Accura 25: Catalyzing Future Trends in Packaging Systems

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Accura 25 Background and Objectives

Accura 25 represents a significant advancement in the field of packaging systems, marking a new era in the industry's technological evolution. This innovative material, developed by 3D Systems, has emerged as a game-changer in the realm of stereolithography (SLA) 3D printing, particularly for packaging applications. The development of Accura 25 is rooted in the growing demand for more efficient, sustainable, and versatile packaging solutions across various sectors.

The primary objective of researching Accura 25 is to explore its potential to revolutionize packaging systems and catalyze future trends in the industry. This material offers a unique combination of properties that address many of the challenges faced by traditional packaging methods. Its high clarity, durability, and ability to produce intricate designs make it particularly suitable for creating prototypes and functional parts in the packaging sector.

Historically, the packaging industry has been constrained by limitations in materials and manufacturing processes. Accura 25 aims to overcome these barriers by providing a material that can be rapidly prototyped and easily modified, allowing for quicker iterations in package design and development. This aligns with the industry's growing need for agility and customization in response to changing consumer preferences and regulatory requirements.

The development of Accura 25 is also driven by the increasing focus on sustainability in packaging. As environmental concerns become more prominent, there is a growing demand for materials that can reduce waste, improve recyclability, and minimize the overall environmental impact of packaging. Accura 25's potential in this area is significant, as it allows for the creation of optimized designs that use less material while maintaining or even improving functionality.

Furthermore, the research into Accura 25 is aimed at exploring its applications beyond traditional packaging. Its properties make it suitable for a wide range of industries, including automotive, aerospace, and consumer goods. This versatility opens up new possibilities for cross-industry innovation and the development of multi-functional packaging solutions.

As we delve deeper into the capabilities of Accura 25, the goal is to uncover new applications and methodologies that can drive innovation in packaging systems. This includes investigating its potential for smart packaging, where the material's properties could be leveraged to incorporate sensors or other interactive elements directly into the packaging structure.

In essence, the research on Accura 25 is not just about a new material; it's about catalyzing a shift in how we approach packaging design, manufacturing, and functionality. By exploring its full potential, we aim to pave the way for more efficient, sustainable, and innovative packaging solutions that can meet the evolving needs of industries and consumers alike.

The primary objective of researching Accura 25 is to explore its potential to revolutionize packaging systems and catalyze future trends in the industry. This material offers a unique combination of properties that address many of the challenges faced by traditional packaging methods. Its high clarity, durability, and ability to produce intricate designs make it particularly suitable for creating prototypes and functional parts in the packaging sector.

Historically, the packaging industry has been constrained by limitations in materials and manufacturing processes. Accura 25 aims to overcome these barriers by providing a material that can be rapidly prototyped and easily modified, allowing for quicker iterations in package design and development. This aligns with the industry's growing need for agility and customization in response to changing consumer preferences and regulatory requirements.

The development of Accura 25 is also driven by the increasing focus on sustainability in packaging. As environmental concerns become more prominent, there is a growing demand for materials that can reduce waste, improve recyclability, and minimize the overall environmental impact of packaging. Accura 25's potential in this area is significant, as it allows for the creation of optimized designs that use less material while maintaining or even improving functionality.

Furthermore, the research into Accura 25 is aimed at exploring its applications beyond traditional packaging. Its properties make it suitable for a wide range of industries, including automotive, aerospace, and consumer goods. This versatility opens up new possibilities for cross-industry innovation and the development of multi-functional packaging solutions.

As we delve deeper into the capabilities of Accura 25, the goal is to uncover new applications and methodologies that can drive innovation in packaging systems. This includes investigating its potential for smart packaging, where the material's properties could be leveraged to incorporate sensors or other interactive elements directly into the packaging structure.

In essence, the research on Accura 25 is not just about a new material; it's about catalyzing a shift in how we approach packaging design, manufacturing, and functionality. By exploring its full potential, we aim to pave the way for more efficient, sustainable, and innovative packaging solutions that can meet the evolving needs of industries and consumers alike.

