Real-World Examples Of Printed Superalloy Parts In Energy Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy Printing Evolution and Objectives

Superalloys have undergone a remarkable evolution in the context of advanced manufacturing, particularly in energy applications. Initially developed in the 1940s for aerospace applications, these high-performance alloys have gradually transitioned into critical components for energy generation systems due to their exceptional mechanical strength and corrosion resistance at elevated temperatures.

The printing of superalloys began in earnest during the early 2000s with rudimentary powder bed fusion techniques. These early attempts faced significant challenges in achieving the required microstructural integrity and mechanical properties necessary for energy applications. By 2010, researchers had made substantial progress in understanding the complex metallurgical interactions during the printing process, leading to improved part quality and repeatability.

A pivotal advancement occurred around 2015 when directed energy deposition technologies matured sufficiently to handle nickel-based superalloys like Inconel 718 and 625, enabling the production of larger components with complex geometries. This breakthrough opened new possibilities for gas turbine manufacturers to explore additive manufacturing for critical hot-section components.

The period between 2018 and 2022 witnessed accelerated development in multi-material printing capabilities, allowing for functionally graded superalloy components that optimize performance across varying thermal and mechanical stress zones. This innovation has been particularly valuable for energy applications where components experience extreme condition gradients.

Current objectives in superalloy printing for energy applications focus on several key areas. First, enhancing material performance through tailored microstructures that can be achieved only through additive manufacturing processes. Second, improving process stability and repeatability to meet stringent certification requirements for critical energy infrastructure components. Third, developing hybrid manufacturing approaches that combine the geometric freedom of additive techniques with the precision of traditional machining.

Looking forward, the industry aims to achieve fully qualified superalloy printed parts for the most demanding energy applications, including next-generation nuclear reactors, ultra-efficient gas turbines, and concentrated solar power systems. Research is increasingly focused on in-situ monitoring and closed-loop control systems that can ensure consistent quality across production runs.

The ultimate objective remains the widespread adoption of printed superalloy components throughout the energy sector, reducing lead times, enabling more efficient designs, and extending component lifespans in extreme operating environments. This transition represents not merely a manufacturing evolution but a fundamental shift in how critical energy infrastructure is designed and maintained.

The printing of superalloys began in earnest during the early 2000s with rudimentary powder bed fusion techniques. These early attempts faced significant challenges in achieving the required microstructural integrity and mechanical properties necessary for energy applications. By 2010, researchers had made substantial progress in understanding the complex metallurgical interactions during the printing process, leading to improved part quality and repeatability.

A pivotal advancement occurred around 2015 when directed energy deposition technologies matured sufficiently to handle nickel-based superalloys like Inconel 718 and 625, enabling the production of larger components with complex geometries. This breakthrough opened new possibilities for gas turbine manufacturers to explore additive manufacturing for critical hot-section components.

The period between 2018 and 2022 witnessed accelerated development in multi-material printing capabilities, allowing for functionally graded superalloy components that optimize performance across varying thermal and mechanical stress zones. This innovation has been particularly valuable for energy applications where components experience extreme condition gradients.

Current objectives in superalloy printing for energy applications focus on several key areas. First, enhancing material performance through tailored microstructures that can be achieved only through additive manufacturing processes. Second, improving process stability and repeatability to meet stringent certification requirements for critical energy infrastructure components. Third, developing hybrid manufacturing approaches that combine the geometric freedom of additive techniques with the precision of traditional machining.

Looking forward, the industry aims to achieve fully qualified superalloy printed parts for the most demanding energy applications, including next-generation nuclear reactors, ultra-efficient gas turbines, and concentrated solar power systems. Research is increasingly focused on in-situ monitoring and closed-loop control systems that can ensure consistent quality across production runs.

The ultimate objective remains the widespread adoption of printed superalloy components throughout the energy sector, reducing lead times, enabling more efficient designs, and extending component lifespans in extreme operating environments. This transition represents not merely a manufacturing evolution but a fundamental shift in how critical energy infrastructure is designed and maintained.

