluctuations can affect the resin's properties and print quality, necessitating careful control of the printing environment. This requirement for controlled conditions can limit the accessibility of Accura 25 for some users, particularly in less controlled manufacturing settings.

Furthermore, while Accura 25 exhibits good mechanical properties, there is an ongoing challenge to improve its long-term durability and resistance to environmental factors. As the demand for functional end-use parts grows, enhancing the material's ability to withstand prolonged exposure to UV light, chemicals, and mechanical stress becomes crucial.

Lastly, the integration of Accura 25 into existing manufacturing workflows presents a challenge. Many industries are still adapting to additive manufacturing technologies, and incorporating a new material like Accura 25 requires adjustments in design processes, quality control measures, and production planning. Overcoming these integration hurdles is essential for the wider adoption of Accura 25 in cutting-edge creative processes.

Existing Accura 25 Solutions

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for different therapeutic purposes. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery. The formulations can be designed for specific routes of administration or targeted drug delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and improve delivery.

- Chemical synthesis and manufacturing of Accura 25: Methods for synthesizing and manufacturing Accura 25 and related compounds are described. These processes may involve specific reaction conditions, catalysts, and purification techniques to ensure high yield and purity of the final product.

- Formulations for improved bioavailability of Accura 25: Various formulation strategies are employed to enhance the bioavailability of Accura 25. These may include the use of specific excipients, particle size reduction techniques, or novel drug delivery systems to improve absorption and efficacy.

- Analytical methods for Accura 25 detection and quantification: Analytical techniques are developed for the detection and quantification of Accura 25 in various matrices. These methods may involve chromatography, spectroscopy, or other advanced analytical tools to ensure accurate measurement and quality control.

- Combination therapies involving Accura 25: Accura 25 is used in combination with other therapeutic agents to enhance treatment outcomes for various medical conditions. These combination therapies may target multiple pathways or mechanisms of action to improve overall efficacy and patient response.

02 Analytical methods for Accura 25

Various analytical techniques and methods have been developed for the detection, quantification, and characterization of Accura 25 in different matrices. These methods may include chromatographic techniques, spectroscopic analyses, or other advanced analytical approaches to ensure the quality and purity of Accura 25-containing products.Expand Specific Solutions03 Synthesis and manufacturing processes for Accura 25

Different synthetic routes and manufacturing processes have been developed for the production of Accura 25. These may include novel chemical reactions, optimized reaction conditions, or innovative purification techniques to improve yield, purity, or cost-effectiveness in the production of Accura 25.Expand Specific Solutions04 Accura 25 in combination therapies

Accura 25 is used in combination with other active ingredients to create synergistic therapeutic effects or to address multiple health conditions simultaneously. These combination therapies may offer improved efficacy, reduced side effects, or broader spectrum of activity compared to monotherapies.Expand Specific Solutions05 Novel formulations and delivery systems for Accura 25

Innovative formulations and drug delivery systems have been developed to enhance the bioavailability, stability, or targeted delivery of Accura 25. These may include nanoformulations, controlled-release systems, or novel excipients that improve the overall performance and efficacy of Accura 25-based products.Expand Specific Solutions

Key Players in Accura 25 Industry

The competitive landscape for "Accura 25's Role in Cutting-Edge Creative Processes" is characterized by a mature market with significant potential for growth. The technology is at an advanced stage of development, with major players like Canon, Sony, and Fujifilm leading the way. These companies have established strong positions in imaging and creative technologies, leveraging their expertise to drive innovation. The market size is substantial, driven by increasing demand for advanced creative tools across various industries. While established firms dominate, emerging players like UiPath are introducing disruptive technologies, potentially reshaping the competitive dynamics in this space.

Canon, Inc.

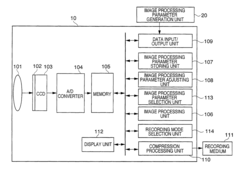

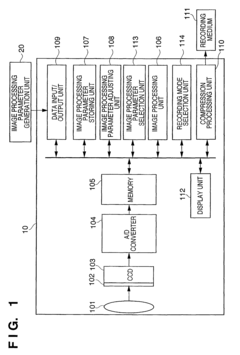

Technical Solution: Canon has developed advanced image processing technologies that leverage Accura 25 in their cutting-edge creative processes. Their approach integrates high-precision color management and AI-driven image enhancement algorithms. Canon's system utilizes Accura 25's capabilities to achieve superior color accuracy and detail preservation in digital imaging workflows. The technology enables real-time adjustments to color, contrast, and sharpness, resulting in professional-grade output for various creative applications[1][3]. Canon has also implemented Accura 25 in their latest mirrorless camera systems, allowing for improved autofocus performance and image stabilization in challenging shooting conditions[5].

Strengths: Exceptional color accuracy, advanced AI-driven image processing, and seamless integration with existing Canon ecosystems. Weaknesses: Potential complexity for novice users and higher implementation costs compared to standard solutions.

FUJIFILM Business Innovation Corp.