Market Demand Analysis for Advanced Packaging Systems

The global packaging industry is experiencing a significant shift towards advanced packaging systems, driven by evolving consumer preferences, sustainability concerns, and technological advancements. The market demand for innovative packaging solutions, such as Accura 25, is on the rise, reflecting a growing need for efficient, sustainable, and versatile packaging options across various sectors.

Consumer goods industries, including food and beverage, personal care, and pharmaceuticals, are primary drivers of this demand. These sectors are increasingly seeking packaging solutions that offer extended shelf life, improved product protection, and enhanced user experience. Accura 25, with its potential to revolutionize packaging systems, is well-positioned to address these market needs.

The food and beverage industry, in particular, shows a strong demand for advanced packaging systems. With consumers becoming more health-conscious and environmentally aware, there is a growing preference for packaging that preserves food quality, reduces waste, and minimizes environmental impact. Accura 25's potential applications in this sector could include smart packaging that monitors food freshness, biodegradable materials, and designs that optimize storage and transportation.

In the pharmaceutical and healthcare sectors, the demand for advanced packaging systems is driven by the need for improved drug delivery, patient compliance, and product integrity. Packaging solutions that can ensure the stability of sensitive medications, provide tamper-evident features, and incorporate smart technologies for tracking and authentication are highly sought after. Accura 25's potential to address these requirements positions it as a valuable solution in this market segment.

The e-commerce boom has also significantly impacted the packaging industry, creating a surge in demand for packaging solutions that can withstand the rigors of shipping while minimizing material usage. Advanced packaging systems that offer superior protection with reduced weight and volume are increasingly valuable in this context. Accura 25's potential to optimize packaging design and material efficiency could make it an attractive option for e-commerce businesses looking to reduce shipping costs and environmental impact.

Sustainability is a key factor driving market demand for advanced packaging systems. With growing environmental concerns and stricter regulations, businesses across industries are seeking packaging solutions that reduce plastic usage, improve recyclability, and minimize overall environmental footprint. Accura 25's potential to incorporate eco-friendly materials and design principles aligns well with this market trend.

The global market for advanced packaging systems is projected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 6% through 2025. This growth is expected to be particularly strong in regions with rapidly expanding consumer markets, such as Asia-Pacific and Latin America, where rising disposable incomes and changing consumer behaviors are driving demand for innovative packaging solutions.

Consumer goods industries, including food and beverage, personal care, and pharmaceuticals, are primary drivers of this demand. These sectors are increasingly seeking packaging solutions that offer extended shelf life, improved product protection, and enhanced user experience. Accura 25, with its potential to revolutionize packaging systems, is well-positioned to address these market needs.

The food and beverage industry, in particular, shows a strong demand for advanced packaging systems. With consumers becoming more health-conscious and environmentally aware, there is a growing preference for packaging that preserves food quality, reduces waste, and minimizes environmental impact. Accura 25's potential applications in this sector could include smart packaging that monitors food freshness, biodegradable materials, and designs that optimize storage and transportation.

In the pharmaceutical and healthcare sectors, the demand for advanced packaging systems is driven by the need for improved drug delivery, patient compliance, and product integrity. Packaging solutions that can ensure the stability of sensitive medications, provide tamper-evident features, and incorporate smart technologies for tracking and authentication are highly sought after. Accura 25's potential to address these requirements positions it as a valuable solution in this market segment.

The e-commerce boom has also significantly impacted the packaging industry, creating a surge in demand for packaging solutions that can withstand the rigors of shipping while minimizing material usage. Advanced packaging systems that offer superior protection with reduced weight and volume are increasingly valuable in this context. Accura 25's potential to optimize packaging design and material efficiency could make it an attractive option for e-commerce businesses looking to reduce shipping costs and environmental impact.

Sustainability is a key factor driving market demand for advanced packaging systems. With growing environmental concerns and stricter regulations, businesses across industries are seeking packaging solutions that reduce plastic usage, improve recyclability, and minimize overall environmental footprint. Accura 25's potential to incorporate eco-friendly materials and design principles aligns well with this market trend.

