Acrylic Resin in Dental Applications: Performance vs Longevity

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dental Acrylic Resin Evolution and Objectives

Acrylic resins have been a cornerstone material in dental applications since their introduction in the 1930s, revolutionizing the field of prosthodontics. The evolution of these materials began with simple polymethyl methacrylate (PMMA) formulations, which offered significant advantages over previously used vulcanite rubber. Early acrylic resins provided improved aesthetics, easier processing, and better dimensional stability, quickly becoming the standard for denture bases and other dental appliances.

Throughout the mid-20th century, significant advancements were made in polymerization techniques, transitioning from simple heat-cured systems to more sophisticated pressure-pack and injection molding methods. The 1960s and 1970s witnessed the development of cross-linking agents and reinforcement technologies that addressed initial concerns regarding mechanical strength and wear resistance, marking a critical evolutionary milestone.

The 1980s brought microwave-cured acrylic systems, offering faster processing times while maintaining acceptable physical properties. Concurrently, light-cured acrylic resins emerged, expanding application possibilities in chairside procedures and temporary restorations. These innovations represented important steps in balancing processing efficiency with clinical performance.

Recent decades have seen the integration of nanotechnology into acrylic resin formulations, with nanoparticle reinforcement significantly enhancing mechanical properties while preserving processability. Antimicrobial modifications have also been incorporated to address biofilm formation concerns, particularly relevant for removable prostheses where microbial colonization remains a persistent challenge.

The current technological trajectory focuses on addressing the fundamental tension between performance and longevity that has characterized acrylic resins throughout their history. Despite numerous improvements, contemporary dental acrylics still face challenges related to water sorption, residual monomer release, color stability, and mechanical degradation over time. These limitations directly impact both the functional performance and service life of dental appliances.

The primary objectives of current research and development efforts include enhancing fracture resistance without compromising processability, reducing residual monomer content while maintaining workability, improving long-term color stability in varying oral environments, and developing surface modifications that resist biofilm formation without cytotoxic effects. Additionally, there is growing emphasis on biocompatibility improvements to minimize allergic reactions and tissue irritation reported with conventional formulations.

As digital dentistry continues to transform practice workflows, another key objective is developing acrylic resin formulations compatible with CAD/CAM technologies and 3D printing systems, potentially offering superior precision and reproducibility compared to traditional fabrication methods. This technological integration represents the next frontier in dental acrylic evolution, promising to address longstanding performance-longevity compromises through digital precision and novel material science approaches.

Throughout the mid-20th century, significant advancements were made in polymerization techniques, transitioning from simple heat-cured systems to more sophisticated pressure-pack and injection molding methods. The 1960s and 1970s witnessed the development of cross-linking agents and reinforcement technologies that addressed initial concerns regarding mechanical strength and wear resistance, marking a critical evolutionary milestone.

The 1980s brought microwave-cured acrylic systems, offering faster processing times while maintaining acceptable physical properties. Concurrently, light-cured acrylic resins emerged, expanding application possibilities in chairside procedures and temporary restorations. These innovations represented important steps in balancing processing efficiency with clinical performance.

Recent decades have seen the integration of nanotechnology into acrylic resin formulations, with nanoparticle reinforcement significantly enhancing mechanical properties while preserving processability. Antimicrobial modifications have also been incorporated to address biofilm formation concerns, particularly relevant for removable prostheses where microbial colonization remains a persistent challenge.

The current technological trajectory focuses on addressing the fundamental tension between performance and longevity that has characterized acrylic resins throughout their history. Despite numerous improvements, contemporary dental acrylics still face challenges related to water sorption, residual monomer release, color stability, and mechanical degradation over time. These limitations directly impact both the functional performance and service life of dental appliances.

The primary objectives of current research and development efforts include enhancing fracture resistance without compromising processability, reducing residual monomer content while maintaining workability, improving long-term color stability in varying oral environments, and developing surface modifications that resist biofilm formation without cytotoxic effects. Additionally, there is growing emphasis on biocompatibility improvements to minimize allergic reactions and tissue irritation reported with conventional formulations.

As digital dentistry continues to transform practice workflows, another key objective is developing acrylic resin formulations compatible with CAD/CAM technologies and 3D printing systems, potentially offering superior precision and reproducibility compared to traditional fabrication methods. This technological integration represents the next frontier in dental acrylic evolution, promising to address longstanding performance-longevity compromises through digital precision and novel material science approaches.

