Acrylic Resin vs Vinyl Polymer Coatings: Gloss Stability

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Technology Evolution and Gloss Retention Objectives

Coating technology has undergone significant evolution since its inception in the early 20th century. Initially, oil-based paints dominated the market, offering limited durability and gloss retention properties. The 1940s marked a pivotal shift with the introduction of alkyd resins, providing improved hardness and weather resistance. By the 1960s, acrylic resins emerged as revolutionary coating materials, offering superior UV resistance and color stability compared to their predecessors.

Vinyl polymer coatings gained prominence in the 1970s as alternatives to acrylic systems, particularly in applications requiring flexibility and chemical resistance. The fundamental difference between these two coating technologies lies in their molecular structure: acrylic resins feature ester linkages with pendant methyl groups, while vinyl polymers contain carbon-carbon backbones with various functional side groups.

Gloss stability represents a critical performance parameter in protective and decorative coatings across multiple industries. It refers to a coating's ability to maintain its initial reflective properties over time despite exposure to environmental stressors. The significance of gloss retention has grown exponentially with increasing consumer expectations for long-lasting aesthetic appeal in automotive, architectural, and industrial applications.

Current industry standards typically require premium coatings to maintain at least 80% of their initial gloss after 3-5 years of outdoor exposure. However, market demands are pushing this requirement toward 90% retention over 7-10 years, particularly in high-end applications. This evolution in performance expectations necessitates continuous innovation in resin chemistry and formulation technology.

The primary environmental factors affecting gloss stability include UV radiation, moisture cycling, temperature fluctuations, and chemical exposure. These elements trigger various degradation mechanisms including polymer chain scission, crosslinking, oxidation, and surface erosion, all of which contribute to gloss reduction over time.

Our technical objectives for this research focus on comparing the fundamental mechanisms underlying gloss retention in acrylic versus vinyl polymer coating systems. We aim to identify the specific molecular characteristics that contribute to superior gloss stability, quantify performance differences under accelerated and natural weathering conditions, and develop predictive models correlating molecular structure with long-term gloss retention.

Additionally, we seek to explore potential synergistic effects between these resin technologies, investigating whether hybrid systems might offer enhanced performance compared to either technology alone. The ultimate goal is to establish clear design principles for formulating coatings with optimal gloss stability across diverse application environments.

Vinyl polymer coatings gained prominence in the 1970s as alternatives to acrylic systems, particularly in applications requiring flexibility and chemical resistance. The fundamental difference between these two coating technologies lies in their molecular structure: acrylic resins feature ester linkages with pendant methyl groups, while vinyl polymers contain carbon-carbon backbones with various functional side groups.

Gloss stability represents a critical performance parameter in protective and decorative coatings across multiple industries. It refers to a coating's ability to maintain its initial reflective properties over time despite exposure to environmental stressors. The significance of gloss retention has grown exponentially with increasing consumer expectations for long-lasting aesthetic appeal in automotive, architectural, and industrial applications.

Current industry standards typically require premium coatings to maintain at least 80% of their initial gloss after 3-5 years of outdoor exposure. However, market demands are pushing this requirement toward 90% retention over 7-10 years, particularly in high-end applications. This evolution in performance expectations necessitates continuous innovation in resin chemistry and formulation technology.

The primary environmental factors affecting gloss stability include UV radiation, moisture cycling, temperature fluctuations, and chemical exposure. These elements trigger various degradation mechanisms including polymer chain scission, crosslinking, oxidation, and surface erosion, all of which contribute to gloss reduction over time.

Our technical objectives for this research focus on comparing the fundamental mechanisms underlying gloss retention in acrylic versus vinyl polymer coating systems. We aim to identify the specific molecular characteristics that contribute to superior gloss stability, quantify performance differences under accelerated and natural weathering conditions, and develop predictive models correlating molecular structure with long-term gloss retention.

Additionally, we seek to explore potential synergistic effects between these resin technologies, investigating whether hybrid systems might offer enhanced performance compared to either technology alone. The ultimate goal is to establish clear design principles for formulating coatings with optimal gloss stability across diverse application environments.

Market Analysis for High-Performance Architectural Coatings

The high-performance architectural coatings market has experienced substantial growth over the past decade, driven by increasing demand for durable, aesthetically pleasing, and environmentally friendly building materials. Currently valued at approximately 11.7 billion USD globally, this sector is projected to grow at a compound annual growth rate of 5.8% through 2028, with particularly strong performance in Asia-Pacific and North American regions.