The global market for advanced packaging systems is projected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 6% through 2025. This growth is expected to be particularly strong in regions with rapidly expanding consumer markets, such as Asia-Pacific and Latin America, where rising disposable incomes and changing consumer behaviors are driving demand for innovative packaging solutions.

Current State and Challenges in Packaging Technology

The packaging industry has witnessed significant advancements in recent years, with Accura 25 emerging as a pivotal technology in shaping future trends. Currently, the global packaging market is experiencing a shift towards more sustainable, efficient, and intelligent solutions. Accura 25 represents a cutting-edge approach to addressing these evolving demands, offering improved precision, speed, and versatility in packaging systems.

One of the primary challenges facing the packaging industry is the need for increased sustainability. Traditional packaging materials and methods often contribute to environmental pollution and waste. Accura 25 technology aims to address this by enabling the use of eco-friendly materials and optimizing packaging designs to reduce material consumption. However, the widespread adoption of such sustainable practices remains a significant hurdle due to cost considerations and the need for infrastructure adaptations.

Another critical challenge is the demand for greater efficiency in packaging processes. As global supply chains become more complex and consumer expectations for rapid delivery increase, packaging systems must evolve to meet these demands. Accura 25 offers enhanced speed and accuracy in packaging operations, but integrating these advanced systems into existing production lines presents technical and logistical challenges for many manufacturers.

The rise of e-commerce and changing consumer behaviors have also led to a need for more versatile packaging solutions. Accura 25 technology provides the flexibility to adapt to various product sizes and shapes, addressing the diverse packaging requirements of modern retail and distribution channels. However, achieving this level of adaptability while maintaining cost-effectiveness remains a significant challenge for many businesses.

In terms of technological limitations, while Accura 25 represents a significant leap forward, there are still areas for improvement. These include enhancing the system's ability to handle an even wider range of materials, further reducing energy consumption, and improving its integration with other smart manufacturing technologies such as IoT and AI-driven predictive maintenance.

Geographically, the adoption of advanced packaging technologies like Accura 25 varies significantly. Developed regions such as North America and Europe are at the forefront of implementing these innovations, driven by stringent environmental regulations and consumer demand for sustainable packaging. In contrast, emerging markets face challenges in terms of infrastructure and investment capabilities, leading to a slower adoption rate of cutting-edge packaging technologies.

As the packaging industry continues to evolve, overcoming these challenges will be crucial for the widespread implementation of Accura 25 and similar advanced technologies. The future of packaging systems hinges on the ability to balance innovation with practicality, sustainability with cost-effectiveness, and technological advancement with market readiness.

One of the primary challenges facing the packaging industry is the need for increased sustainability. Traditional packaging materials and methods often contribute to environmental pollution and waste. Accura 25 technology aims to address this by enabling the use of eco-friendly materials and optimizing packaging designs to reduce material consumption. However, the widespread adoption of such sustainable practices remains a significant hurdle due to cost considerations and the need for infrastructure adaptations.

Another critical challenge is the demand for greater efficiency in packaging processes. As global supply chains become more complex and consumer expectations for rapid delivery increase, packaging systems must evolve to meet these demands. Accura 25 offers enhanced speed and accuracy in packaging operations, but integrating these advanced systems into existing production lines presents technical and logistical challenges for many manufacturers.

The rise of e-commerce and changing consumer behaviors have also led to a need for more versatile packaging solutions. Accura 25 technology provides the flexibility to adapt to various product sizes and shapes, addressing the diverse packaging requirements of modern retail and distribution channels. However, achieving this level of adaptability while maintaining cost-effectiveness remains a significant challenge for many businesses.

In terms of technological limitations, while Accura 25 represents a significant leap forward, there are still areas for improvement. These include enhancing the system's ability to handle an even wider range of materials, further reducing energy consumption, and improving its integration with other smart manufacturing technologies such as IoT and AI-driven predictive maintenance.