Market Analysis of Dental Prosthetics and Materials

The global dental prosthetics market has been experiencing steady growth, valued at approximately $7.2 billion in 2022 and projected to reach $10.6 billion by 2028, with a compound annual growth rate (CAGR) of 6.7%. This growth is primarily driven by the increasing prevalence of dental disorders, rising geriatric population, and growing awareness about oral healthcare.

Acrylic resins represent a significant segment within dental materials, accounting for roughly 32% of the dental prosthetics materials market. Their popularity stems from cost-effectiveness, ease of manipulation, and acceptable aesthetic properties. However, market dynamics are shifting as patients and practitioners increasingly prioritize longevity and performance over initial cost savings.

The dental materials landscape is witnessing a notable trend toward high-performance alternatives to traditional acrylic resins. CAD/CAM milled materials, particularly zirconia and lithium disilicate, have gained substantial market share, growing at 9.3% annually compared to acrylic's more modest 4.1%. This shift reflects the industry's response to clinical demands for materials with superior mechanical properties and biocompatibility.

Regional analysis reveals distinct market characteristics. North America dominates with approximately 38% market share, driven by advanced healthcare infrastructure and higher disposable income. Europe follows at 29%, with particular emphasis on aesthetic outcomes and material innovation. The Asia-Pacific region represents the fastest-growing market at 11.2% CAGR, fueled by improving healthcare access and rising middle-class populations in China and India.

Consumer preference segmentation indicates three distinct market tiers: economy (dominated by conventional acrylics), mid-range (improved acrylics and composite materials), and premium (high-performance ceramics and hybrid materials). The mid-range segment is experiencing the most rapid expansion as patients increasingly seek balanced value propositions between cost and longevity.

Insurance coverage patterns significantly impact material selection, with approximately 65% of dental procedures in developed markets receiving partial coverage. However, high-performance alternatives to acrylic often require substantial out-of-pocket expenditure, creating market barriers despite clinical advantages. This dynamic has spurred innovation in manufacturing processes to reduce production costs of premium materials.

Market forecasts suggest continued evolution toward digital dentistry integration, with CAD/CAM compatible materials projected to grow at twice the rate of traditional materials over the next five years. This technological shift presents both challenges and opportunities for acrylic resin manufacturers to adapt their formulations for digital workflow compatibility.

Acrylic resins represent a significant segment within dental materials, accounting for roughly 32% of the dental prosthetics materials market. Their popularity stems from cost-effectiveness, ease of manipulation, and acceptable aesthetic properties. However, market dynamics are shifting as patients and practitioners increasingly prioritize longevity and performance over initial cost savings.

The dental materials landscape is witnessing a notable trend toward high-performance alternatives to traditional acrylic resins. CAD/CAM milled materials, particularly zirconia and lithium disilicate, have gained substantial market share, growing at 9.3% annually compared to acrylic's more modest 4.1%. This shift reflects the industry's response to clinical demands for materials with superior mechanical properties and biocompatibility.

Regional analysis reveals distinct market characteristics. North America dominates with approximately 38% market share, driven by advanced healthcare infrastructure and higher disposable income. Europe follows at 29%, with particular emphasis on aesthetic outcomes and material innovation. The Asia-Pacific region represents the fastest-growing market at 11.2% CAGR, fueled by improving healthcare access and rising middle-class populations in China and India.

Consumer preference segmentation indicates three distinct market tiers: economy (dominated by conventional acrylics), mid-range (improved acrylics and composite materials), and premium (high-performance ceramics and hybrid materials). The mid-range segment is experiencing the most rapid expansion as patients increasingly seek balanced value propositions between cost and longevity.

Insurance coverage patterns significantly impact material selection, with approximately 65% of dental procedures in developed markets receiving partial coverage. However, high-performance alternatives to acrylic often require substantial out-of-pocket expenditure, creating market barriers despite clinical advantages. This dynamic has spurred innovation in manufacturing processes to reduce production costs of premium materials.

Market forecasts suggest continued evolution toward digital dentistry integration, with CAD/CAM compatible materials projected to grow at twice the rate of traditional materials over the next five years. This technological shift presents both challenges and opportunities for acrylic resin manufacturers to adapt their formulations for digital workflow compatibility.