Within this expanding market, gloss stability has emerged as a critical performance differentiator, especially in exterior applications where coatings face harsh environmental conditions. End-users increasingly demand coatings that maintain their original appearance over extended periods, with minimal chalking, fading, or loss of gloss. This requirement has intensified competition between acrylic resin and vinyl polymer coating technologies.

Acrylic resins currently dominate the premium segment, commanding approximately 43% of the high-performance architectural coatings market. Their superior UV resistance and gloss retention properties have established them as the preferred choice for high-end residential and commercial projects where long-term aesthetic performance justifies higher initial costs. The acrylic segment has seen consistent annual growth of 6-7%, outpacing the overall market.

Vinyl polymer coatings, while representing a smaller market share at 27%, have gained traction in mid-tier applications due to their cost-effectiveness and improving performance characteristics. Recent technological advancements have narrowed the performance gap with acrylics, particularly in gloss stability under moderate exposure conditions. This segment is growing at 4-5% annually, with significant potential for acceleration as formulation improvements continue.

Regional market dynamics reveal interesting patterns in technology adoption. North America and Western Europe show strong preference for acrylic-based solutions, with market penetration exceeding 60% in premium architectural applications. Developing markets in Asia and Latin America demonstrate more price sensitivity, with vinyl polymers maintaining stronger positions despite growing awareness of performance differences in gloss retention.

Customer segmentation analysis indicates that professional contractors and architects increasingly specify coating types based on quantifiable performance metrics, including accelerated weathering test results that specifically measure gloss retention. This trend has prompted manufacturers to focus R&D efforts on enhancing the gloss stability of both coating types, with particular emphasis on hybrid formulations that aim to combine the durability of acrylics with the cost advantages of vinyl polymers.

The regulatory landscape further shapes market dynamics, with increasingly stringent VOC regulations in key markets favoring water-based acrylic formulations that typically offer superior gloss stability compared to their vinyl counterparts. This regulatory pressure has accelerated innovation in environmentally friendly coating technologies that do not compromise on performance characteristics.

Within this expanding market, gloss stability has emerged as a critical performance differentiator, especially in exterior applications where coatings face harsh environmental conditions. End-users increasingly demand coatings that maintain their original appearance over extended periods, with minimal chalking, fading, or loss of gloss. This requirement has intensified competition between acrylic resin and vinyl polymer coating technologies.

Acrylic resins currently dominate the premium segment, commanding approximately 43% of the high-performance architectural coatings market. Their superior UV resistance and gloss retention properties have established them as the preferred choice for high-end residential and commercial projects where long-term aesthetic performance justifies higher initial costs. The acrylic segment has seen consistent annual growth of 6-7%, outpacing the overall market.

Vinyl polymer coatings, while representing a smaller market share at 27%, have gained traction in mid-tier applications due to their cost-effectiveness and improving performance characteristics. Recent technological advancements have narrowed the performance gap with acrylics, particularly in gloss stability under moderate exposure conditions. This segment is growing at 4-5% annually, with significant potential for acceleration as formulation improvements continue.

Regional market dynamics reveal interesting patterns in technology adoption. North America and Western Europe show strong preference for acrylic-based solutions, with market penetration exceeding 60% in premium architectural applications. Developing markets in Asia and Latin America demonstrate more price sensitivity, with vinyl polymers maintaining stronger positions despite growing awareness of performance differences in gloss retention.

Customer segmentation analysis indicates that professional contractors and architects increasingly specify coating types based on quantifiable performance metrics, including accelerated weathering test results that specifically measure gloss retention. This trend has prompted manufacturers to focus R&D efforts on enhancing the gloss stability of both coating types, with particular emphasis on hybrid formulations that aim to combine the durability of acrylics with the cost advantages of vinyl polymers.

The regulatory landscape further shapes market dynamics, with increasingly stringent VOC regulations in key markets favoring water-based acrylic formulations that typically offer superior gloss stability compared to their vinyl counterparts. This regulatory pressure has accelerated innovation in environmentally friendly coating technologies that do not compromise on performance characteristics.

