Acoustic performance optimization in L92 engine exhausts

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Exhaust Acoustics: Background and Objectives

The L92 engine, a prominent V8 powerplant developed by General Motors, has been a cornerstone in the automotive industry since its introduction. As engine technology evolves, the focus on acoustic performance optimization in exhaust systems has become increasingly critical. This emphasis stems from the growing demand for vehicles that balance power with environmental considerations and driver comfort.

The evolution of exhaust acoustics in L92 engines reflects broader trends in automotive engineering. Initially, exhaust systems were primarily designed for efficient removal of combustion gases. However, as consumer expectations and regulatory standards have advanced, the role of exhaust systems has expanded to encompass noise reduction, performance enhancement, and emissions control.

In recent years, the automotive industry has witnessed a paradigm shift towards more stringent noise regulations and heightened consumer awareness of vehicle acoustics. This has propelled exhaust system design to the forefront of engine development, particularly for high-performance engines like the L92. The challenge lies in optimizing acoustic performance without compromising the engine's power output or efficiency.

The primary objective of acoustic performance optimization in L92 engine exhausts is to achieve a harmonious balance between noise reduction and performance enhancement. This involves minimizing unwanted noise frequencies while preserving or even accentuating the desirable acoustic characteristics that contribute to the engine's perceived quality and sportiness.

Another crucial goal is to comply with increasingly stringent noise emission regulations across various markets. This necessitates innovative approaches to exhaust system design that can effectively attenuate noise across a wide range of operating conditions and engine speeds.

Furthermore, the optimization process aims to integrate acoustic performance with other critical exhaust system functions. These include maintaining optimal back pressure for engine efficiency, ensuring effective catalytic conversion for emissions control, and managing heat dissipation to protect surrounding components and improve overall vehicle thermal management.

The pursuit of these objectives has led to the exploration of advanced materials, innovative geometries, and sophisticated acoustic tuning techniques. Technologies such as active noise control, variable geometry exhausts, and advanced computational fluid dynamics (CFD) simulations are being increasingly employed in the quest for optimal acoustic performance.

As we delve deeper into the technical aspects of L92 engine exhaust acoustics, it becomes evident that this field represents a convergence of multiple engineering disciplines. It encompasses not only mechanical and acoustic engineering but also materials science, fluid dynamics, and even psychoacoustics, considering the subjective nature of sound perception.

The evolution of exhaust acoustics in L92 engines reflects broader trends in automotive engineering. Initially, exhaust systems were primarily designed for efficient removal of combustion gases. However, as consumer expectations and regulatory standards have advanced, the role of exhaust systems has expanded to encompass noise reduction, performance enhancement, and emissions control.

In recent years, the automotive industry has witnessed a paradigm shift towards more stringent noise regulations and heightened consumer awareness of vehicle acoustics. This has propelled exhaust system design to the forefront of engine development, particularly for high-performance engines like the L92. The challenge lies in optimizing acoustic performance without compromising the engine's power output or efficiency.

The primary objective of acoustic performance optimization in L92 engine exhausts is to achieve a harmonious balance between noise reduction and performance enhancement. This involves minimizing unwanted noise frequencies while preserving or even accentuating the desirable acoustic characteristics that contribute to the engine's perceived quality and sportiness.

Another crucial goal is to comply with increasingly stringent noise emission regulations across various markets. This necessitates innovative approaches to exhaust system design that can effectively attenuate noise across a wide range of operating conditions and engine speeds.

Furthermore, the optimization process aims to integrate acoustic performance with other critical exhaust system functions. These include maintaining optimal back pressure for engine efficiency, ensuring effective catalytic conversion for emissions control, and managing heat dissipation to protect surrounding components and improve overall vehicle thermal management.

The pursuit of these objectives has led to the exploration of advanced materials, innovative geometries, and sophisticated acoustic tuning techniques. Technologies such as active noise control, variable geometry exhausts, and advanced computational fluid dynamics (CFD) simulations are being increasingly employed in the quest for optimal acoustic performance.