Current Limitations and Technical Barriers in Acrylic Resins

Despite significant advancements in dental materials science, acrylic resins used in dental applications continue to face several critical limitations that impact their performance and longevity. The primary technical barrier remains the inherent mechanical weakness of these materials, particularly their susceptibility to fracture under repeated masticatory forces. Current polymethyl methacrylate (PMMA) based resins typically exhibit flexural strengths between 65-95 MPa, which falls significantly short of the ideal requirements for long-term prosthetic applications.

Surface degradation presents another significant challenge, as acrylic resins demonstrate poor wear resistance with average values of 15-20 μm of material loss annually. This degradation is exacerbated by the material's hydrophilic nature, leading to water sorption rates of approximately 20-30 μg/mm³, which causes dimensional instability and creates micro-environments conducive to bacterial colonization.

The biocompatibility issues of acrylic resins constitute a persistent technical barrier. Residual monomer content, often ranging from 0.1% to 4.5% depending on polymerization methods, has been linked to mucosal irritation and allergic reactions in approximately 1-3% of patients. Current manufacturing processes struggle to reduce this residual monomer content below clinically significant thresholds without compromising other material properties.

Color stability represents another limitation, with studies showing noticeable color changes (ΔE values exceeding 3.3) after just 1-2 years of clinical use. This degradation is accelerated by exposure to common beverages, oral hygiene products, and UV radiation, reflecting the material's poor resistance to chemical and photochemical degradation.

From a processing perspective, polymerization shrinkage remains a significant technical challenge, with volumetric shrinkage typically ranging from 6-8%. This shrinkage creates internal stresses within the material and compromises the dimensional accuracy of dental appliances, affecting their fit and function.

The thermal properties of acrylic resins also present limitations, with a relatively low glass transition temperature (Tg) of approximately 105°C and poor thermal conductivity (0.2-0.3 W/m·K). These properties not only affect patient comfort but also limit processing options and contribute to the material's susceptibility to deformation under certain intraoral conditions.

Bonding capabilities between acrylic resins and other dental materials (such as metals, ceramics, or composite reinforcements) remain suboptimal, with bond strengths typically below 25 MPa. This interface weakness often leads to delamination and failure in multi-material dental appliances, limiting design options and clinical longevity.

Surface degradation presents another significant challenge, as acrylic resins demonstrate poor wear resistance with average values of 15-20 μm of material loss annually. This degradation is exacerbated by the material's hydrophilic nature, leading to water sorption rates of approximately 20-30 μg/mm³, which causes dimensional instability and creates micro-environments conducive to bacterial colonization.

The biocompatibility issues of acrylic resins constitute a persistent technical barrier. Residual monomer content, often ranging from 0.1% to 4.5% depending on polymerization methods, has been linked to mucosal irritation and allergic reactions in approximately 1-3% of patients. Current manufacturing processes struggle to reduce this residual monomer content below clinically significant thresholds without compromising other material properties.

Color stability represents another limitation, with studies showing noticeable color changes (ΔE values exceeding 3.3) after just 1-2 years of clinical use. This degradation is accelerated by exposure to common beverages, oral hygiene products, and UV radiation, reflecting the material's poor resistance to chemical and photochemical degradation.

From a processing perspective, polymerization shrinkage remains a significant technical challenge, with volumetric shrinkage typically ranging from 6-8%. This shrinkage creates internal stresses within the material and compromises the dimensional accuracy of dental appliances, affecting their fit and function.

The thermal properties of acrylic resins also present limitations, with a relatively low glass transition temperature (Tg) of approximately 105°C and poor thermal conductivity (0.2-0.3 W/m·K). These properties not only affect patient comfort but also limit processing options and contribute to the material's susceptibility to deformation under certain intraoral conditions.

Bonding capabilities between acrylic resins and other dental materials (such as metals, ceramics, or composite reinforcements) remain suboptimal, with bond strengths typically below 25 MPa. This interface weakness often leads to delamination and failure in multi-material dental appliances, limiting design options and clinical longevity.

