Additive Manufacturing Of Functionally Graded Superalloys: Methods And Benefits

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy AM Evolution and Objectives

Superalloys have been a cornerstone material in high-performance applications since their development in the 1940s, primarily serving aerospace, power generation, and other industries requiring exceptional mechanical strength and corrosion resistance at elevated temperatures. The evolution of superalloy manufacturing has transitioned from conventional casting and forging methods to more sophisticated powder metallurgy techniques, enabling greater control over microstructure and properties. This technological progression has culminated in the recent integration of superalloys with additive manufacturing (AM) technologies, marking a significant paradigm shift in fabrication capabilities.

The convergence of superalloys and AM began in earnest during the early 2000s, with initial experiments focusing on simple geometries and homogeneous compositions. These early efforts were primarily constrained by limited understanding of process parameters and their effects on microstructural development. By the 2010s, significant advancements in laser and electron beam technologies facilitated more precise control over energy input, enabling the production of increasingly complex superalloy components with improved mechanical properties.

The current technological frontier lies in functionally graded superalloys (FGS), which represent a sophisticated evolution in AM capabilities. These materials feature deliberately engineered compositional or microstructural gradients that optimize performance characteristics across different regions of a single component. This approach addresses the inherent limitations of homogeneous superalloys, where material properties optimized for one performance aspect often compromise others.

The primary objectives driving FGS development through AM include achieving unprecedented combinations of properties such as high-temperature strength coupled with room-temperature ductility, or oxidation resistance paired with thermal fatigue resistance. Additionally, there is significant interest in reducing material usage and component weight while maintaining or enhancing performance metrics critical for aerospace and energy applications.

Looking forward, the technological trajectory points toward several key objectives: developing robust process parameters for consistent FGS production; establishing comprehensive material property databases for various gradient configurations; creating advanced simulation tools to predict performance; and formulating standardized testing methodologies specific to functionally graded materials. These objectives collectively aim to transition FGS from laboratory curiosities to industrially viable manufacturing solutions.

The ultimate goal is to enable design engineers to precisely tailor material properties throughout a component, optimizing performance for specific operating conditions while minimizing material usage and manufacturing complexity. This capability would revolutionize high-performance component design across multiple industries, potentially enabling previously impossible engineering solutions to critical challenges in energy efficiency, emissions reduction, and system reliability.

The convergence of superalloys and AM began in earnest during the early 2000s, with initial experiments focusing on simple geometries and homogeneous compositions. These early efforts were primarily constrained by limited understanding of process parameters and their effects on microstructural development. By the 2010s, significant advancements in laser and electron beam technologies facilitated more precise control over energy input, enabling the production of increasingly complex superalloy components with improved mechanical properties.

The current technological frontier lies in functionally graded superalloys (FGS), which represent a sophisticated evolution in AM capabilities. These materials feature deliberately engineered compositional or microstructural gradients that optimize performance characteristics across different regions of a single component. This approach addresses the inherent limitations of homogeneous superalloys, where material properties optimized for one performance aspect often compromise others.

The primary objectives driving FGS development through AM include achieving unprecedented combinations of properties such as high-temperature strength coupled with room-temperature ductility, or oxidation resistance paired with thermal fatigue resistance. Additionally, there is significant interest in reducing material usage and component weight while maintaining or enhancing performance metrics critical for aerospace and energy applications.

Looking forward, the technological trajectory points toward several key objectives: developing robust process parameters for consistent FGS production; establishing comprehensive material property databases for various gradient configurations; creating advanced simulation tools to predict performance; and formulating standardized testing methodologies specific to functionally graded materials. These objectives collectively aim to transition FGS from laboratory curiosities to industrially viable manufacturing solutions.

The ultimate goal is to enable design engineers to precisely tailor material properties throughout a component, optimizing performance for specific operating conditions while minimizing material usage and manufacturing complexity. This capability would revolutionize high-performance component design across multiple industries, potentially enabling previously impossible engineering solutions to critical challenges in energy efficiency, emissions reduction, and system reliability.

Market Analysis for FGM Superalloy Components

The global market for functionally graded superalloy components is experiencing significant growth, driven by increasing demands in aerospace, energy, and defense sectors. These industries require materials that can withstand extreme operating conditions while maintaining structural integrity and performance. The market value for advanced superalloys is currently estimated at $7.5 billion, with functionally graded materials (FGM) representing an emerging segment showing annual growth rates of 12-15%.