Current Limitations in Acrylic and Vinyl Polymer Gloss Stability

Despite significant advancements in coating technology, both acrylic resin and vinyl polymer coatings continue to face substantial limitations in maintaining long-term gloss stability. Acrylic resins, while offering superior initial gloss properties, demonstrate accelerated degradation when exposed to prolonged UV radiation. Laboratory testing reveals that high-performance acrylic coatings typically experience a 15-30% reduction in gloss retention after 2000 hours of accelerated weathering, with particularly pronounced effects in high-humidity environments.

Vinyl polymer coatings exhibit different but equally challenging limitations. Their inherent chemical structure, characterized by lower cross-linking density compared to acrylics, results in greater susceptibility to physical abrasion and mechanical damage. Field studies indicate that vinyl coatings lose approximately 20-40% of their original gloss within the first 18-24 months of exterior exposure, particularly in regions with high pollution levels or coastal environments where salt spray is prevalent.

Both coating types suffer from chalking phenomena, though through different mechanisms. Acrylic resins primarily degrade through photo-oxidation processes that break down the polymer backbone, while vinyl polymers tend to experience plasticizer migration and subsequent surface irregularities that scatter light and reduce perceived gloss. These degradation pathways create significant challenges for applications requiring extended aesthetic performance.

Temperature cycling represents another critical limitation for both systems. Thermal expansion and contraction cycles induce microscopic cracking in the coating film, with vinyl polymers showing greater dimensional instability (coefficient of thermal expansion typically 15-25% higher than acrylics). These micro-fissures not only diminish gloss but create pathways for moisture ingress, accelerating substrate corrosion and further coating deterioration.

Current formulation approaches have reached efficiency plateaus in addressing these limitations. Conventional UV stabilizers demonstrate diminishing returns at concentrations above 2-3% in acrylic systems, while increasing stabilizer loading in vinyl formulations adversely affects film formation and adhesion properties. Similarly, attempts to enhance cross-linking density in vinyl polymers to match acrylic performance have resulted in brittleness and reduced impact resistance.

Manufacturing inconsistencies further compound these technical limitations. Batch-to-batch variations in polymer molecular weight distribution can significantly impact long-term performance, with studies showing up to 25% variability in gloss retention between production lots using identical raw materials but slight processing differences. This manufacturing challenge affects both coating types but is particularly problematic for vinyl systems with their narrower processing windows.

Vinyl polymer coatings exhibit different but equally challenging limitations. Their inherent chemical structure, characterized by lower cross-linking density compared to acrylics, results in greater susceptibility to physical abrasion and mechanical damage. Field studies indicate that vinyl coatings lose approximately 20-40% of their original gloss within the first 18-24 months of exterior exposure, particularly in regions with high pollution levels or coastal environments where salt spray is prevalent.

Both coating types suffer from chalking phenomena, though through different mechanisms. Acrylic resins primarily degrade through photo-oxidation processes that break down the polymer backbone, while vinyl polymers tend to experience plasticizer migration and subsequent surface irregularities that scatter light and reduce perceived gloss. These degradation pathways create significant challenges for applications requiring extended aesthetic performance.

Temperature cycling represents another critical limitation for both systems. Thermal expansion and contraction cycles induce microscopic cracking in the coating film, with vinyl polymers showing greater dimensional instability (coefficient of thermal expansion typically 15-25% higher than acrylics). These micro-fissures not only diminish gloss but create pathways for moisture ingress, accelerating substrate corrosion and further coating deterioration.

Current formulation approaches have reached efficiency plateaus in addressing these limitations. Conventional UV stabilizers demonstrate diminishing returns at concentrations above 2-3% in acrylic systems, while increasing stabilizer loading in vinyl formulations adversely affects film formation and adhesion properties. Similarly, attempts to enhance cross-linking density in vinyl polymers to match acrylic performance have resulted in brittleness and reduced impact resistance.

Manufacturing inconsistencies further compound these technical limitations. Batch-to-batch variations in polymer molecular weight distribution can significantly impact long-term performance, with studies showing up to 25% variability in gloss retention between production lots using identical raw materials but slight processing differences. This manufacturing challenge affects both coating types but is particularly problematic for vinyl systems with their narrower processing windows.