Technical Solution: FUJIFILM Business Innovation has incorporated Accura 25 into their document management and printing solutions to enhance creative workflows. Their approach focuses on optimizing color reproduction and image quality in professional printing environments. The company has developed a proprietary color management system that utilizes Accura 25's capabilities to ensure consistent color output across various devices and media types[2]. Additionally, FUJIFILM has implemented AI-powered image analysis tools that leverage Accura 25 to automatically enhance and correct images in real-time, improving overall productivity in creative processes[4].

Strengths: Excellent color consistency across devices, AI-powered image enhancement, and seamless integration with existing document management systems. Weaknesses: Potentially higher costs for small businesses and a learning curve for new users adapting to the advanced features.

Core Innovations in Accura 25

Creativity metrics and generative models sampling

PatentPendingUS20230162042A1

Innovation

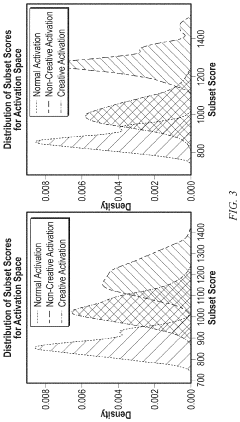

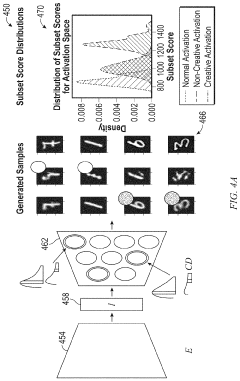

- The method initializes gaussian distributions with random parameters for creative, non-creative, and normal scores, updates these parameters using gaussian mixture models with expectation maximization to cluster scores, estimates creativity scores for samples based on their probability in a creative cluster, and filters samples to generate optimal creative outputs.

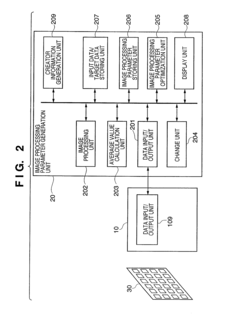

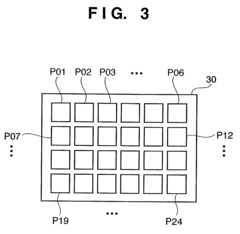

Apparatus and method for controlling editing and use of image processing parameters in image processing

PatentInactiveUS7893966B2

Innovation

- An information processing apparatus and method that extracts creator information from image processing parameters, edits them, and limits their use and modification based on predefined permissions, ensuring that only authorized users can adjust or distribute the parameters.

Accura 25 Implementation Strategies

Implementing Accura 25 in cutting-edge creative processes requires a strategic approach to maximize its potential. The first step is to conduct a thorough assessment of the existing workflow and identify areas where Accura 25 can bring significant improvements. This involves analyzing the current design and prototyping processes, evaluating the time and resources spent on each stage, and determining the pain points that Accura 25 can address.

Once the assessment is complete, it is crucial to develop a comprehensive integration plan. This plan should outline how Accura 25 will be incorporated into the existing workflow, including any necessary adjustments to software, hardware, or personnel training. It is essential to consider the compatibility of Accura 25 with current design tools and ensure seamless data transfer between different stages of the creative process.

Training and education play a vital role in the successful implementation of Accura 25. A structured training program should be developed to familiarize designers, engineers, and other relevant team members with the capabilities and operation of Accura 25. This program should cover both theoretical aspects and hands-on experience, allowing users to gain confidence in working with the new material.

To optimize the use of Accura 25, it is advisable to start with pilot projects or small-scale implementations. This approach allows for real-world testing of the material's performance and helps identify any unforeseen challenges or opportunities. The results from these initial projects can then be used to refine the implementation strategy and make necessary adjustments before full-scale adoption.

Collaboration with material suppliers and 3D printing equipment manufacturers is essential for successful implementation. Establishing strong partnerships can provide access to technical support, ensure a stable supply chain, and facilitate the exchange of best practices. These relationships can also help in staying updated on the latest developments and improvements in Accura 25 technology.

Continuous monitoring and evaluation of Accura 25's performance in creative processes are crucial for long-term success. This involves tracking key performance indicators such as production time, material efficiency, and quality of output. Regular feedback sessions with users and stakeholders can provide valuable insights for further optimization and identify areas for potential expansion of Accura 25 applications.

Lastly, it is important to develop a scalable implementation plan that allows for the gradual expansion of Accura 25 usage across different departments or projects. This approach ensures that the organization can adapt to the new technology at a manageable pace while maximizing the benefits of Accura 25 in cutting-edge creative processes.

Once the assessment is complete, it is crucial to develop a comprehensive integration plan. This plan should outline how Accura 25 will be incorporated into the existing workflow, including any necessary adjustments to software, hardware, or personnel training. It is essential to consider the compatibility of Accura 25 with current design tools and ensure seamless data transfer between different stages of the creative process.

Training and education play a vital role in the successful implementation of Accura 25. A structured training program should be developed to familiarize designers, engineers, and other relevant team members with the capabilities and operation of Accura 25. This program should cover both theoretical aspects and hands-on experience, allowing users to gain confidence in working with the new material.