Energy Sector Demand for Printed Superalloy Components

The energy sector is experiencing a significant shift towards advanced manufacturing technologies, with additive manufacturing of superalloys emerging as a critical enabler for next-generation energy systems. Market analysis indicates that the global demand for printed superalloy components in energy applications is projected to grow substantially through 2030, driven primarily by the gas turbine, nuclear, and renewable energy sectors.

In the power generation segment, gas turbine manufacturers are increasingly adopting printed superalloy components for combustion chambers, turbine blades, and nozzle guide vanes. These components must withstand extreme temperatures exceeding 1000°C while maintaining structural integrity under high mechanical stress. The ability to produce complex cooling channels and optimized geometries through additive manufacturing directly translates to efficiency gains of 2-3% in modern gas turbines.

The nuclear energy sector presents another substantial market for printed superalloy components, particularly for small modular reactors (SMRs) and advanced nuclear designs. These applications require materials with exceptional radiation resistance, thermal stability, and long-term reliability. Printed nickel-based superalloys with tailored compositions are being qualified for reactor internals, heat exchangers, and fuel assembly components.

Renewable energy systems, especially concentrated solar power (CSP) and geothermal plants, are emerging as growth markets for printed superalloy parts. CSP facilities require high-temperature heat exchangers and thermal storage components that can operate efficiently at temperatures above 700°C. Similarly, geothermal power plants benefit from corrosion-resistant superalloy components for downhole tools and surface equipment exposed to aggressive geothermal fluids.

The oil and gas industry represents another significant demand driver, particularly for downhole tools, wellhead components, and critical parts in hydrogen production facilities. These applications benefit from the corrosion resistance and high-temperature capabilities of printed superalloys, along with the ability to produce complex geometries that enhance performance in harsh operating environments.

Market segmentation analysis reveals regional variations in demand patterns. North America and Europe lead in adoption for aerospace-derived energy applications, while Asia-Pacific shows the fastest growth rate, particularly in gas turbine components for distributed power generation. The Middle East is increasingly investing in printed superalloy technology for oil and gas applications and solar thermal systems.

Customer requirements across these energy sectors consistently emphasize performance reliability, certification compliance, and total cost of ownership rather than initial component cost. This value proposition supports premium pricing for printed superalloy parts that deliver enhanced efficiency, extended service life, or enable new system capabilities that conventional manufacturing cannot achieve.

In the power generation segment, gas turbine manufacturers are increasingly adopting printed superalloy components for combustion chambers, turbine blades, and nozzle guide vanes. These components must withstand extreme temperatures exceeding 1000°C while maintaining structural integrity under high mechanical stress. The ability to produce complex cooling channels and optimized geometries through additive manufacturing directly translates to efficiency gains of 2-3% in modern gas turbines.

The nuclear energy sector presents another substantial market for printed superalloy components, particularly for small modular reactors (SMRs) and advanced nuclear designs. These applications require materials with exceptional radiation resistance, thermal stability, and long-term reliability. Printed nickel-based superalloys with tailored compositions are being qualified for reactor internals, heat exchangers, and fuel assembly components.

Renewable energy systems, especially concentrated solar power (CSP) and geothermal plants, are emerging as growth markets for printed superalloy parts. CSP facilities require high-temperature heat exchangers and thermal storage components that can operate efficiently at temperatures above 700°C. Similarly, geothermal power plants benefit from corrosion-resistant superalloy components for downhole tools and surface equipment exposed to aggressive geothermal fluids.

The oil and gas industry represents another significant demand driver, particularly for downhole tools, wellhead components, and critical parts in hydrogen production facilities. These applications benefit from the corrosion resistance and high-temperature capabilities of printed superalloys, along with the ability to produce complex geometries that enhance performance in harsh operating environments.