As we delve deeper into the technical aspects of L92 engine exhaust acoustics, it becomes evident that this field represents a convergence of multiple engineering disciplines. It encompasses not only mechanical and acoustic engineering but also materials science, fluid dynamics, and even psychoacoustics, considering the subjective nature of sound perception.

Market Demand for Optimized Exhaust Systems

The market demand for optimized exhaust systems in L92 engines has been steadily growing, driven by several key factors. Stringent environmental regulations worldwide are pushing automotive manufacturers to develop more efficient and cleaner engines. This has led to an increased focus on exhaust system optimization, particularly in high-performance engines like the L92.

Consumer preferences are also shifting towards vehicles that offer both power and fuel efficiency. The L92 engine, known for its high output, requires advanced exhaust systems to maintain performance while meeting emission standards. This has created a significant market opportunity for exhaust system manufacturers specializing in acoustic performance optimization.

In the performance automotive sector, there is a growing demand for exhaust systems that can enhance engine sound while complying with noise regulations. Enthusiasts and performance car owners are willing to invest in aftermarket exhaust systems that offer improved acoustics without compromising engine efficiency. This trend has expanded the market for specialized L92 engine exhaust systems.

The commercial vehicle segment, where L92 engines are sometimes used, is another area of growing demand. Fleet operators are increasingly looking for ways to reduce fuel consumption and emissions while maintaining vehicle performance. Optimized exhaust systems play a crucial role in achieving these goals, driving demand in this sector.

Emerging markets, particularly in Asia and South America, are showing increased interest in high-performance engines like the L92. As these markets mature, the demand for sophisticated exhaust systems is expected to rise, opening new opportunities for manufacturers and suppliers.

The aftermarket sector for L92 engine exhaust systems is particularly robust. Car enthusiasts and performance shops frequently upgrade stock exhaust systems to improve both performance and sound quality. This has created a thriving market for customized and high-performance exhaust solutions.

Technological advancements in materials science and manufacturing processes are enabling the development of more efficient and durable exhaust systems. This is attracting investment in research and development, further driving market growth and innovation in acoustic performance optimization for L92 engine exhausts.

As the automotive industry moves towards electrification, there is a parallel trend of enhancing the performance and efficiency of traditional combustion engines. This has led to increased focus on exhaust system optimization as a key area for improving overall engine performance, ensuring a sustained market demand for advanced exhaust solutions in high-performance engines like the L92.

Consumer preferences are also shifting towards vehicles that offer both power and fuel efficiency. The L92 engine, known for its high output, requires advanced exhaust systems to maintain performance while meeting emission standards. This has created a significant market opportunity for exhaust system manufacturers specializing in acoustic performance optimization.

In the performance automotive sector, there is a growing demand for exhaust systems that can enhance engine sound while complying with noise regulations. Enthusiasts and performance car owners are willing to invest in aftermarket exhaust systems that offer improved acoustics without compromising engine efficiency. This trend has expanded the market for specialized L92 engine exhaust systems.

The commercial vehicle segment, where L92 engines are sometimes used, is another area of growing demand. Fleet operators are increasingly looking for ways to reduce fuel consumption and emissions while maintaining vehicle performance. Optimized exhaust systems play a crucial role in achieving these goals, driving demand in this sector.

Emerging markets, particularly in Asia and South America, are showing increased interest in high-performance engines like the L92. As these markets mature, the demand for sophisticated exhaust systems is expected to rise, opening new opportunities for manufacturers and suppliers.

The aftermarket sector for L92 engine exhaust systems is particularly robust. Car enthusiasts and performance shops frequently upgrade stock exhaust systems to improve both performance and sound quality. This has created a thriving market for customized and high-performance exhaust solutions.

Technological advancements in materials science and manufacturing processes are enabling the development of more efficient and durable exhaust systems. This is attracting investment in research and development, further driving market growth and innovation in acoustic performance optimization for L92 engine exhausts.

As the automotive industry moves towards electrification, there is a parallel trend of enhancing the performance and efficiency of traditional combustion engines. This has led to increased focus on exhaust system optimization as a key area for improving overall engine performance, ensuring a sustained market demand for advanced exhaust solutions in high-performance engines like the L92.