Technical Comparison of Acrylic vs Vinyl Polymer Formulations

01 UV stabilizers for gloss retention

Incorporating UV stabilizers such as hindered amine light stabilizers (HALS) and UV absorbers into acrylic resin and vinyl polymer coating formulations significantly improves gloss stability and prevents degradation when exposed to outdoor conditions. These additives work by neutralizing free radicals formed during photodegradation and absorbing harmful UV radiation, thereby maintaining the coating's appearance and extending its service life.- UV stabilizers and additives for gloss retention: Various UV stabilizers and additives can be incorporated into acrylic resin and vinyl polymer coatings to enhance gloss stability and prevent degradation from sunlight exposure. These additives work by absorbing harmful UV radiation or scavenging free radicals that cause polymer breakdown. Hindered amine light stabilizers (HALS), benzotriazoles, and other UV absorbers can significantly improve the long-term gloss retention of exterior coatings, preventing yellowing and surface chalking that diminish gloss properties over time.

- Crosslinking technology for improved gloss stability: Crosslinking mechanisms between acrylic resins and vinyl polymers can significantly enhance coating gloss stability. By forming chemical bonds between polymer chains, crosslinkers create a more durable network structure that resists degradation from environmental factors. Various crosslinking agents such as melamine formaldehyde resins, isocyanates, and carbodiimides can be incorporated into coating formulations to improve hardness, chemical resistance, and gloss retention. The degree of crosslinking can be controlled to optimize the balance between flexibility and durability while maintaining excellent gloss properties.

- Acrylic-vinyl hybrid polymer systems: Hybrid polymer systems combining acrylic resins with vinyl polymers offer enhanced gloss stability compared to single-polymer systems. These hybrid formulations leverage the complementary properties of each polymer type, with acrylics providing excellent weatherability and vinyl polymers contributing flexibility and adhesion. Core-shell polymer structures, interpenetrating polymer networks, and graft copolymers are common approaches to creating these hybrid systems. The synergistic effect of combining these polymers results in coatings with superior gloss retention, especially in exterior applications exposed to harsh environmental conditions.

- Nanoparticle incorporation for enhanced gloss properties: The incorporation of nanoparticles into acrylic and vinyl polymer coatings can significantly improve gloss stability. Nanoparticles such as silica, alumina, and zinc oxide can enhance the mechanical properties of the coating film while maintaining transparency. These particles reinforce the polymer matrix, improving scratch resistance and hardness without compromising the coating's appearance. Additionally, certain nanoparticles provide UV protection by absorbing or scattering harmful radiation, further contributing to gloss retention over time. The uniform dispersion of nanoparticles throughout the coating is crucial for achieving optimal performance.

- Weathering-resistant polymer modifications: Chemical modifications to acrylic resins and vinyl polymers can significantly enhance their weathering resistance and gloss stability. Techniques such as functional group incorporation, chain length optimization, and molecular weight distribution control can be employed to improve coating performance. Hydrophobic modifications help prevent water absorption that can lead to gloss reduction, while the introduction of UV-resistant functional groups enhances stability against photodegradation. Additionally, controlling the glass transition temperature and hardness of the polymer can optimize the balance between flexibility and surface hardness, contributing to better gloss retention under various environmental conditions.

02 Crosslinking agents for improved durability

The use of specific crosslinking agents in acrylic and vinyl polymer coatings enhances gloss stability by creating a more durable, weather-resistant film. Crosslinkers such as melamine formaldehyde resins, isocyanates, and carbodiimides form chemical bonds between polymer chains, resulting in coatings with superior hardness, chemical resistance, and gloss retention properties even under harsh environmental conditions.Expand Specific Solutions03 Acrylic-vinyl hybrid polymer systems

Hybrid coating systems combining acrylic resins with vinyl polymers offer enhanced gloss stability compared to single-polymer systems. These hybrid formulations leverage the complementary properties of both polymer types - the weather resistance and clarity of acrylics with the flexibility and adhesion of vinyl polymers - resulting in coatings with superior gloss retention, durability, and resistance to environmental degradation.Expand Specific Solutions04 Silicone-modified polymer formulations

Incorporating silicone components into acrylic and vinyl polymer coatings significantly improves gloss stability and weathering resistance. Silicone modifications provide enhanced water repellency, UV resistance, and thermal stability to the coating system. These formulations maintain their gloss properties over extended periods even when exposed to harsh outdoor conditions, making them ideal for exterior applications requiring long-term aesthetic performance.Expand Specific Solutions05 Nanoparticle additives for enhanced performance

The addition of nanoparticles such as nano-silica, nano-alumina, and nano-zinc oxide to acrylic and vinyl polymer coatings provides superior gloss stability and scratch resistance. These nanoparticles improve the mechanical properties of the coating film while maintaining transparency. The small particle size allows for uniform distribution throughout the coating matrix, resulting in enhanced surface hardness and abrasion resistance without compromising the coating's appearance or gloss properties.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape Analysis