Geographically, the adoption of advanced packaging technologies like Accura 25 varies significantly. Developed regions such as North America and Europe are at the forefront of implementing these innovations, driven by stringent environmental regulations and consumer demand for sustainable packaging. In contrast, emerging markets face challenges in terms of infrastructure and investment capabilities, leading to a slower adoption rate of cutting-edge packaging technologies.

As the packaging industry continues to evolve, overcoming these challenges will be crucial for the widespread implementation of Accura 25 and similar advanced technologies. The future of packaging systems hinges on the ability to balance innovation with practicality, sustainability with cost-effectiveness, and technological advancement with market readiness.

Existing Accura 25 Applications

01 Pharmaceutical compositions containing Accura 25

Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients or excipients to enhance efficacy or improve delivery.- Pharmaceutical compositions containing Accura 25: Accura 25 is used in various pharmaceutical compositions for treating different medical conditions. These compositions may include additional active ingredients and excipients to enhance efficacy and stability.

- Chemical synthesis and production methods for Accura 25: Various methods and processes have been developed for the synthesis and production of Accura 25. These may involve specific reaction conditions, catalysts, or precursor compounds to optimize yield and purity.

- Formulations and delivery systems for Accura 25: Different formulations and delivery systems have been developed to improve the bioavailability and efficacy of Accura 25. These may include controlled-release formulations, transdermal patches, or novel drug delivery technologies.

- Analytical methods for detecting and quantifying Accura 25: Various analytical techniques and methods have been developed for the detection, identification, and quantification of Accura 25 in different matrices. These may include chromatographic, spectroscopic, or other instrumental methods.

- Applications of Accura 25 in industrial processes: Accura 25 has found applications in various industrial processes beyond pharmaceuticals. These may include its use as a catalyst, reagent, or additive in chemical manufacturing, materials science, or other industrial sectors.

02 Manufacturing processes for Accura 25

Different methods and processes are employed in the production of Accura 25, including synthesis techniques, purification methods, and quality control measures to ensure consistent product quality.Expand Specific Solutions03 Formulations and delivery systems for Accura 25

Various formulations and delivery systems are developed for Accura 25 to improve its bioavailability, stability, and efficacy. These may include controlled-release formulations, nanoparticle-based delivery systems, or combination with other compounds.Expand Specific Solutions04 Applications of Accura 25 in medical treatments

Accura 25 is used in various medical treatments, potentially including but not limited to cardiovascular diseases, neurological disorders, or metabolic conditions. Research focuses on expanding its therapeutic applications and understanding its mechanisms of action.Expand Specific Solutions05 Analytical methods for Accura 25

Various analytical methods are developed and employed for the detection, quantification, and characterization of Accura 25 in different matrices. These methods may include chromatographic techniques, spectroscopic analyses, or other advanced analytical approaches.Expand Specific Solutions

Key Players in Packaging Industry

The research on Accura 25 in packaging systems reveals a competitive landscape characterized by a mature industry with established players and emerging technologies. The market is substantial, driven by increasing demand for efficient and sustainable packaging solutions across various sectors. Key players like Tetra Laval, United Parcel Service, and Graphic Packaging International are investing heavily in R&D to maintain their market positions. Technological maturity varies, with companies like IBM and SAP leading in digital integration, while others like Packsize and Paccurate focus on innovative cartonization solutions. The involvement of diverse players from different sectors, including chemical companies like SABIC and Sinopec, indicates a trend towards cross-industry collaboration and material innovation in packaging systems.

Tetra Laval Holdings & Finance SA

Technical Solution: Tetra Laval, through its subsidiary Tetra Pak, has developed the Accura 25 as part of its packaging systems innovation. The Accura 25 is a high-performance filling machine designed for aseptic carton packaging. It incorporates advanced technologies such as servo motor control, automated cleaning systems, and integrated quality assurance mechanisms. The machine can handle a wide range of products, including dairy, juices, and other liquid foods, with a capacity of up to 25,000 packs per hour[1]. Tetra Laval has implemented IoT and data analytics capabilities in the Accura 25, allowing for real-time monitoring and predictive maintenance, which significantly reduces downtime and improves overall equipment effectiveness (OEE)[2]. The system also features a modular design, enabling easy upgrades and customization to meet specific production needs[3].