Current Challenges in L92 Exhaust Acoustic Performance

The L92 engine, known for its high performance and efficiency, faces several challenges in optimizing its exhaust acoustic performance. One of the primary issues is the balance between noise reduction and engine efficiency. As stricter noise regulations are implemented globally, manufacturers must find ways to minimize exhaust noise without compromising the engine's power output or fuel efficiency.

A significant challenge lies in the complex nature of exhaust noise generation. The L92 engine's exhaust system produces a wide range of frequencies, from low-frequency rumble to high-frequency hiss. This diverse acoustic profile makes it difficult to implement a one-size-fits-all solution for noise reduction. Engineers must develop strategies that address multiple frequency ranges simultaneously without creating unintended resonances or backpressure issues.

The packaging constraints of modern vehicles present another hurdle for L92 exhaust acoustic optimization. As vehicle designs become more compact and aerodynamic, the space available for exhaust systems is increasingly limited. This restriction makes it challenging to incorporate traditional noise reduction techniques, such as large mufflers or resonators, without impacting vehicle design or performance.

Material selection for exhaust components adds another layer of complexity. While certain materials may offer superior noise dampening properties, they may not withstand the high temperatures and corrosive environment of the exhaust system over extended periods. Engineers must find materials that strike a balance between acoustic performance, durability, and cost-effectiveness.

The variability in operating conditions also poses a significant challenge. The L92 engine's acoustic profile changes dramatically across different RPM ranges and load conditions. Developing a system that maintains optimal noise reduction across all operating scenarios without introducing unwanted drone or resonance is a complex task that requires sophisticated modeling and testing.

Furthermore, the increasing demand for customizable exhaust notes adds another dimension to the challenge. Many consumers desire a sporty or aggressive exhaust sound under certain conditions while preferring quieter operation in others. This requirement for adaptive acoustic performance introduces the need for advanced active noise control systems, which bring their own set of integration and reliability challenges.

Lastly, the push towards electrification and hybrid powertrains introduces new acoustic challenges for the L92 engine. In hybrid applications, the intermittent operation of the combustion engine can create abrupt changes in noise levels, requiring innovative solutions to manage these transitions smoothly and unobtrusively.

A significant challenge lies in the complex nature of exhaust noise generation. The L92 engine's exhaust system produces a wide range of frequencies, from low-frequency rumble to high-frequency hiss. This diverse acoustic profile makes it difficult to implement a one-size-fits-all solution for noise reduction. Engineers must develop strategies that address multiple frequency ranges simultaneously without creating unintended resonances or backpressure issues.

The packaging constraints of modern vehicles present another hurdle for L92 exhaust acoustic optimization. As vehicle designs become more compact and aerodynamic, the space available for exhaust systems is increasingly limited. This restriction makes it challenging to incorporate traditional noise reduction techniques, such as large mufflers or resonators, without impacting vehicle design or performance.

Material selection for exhaust components adds another layer of complexity. While certain materials may offer superior noise dampening properties, they may not withstand the high temperatures and corrosive environment of the exhaust system over extended periods. Engineers must find materials that strike a balance between acoustic performance, durability, and cost-effectiveness.

The variability in operating conditions also poses a significant challenge. The L92 engine's acoustic profile changes dramatically across different RPM ranges and load conditions. Developing a system that maintains optimal noise reduction across all operating scenarios without introducing unwanted drone or resonance is a complex task that requires sophisticated modeling and testing.

Furthermore, the increasing demand for customizable exhaust notes adds another dimension to the challenge. Many consumers desire a sporty or aggressive exhaust sound under certain conditions while preferring quieter operation in others. This requirement for adaptive acoustic performance introduces the need for advanced active noise control systems, which bring their own set of integration and reliability challenges.

Lastly, the push towards electrification and hybrid powertrains introduces new acoustic challenges for the L92 engine. In hybrid applications, the intermittent operation of the combustion engine can create abrupt changes in noise levels, requiring innovative solutions to manage these transitions smoothly and unobtrusively.