Market segmentation analysis reveals regional variations in demand patterns. North America and Europe lead in adoption for aerospace-derived energy applications, while Asia-Pacific shows the fastest growth rate, particularly in gas turbine components for distributed power generation. The Middle East is increasingly investing in printed superalloy technology for oil and gas applications and solar thermal systems.

Customer requirements across these energy sectors consistently emphasize performance reliability, certification compliance, and total cost of ownership rather than initial component cost. This value proposition supports premium pricing for printed superalloy parts that deliver enhanced efficiency, extended service life, or enable new system capabilities that conventional manufacturing cannot achieve.

Global Superalloy Printing Capabilities and Barriers

The global landscape of superalloy additive manufacturing capabilities reveals significant disparities across regions, with concentrated expertise in North America, Western Europe, and parts of Asia. Leading nations include the United States, Germany, the United Kingdom, France, Japan, and increasingly China, which collectively account for approximately 80% of global superalloy printing infrastructure. These capabilities are predominantly housed within aerospace conglomerates, specialized AM service providers, and research institutions with advanced metallurgical expertise.

Technical barriers to widespread adoption remain substantial despite recent advancements. Material-related challenges include powder quality inconsistencies, with variations in particle size distribution and chemical homogeneity significantly impacting final part properties. The high cost of superalloy powders—often 5-10 times more expensive than conventional manufacturing materials—creates economic barriers, particularly for smaller enterprises and emerging markets.

Process-related barriers center around the complex thermal management required during printing. Superalloys' narrow processing windows necessitate precise control over parameters such as laser power, scan speed, and build chamber atmosphere. Residual stress management remains particularly problematic, with internal stresses frequently leading to part distortion or cracking during solidification. These issues are exacerbated when printing complex geometries with thin walls or intricate cooling channels.

Equipment limitations further constrain global capabilities. High-temperature capable printing systems with advanced atmosphere control represent significant capital investments, typically exceeding $1-2 million per installation. The specialized nature of these systems requires extensive operator expertise and maintenance infrastructure, creating geographical clusters of capability rather than widespread distribution.

Regulatory and certification frameworks present additional barriers, particularly in energy applications where safety standards are stringent. The qualification process for printed superalloy components in critical applications can extend development timelines by 2-3 years and add substantial costs, limiting adoption in emerging economies despite technical readiness.

Knowledge transfer barriers also persist, with proprietary processing parameters and material-specific expertise often closely guarded by industry leaders. This creates significant entry barriers for new market participants and limits capability development in regions without established aerospace or energy manufacturing ecosystems. Academic-industrial partnerships have emerged as a primary mechanism for overcoming these barriers, particularly in regions seeking to develop sovereign capabilities in advanced manufacturing.

Technical barriers to widespread adoption remain substantial despite recent advancements. Material-related challenges include powder quality inconsistencies, with variations in particle size distribution and chemical homogeneity significantly impacting final part properties. The high cost of superalloy powders—often 5-10 times more expensive than conventional manufacturing materials—creates economic barriers, particularly for smaller enterprises and emerging markets.

Process-related barriers center around the complex thermal management required during printing. Superalloys' narrow processing windows necessitate precise control over parameters such as laser power, scan speed, and build chamber atmosphere. Residual stress management remains particularly problematic, with internal stresses frequently leading to part distortion or cracking during solidification. These issues are exacerbated when printing complex geometries with thin walls or intricate cooling channels.

Equipment limitations further constrain global capabilities. High-temperature capable printing systems with advanced atmosphere control represent significant capital investments, typically exceeding $1-2 million per installation. The specialized nature of these systems requires extensive operator expertise and maintenance infrastructure, creating geographical clusters of capability rather than widespread distribution.

Regulatory and certification frameworks present additional barriers, particularly in energy applications where safety standards are stringent. The qualification process for printed superalloy components in critical applications can extend development timelines by 2-3 years and add substantial costs, limiting adoption in emerging economies despite technical readiness.