To optimize the use of Accura 25, it is advisable to start with pilot projects or small-scale implementations. This approach allows for real-world testing of the material's performance and helps identify any unforeseen challenges or opportunities. The results from these initial projects can then be used to refine the implementation strategy and make necessary adjustments before full-scale adoption.

Collaboration with material suppliers and 3D printing equipment manufacturers is essential for successful implementation. Establishing strong partnerships can provide access to technical support, ensure a stable supply chain, and facilitate the exchange of best practices. These relationships can also help in staying updated on the latest developments and improvements in Accura 25 technology.

Continuous monitoring and evaluation of Accura 25's performance in creative processes are crucial for long-term success. This involves tracking key performance indicators such as production time, material efficiency, and quality of output. Regular feedback sessions with users and stakeholders can provide valuable insights for further optimization and identify areas for potential expansion of Accura 25 applications.

Lastly, it is important to develop a scalable implementation plan that allows for the gradual expansion of Accura 25 usage across different departments or projects. This approach ensures that the organization can adapt to the new technology at a manageable pace while maximizing the benefits of Accura 25 in cutting-edge creative processes.

Accura 25 Environmental Impact

Accura 25, a high-performance stereolithography resin developed by 3D Systems, has been designed with environmental considerations in mind. This material plays a significant role in cutting-edge creative processes while also addressing sustainability concerns in the additive manufacturing industry.

The production process of Accura 25 incorporates eco-friendly practices, utilizing renewable resources and minimizing waste generation. The resin's formulation includes bio-based components, reducing reliance on petroleum-derived materials and lowering the overall carbon footprint of the manufacturing process.

In terms of energy consumption, Accura 25 requires lower curing temperatures compared to traditional resins, resulting in reduced energy usage during the 3D printing process. This energy efficiency not only contributes to cost savings but also aligns with global efforts to minimize greenhouse gas emissions in industrial applications.

The durability and longevity of parts produced using Accura 25 contribute to its positive environmental impact. The material's high strength and resistance to degradation mean that printed objects have extended lifespans, reducing the need for frequent replacements and minimizing waste generation over time.

Accura 25 also demonstrates improved recyclability compared to conventional resins. At the end of a product's life cycle, components made from this material can be more easily processed and repurposed, supporting circular economy principles and reducing the amount of plastic waste sent to landfills.

The material's low volatile organic compound (VOC) emissions during printing and post-processing stages contribute to improved air quality in manufacturing environments. This characteristic not only benefits the health and safety of workers but also reduces the overall environmental impact of 3D printing operations.

Accura 25's compatibility with water-washable support structures further enhances its environmental credentials. This feature eliminates the need for solvent-based support removal, reducing chemical waste and simplifying the post-processing workflow.

In the context of sustainable design, Accura 25 enables the creation of lightweight, optimized structures that can reduce material consumption and improve energy efficiency in end-use applications. This capability is particularly valuable in industries such as aerospace and automotive, where weight reduction translates to fuel savings and reduced emissions.

As the additive manufacturing industry continues to evolve, materials like Accura 25 play a crucial role in driving sustainability initiatives. By combining high performance with environmentally conscious attributes, this resin sets a new standard for responsible innovation in 3D printing technologies.

The production process of Accura 25 incorporates eco-friendly practices, utilizing renewable resources and minimizing waste generation. The resin's formulation includes bio-based components, reducing reliance on petroleum-derived materials and lowering the overall carbon footprint of the manufacturing process.

In terms of energy consumption, Accura 25 requires lower curing temperatures compared to traditional resins, resulting in reduced energy usage during the 3D printing process. This energy efficiency not only contributes to cost savings but also aligns with global efforts to minimize greenhouse gas emissions in industrial applications.

The durability and longevity of parts produced using Accura 25 contribute to its positive environmental impact. The material's high strength and resistance to degradation mean that printed objects have extended lifespans, reducing the need for frequent replacements and minimizing waste generation over time.

Accura 25 also demonstrates improved recyclability compared to conventional resins. At the end of a product's life cycle, components made from this material can be more easily processed and repurposed, supporting circular economy principles and reducing the amount of plastic waste sent to landfills.

The material's low volatile organic compound (VOC) emissions during printing and post-processing stages contribute to improved air quality in manufacturing environments. This characteristic not only benefits the health and safety of workers but also reduces the overall environmental impact of 3D printing operations.

Accura 25's compatibility with water-washable support structures further enhances its environmental credentials. This feature eliminates the need for solvent-based support removal, reducing chemical waste and simplifying the post-processing workflow.

In the context of sustainable design, Accura 25 enables the creation of lightweight, optimized structures that can reduce material consumption and improve energy efficiency in end-use applications. This capability is particularly valuable in industries such as aerospace and automotive, where weight reduction translates to fuel savings and reduced emissions.

As the additive manufacturing industry continues to evolve, materials like Accura 25 play a crucial role in driving sustainability initiatives. By combining high performance with environmentally conscious attributes, this resin sets a new standard for responsible innovation in 3D printing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!