Existing L92 Exhaust Acoustic Solutions

01 Muffler design for acoustic performance

Innovative muffler designs are employed to enhance the acoustic performance of L92 engine exhausts. These designs may include multiple chambers, baffles, and resonators to attenuate sound across various frequency ranges. The muffler's internal structure is optimized to reduce backpressure while effectively dampening exhaust noise.- Muffler design for acoustic performance: Innovative muffler designs are employed to enhance the acoustic performance of L92 engine exhausts. These designs may include multiple chambers, baffles, or resonators to attenuate sound waves and reduce noise levels. The muffler's internal structure is optimized to balance noise reduction with minimal impact on engine performance.

- Active noise control systems: Active noise control systems are implemented to improve the acoustic performance of L92 engine exhausts. These systems use electronic sensors and actuators to generate sound waves that cancel out unwanted noise. By analyzing the exhaust sound in real-time, the system can adapt to varying engine conditions and effectively reduce noise across a wide range of frequencies.

- Exhaust pipe geometry optimization: The geometry of exhaust pipes is optimized to enhance acoustic performance. This includes adjusting pipe lengths, diameters, and bend angles to create specific resonance characteristics. By fine-tuning these parameters, engineers can achieve a desired sound quality while also managing back pressure and flow efficiency.

- Acoustic materials and coatings: Specialized acoustic materials and coatings are applied to exhaust system components to improve sound absorption and reduce noise transmission. These materials may include high-temperature resistant foams, fibers, or composites that can withstand the harsh environment of the exhaust system while effectively dampening sound waves.

- Exhaust valve timing and control: Advanced exhaust valve timing and control strategies are employed to optimize acoustic performance. By precisely controlling the opening and closing of exhaust valves, engineers can manage exhaust gas pulsations and reduce noise-generating harmonics. This approach may involve variable valve timing systems or electronically controlled exhaust valves to adapt to different engine operating conditions.

02 Active noise control systems

Active noise control systems are implemented to improve the acoustic performance of L92 engine exhausts. These systems use electronic sensors, controllers, and actuators to generate sound waves that cancel out unwanted exhaust noise. This technology allows for dynamic adjustment of exhaust sound characteristics based on engine operating conditions.Expand Specific Solutions03 Exhaust gas recirculation (EGR) for noise reduction

Exhaust gas recirculation systems are utilized to reduce noise in L92 engine exhausts. By recirculating a portion of the exhaust gases back into the engine intake, the overall exhaust flow is reduced, leading to lower noise levels. This approach also helps in reducing emissions and improving engine efficiency.Expand Specific Solutions04 Variable geometry exhaust systems

Variable geometry exhaust systems are employed to optimize acoustic performance across different engine operating conditions. These systems use adjustable components, such as movable baffles or variable-length pipes, to alter the exhaust flow characteristics. This adaptability allows for improved noise control and performance tuning.Expand Specific Solutions05 Acoustic materials and coatings

Specialized acoustic materials and coatings are applied to L92 engine exhaust components to enhance sound absorption and reduce noise transmission. These materials may include high-temperature resistant foams, fibrous materials, or advanced composite materials that effectively dampen vibrations and attenuate sound across a wide frequency range.Expand Specific Solutions

Key Players in Automotive Exhaust Systems

The acoustic performance optimization in L92 engine exhausts is a mature field within the automotive industry, currently in a growth phase. The market size is substantial, driven by increasing demand for quieter and more efficient vehicles. Technologically, the sector is advancing rapidly, with companies like Tenneco GmbH, Mercedes-Benz Group AG, and BMW AG leading innovation. These firms are investing heavily in research and development, focusing on advanced materials and computational modeling to enhance exhaust system performance. Emerging players such as Guangzhou Automobile Group and Huahuan Automotive Technology are also contributing to the competitive landscape, particularly in the Asian market.