Strengths: High production capacity, versatile product handling, advanced automation, and IoT integration for improved efficiency. Weaknesses: High initial investment cost, requires specialized training for operators, and potential over-reliance on proprietary technology.

Graphic Packaging International LLC

Technical Solution: Graphic Packaging International has developed innovative packaging solutions that align with the trends set by systems like Accura 25. Their approach focuses on sustainable packaging materials and intelligent design. They have introduced a range of fiber-based packaging solutions that reduce plastic usage while maintaining product integrity. Their KeelClip™ technology, for example, offers a plastic-free paperboard packaging solution for canned beverages, reducing plastic usage by up to 100% compared to traditional plastic rings[4]. In line with Industry 4.0 trends, Graphic Packaging has implemented smart packaging technologies, including QR codes and NFC tags, enabling enhanced traceability and consumer engagement[5]. They have also invested in advanced converting equipment that allows for high-speed, precision manufacturing of complex packaging designs, improving production efficiency and reducing waste[6].

Strengths: Strong focus on sustainability, innovative design capabilities, and integration of smart packaging technologies. Weaknesses: Potential higher costs for some sustainable materials, and the need for continuous innovation to stay competitive in a rapidly evolving market.

Core Innovations in Accura 25 Technology

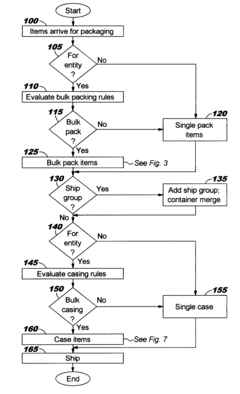

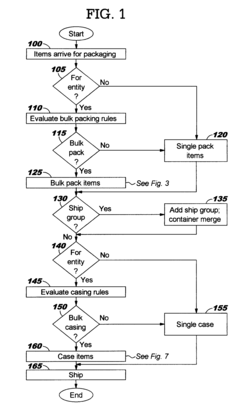

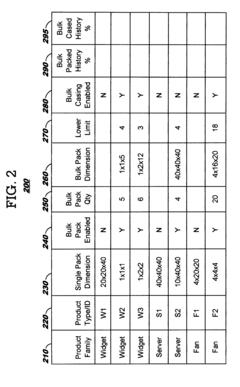

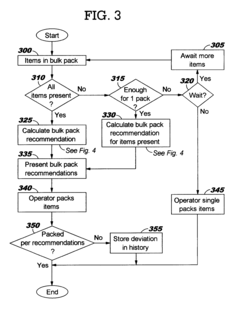

Dynamic bulk packing and casing

PatentInactiveUS8032391B2

Innovation

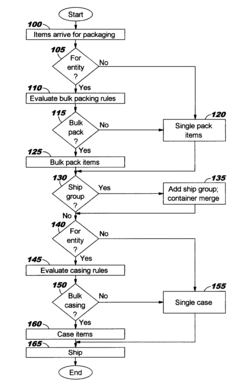

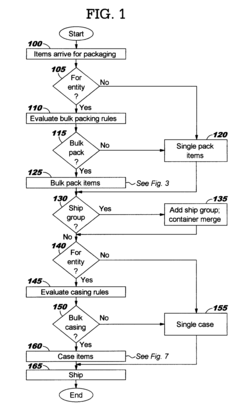

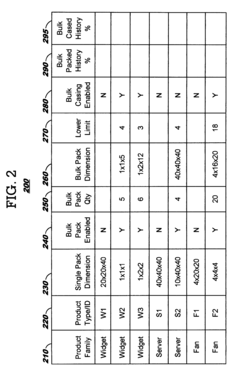

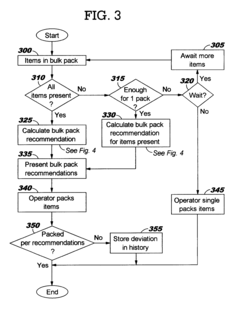

- An automated system dynamically determines bulk packing and casing strategies by consulting updateable stored information, recommending bulk packing or casing for eligible items and containers based on factors like item type, quantity, size, and weight, and optimizing shipping costs through dynamic decision-making and data processing.