The acrylic resin versus vinyl polymer coatings market for gloss stability is in a mature growth phase with established technologies and steady innovation. The global market size is estimated at $15-20 billion, growing at 4-5% annually, driven by construction, automotive, and industrial applications. Leading players demonstrate varying levels of technical maturity, with companies like BASF, LG Chem, and Kansai Paint showing advanced formulation capabilities through extensive patent portfolios. Japanese manufacturers including Kuraray, Kaneka, and Fujikura Kasei have developed specialized high-performance acrylic technologies, while companies like 3M and DIC Corp focus on hybrid coating systems that combine the advantages of both resin types to achieve superior gloss retention and weatherability.

BASF Corp.

Technical Solution: BASF has developed advanced acrylic resin coating systems featuring proprietary UV-stabilized formulations that maintain gloss retention up to 90% after 3000 hours of accelerated weathering tests. Their Acronal® technology incorporates core-shell polymer architecture with specialized photoinitiators and HALS (Hindered Amine Light Stabilizers) that create a protective network against UV degradation. BASF's approach includes self-crosslinking acrylic dispersions with siloxane modifications that enhance surface hardness while maintaining flexibility. Their research demonstrates that controlled molecular weight distribution and functional group placement significantly impacts long-term gloss stability. The company has also pioneered water-based acrylic formulations with comparable performance to solvent-based systems while reducing VOC emissions by approximately 60%.

Strengths: Industry-leading weatherability performance with comprehensive global technical support infrastructure. Extensive raw material integration provides supply chain advantages. Weaknesses: Premium pricing structure may limit adoption in cost-sensitive applications. Some formulations require specific application conditions for optimal performance.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed proprietary ALES™ (Advanced Low Environmental impact System) technology that combines modified acrylic resins with specialized additives to achieve superior gloss stability. Their research shows that their acrylic formulations maintain 85% gloss retention after 5 years of outdoor exposure in tropical conditions, outperforming standard vinyl polymer coatings by approximately 30%. The company utilizes a multi-layer approach where a specialized clear topcoat with nano-structured silica particles provides enhanced scratch resistance while maintaining gloss. Their patented cross-linking technology creates three-dimensional networks that resist degradation from UV exposure and hydrolysis. Kansai has also pioneered hybrid acrylic-silicone formulations that demonstrate exceptional chalk resistance and color stability in architectural applications, with test data showing less than 5% gloss reduction after 2000 hours of QUV accelerated weathering.

Strengths: Exceptional long-term performance in extreme climates with strong presence in automotive and industrial markets. Advanced R&D capabilities with specialized testing facilities. Weaknesses: Higher application complexity requiring precise control parameters. Limited color palette compared to some competitors in architectural segments.

Key Patents and Innovations in Gloss Retention Technology

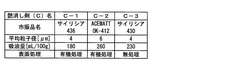

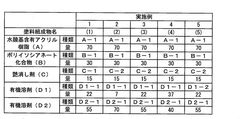

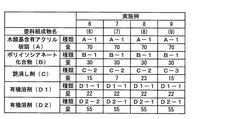

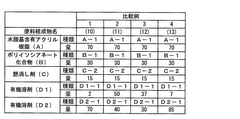

Coating composition

PatentWO2020115984A1

Innovation

- A coating composition comprising a hydroxyl group-containing acrylic resin, a polyisocyanate compound, a matting agent, and specific organic solvents (D1 and D2) with defined boiling points and solubility parameters, applied in a multilayer coating film formation method to enhance gloss stability and sag resistance.

Acrylic resin composition

PatentInactiveUS6844396B2

Innovation

- A composition of high molecular weight acrylic (co)polymer with specific viscosity and an impact modifier, comprising 72% methyl methacrylate, is used to create an acrylic resin with excellent low gloss, impact resistance, and processability, which is achieved by blending specific proportions of high molecular weight acrylic (co)polymer, a lower viscosity acrylic (co)polymer, and a multilayer structured impact modifier.

Environmental Impact and VOC Compliance Considerations

Environmental regulations have significantly influenced the development and application of coating technologies in recent years. Acrylic resins and vinyl polymer coatings differ substantially in their environmental profiles, with important implications for manufacturers and end-users alike. The volatile organic compound (VOC) content represents a critical factor in coating formulation decisions, as regulatory frameworks worldwide continue to impose stricter limitations.