Bayerische Motoren Werke AG

Technical Solution: BMW has implemented a holistic approach to acoustic performance optimization in L92 engine exhausts. Their solution incorporates a digitally controlled exhaust valve system that can adjust the exhaust flow path and backpressure based on driving conditions and driver preferences[1]. BMW utilizes advanced acoustic modeling software to predict and fine-tune exhaust note characteristics across the engine's operating range[2]. The company has also developed a lightweight, multi-layer exhaust system that combines sound-absorbing materials with precisely designed resonator chambers to attenuate specific frequencies[3]. BMW's exhaust systems feature integrated Helmholtz resonators and quarter-wave tubes strategically placed to cancel out unwanted harmonics[4]. Additionally, they have implemented active sound design technology that can enhance desirable engine notes while suppressing less pleasant frequencies, creating a carefully crafted acoustic experience[5].

Strengths: Highly customizable exhaust sound, integration with vehicle driving modes, and advanced acoustic modeling capabilities. Weaknesses: Potential for system complexity leading to higher production and maintenance costs, reliance on electronic controls that may be prone to failures.

Ford Global Technologies LLC

Technical Solution: Ford has implemented a multi-faceted approach to acoustic performance optimization in L92 engine exhausts. Their solution includes the use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) to model exhaust flow dynamics and acoustic behavior[1]. Ford has developed a variable geometry exhaust system that can adjust its internal structure to optimize sound characteristics across different engine speeds and loads[2]. The company utilizes advanced materials, including micro-perforated stainless steel and high-temperature resistant acoustic foams, to enhance sound attenuation while maintaining durability[3]. Ford's exhaust systems incorporate multiple expansion chambers and Helmholtz resonators, precisely tuned to target specific frequency ranges[4]. Additionally, they have implemented an active valve exhaust system that can modify exhaust flow paths to alter the acoustic signature based on driving mode and user preferences[5].

Strengths: Adaptive exhaust geometry, advanced material usage, and comprehensive acoustic modeling capabilities. Weaknesses: Potential for increased manufacturing complexity and cost, possible reliability concerns with moving parts in the variable geometry system.

Core Innovations in Exhaust Noise Reduction

Exhaust system for an internal combustion engine and method for operating the exhaust system

PatentActiveEP2997240A1

Innovation

- The exhaust system features a symmetrical design with identical parts and adjustable shut-off devices that minimize back pressure and allow for flexible acoustic adjustments, incorporating a coiled or shell silencer construction with perforated damping pipes and integrated resonators, enabling efficient sound management and reduced manufacturing costs.

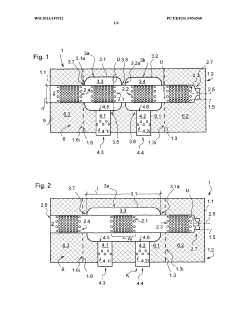

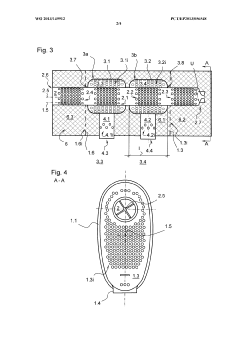

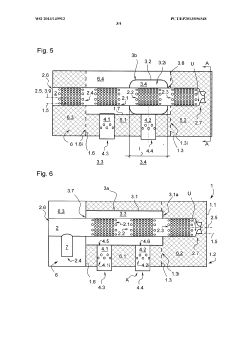

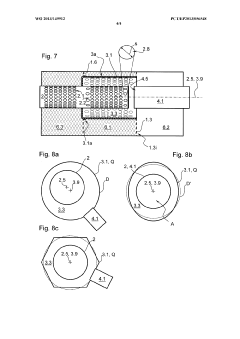

Muffler having coupling of a tailpipe by means of a coupling chamber

PatentWO2013149912A1

Innovation

- The design incorporates a coupling chamber within the muffler housing where the inlet and outlet pipes form a flow channel, with a chamber wall that connects the pipes and is mechanically connected to the housing, optimizing the diameter ratio and geometry to increase the effective length of the exhaust pipe for improved acoustic performance.

Environmental Regulations Impact on Exhaust Design

Environmental regulations have become increasingly stringent in recent years, significantly impacting the design and optimization of engine exhaust systems, particularly in the context of acoustic performance for L92 engines. These regulations aim to reduce noise pollution and emissions, forcing manufacturers to adapt their exhaust designs to meet new standards while maintaining optimal engine performance.