Aerospace remains the dominant application sector, accounting for approximately 45% of the total market share. The commercial aviation industry's push toward more fuel-efficient engines with higher operating temperatures directly drives demand for advanced superalloy components with gradient properties. Major aircraft engine manufacturers have increased R&D investments in this technology by 18% over the past three years.

The energy sector, particularly gas turbines for power generation, constitutes the second-largest market at 30%. As global energy demands rise and efficiency standards become more stringent, the need for components that can operate at higher temperatures while maintaining longer service lives has intensified. Industry analysts project this segment to grow at 14% annually through 2028.

Defense applications represent 15% of the market, with particular emphasis on propulsion systems for advanced military aircraft and hypersonic vehicles. Government funding for research in this area has increased substantially, with the US Department of Defense allocating $320 million specifically for advanced materials development programs that include functionally graded superalloys.

Regional analysis shows North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the fastest growth is occurring in Asia-Pacific markets, particularly China and India, where aerospace and energy infrastructure development is accelerating rapidly.

Customer requirements are evolving toward components with longer service life, reduced maintenance needs, and improved performance under thermal cycling. This has created a premium segment within the market where functionally graded superalloy components command 30-40% higher prices than their conventional counterparts due to superior performance characteristics.

Supply chain analysis reveals potential constraints in raw material availability, particularly for elements like rhenium, hafnium, and certain rare earth metals essential for next-generation superalloys. These supply limitations could impact market growth and pricing dynamics over the next five years unless alternative material systems or recycling technologies are developed.

Aerospace remains the dominant application sector, accounting for approximately 45% of the total market share. The commercial aviation industry's push toward more fuel-efficient engines with higher operating temperatures directly drives demand for advanced superalloy components with gradient properties. Major aircraft engine manufacturers have increased R&D investments in this technology by 18% over the past three years.

The energy sector, particularly gas turbines for power generation, constitutes the second-largest market at 30%. As global energy demands rise and efficiency standards become more stringent, the need for components that can operate at higher temperatures while maintaining longer service lives has intensified. Industry analysts project this segment to grow at 14% annually through 2028.

Defense applications represent 15% of the market, with particular emphasis on propulsion systems for advanced military aircraft and hypersonic vehicles. Government funding for research in this area has increased substantially, with the US Department of Defense allocating $320 million specifically for advanced materials development programs that include functionally graded superalloys.

Regional analysis shows North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the fastest growth is occurring in Asia-Pacific markets, particularly China and India, where aerospace and energy infrastructure development is accelerating rapidly.

Customer requirements are evolving toward components with longer service life, reduced maintenance needs, and improved performance under thermal cycling. This has created a premium segment within the market where functionally graded superalloy components command 30-40% higher prices than their conventional counterparts due to superior performance characteristics.

Supply chain analysis reveals potential constraints in raw material availability, particularly for elements like rhenium, hafnium, and certain rare earth metals essential for next-generation superalloys. These supply limitations could impact market growth and pricing dynamics over the next five years unless alternative material systems or recycling technologies are developed.

Current Capabilities and Technical Barriers

The additive manufacturing (AM) of functionally graded superalloys has witnessed significant advancements in recent years. Current capabilities include the successful fabrication of components with controlled compositional gradients using various AM techniques such as Laser Powder Bed Fusion (LPBF), Direct Energy Deposition (DED), and Electron Beam Melting (EBM). These methods allow for the strategic placement of different superalloy compositions within a single component, enabling tailored mechanical properties across different regions.

LPBF technology has demonstrated the ability to create fine microstructural features with resolution down to 20-50 μm, making it suitable for complex geometries with internal cooling channels or lattice structures. DED processes offer higher deposition rates (up to 10 kg/h) and larger build volumes, proving advantageous for repair applications and larger components. Recent developments have also shown promising results in controlling the transition zones between different superalloy compositions, with gradient widths as narrow as 1-2 mm being achieved in laboratory settings.

Despite these advancements, several technical barriers persist in the AM of functionally graded superalloys. Thermal management during fabrication remains challenging, as different superalloy compositions exhibit varying thermal properties, leading to residual stress accumulation and potential cracking at interfaces. The mismatch in coefficient of thermal expansion between different superalloy regions can reach up to 20%, creating significant internal stresses during cooling cycles.

Material compatibility issues present another major hurdle, particularly when combining superalloys with substantially different elemental compositions. Elements like titanium, aluminum, and tantalum, which are critical for γ' precipitation strengthening, can cause segregation and unwanted phase formation at gradient interfaces. Current process control systems struggle to manage the complex parameter adjustments needed when transitioning between different superalloy compositions within a single build.