Acrylic resin systems generally demonstrate superior environmental performance compared to traditional vinyl polymer formulations. Water-based acrylic coatings typically contain VOC levels ranging from 50-250 g/L, significantly lower than solvent-based vinyl alternatives that often exceed 400-600 g/L. This distinction has become increasingly important as regions like California (SCAQMD), the European Union (Decopaint Directive), and various Asian markets implement progressively stringent VOC thresholds.

The manufacturing processes for these coating systems also present distinct environmental considerations. Acrylic resin production typically requires less energy input and generates fewer hazardous byproducts than vinyl polymer synthesis. Life cycle assessments indicate that acrylic systems generally produce 15-30% lower carbon footprints across their production, application, and disposal phases compared to vinyl alternatives.

Recent technological innovations have focused on developing high-performance, low-VOC formulations in both categories. Advanced acrylic technologies now include VOC-free options that maintain excellent gloss stability while meeting the most stringent environmental regulations. Meanwhile, vinyl polymer systems have evolved to incorporate water-dispersible technologies and VOC-exempt solvents, though they typically still contain higher levels of regulated compounds than their acrylic counterparts.

Compliance considerations extend beyond VOC content to encompass other hazardous air pollutants (HAPs) and substances of very high concern (SVHCs). Acrylic formulations generally contain fewer restricted substances under frameworks like REACH and California Proposition 65. This regulatory advantage translates to simplified compliance documentation and reduced risk of future reformulation requirements as chemical restrictions continue to expand globally.

The disposal and recyclability aspects further differentiate these coating technologies. Cured acrylic coatings typically demonstrate lower environmental persistence and ecotoxicity profiles compared to vinyl polymers. Additionally, acrylic coating waste streams are generally more compatible with existing recycling infrastructure, though end-of-life management remains challenging for both coating types when applied to complex substrates.

Market trends indicate growing consumer and industrial preference for environmentally responsible coating options, creating competitive advantages for formulations with stronger sustainability credentials. This shift has accelerated research into bio-based alternatives for both acrylic and vinyl polymer systems, though commercial viability remains limited for applications requiring premium gloss stability performance.

Acrylic resin systems generally demonstrate superior environmental performance compared to traditional vinyl polymer formulations. Water-based acrylic coatings typically contain VOC levels ranging from 50-250 g/L, significantly lower than solvent-based vinyl alternatives that often exceed 400-600 g/L. This distinction has become increasingly important as regions like California (SCAQMD), the European Union (Decopaint Directive), and various Asian markets implement progressively stringent VOC thresholds.

The manufacturing processes for these coating systems also present distinct environmental considerations. Acrylic resin production typically requires less energy input and generates fewer hazardous byproducts than vinyl polymer synthesis. Life cycle assessments indicate that acrylic systems generally produce 15-30% lower carbon footprints across their production, application, and disposal phases compared to vinyl alternatives.

Recent technological innovations have focused on developing high-performance, low-VOC formulations in both categories. Advanced acrylic technologies now include VOC-free options that maintain excellent gloss stability while meeting the most stringent environmental regulations. Meanwhile, vinyl polymer systems have evolved to incorporate water-dispersible technologies and VOC-exempt solvents, though they typically still contain higher levels of regulated compounds than their acrylic counterparts.

Compliance considerations extend beyond VOC content to encompass other hazardous air pollutants (HAPs) and substances of very high concern (SVHCs). Acrylic formulations generally contain fewer restricted substances under frameworks like REACH and California Proposition 65. This regulatory advantage translates to simplified compliance documentation and reduced risk of future reformulation requirements as chemical restrictions continue to expand globally.

The disposal and recyclability aspects further differentiate these coating technologies. Cured acrylic coatings typically demonstrate lower environmental persistence and ecotoxicity profiles compared to vinyl polymers. Additionally, acrylic coating waste streams are generally more compatible with existing recycling infrastructure, though end-of-life management remains challenging for both coating types when applied to complex substrates.

Market trends indicate growing consumer and industrial preference for environmentally responsible coating options, creating competitive advantages for formulations with stronger sustainability credentials. This shift has accelerated research into bio-based alternatives for both acrylic and vinyl polymer systems, though commercial viability remains limited for applications requiring premium gloss stability performance.