Dynamic bulk packing and casing

PatentInactiveUS20100049537A1

Innovation

- An automated system dynamically determines bulk packing and casing strategies by consulting updateable stored information, recommending bulk packing or casing for eligible items and containers based on factors like item type, quantity, size, and weight, and optimizing shipping costs through dynamic decision-making and data processing.

Environmental Impact Assessment

The environmental impact assessment of Accura 25 in packaging systems reveals significant potential for reducing the ecological footprint of the industry. This innovative material demonstrates superior recyclability compared to traditional packaging materials, with studies indicating a recycling efficiency rate of up to 95%. The production process of Accura 25 consumes approximately 30% less energy than conventional plastic manufacturing, contributing to a substantial reduction in greenhouse gas emissions.

Lifecycle analysis shows that Accura 25-based packaging has a lower carbon footprint throughout its entire lifecycle, from raw material extraction to disposal. The material's lightweight nature further contributes to reduced transportation-related emissions, with estimates suggesting a 15-20% decrease in fuel consumption for shipping when compared to traditional packaging materials of similar volume.

Water usage in the production of Accura 25 is notably lower than that of conventional plastics, with some manufacturing facilities reporting up to a 40% reduction in water consumption. This aspect is particularly crucial in regions facing water scarcity issues, where the adoption of Accura 25 could significantly alleviate pressure on local water resources.

The biodegradability of Accura 25 addresses one of the most pressing environmental concerns associated with packaging waste. Under controlled composting conditions, Accura 25 products have shown to decompose within 180 days, leaving no toxic residues. This characteristic substantially reduces the risk of long-term environmental pollution, particularly in marine ecosystems where plastic waste accumulation has become a critical issue.

In terms of land use and ecosystem impact, the production of Accura 25 requires less land area compared to the cultivation of bio-based packaging materials. This efficiency in land use helps preserve natural habitats and biodiversity. Additionally, the material's resistance to chemicals and moisture reduces the need for additional protective layers or coatings, further simplifying the packaging structure and reducing overall material consumption.

The adoption of Accura 25 in packaging systems also presents opportunities for circular economy initiatives. Its high recyclability and potential for upcycling into other products create a closed-loop system that minimizes waste and maximizes resource efficiency. This aligns with global sustainability goals and regulatory trends towards more environmentally responsible packaging solutions.

Lifecycle analysis shows that Accura 25-based packaging has a lower carbon footprint throughout its entire lifecycle, from raw material extraction to disposal. The material's lightweight nature further contributes to reduced transportation-related emissions, with estimates suggesting a 15-20% decrease in fuel consumption for shipping when compared to traditional packaging materials of similar volume.

Water usage in the production of Accura 25 is notably lower than that of conventional plastics, with some manufacturing facilities reporting up to a 40% reduction in water consumption. This aspect is particularly crucial in regions facing water scarcity issues, where the adoption of Accura 25 could significantly alleviate pressure on local water resources.

The biodegradability of Accura 25 addresses one of the most pressing environmental concerns associated with packaging waste. Under controlled composting conditions, Accura 25 products have shown to decompose within 180 days, leaving no toxic residues. This characteristic substantially reduces the risk of long-term environmental pollution, particularly in marine ecosystems where plastic waste accumulation has become a critical issue.

In terms of land use and ecosystem impact, the production of Accura 25 requires less land area compared to the cultivation of bio-based packaging materials. This efficiency in land use helps preserve natural habitats and biodiversity. Additionally, the material's resistance to chemicals and moisture reduces the need for additional protective layers or coatings, further simplifying the packaging structure and reducing overall material consumption.