Post-processing treatments also pose significant challenges. Conventional heat treatments designed for homogeneous superalloys often prove inadequate for functionally graded components, as optimal treatment parameters differ across the compositional gradient. This necessitates the development of novel, spatially-varied heat treatment approaches that have yet to be fully realized in industrial settings.

Quality assurance and non-destructive testing methods for functionally graded superalloys remain underdeveloped. Current inspection techniques struggle to accurately characterize the complex microstructures and potential defects at gradient interfaces, limiting certification pathways for critical applications in aerospace and energy sectors. The lack of standardized testing protocols specifically designed for graded superalloy components further complicates qualification processes.

LPBF technology has demonstrated the ability to create fine microstructural features with resolution down to 20-50 μm, making it suitable for complex geometries with internal cooling channels or lattice structures. DED processes offer higher deposition rates (up to 10 kg/h) and larger build volumes, proving advantageous for repair applications and larger components. Recent developments have also shown promising results in controlling the transition zones between different superalloy compositions, with gradient widths as narrow as 1-2 mm being achieved in laboratory settings.

Despite these advancements, several technical barriers persist in the AM of functionally graded superalloys. Thermal management during fabrication remains challenging, as different superalloy compositions exhibit varying thermal properties, leading to residual stress accumulation and potential cracking at interfaces. The mismatch in coefficient of thermal expansion between different superalloy regions can reach up to 20%, creating significant internal stresses during cooling cycles.

Material compatibility issues present another major hurdle, particularly when combining superalloys with substantially different elemental compositions. Elements like titanium, aluminum, and tantalum, which are critical for γ' precipitation strengthening, can cause segregation and unwanted phase formation at gradient interfaces. Current process control systems struggle to manage the complex parameter adjustments needed when transitioning between different superalloy compositions within a single build.

Post-processing treatments also pose significant challenges. Conventional heat treatments designed for homogeneous superalloys often prove inadequate for functionally graded components, as optimal treatment parameters differ across the compositional gradient. This necessitates the development of novel, spatially-varied heat treatment approaches that have yet to be fully realized in industrial settings.

Quality assurance and non-destructive testing methods for functionally graded superalloys remain underdeveloped. Current inspection techniques struggle to accurately characterize the complex microstructures and potential defects at gradient interfaces, limiting certification pathways for critical applications in aerospace and energy sectors. The lack of standardized testing protocols specifically designed for graded superalloy components further complicates qualification processes.

State-of-the-Art Manufacturing Approaches

01 Manufacturing methods for functionally graded superalloys

Various manufacturing techniques are employed to create functionally graded superalloys with tailored properties across different regions. These methods include additive manufacturing, powder metallurgy, and specialized casting processes that allow for controlled composition and microstructure gradation. The gradual transition in properties enables components to withstand varying operational conditions in different areas of the same part, optimizing performance for high-temperature applications such as turbine blades and aerospace components.- Manufacturing methods for functionally graded superalloys: Various manufacturing techniques are employed to create functionally graded superalloys with tailored properties across different regions. These methods include additive manufacturing, powder metallurgy, and directional solidification processes that allow for controlled composition and microstructure gradients. The gradation can be achieved through selective alloying, heat treatment, or deposition techniques that result in components with optimized performance characteristics for specific applications.

- Thermal barrier applications of functionally graded superalloys: Functionally graded superalloys are utilized in thermal barrier applications where temperature gradients are significant. By creating gradual transitions in composition and microstructure, these materials can withstand extreme thermal conditions while maintaining structural integrity. The gradation helps minimize thermal stresses, improve thermal fatigue resistance, and enhance overall component durability in high-temperature environments such as gas turbine engines and combustion systems.

- Microstructural control in functionally graded superalloys: Controlling the microstructure of functionally graded superalloys is essential for achieving desired mechanical properties. Techniques involve manipulating grain size, precipitate distribution, and phase composition across the material. Advanced processing methods allow for tailored microstructures that optimize strength, creep resistance, and fatigue properties in different regions of the component, resulting in superior performance compared to homogeneous superalloys.

- Imaging and characterization techniques for functionally graded materials: Specialized imaging and characterization techniques are employed to analyze and validate the functional gradation in superalloys. These methods include advanced microscopy, spectroscopy, and computational analysis to map composition, microstructure, and property variations across the material. Non-destructive evaluation techniques help ensure quality control and provide data for optimizing the gradation process to achieve desired performance characteristics.