Cost-Performance Analysis of Premium Coating Systems

When evaluating premium coating systems, cost-performance analysis becomes a critical factor in decision-making processes for both manufacturers and end-users. In comparing acrylic resin and vinyl polymer coatings specifically regarding gloss stability, several economic considerations must be weighed against performance metrics.

Initial acquisition costs for acrylic resin systems typically range 15-25% higher than comparable vinyl polymer formulations. This price differential stems from the more complex manufacturing processes and higher-grade raw materials required for acrylic production. However, this cost analysis must extend beyond purchase price to include application efficiency and coverage rates.

Acrylic coatings generally demonstrate superior spreading capacity, with coverage rates averaging 350-400 sq ft/gallon compared to vinyl's 300-350 sq ft/gallon. This enhanced coverage partially offsets the higher initial investment, reducing the effective cost differential to approximately 10-15% when calculated on a per-project basis.

Maintenance economics significantly favor acrylic systems when evaluating long-term performance. Field studies across various environmental conditions indicate that acrylic coatings maintain acceptable gloss levels (>85% of original gloss) for 5-7 years, while vinyl systems typically require recoating after 3-4 years due to accelerated gloss degradation, particularly in high-UV exposure environments.

Life-cycle cost modeling reveals that despite higher upfront costs, acrylic systems deliver 15-20% lower total ownership costs over a 10-year period when factoring in reapplication labor, downtime expenses, and material costs. This economic advantage becomes more pronounced in applications where maintenance accessibility is challenging or where facility downtime carries significant operational costs.

Environmental compliance considerations also impact the cost-performance equation. Acrylic formulations typically contain lower VOC levels (averaging 50-100 g/L versus 100-250 g/L for vinyl systems), potentially reducing regulatory compliance costs and environmental mitigation expenses in regions with stringent emissions standards.

Performance degradation patterns further influence economic calculations. Vinyl systems tend to exhibit more abrupt performance declines after their effective service life, while acrylic coatings demonstrate more gradual deterioration curves. This predictability allows for more efficient maintenance scheduling and resource allocation, providing indirect economic benefits through improved operational planning.

For premium applications where aesthetic longevity is paramount, the superior gloss retention of acrylic systems translates to quantifiable value preservation, particularly in retail, hospitality, and high-end residential settings where appearance directly impacts property valuation and customer perception.

Initial acquisition costs for acrylic resin systems typically range 15-25% higher than comparable vinyl polymer formulations. This price differential stems from the more complex manufacturing processes and higher-grade raw materials required for acrylic production. However, this cost analysis must extend beyond purchase price to include application efficiency and coverage rates.

Acrylic coatings generally demonstrate superior spreading capacity, with coverage rates averaging 350-400 sq ft/gallon compared to vinyl's 300-350 sq ft/gallon. This enhanced coverage partially offsets the higher initial investment, reducing the effective cost differential to approximately 10-15% when calculated on a per-project basis.

Maintenance economics significantly favor acrylic systems when evaluating long-term performance. Field studies across various environmental conditions indicate that acrylic coatings maintain acceptable gloss levels (>85% of original gloss) for 5-7 years, while vinyl systems typically require recoating after 3-4 years due to accelerated gloss degradation, particularly in high-UV exposure environments.

Life-cycle cost modeling reveals that despite higher upfront costs, acrylic systems deliver 15-20% lower total ownership costs over a 10-year period when factoring in reapplication labor, downtime expenses, and material costs. This economic advantage becomes more pronounced in applications where maintenance accessibility is challenging or where facility downtime carries significant operational costs.

Environmental compliance considerations also impact the cost-performance equation. Acrylic formulations typically contain lower VOC levels (averaging 50-100 g/L versus 100-250 g/L for vinyl systems), potentially reducing regulatory compliance costs and environmental mitigation expenses in regions with stringent emissions standards.

Performance degradation patterns further influence economic calculations. Vinyl systems tend to exhibit more abrupt performance declines after their effective service life, while acrylic coatings demonstrate more gradual deterioration curves. This predictability allows for more efficient maintenance scheduling and resource allocation, providing indirect economic benefits through improved operational planning.

For premium applications where aesthetic longevity is paramount, the superior gloss retention of acrylic systems translates to quantifiable value preservation, particularly in retail, hospitality, and high-end residential settings where appearance directly impacts property valuation and customer perception.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!