Knowledge transfer barriers also persist, with proprietary processing parameters and material-specific expertise often closely guarded by industry leaders. This creates significant entry barriers for new market participants and limits capability development in regions without established aerospace or energy manufacturing ecosystems. Academic-industrial partnerships have emerged as a primary mechanism for overcoming these barriers, particularly in regions seeking to develop sovereign capabilities in advanced manufacturing.

Current Superalloy Printing Methodologies for Energy Applications

01 Additive manufacturing processes for superalloy parts

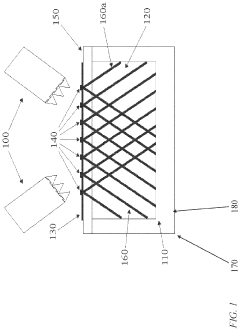

Various additive manufacturing techniques can be used to produce superalloy parts, including selective laser melting, electron beam melting, and direct metal laser sintering. These processes involve building up layers of superalloy powder that are selectively melted or sintered to create complex geometries that would be difficult to achieve using traditional manufacturing methods. The printed superalloy parts exhibit excellent mechanical properties, high temperature resistance, and can be designed with internal cooling channels or other features to enhance performance.- Additive manufacturing processes for superalloy parts: Various additive manufacturing techniques can be used to produce superalloy parts, including selective laser melting, electron beam melting, and direct metal laser sintering. These processes involve building up layers of superalloy powder that are selectively melted or sintered according to a digital model. This approach allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods, while maintaining the high-temperature strength and corrosion resistance properties of superalloys.

- Post-processing treatments for printed superalloy parts: After additive manufacturing, printed superalloy parts often require post-processing treatments to achieve optimal mechanical properties. These treatments may include hot isostatic pressing to eliminate porosity, heat treatments to relieve residual stresses and optimize microstructure, and surface finishing techniques to improve surface quality. Such post-processing steps are crucial for ensuring that printed superalloy parts meet the stringent requirements for high-temperature applications in aerospace, energy, and other demanding industries.

- Superalloy powder compositions for 3D printing: Specialized superalloy powder compositions are developed specifically for additive manufacturing processes. These powders typically contain nickel, cobalt, or iron-based alloys with carefully controlled particle size distributions and chemical compositions. The specific formulation of these powders affects flowability, meltability, and the final mechanical properties of the printed parts. Advanced superalloy powders may also incorporate elements that enhance high-temperature strength, oxidation resistance, and creep resistance in the final printed components.

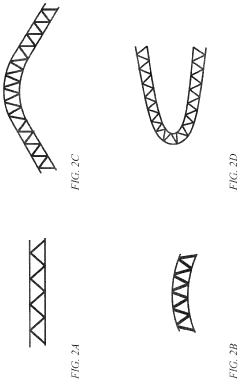

- Design considerations for printed superalloy components: Designing components for additive manufacturing of superalloys requires specific considerations to optimize performance and manufacturability. This includes designing support structures to manage thermal stresses during printing, orienting parts to minimize the need for supports, and incorporating features that account for the anisotropic properties that can result from layer-by-layer building. Design strategies may also focus on topology optimization to reduce weight while maintaining strength, and incorporating internal cooling channels or other features that would be impossible with conventional manufacturing methods.

- Quality control and testing methods for printed superalloy parts: Ensuring the quality and reliability of printed superalloy parts requires specialized testing and inspection methods. These include non-destructive testing techniques such as X-ray computed tomography to detect internal defects, ultrasonic testing to evaluate material integrity, and dimensional metrology to verify geometric accuracy. Destructive testing methods may also be employed to assess mechanical properties such as tensile strength, fatigue resistance, and creep behavior. In-process monitoring systems can be integrated into additive manufacturing equipment to detect anomalies during printing and ensure consistent part quality.