- Applications of functionally graded superalloys in advanced systems: Functionally graded superalloys find applications in various advanced systems where performance requirements vary across components. These include aerospace propulsion systems, power generation equipment, and high-temperature industrial processes. The ability to tailor material properties through gradation allows for optimized designs that can withstand complex loading conditions, thermal cycling, and corrosive environments while maintaining structural integrity and extending component life.

02 Microstructural control in functionally graded superalloys

Controlling the microstructure across the gradient is essential for achieving desired mechanical properties in functionally graded superalloys. This involves manipulating grain size, precipitate distribution, and phase composition throughout the material. Advanced techniques for microstructural engineering include heat treatments, controlled cooling rates, and the addition of specific alloying elements that promote particular crystallographic structures. These approaches enable the creation of superalloys with optimized strength, creep resistance, and thermal stability across functional gradients.Expand Specific Solutions03 Thermal and mechanical property gradation in superalloys

Functionally graded superalloys are designed with varying thermal and mechanical properties across their structure. This gradation allows for optimized performance under complex loading conditions and temperature gradients. By engineering specific regions with different coefficients of thermal expansion, thermal conductivity, and mechanical strength, these materials can better withstand thermal cycling and mechanical stresses. The controlled variation in properties helps minimize thermal stresses and extend component life in extreme environments such as gas turbine engines.Expand Specific Solutions04 Computational modeling and analysis of functionally graded superalloys

Advanced computational methods are essential for designing and analyzing functionally graded superalloys. These include finite element analysis, computational fluid dynamics, and microstructural evolution models that predict material behavior under various conditions. Machine learning and artificial intelligence approaches are increasingly being applied to optimize gradation profiles and processing parameters. These computational tools enable engineers to simulate performance, predict failure mechanisms, and design optimal gradation profiles before physical manufacturing, reducing development time and costs.Expand Specific Solutions05 Optical and imaging techniques for characterization of functional gradation

Specialized optical and imaging techniques are employed to characterize and validate the functional gradation in superalloys. These methods include holographic imaging, laser scanning, and advanced microscopy that can detect compositional and microstructural variations across the material. Non-destructive testing approaches help verify that the intended gradation has been achieved during manufacturing. These characterization techniques are crucial for quality control and for understanding the relationship between processing parameters and the resulting functional gradation in superalloys.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The additive manufacturing of functionally graded superalloys is currently in a growth phase, with the market expanding rapidly as aerospace and energy sectors seek advanced materials solutions. The global market is estimated to reach significant scale as industrial applications increase, particularly in high-temperature components. Technology maturity varies across players, with established aerospace and energy companies like Rolls-Royce, Siemens Energy, and GE leading commercial implementation. Academic institutions such as MIT, Huazhong University of Science & Technology, and Harbin Institute of Technology are advancing fundamental research. The competitive landscape shows a collaborative ecosystem where industrial leaders partner with research institutions to overcome technical challenges in material composition control, process stability, and quality assurance for these complex gradient structures.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered a hybrid additive manufacturing approach for functionally graded superalloys that combines Laser Metal Deposition (LMD) with in-situ heat treatment. Their proprietary process creates controlled microstructural gradients in nickel-based superalloys for aerospace applications. The company utilizes a multi-axis deposition system with dual powder feeders to achieve precise compositional control, allowing for tailored mechanical properties across different sections of a single component. Rolls-Royce's technology incorporates predictive modeling software that simulates the thermal history during deposition to optimize process parameters and predict resultant microstructures[2]. Their method has been successfully applied to high-pressure turbine blades, creating components with optimized creep resistance at the airfoil while maintaining superior fatigue resistance at the root. Testing has demonstrated up to 40% improvement in thermal-mechanical fatigue resistance compared to conventionally manufactured parts, with reduced internal stresses at material transition zones.

Strengths: Extensive aerospace qualification data; sophisticated thermal modeling capabilities; demonstrated performance improvements in flight-critical components. Weaknesses: Process is relatively slow compared to conventional manufacturing; requires significant post-processing for surface finishing; limited to certain size components due to chamber constraints.

Siemens AG

Technical Solution: Siemens AG has developed advanced Direct Energy Deposition (DED) and Selective Laser Melting (SLM) processes specifically optimized for functionally graded superalloys. Their approach involves precise control of powder feed rates and laser parameters to create gradual transitions between different superalloy compositions. Siemens has implemented a multi-material deposition system that can blend up to four different metal powders simultaneously, allowing for customized material gradients across critical components like turbine blades. Their process incorporates real-time monitoring with thermal imaging to ensure consistent material properties throughout the build. Siemens has successfully produced gas turbine components with optimized microstructures that feature heat-resistant Inconel at high-temperature zones transitioning to more ductile alloys in lower-stress regions[1][3]. This technology has enabled them to manufacture parts with 30% longer service life compared to conventional single-alloy components.