One of the primary challenges in exhaust design is balancing the need for effective noise reduction with the requirement to minimize back pressure, which can negatively impact engine efficiency. As regulations tighten, engineers must develop innovative solutions to achieve this balance. This has led to the adoption of advanced materials and manufacturing techniques, such as high-temperature resistant alloys and precision-engineered muffler components.

The implementation of Euro 6 and EPA Tier 3 standards has particularly influenced exhaust system design, requiring more sophisticated catalytic converters and particulate filters. These components, while essential for emissions control, can introduce additional complexities in managing exhaust flow and acoustic properties. As a result, computational fluid dynamics (CFD) and finite element analysis (FEA) have become crucial tools in the design process, allowing engineers to optimize exhaust geometry for both emissions control and sound management.

Another significant impact of environmental regulations is the push towards lightweight materials in exhaust system construction. This trend is driven by the need to reduce overall vehicle weight to improve fuel efficiency and reduce emissions. However, lightweight materials can present challenges in terms of durability and heat management, necessitating careful material selection and design considerations.

The focus on reducing cold-start emissions has also influenced exhaust design, leading to the development of close-coupled catalysts and advanced thermal management systems. These innovations aim to rapidly bring catalysts up to operating temperature, but they can affect the acoustic characteristics of the exhaust system, requiring additional tuning to maintain desired sound qualities.

Furthermore, the growing emphasis on electric and hybrid vehicles has introduced new challenges in exhaust system design. While these vehicles may have reduced or no exhaust emissions, they still require careful acoustic management to meet noise regulations and consumer expectations. This has led to the development of active noise control systems and synthetic sound generators, which must be integrated with traditional passive exhaust noise reduction techniques.

In response to these regulatory pressures, manufacturers are increasingly turning to modular exhaust system designs. These allow for greater flexibility in meeting diverse regulatory requirements across different markets while minimizing development costs. Such modular approaches enable rapid adaptation to changing regulations and market demands, ensuring compliance while maintaining optimal acoustic performance.

One of the primary challenges in exhaust design is balancing the need for effective noise reduction with the requirement to minimize back pressure, which can negatively impact engine efficiency. As regulations tighten, engineers must develop innovative solutions to achieve this balance. This has led to the adoption of advanced materials and manufacturing techniques, such as high-temperature resistant alloys and precision-engineered muffler components.

The implementation of Euro 6 and EPA Tier 3 standards has particularly influenced exhaust system design, requiring more sophisticated catalytic converters and particulate filters. These components, while essential for emissions control, can introduce additional complexities in managing exhaust flow and acoustic properties. As a result, computational fluid dynamics (CFD) and finite element analysis (FEA) have become crucial tools in the design process, allowing engineers to optimize exhaust geometry for both emissions control and sound management.

Another significant impact of environmental regulations is the push towards lightweight materials in exhaust system construction. This trend is driven by the need to reduce overall vehicle weight to improve fuel efficiency and reduce emissions. However, lightweight materials can present challenges in terms of durability and heat management, necessitating careful material selection and design considerations.

The focus on reducing cold-start emissions has also influenced exhaust design, leading to the development of close-coupled catalysts and advanced thermal management systems. These innovations aim to rapidly bring catalysts up to operating temperature, but they can affect the acoustic characteristics of the exhaust system, requiring additional tuning to maintain desired sound qualities.

Furthermore, the growing emphasis on electric and hybrid vehicles has introduced new challenges in exhaust system design. While these vehicles may have reduced or no exhaust emissions, they still require careful acoustic management to meet noise regulations and consumer expectations. This has led to the development of active noise control systems and synthetic sound generators, which must be integrated with traditional passive exhaust noise reduction techniques.

In response to these regulatory pressures, manufacturers are increasingly turning to modular exhaust system designs. These allow for greater flexibility in meeting diverse regulatory requirements across different markets while minimizing development costs. Such modular approaches enable rapid adaptation to changing regulations and market demands, ensuring compliance while maintaining optimal acoustic performance.