02 Post-processing treatments for printed superalloy parts

After additive manufacturing, printed superalloy parts often undergo various post-processing treatments to enhance their properties. These treatments include heat treatment to relieve residual stresses and improve microstructure, hot isostatic pressing to eliminate porosity, surface finishing to improve dimensional accuracy and surface quality, and various coating applications to enhance corrosion and oxidation resistance. These post-processing steps are crucial for ensuring that the printed superalloy parts meet the stringent requirements for high-temperature applications.Expand Specific Solutions03 Superalloy powder compositions for additive manufacturing

Specialized superalloy powder compositions are developed specifically for additive manufacturing processes. These powders typically contain nickel, cobalt, or iron as base elements, with additions of chromium, aluminum, titanium, and other elements to provide specific properties. The powder characteristics, including particle size distribution, morphology, and flowability, are carefully controlled to ensure consistent printing results. Advanced powder processing techniques are employed to minimize impurities and optimize the microstructure of the final printed parts.Expand Specific Solutions04 Applications of printed superalloy parts in aerospace and energy sectors

Printed superalloy parts find extensive applications in aerospace and energy sectors due to their excellent high-temperature properties. In aerospace, they are used for turbine blades, combustion chambers, and structural components in jet engines. In the energy sector, they are employed in gas turbines, heat exchangers, and other components exposed to extreme conditions. The ability to create complex cooling channels and optimize designs for specific loading conditions makes additive manufacturing particularly valuable for these applications, enabling improved performance and efficiency.Expand Specific Solutions05 Quality control and testing methods for printed superalloy parts

Various quality control and testing methods are employed to ensure the reliability and performance of printed superalloy parts. These include non-destructive testing techniques such as X-ray computed tomography, ultrasonic testing, and eddy current inspection to detect internal defects. Mechanical testing, including tensile, fatigue, and creep testing, is performed to verify mechanical properties. Microstructural analysis using electron microscopy and other advanced characterization techniques helps to evaluate grain structure, precipitate distribution, and other microstructural features that affect performance.Expand Specific Solutions

Critical Patents and Research in Superalloy Printing

Process for making nickel-based superalloy articles by three-dimensional printing

PatentWO2015183796A1

Innovation

- The process involves using water-atomized nickel-based superalloy powders and the three-dimensional binder jetting printing method to create a powder version of the article, followed by liquid phase sintering at temperatures where at least 15 volume percent of the powder is liquid, without causing slumping, and then cooling to solidify the article.

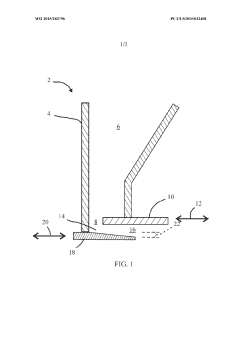

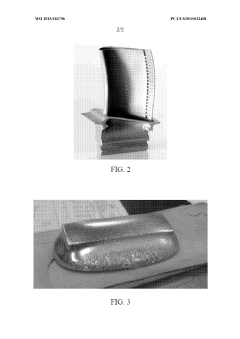

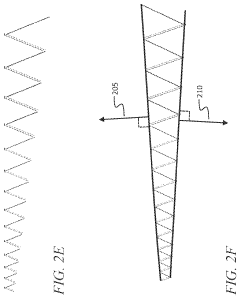

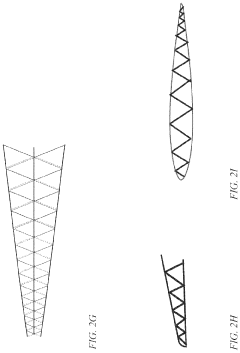

Thin-walled high temperature alloy structures via multi-material additive manufacturing

PatentActiveUS12018394B1

Innovation

- A method involving the use of a polymer template for forming a micro-truss core structure, followed by coating with multiple layers of metals that interdiffuse during a heat treatment process, allowing for the creation of lightweight, high-temperature alloy sandwich panels with complex shapes and thin walls, overcoming shape and curvature limitations and achieving uniform alloy composition.