Strengths: Superior control over material composition gradients; integrated quality monitoring systems; proven implementation in commercial power generation equipment. Weaknesses: High equipment costs; complex process parameters requiring significant expertise; longer production times compared to conventional manufacturing methods.

Critical Patents and Research Breakthroughs

Method for the additive manufacturing of a structure having coolant conduction, component and device

PatentWO2020001849A1

Innovation

- A method for layer-by-layer additive production using a powder bed process that incorporates a coolant guide within the structure to actively cool the component during construction, preventing the formation of intermetallic phases and reducing temperature gradients, allowing for controlled heat management and suppression of crack formation.

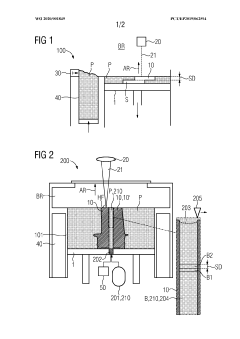

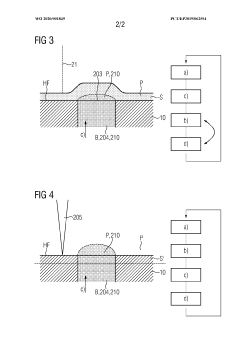

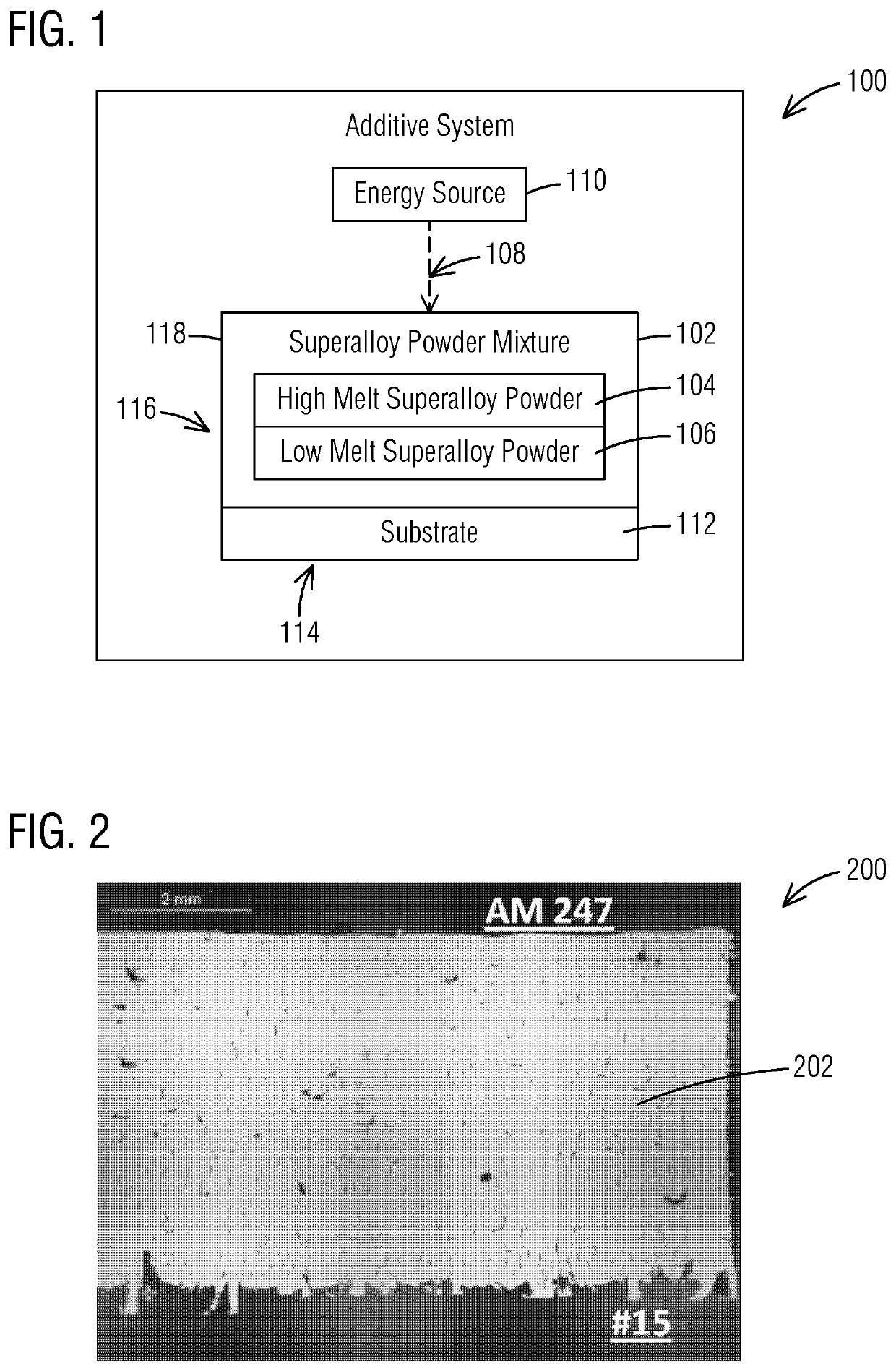

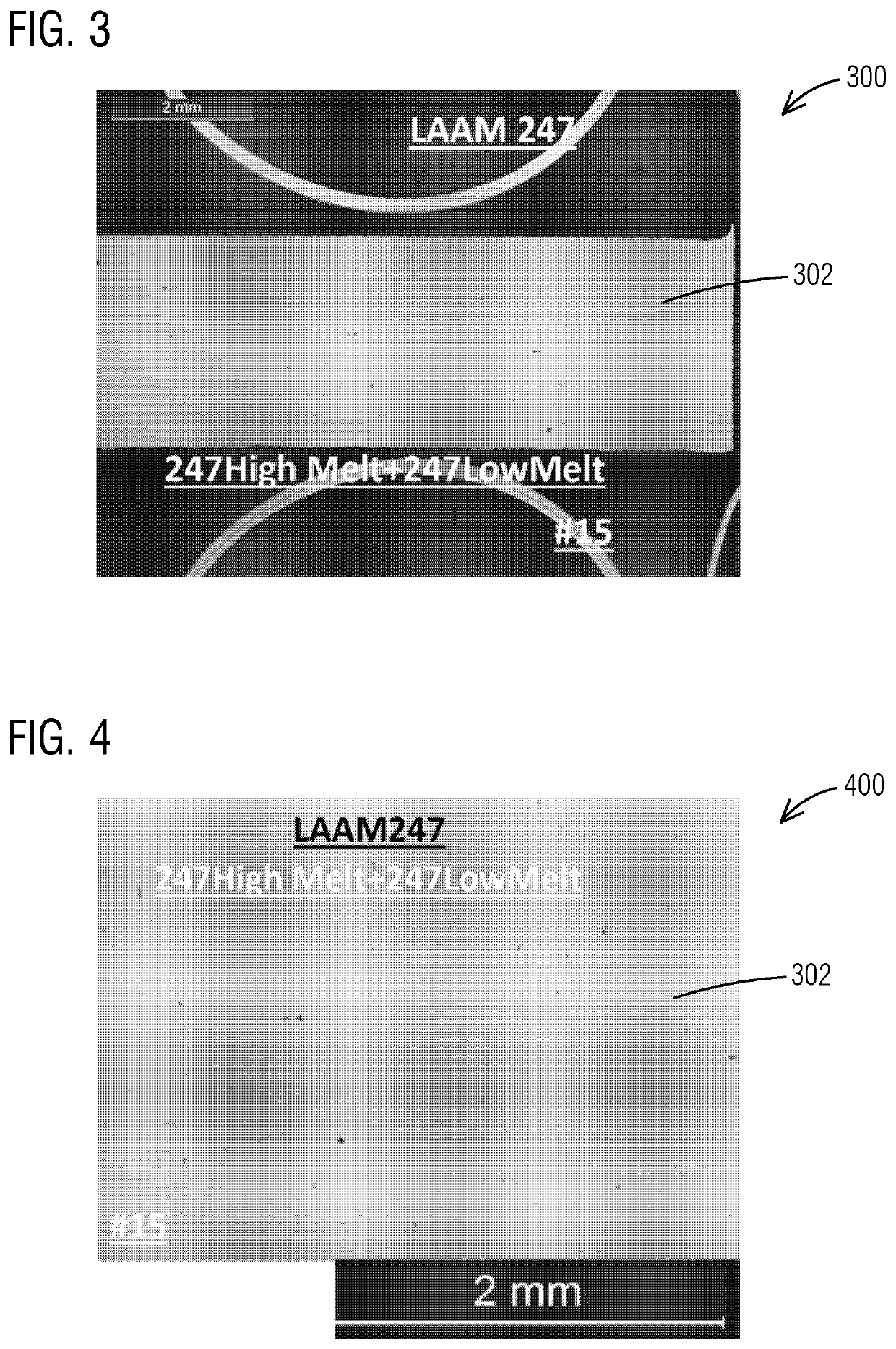

Superalloy powder mixture for liquid assisted additive manufacturing of a superalloy component