Materials Advancements for Acoustic Optimization

Recent advancements in materials science have opened new avenues for acoustic performance optimization in L92 engine exhausts. Traditional materials like steel and aluminum are being supplemented or replaced by innovative composites and alloys that offer superior sound-dampening properties while maintaining structural integrity and heat resistance.

Ceramic matrix composites (CMCs) have emerged as a promising material for exhaust systems. These materials combine the high-temperature resistance of ceramics with the toughness of composite structures. CMCs can withstand extreme temperatures while providing excellent acoustic absorption, making them ideal for reducing engine noise without compromising performance.

Another significant development is the use of shape memory alloys (SMAs) in exhaust systems. These materials can change their shape in response to temperature variations, allowing for adaptive noise control. By incorporating SMAs into exhaust components, engineers can create systems that automatically adjust their geometry to optimize acoustic performance across different engine operating conditions.

Nano-engineered materials are also making their mark in acoustic optimization. Carbon nanotubes and graphene-based composites are being explored for their exceptional strength-to-weight ratio and acoustic damping properties. These materials can be integrated into exhaust liners to create lightweight yet highly effective sound-absorbing structures.

Metamaterials, artificially structured materials designed to manipulate sound waves, represent a cutting-edge approach to acoustic optimization. By carefully engineering the structure of these materials at the microscopic level, researchers can create exhaust components that selectively block or redirect specific frequencies of sound, offering unprecedented control over engine noise.

Hybrid materials that combine multiple acoustic optimization strategies are gaining traction. For instance, multi-layered structures incorporating porous absorbers, resonant chambers, and viscoelastic damping materials can provide broadband noise reduction across a wide range of frequencies.

The integration of smart materials with embedded sensors and actuators is paving the way for active noise control systems in exhaust design. These materials can detect and counteract sound waves in real-time, offering dynamic acoustic optimization that adapts to changing engine conditions and environmental factors.

As research in materials science continues to advance, the potential for further improvements in acoustic performance optimization for L92 engine exhausts remains significant. The challenge lies in balancing acoustic properties with other critical factors such as durability, cost-effectiveness, and manufacturability to create practical solutions for the automotive industry.

Ceramic matrix composites (CMCs) have emerged as a promising material for exhaust systems. These materials combine the high-temperature resistance of ceramics with the toughness of composite structures. CMCs can withstand extreme temperatures while providing excellent acoustic absorption, making them ideal for reducing engine noise without compromising performance.

Another significant development is the use of shape memory alloys (SMAs) in exhaust systems. These materials can change their shape in response to temperature variations, allowing for adaptive noise control. By incorporating SMAs into exhaust components, engineers can create systems that automatically adjust their geometry to optimize acoustic performance across different engine operating conditions.

Nano-engineered materials are also making their mark in acoustic optimization. Carbon nanotubes and graphene-based composites are being explored for their exceptional strength-to-weight ratio and acoustic damping properties. These materials can be integrated into exhaust liners to create lightweight yet highly effective sound-absorbing structures.

Metamaterials, artificially structured materials designed to manipulate sound waves, represent a cutting-edge approach to acoustic optimization. By carefully engineering the structure of these materials at the microscopic level, researchers can create exhaust components that selectively block or redirect specific frequencies of sound, offering unprecedented control over engine noise.

Hybrid materials that combine multiple acoustic optimization strategies are gaining traction. For instance, multi-layered structures incorporating porous absorbers, resonant chambers, and viscoelastic damping materials can provide broadband noise reduction across a wide range of frequencies.

The integration of smart materials with embedded sensors and actuators is paving the way for active noise control systems in exhaust design. These materials can detect and counteract sound waves in real-time, offering dynamic acoustic optimization that adapts to changing engine conditions and environmental factors.

As research in materials science continues to advance, the potential for further improvements in acoustic performance optimization for L92 engine exhausts remains significant. The challenge lies in balancing acoustic properties with other critical factors such as durability, cost-effectiveness, and manufacturability to create practical solutions for the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!