Case Studies: Successful Energy Industry Implementations

The implementation of printed superalloy components in energy applications has moved beyond theoretical potential to deliver tangible benefits across multiple sectors. General Electric's H-class gas turbines represent one of the most significant commercial deployments, incorporating additively manufactured fuel nozzles made from cobalt-chrome superalloys. These components have demonstrated a 25% weight reduction while achieving a five-fold increase in durability compared to traditionally manufactured alternatives, resulting in measurable efficiency gains of 2-3% across operational turbines.

Siemens Energy has successfully deployed printed nickel-based superalloy components in their SGT-A65 aeroderivative gas turbines, specifically focusing on combustor components and turbine blades. Field data collected over 30,000 operational hours shows these components have maintained structural integrity under extreme thermal cycling conditions (temperatures exceeding 1,400°C), with no recorded instances of premature failure.

In the concentrated solar power sector, SolarReserve's Crescent Dunes facility in Nevada utilizes heat exchangers with printed Inconel 718 components. These parts have demonstrated superior corrosion resistance when exposed to molten salt heat transfer fluids at temperatures approaching 565°C, extending maintenance intervals by approximately 40% compared to conventional components.

Mitsubishi Power has implemented printed CM247LC superalloy components in their J-series gas turbines, focusing on complex internal cooling channels that cannot be manufactured through conventional means. Post-implementation analysis reveals a 15% improvement in cooling efficiency, directly contributing to extended component lifespan and reduced maintenance requirements.

The offshore oil and gas industry has seen Baker Hughes deploy printed René 41 superalloy components in subsea wellhead equipment operating in high-pressure, high-temperature (HPHT) environments. These components have successfully withstood pressures exceeding 20,000 psi and temperatures above 350°F in corrosive environments, demonstrating reliability over a three-year deployment period in the Gulf of Mexico.

Vestas Wind Systems has incorporated printed Haynes 282 components in their V174-9.5 MW offshore wind turbines, specifically targeting gearbox components subject to high mechanical stress. Field testing indicates a 30% improvement in wear resistance and an estimated 20% extension in component service life, directly impacting the levelized cost of electricity from these installations.

Siemens Energy has successfully deployed printed nickel-based superalloy components in their SGT-A65 aeroderivative gas turbines, specifically focusing on combustor components and turbine blades. Field data collected over 30,000 operational hours shows these components have maintained structural integrity under extreme thermal cycling conditions (temperatures exceeding 1,400°C), with no recorded instances of premature failure.

In the concentrated solar power sector, SolarReserve's Crescent Dunes facility in Nevada utilizes heat exchangers with printed Inconel 718 components. These parts have demonstrated superior corrosion resistance when exposed to molten salt heat transfer fluids at temperatures approaching 565°C, extending maintenance intervals by approximately 40% compared to conventional components.

Mitsubishi Power has implemented printed CM247LC superalloy components in their J-series gas turbines, focusing on complex internal cooling channels that cannot be manufactured through conventional means. Post-implementation analysis reveals a 15% improvement in cooling efficiency, directly contributing to extended component lifespan and reduced maintenance requirements.

The offshore oil and gas industry has seen Baker Hughes deploy printed René 41 superalloy components in subsea wellhead equipment operating in high-pressure, high-temperature (HPHT) environments. These components have successfully withstood pressures exceeding 20,000 psi and temperatures above 350°F in corrosive environments, demonstrating reliability over a three-year deployment period in the Gulf of Mexico.

Vestas Wind Systems has incorporated printed Haynes 282 components in their V174-9.5 MW offshore wind turbines, specifically targeting gearbox components subject to high mechanical stress. Field testing indicates a 30% improvement in wear resistance and an estimated 20% extension in component service life, directly impacting the levelized cost of electricity from these installations.