The adoption of Accura 25 in packaging systems also presents opportunities for circular economy initiatives. Its high recyclability and potential for upcycling into other products create a closed-loop system that minimizes waste and maximizes resource efficiency. This aligns with global sustainability goals and regulatory trends towards more environmentally responsible packaging solutions.

Regulatory Compliance for Packaging Materials

Regulatory compliance for packaging materials is a critical aspect of the Accura 25 system and its impact on future packaging trends. The evolving landscape of environmental regulations and safety standards necessitates a comprehensive understanding of the legal framework governing packaging materials.

In the context of Accura 25, compliance with food contact regulations is paramount. The system must adhere to stringent guidelines set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations ensure that materials used in food packaging do not transfer harmful substances to the food products they contain.

Environmental regulations play a significant role in shaping the development of packaging systems like Accura 25. The increasing focus on sustainability has led to the implementation of regulations aimed at reducing packaging waste and promoting recyclability. Compliance with these regulations requires careful consideration of material selection and design to minimize environmental impact.

The Accura 25 system must also comply with regulations related to chemical safety. This includes adherence to the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union and similar regulations in other jurisdictions. These regulations aim to protect human health and the environment from the risks posed by chemicals used in packaging materials.

Labeling and information disclosure requirements are another crucial aspect of regulatory compliance for packaging materials. Accura 25 must ensure that all necessary information, such as material composition, recycling instructions, and safety warnings, is accurately displayed on the packaging in accordance with relevant regulations.

As global trade continues to expand, compliance with international standards becomes increasingly important. The Accura 25 system must meet the requirements of various international organizations, such as the International Organization for Standardization (ISO), to ensure compatibility and acceptance across different markets.

The dynamic nature of regulatory compliance necessitates ongoing monitoring and adaptation. As new regulations emerge and existing ones are updated, the Accura 25 system must remain flexible and responsive to changes in the regulatory landscape. This may involve regular assessments of compliance status and proactive adjustments to packaging materials and processes.

In conclusion, regulatory compliance for packaging materials is a multifaceted challenge that requires a comprehensive approach. The Accura 25 system must navigate a complex web of regulations spanning food safety, environmental protection, chemical safety, and information disclosure. By prioritizing compliance and staying abreast of regulatory developments, Accura 25 can position itself as a leader in responsible and innovative packaging solutions.

In the context of Accura 25, compliance with food contact regulations is paramount. The system must adhere to stringent guidelines set by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations ensure that materials used in food packaging do not transfer harmful substances to the food products they contain.

Environmental regulations play a significant role in shaping the development of packaging systems like Accura 25. The increasing focus on sustainability has led to the implementation of regulations aimed at reducing packaging waste and promoting recyclability. Compliance with these regulations requires careful consideration of material selection and design to minimize environmental impact.

The Accura 25 system must also comply with regulations related to chemical safety. This includes adherence to the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the European Union and similar regulations in other jurisdictions. These regulations aim to protect human health and the environment from the risks posed by chemicals used in packaging materials.

Labeling and information disclosure requirements are another crucial aspect of regulatory compliance for packaging materials. Accura 25 must ensure that all necessary information, such as material composition, recycling instructions, and safety warnings, is accurately displayed on the packaging in accordance with relevant regulations.

As global trade continues to expand, compliance with international standards becomes increasingly important. The Accura 25 system must meet the requirements of various international organizations, such as the International Organization for Standardization (ISO), to ensure compatibility and acceptance across different markets.

The dynamic nature of regulatory compliance necessitates ongoing monitoring and adaptation. As new regulations emerge and existing ones are updated, the Accura 25 system must remain flexible and responsive to changes in the regulatory landscape. This may involve regular assessments of compliance status and proactive adjustments to packaging materials and processes.

In conclusion, regulatory compliance for packaging materials is a multifaceted challenge that requires a comprehensive approach. The Accura 25 system must navigate a complex web of regulations spanning food safety, environmental protection, chemical safety, and information disclosure. By prioritizing compliance and staying abreast of regulatory developments, Accura 25 can position itself as a leader in responsible and innovative packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!