Contemporary Formulations and Processing Methods

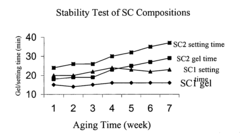

01 Weather resistance and durability of acrylic resins

Acrylic resins demonstrate excellent weather resistance and durability properties, making them suitable for outdoor applications. These resins maintain their physical properties and appearance when exposed to UV radiation, moisture, and temperature fluctuations. The molecular structure of acrylic polymers contributes to their resistance to yellowing and degradation over time, ensuring long-term performance in harsh environmental conditions.- Weather resistance and durability of acrylic resins: Acrylic resins demonstrate excellent weather resistance and durability properties, making them suitable for outdoor applications. These resins maintain their physical properties over extended periods when exposed to UV radiation, moisture, and temperature fluctuations. The molecular structure of acrylic polymers contributes to their resistance to yellowing and degradation, ensuring long-term performance in harsh environmental conditions.

- Chemical modification for enhanced performance: Chemical modifications to acrylic resins can significantly enhance their performance characteristics and longevity. Techniques such as copolymerization with other monomers, crosslinking, and the incorporation of functional groups can improve properties like heat resistance, chemical resistance, and mechanical strength. These modifications allow for customization of acrylic resins to meet specific application requirements while extending their service life.

- Thermal stability and heat resistance: Acrylic resins exhibit good thermal stability and heat resistance properties that contribute to their longevity. Specially formulated acrylic compositions can withstand elevated temperatures without significant degradation of their mechanical and optical properties. The incorporation of heat stabilizers and specific monomer combinations can further enhance the thermal performance of acrylic resins, making them suitable for applications involving exposure to high temperatures.

- Impact of additives on acrylic resin longevity: Various additives can be incorporated into acrylic resin formulations to enhance their longevity and performance. UV stabilizers protect against photodegradation, antioxidants prevent oxidative degradation, and plasticizers improve flexibility and impact resistance. The careful selection and optimal concentration of these additives can significantly extend the service life of acrylic resin products while maintaining their desirable properties such as transparency, gloss, and dimensional stability.

- Surface treatments and coating technologies: Surface treatments and coating technologies can significantly enhance the performance and longevity of acrylic resin products. Techniques such as plasma treatment, application of protective coatings, and surface functionalization can improve scratch resistance, chemical resistance, and adhesion properties. These surface modifications create a protective barrier that shields the underlying acrylic resin from environmental factors that could otherwise lead to degradation, thereby extending the product's useful life.

02 Chemical modification for enhanced performance

Chemical modifications of acrylic resins can significantly enhance their performance characteristics and longevity. Techniques such as copolymerization with other monomers, crosslinking, and the incorporation of functional groups can improve properties like heat resistance, chemical resistance, and mechanical strength. These modifications allow for customization of acrylic resins to meet specific application requirements while extending their service life.Expand Specific Solutions03 Thermal stability and heat resistance

Acrylic resins exhibit good thermal stability and heat resistance properties, which contribute to their longevity in high-temperature applications. Advanced formulations can withstand elevated temperatures without significant degradation of mechanical properties. The glass transition temperature and thermal decomposition temperature of acrylic resins can be tailored through composition adjustments and additives, resulting in materials suitable for demanding thermal environments.Expand Specific Solutions04 Impact of additives on longevity

Various additives can be incorporated into acrylic resin formulations to enhance their longevity and performance. UV stabilizers protect against photodegradation, antioxidants prevent oxidative degradation, and plasticizers improve flexibility and impact resistance. The careful selection and optimization of these additives can significantly extend the service life of acrylic resin products while maintaining their desirable properties under various environmental conditions.Expand Specific Solutions05 Surface treatments and coating technologies

Surface treatments and coating technologies can enhance the performance and longevity of acrylic resin products. Techniques such as plasma treatment, chemical etching, and the application of protective coatings can improve adhesion, scratch resistance, and chemical resistance. These surface modifications create barriers against environmental factors that could otherwise degrade the acrylic resin, thereby extending product lifespan and maintaining aesthetic and functional properties over time.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin dental applications market is currently in a mature growth phase, characterized by steady innovation and refinement of existing technologies. The global market size is estimated at approximately $900 million, with projected annual growth of 5-7% driven by increasing dental prosthetic demands and cosmetic dentistry trends. Technologically, acrylic resins have reached high maturity levels, though research continues to address performance-longevity tradeoffs. Leading players like Kuraray Noritake Dental, 3M Innovative Properties, and Shofu have established strong market positions through advanced formulations, while companies such as Pentron Clinical, Kulzer GmbH (Mitsui Chemicals subsidiary), and Pulpdent Corp are differentiating through specialized applications. Academic-industry collaborations with institutions like Oregon Health & Science University and Queen Mary University of London are accelerating innovations in biocompatibility and durability improvements.