PatentPendingUS20220226893A1

Innovation

- A superalloy powder mixture comprising a high melt superalloy powder and a low melt superalloy powder, with specific weight ratios and chemical compositions, is used for additive manufacturing and welding, where the low melt superalloy powder has a lower solidus temperature than the high melt superalloy powder, reducing microcracking and eliminating the need for hot isostatic pressing.

Material-Process Interaction Fundamentals

The interaction between superalloy materials and additive manufacturing processes represents a critical foundation for understanding functionally graded superalloys. When superalloys encounter the extreme thermal conditions of additive manufacturing, complex metallurgical phenomena occur that significantly influence the final material properties. These interactions are governed by fundamental principles of heat transfer, solidification kinetics, and phase transformation dynamics.

Superalloys, particularly nickel-based variants, exhibit distinctive behavior during rapid heating and cooling cycles characteristic of additive manufacturing processes. The thermal gradient and cooling rate directly impact grain structure formation, with steeper gradients typically producing columnar grains oriented in the build direction. This directional solidification effect can be either advantageous or detrimental depending on the intended application of the component.

Elemental segregation presents a significant challenge during the processing of superalloys. Heavy elements like tungsten, molybdenum, and tantalum tend to concentrate in interdendritic regions during solidification, creating compositional heterogeneity. This segregation behavior becomes more complex in functionally graded materials where intentional compositional variations are introduced across the component.

The melt pool dynamics in powder-based additive manufacturing processes significantly influence material-process interactions. Parameters such as laser power, scan speed, and hatch spacing determine the melt pool geometry, temperature distribution, and solidification behavior. These factors directly affect the microstructural evolution, including precipitate formation, grain size distribution, and defect generation in superalloys.

Oxidation reactions represent another critical aspect of material-process interactions. The high processing temperatures combined with residual oxygen in the build chamber can lead to oxide formation, particularly for reactive elements like aluminum and titanium commonly found in superalloys. These oxides can serve as nucleation sites for defects or alter the local chemistry, affecting mechanical properties.

The precipitation kinetics of strengthening phases (γ', γ", carbides) in superalloys are highly sensitive to thermal history. The rapid solidification inherent to additive manufacturing often suppresses equilibrium phase formation, resulting in supersaturated solid solutions. This non-equilibrium state creates opportunities for tailored post-processing heat treatments to optimize the microstructure of functionally graded superalloys.

Understanding these fundamental material-process interactions enables the strategic design of functionally graded superalloys with location-specific properties. By manipulating process parameters across different regions of a component, manufacturers can create controlled variations in microstructure and composition that enhance performance in demanding aerospace, energy, and industrial applications.

Superalloys, particularly nickel-based variants, exhibit distinctive behavior during rapid heating and cooling cycles characteristic of additive manufacturing processes. The thermal gradient and cooling rate directly impact grain structure formation, with steeper gradients typically producing columnar grains oriented in the build direction. This directional solidification effect can be either advantageous or detrimental depending on the intended application of the component.

Elemental segregation presents a significant challenge during the processing of superalloys. Heavy elements like tungsten, molybdenum, and tantalum tend to concentrate in interdendritic regions during solidification, creating compositional heterogeneity. This segregation behavior becomes more complex in functionally graded materials where intentional compositional variations are introduced across the component.

The melt pool dynamics in powder-based additive manufacturing processes significantly influence material-process interactions. Parameters such as laser power, scan speed, and hatch spacing determine the melt pool geometry, temperature distribution, and solidification behavior. These factors directly affect the microstructural evolution, including precipitate formation, grain size distribution, and defect generation in superalloys.

Oxidation reactions represent another critical aspect of material-process interactions. The high processing temperatures combined with residual oxygen in the build chamber can lead to oxide formation, particularly for reactive elements like aluminum and titanium commonly found in superalloys. These oxides can serve as nucleation sites for defects or alter the local chemistry, affecting mechanical properties.