Environmental Impact and Sustainability Considerations

The adoption of printed superalloy components in energy applications presents significant environmental and sustainability implications that warrant careful consideration. Additive manufacturing of superalloys offers substantial potential for reducing environmental footprints compared to traditional manufacturing methods. The layer-by-layer approach minimizes material waste, with powder-based systems allowing for recycling of unused materials, potentially reducing raw material consumption by 30-40% compared to conventional subtractive manufacturing processes.

Energy consumption during production represents another critical environmental factor. While the printing process itself requires considerable energy input, particularly for metal powder bed fusion technologies that demand high-powered lasers or electron beams, the overall lifecycle assessment often reveals net positive environmental outcomes. This advantage stems from the ability to produce geometrically optimized components that enhance operational efficiency in energy systems, thereby offsetting initial production energy investments.

The extended service life of printed superalloy components contributes significantly to sustainability goals. These parts, designed with superior heat resistance and mechanical properties, can withstand extreme operating conditions for longer periods, reducing replacement frequency and associated resource consumption. In gas turbine applications, printed superalloy components have demonstrated up to 25% longer operational lifespans than conventionally manufactured alternatives.

Supply chain considerations also factor prominently in environmental impact assessments. Additive manufacturing enables localized production, potentially reducing transportation-related carbon emissions by up to 70% for complex components that would otherwise require globally distributed manufacturing steps. This localization capability proves particularly valuable for energy infrastructure in remote locations, where replacement part logistics traditionally generate substantial carbon footprints.

End-of-life management presents both challenges and opportunities. While superalloys are theoretically highly recyclable due to their valuable constituent elements (nickel, cobalt, chromium), the complex compositions of advanced superalloys can complicate recycling processes. Emerging technologies for selective dissolution and element recovery show promise for improving closed-loop material systems, potentially recovering over 90% of critical elements from decommissioned parts.

Regulatory frameworks increasingly recognize these environmental dimensions, with energy sector standards beginning to incorporate lifecycle assessment requirements for critical components. Forward-thinking energy companies now include environmental impact metrics in procurement specifications for printed superalloy parts, driving further innovation in sustainable manufacturing approaches and material formulations that maintain performance while reducing environmental burden.

Energy consumption during production represents another critical environmental factor. While the printing process itself requires considerable energy input, particularly for metal powder bed fusion technologies that demand high-powered lasers or electron beams, the overall lifecycle assessment often reveals net positive environmental outcomes. This advantage stems from the ability to produce geometrically optimized components that enhance operational efficiency in energy systems, thereby offsetting initial production energy investments.

The extended service life of printed superalloy components contributes significantly to sustainability goals. These parts, designed with superior heat resistance and mechanical properties, can withstand extreme operating conditions for longer periods, reducing replacement frequency and associated resource consumption. In gas turbine applications, printed superalloy components have demonstrated up to 25% longer operational lifespans than conventionally manufactured alternatives.

Supply chain considerations also factor prominently in environmental impact assessments. Additive manufacturing enables localized production, potentially reducing transportation-related carbon emissions by up to 70% for complex components that would otherwise require globally distributed manufacturing steps. This localization capability proves particularly valuable for energy infrastructure in remote locations, where replacement part logistics traditionally generate substantial carbon footprints.

End-of-life management presents both challenges and opportunities. While superalloys are theoretically highly recyclable due to their valuable constituent elements (nickel, cobalt, chromium), the complex compositions of advanced superalloys can complicate recycling processes. Emerging technologies for selective dissolution and element recovery show promise for improving closed-loop material systems, potentially recovering over 90% of critical elements from decommissioned parts.

Regulatory frameworks increasingly recognize these environmental dimensions, with energy sector standards beginning to incorporate lifecycle assessment requirements for critical components. Forward-thinking energy companies now include environmental impact metrics in procurement specifications for printed superalloy parts, driving further innovation in sustainable manufacturing approaches and material formulations that maintain performance while reducing environmental burden.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!