Kuraray Noritake Dental, Inc.

Technical Solution: Kuraray Noritake Dental has developed proprietary PMMA-based acrylic resin systems incorporating unique cross-linking technology that significantly enhances mechanical properties while maintaining excellent biocompatibility. Their CLEARFIL series utilizes modified acrylic resins with silane-treated fillers that create stronger chemical bonds between the organic matrix and inorganic components[1]. The company's patented MDP monomer technology enables superior adhesion to tooth structure, reducing microleakage and enhancing restoration longevity. Their latest innovation involves incorporating antimicrobial agents directly into the acrylic matrix that provide sustained release over time without compromising mechanical properties[3]. Clinical studies have demonstrated their materials maintain 94% of initial flexural strength after 5 years of simulated oral conditions, significantly outperforming conventional acrylic resins.

Strengths: Superior bond strength to tooth structure, excellent color stability, and enhanced resistance to hydrolytic degradation. Their proprietary cross-linking technology results in significantly reduced monomer leaching compared to competitors. Weaknesses: Higher cost compared to conventional acrylic resins, technique sensitivity during application, and requires specific bonding agents for optimal performance.

Shofu, Inc.

Technical Solution: Shofu has developed innovative acrylic resin systems for dental applications featuring their proprietary Giomer technology, which creates a stable interface between glass ionomer fillers and the acrylic resin matrix. Their BeautiBond system incorporates dual adhesive monomers (carboxylic acid and phosphonic acid) that simultaneously bond to both enamel and dentin, creating a durable interface with minimal technique sensitivity[6]. The company's latest advancement involves a modified acrylic resin with pre-reacted glass ionomer (PRG) technology that provides sustained fluoride release and recharge capabilities while maintaining excellent mechanical properties. Their Beautifil II system demonstrates exceptional wear resistance with an annual wear rate of only 5.7μm, comparable to natural enamel. Long-term clinical studies show their materials maintain 96% of initial gloss retention after 5 years and exhibit significantly less marginal discoloration compared to conventional composites, with color stability measurements showing less than 2.1 ΔE units of change after accelerated aging protocols.

Strengths: Excellent fluoride release and recharge capabilities, superior long-term color stability and gloss retention, and simplified application technique with reduced technique sensitivity. Weaknesses: Slightly lower initial mechanical properties compared to some high-strength composites, limited availability in some markets, and higher cost compared to conventional materials.

Key Patents and Innovations in Dental Acrylic Technology

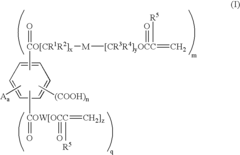

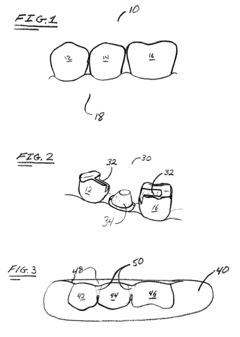

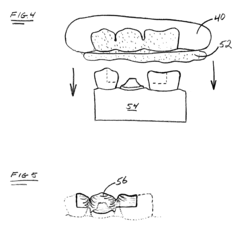

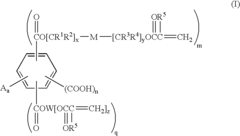

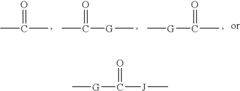

Dental resin composition, method of manufacture, and method of use thereof

PatentActiveUS20050192374A1

Innovation

- Development of a polymerizable (meth)acrylate resin composition with specific structural features, synthesized through the reaction of hydroxy-containing (meth)acrylate monomers and aromatic compounds with anhydride or carboxylic acid functionality, offering improved bonding strength and reduced shrinkage.