The precipitation kinetics of strengthening phases (γ', γ", carbides) in superalloys are highly sensitive to thermal history. The rapid solidification inherent to additive manufacturing often suppresses equilibrium phase formation, resulting in supersaturated solid solutions. This non-equilibrium state creates opportunities for tailored post-processing heat treatments to optimize the microstructure of functionally graded superalloys.

Understanding these fundamental material-process interactions enables the strategic design of functionally graded superalloys with location-specific properties. By manipulating process parameters across different regions of a component, manufacturers can create controlled variations in microstructure and composition that enhance performance in demanding aerospace, energy, and industrial applications.

Sustainability and Resource Efficiency

The additive manufacturing of functionally graded superalloys presents significant opportunities for enhancing sustainability and resource efficiency in advanced manufacturing sectors. Traditional manufacturing methods for superalloys typically involve extensive material waste, with buy-to-fly ratios often exceeding 10:1 in aerospace applications. In contrast, additive manufacturing approaches can reduce this ratio to nearly 1:1, representing a dramatic improvement in material utilization efficiency.

Functionally graded superalloy components manufactured through additive processes demonstrate exceptional resource optimization by enabling precise material placement only where specific properties are required. This targeted material distribution eliminates unnecessary use of rare and expensive elements such as rhenium, ruthenium, and hafnium that are commonly found in superalloys. The strategic allocation of these critical materials not only reduces raw material consumption but also addresses supply chain vulnerabilities associated with these geopolitically sensitive resources.

Energy efficiency represents another substantial sustainability benefit of additive manufacturing for functionally graded superalloys. Conventional manufacturing routes for superalloys involve multiple energy-intensive steps including vacuum induction melting, electroslag remelting, and extensive machining operations. Additive processes consolidate these steps into a single manufacturing operation, potentially reducing energy consumption by 50-70% according to recent life cycle assessments of aerospace components.

The extended service life of functionally graded superalloy components further enhances their sustainability profile. By optimizing material composition and microstructure for specific loading conditions, these components demonstrate superior resistance to thermal fatigue, creep, and oxidation—common failure modes in high-temperature applications. This longevity reduces the frequency of replacement and associated environmental impacts throughout the product lifecycle.

Waste reduction extends beyond the manufacturing phase to end-of-life considerations. The precise composition control in additively manufactured functionally graded superalloys facilitates more effective recycling processes. Unlike conventional superalloy components with homogeneous compositions, the controlled compositional gradients can be mapped and documented, enabling more targeted recycling strategies that preserve the value of constituent elements.

Water conservation represents an often-overlooked sustainability benefit of additive manufacturing processes for superalloys. Traditional manufacturing routes typically require significant quantities of water for cooling and cleaning operations, whereas powder-based additive manufacturing systems operate in closed environments with minimal water requirements, reducing the water footprint by up to 80% in some applications.

Functionally graded superalloy components manufactured through additive processes demonstrate exceptional resource optimization by enabling precise material placement only where specific properties are required. This targeted material distribution eliminates unnecessary use of rare and expensive elements such as rhenium, ruthenium, and hafnium that are commonly found in superalloys. The strategic allocation of these critical materials not only reduces raw material consumption but also addresses supply chain vulnerabilities associated with these geopolitically sensitive resources.

Energy efficiency represents another substantial sustainability benefit of additive manufacturing for functionally graded superalloys. Conventional manufacturing routes for superalloys involve multiple energy-intensive steps including vacuum induction melting, electroslag remelting, and extensive machining operations. Additive processes consolidate these steps into a single manufacturing operation, potentially reducing energy consumption by 50-70% according to recent life cycle assessments of aerospace components.

The extended service life of functionally graded superalloy components further enhances their sustainability profile. By optimizing material composition and microstructure for specific loading conditions, these components demonstrate superior resistance to thermal fatigue, creep, and oxidation—common failure modes in high-temperature applications. This longevity reduces the frequency of replacement and associated environmental impacts throughout the product lifecycle.

Waste reduction extends beyond the manufacturing phase to end-of-life considerations. The precise composition control in additively manufactured functionally graded superalloys facilitates more effective recycling processes. Unlike conventional superalloy components with homogeneous compositions, the controlled compositional gradients can be mapped and documented, enabling more targeted recycling strategies that preserve the value of constituent elements.

Water conservation represents an often-overlooked sustainability benefit of additive manufacturing processes for superalloys. Traditional manufacturing routes typically require significant quantities of water for cooling and cleaning operations, whereas powder-based additive manufacturing systems operate in closed environments with minimal water requirements, reducing the water footprint by up to 80% in some applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!