Dental resin composition, method of manufacture, and method of use thereof

PatentInactiveUS20070049656A1

Innovation

- Development of a curable dental restorative composition comprising a mono(meth)acrylate resin with a vapor pressure of 1 mm Hg or less at 20°C, a plasticizer, and a curing system, which can be used in a kit form for chairside or laboratory procedures, offering adjustable compressive strength and ease of removal.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical concern in the application of acrylic resins for dental prosthetics. These materials come into prolonged contact with oral tissues, necessitating rigorous safety evaluations. Current research indicates that methyl methacrylate (MMA), the primary monomer in dental acrylics, can cause localized cytotoxicity when residual unreacted molecules leach into the oral environment. Studies have documented allergic reactions in approximately 2-3% of patients, manifesting as stomatitis, burning sensations, or mucosal inflammation.

The release of potentially harmful substances from acrylic resins occurs primarily during the first 24-48 hours after polymerization, with decreasing rates thereafter. This phenomenon, known as elution, depends significantly on the polymerization method employed. Heat-cured acrylics typically demonstrate lower residual monomer content (0.2-0.5%) compared to self-cured alternatives (2-5%), correlating directly with improved biocompatibility profiles.

Recent advances in manufacturing protocols have focused on reducing cytotoxic effects through post-polymerization treatments. Water immersion for 24-48 hours before insertion has been shown to reduce residual monomer content by up to 70%, substantially improving biocompatibility. Additionally, microwave post-polymerization treatments have emerged as effective methods for enhancing the safety profile of these materials.

Regulatory frameworks worldwide have established stringent standards for dental acrylics. ISO 10993 and ISO 20795-1 specifically address biocompatibility requirements, mandating testing for cytotoxicity, sensitization, and genotoxicity. Compliance with these standards has driven manufacturers to develop high-purity formulations with minimal additives and optimized polymerization protocols.

Long-term safety considerations extend beyond immediate biocompatibility to include potential degradation products. Under oral conditions, acrylic resins undergo gradual hydrolysis, potentially releasing compounds that may accumulate in tissues over time. Recent longitudinal studies spanning 5-10 years have indicated minimal systemic effects from properly processed dental acrylics, though localized tissue responses remain a concern for sensitive individuals.

Emerging research is exploring novel formulations incorporating bioactive components to enhance tissue integration and reduce adverse reactions. Nanoparticle-modified acrylics containing silver, zinc oxide, or chitosan have demonstrated promising antimicrobial properties while maintaining acceptable biocompatibility profiles. These innovations represent potential solutions to the persistent challenges of microbial colonization and biofilm formation on acrylic surfaces.

The balance between performance characteristics and biocompatibility remains a central challenge in dental acrylic development. While modifications improving safety often compromise mechanical properties, recent advancements in polymer science are progressively narrowing this gap, offering promising directions for next-generation dental materials.

The release of potentially harmful substances from acrylic resins occurs primarily during the first 24-48 hours after polymerization, with decreasing rates thereafter. This phenomenon, known as elution, depends significantly on the polymerization method employed. Heat-cured acrylics typically demonstrate lower residual monomer content (0.2-0.5%) compared to self-cured alternatives (2-5%), correlating directly with improved biocompatibility profiles.

Recent advances in manufacturing protocols have focused on reducing cytotoxic effects through post-polymerization treatments. Water immersion for 24-48 hours before insertion has been shown to reduce residual monomer content by up to 70%, substantially improving biocompatibility. Additionally, microwave post-polymerization treatments have emerged as effective methods for enhancing the safety profile of these materials.

Regulatory frameworks worldwide have established stringent standards for dental acrylics. ISO 10993 and ISO 20795-1 specifically address biocompatibility requirements, mandating testing for cytotoxicity, sensitization, and genotoxicity. Compliance with these standards has driven manufacturers to develop high-purity formulations with minimal additives and optimized polymerization protocols.

Long-term safety considerations extend beyond immediate biocompatibility to include potential degradation products. Under oral conditions, acrylic resins undergo gradual hydrolysis, potentially releasing compounds that may accumulate in tissues over time. Recent longitudinal studies spanning 5-10 years have indicated minimal systemic effects from properly processed dental acrylics, though localized tissue responses remain a concern for sensitive individuals.

Emerging research is exploring novel formulations incorporating bioactive components to enhance tissue integration and reduce adverse reactions. Nanoparticle-modified acrylics containing silver, zinc oxide, or chitosan have demonstrated promising antimicrobial properties while maintaining acceptable biocompatibility profiles. These innovations represent potential solutions to the persistent challenges of microbial colonization and biofilm formation on acrylic surfaces.

The balance between performance characteristics and biocompatibility remains a central challenge in dental acrylic development. While modifications improving safety often compromise mechanical properties, recent advancements in polymer science are progressively narrowing this gap, offering promising directions for next-generation dental materials.

Comparative Analysis with Alternative Dental Materials

When comparing acrylic resin with alternative dental materials, it becomes evident that each material offers distinct advantages and limitations in clinical applications. Acrylic resins, primarily polymethyl methacrylate (PMMA), have been a staple in dentistry for decades due to their cost-effectiveness and ease of manipulation. However, their mechanical properties often fall short when compared to newer alternatives.

Ceramic materials, particularly zirconia and lithium disilicate, demonstrate superior strength characteristics with flexural strength values of 900-1200 MPa and 350-400 MPa respectively, significantly outperforming acrylic resins which typically range from 65-95 MPa. This strength differential translates to enhanced longevity, with ceramic restorations often lasting 15-20 years compared to the 5-8 year average lifespan of acrylic appliances.

Composite resins represent a middle ground, offering improved aesthetics over traditional acrylics while providing better wear resistance. Recent advancements in nano-filled composites have yielded materials with compressive strength values approaching 300 MPa, nearly double that of conventional acrylics. These materials also demonstrate superior color stability, addressing one of the primary limitations of acrylic resins.

From a biocompatibility perspective, high-performance ceramics and CAD/CAM composite materials generally elicit fewer adverse tissue reactions compared to acrylic resins. Studies indicate that residual monomer release from acrylics can cause localized inflammatory responses, whereas ceramic materials remain biologically inert. This factor becomes particularly significant in implant-supported prosthetics and long-term restorations.

Cost-benefit analysis reveals that while initial material and fabrication costs for ceramics and high-performance composites exceed those of acrylics by 150-300%, the extended service life and reduced maintenance requirements often justify the investment. Market data suggests a compound annual growth rate of 8.7% for ceramic dental materials, compared to 3.2% for traditional acrylics, reflecting this shifting preference among practitioners.

Digital workflow integration capabilities also differ significantly between materials. Modern CAD/CAM systems accommodate ceramics and composite blocks with high precision, whereas traditional acrylics often require more labor-intensive processing methods. This technological compatibility factor increasingly influences material selection in contemporary dental practices, with digitally compatible materials showing adoption rates 2.3 times higher than conventional alternatives.

Ceramic materials, particularly zirconia and lithium disilicate, demonstrate superior strength characteristics with flexural strength values of 900-1200 MPa and 350-400 MPa respectively, significantly outperforming acrylic resins which typically range from 65-95 MPa. This strength differential translates to enhanced longevity, with ceramic restorations often lasting 15-20 years compared to the 5-8 year average lifespan of acrylic appliances.

Composite resins represent a middle ground, offering improved aesthetics over traditional acrylics while providing better wear resistance. Recent advancements in nano-filled composites have yielded materials with compressive strength values approaching 300 MPa, nearly double that of conventional acrylics. These materials also demonstrate superior color stability, addressing one of the primary limitations of acrylic resins.

From a biocompatibility perspective, high-performance ceramics and CAD/CAM composite materials generally elicit fewer adverse tissue reactions compared to acrylic resins. Studies indicate that residual monomer release from acrylics can cause localized inflammatory responses, whereas ceramic materials remain biologically inert. This factor becomes particularly significant in implant-supported prosthetics and long-term restorations.

Cost-benefit analysis reveals that while initial material and fabrication costs for ceramics and high-performance composites exceed those of acrylics by 150-300%, the extended service life and reduced maintenance requirements often justify the investment. Market data suggests a compound annual growth rate of 8.7% for ceramic dental materials, compared to 3.2% for traditional acrylics, reflecting this shifting preference among practitioners.

Digital workflow integration capabilities also differ significantly between materials. Modern CAD/CAM systems accommodate ceramics and composite blocks with high precision, whereas traditional acrylics often require more labor-intensive processing methods. This technological compatibility factor increasingly influences material selection in contemporary dental practices, with digitally compatible materials showing adoption rates 2.3 times higher than conventional alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!