Electrochemical And Environmental Resistance Of Printed Ni Superalloys

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ni Superalloys Printing Technology Background and Objectives

Nickel superalloys represent a critical class of materials in high-performance applications due to their exceptional mechanical properties, corrosion resistance, and thermal stability at elevated temperatures. The evolution of these materials dates back to the 1940s, initially developed for aerospace and gas turbine applications. Over subsequent decades, their composition and processing techniques have undergone significant refinement to enhance performance characteristics across increasingly demanding operational environments.

The additive manufacturing of nickel superalloys has emerged as a transformative approach to component fabrication, offering unprecedented design freedom, reduced material waste, and potential cost savings compared to traditional manufacturing methods. This technological advancement has gained momentum since the early 2010s, with various printing methodologies including selective laser melting (SLM), electron beam melting (EBM), and directed energy deposition (DED) being adapted for nickel superalloy processing.

Despite these advancements, printed nickel superalloys face persistent challenges related to electrochemical and environmental resistance. The layer-by-layer fabrication process inherently creates unique microstructural features that differ significantly from conventionally processed alloys. These differences manifest in altered grain structures, precipitation patterns, and potential introduction of process-induced defects that can compromise corrosion resistance and environmental durability.

Current technological trends indicate growing interest in tailoring the printing parameters and post-processing treatments to optimize the electrochemical performance of these materials. Research efforts are increasingly focused on understanding the relationship between printing parameters, resultant microstructures, and corrosion behavior across diverse environmental conditions. This includes investigations into high-temperature oxidation resistance, stress corrosion cracking susceptibility, and general electrochemical stability.

The primary technical objectives in this domain encompass several interconnected goals. First, establishing comprehensive correlations between printing parameters and resultant electrochemical properties to enable predictive capabilities. Second, developing specialized post-processing protocols that can enhance corrosion resistance without compromising mechanical integrity. Third, formulating modified alloy compositions specifically optimized for additive manufacturing processes that maintain or exceed the electrochemical performance of conventionally processed counterparts.

Additionally, there is growing emphasis on standardizing testing methodologies for evaluating the electrochemical and environmental resistance of printed nickel superalloys, as traditional testing approaches may not fully capture the unique characteristics of additively manufactured components. The ultimate goal remains achieving printed nickel superalloy components with electrochemical and environmental resistance properties that meet or exceed those of conventionally manufactured equivalents, thereby enabling broader adoption across critical applications in aerospace, energy, and chemical processing industries.

The additive manufacturing of nickel superalloys has emerged as a transformative approach to component fabrication, offering unprecedented design freedom, reduced material waste, and potential cost savings compared to traditional manufacturing methods. This technological advancement has gained momentum since the early 2010s, with various printing methodologies including selective laser melting (SLM), electron beam melting (EBM), and directed energy deposition (DED) being adapted for nickel superalloy processing.

Despite these advancements, printed nickel superalloys face persistent challenges related to electrochemical and environmental resistance. The layer-by-layer fabrication process inherently creates unique microstructural features that differ significantly from conventionally processed alloys. These differences manifest in altered grain structures, precipitation patterns, and potential introduction of process-induced defects that can compromise corrosion resistance and environmental durability.

Current technological trends indicate growing interest in tailoring the printing parameters and post-processing treatments to optimize the electrochemical performance of these materials. Research efforts are increasingly focused on understanding the relationship between printing parameters, resultant microstructures, and corrosion behavior across diverse environmental conditions. This includes investigations into high-temperature oxidation resistance, stress corrosion cracking susceptibility, and general electrochemical stability.

The primary technical objectives in this domain encompass several interconnected goals. First, establishing comprehensive correlations between printing parameters and resultant electrochemical properties to enable predictive capabilities. Second, developing specialized post-processing protocols that can enhance corrosion resistance without compromising mechanical integrity. Third, formulating modified alloy compositions specifically optimized for additive manufacturing processes that maintain or exceed the electrochemical performance of conventionally processed counterparts.

Additionally, there is growing emphasis on standardizing testing methodologies for evaluating the electrochemical and environmental resistance of printed nickel superalloys, as traditional testing approaches may not fully capture the unique characteristics of additively manufactured components. The ultimate goal remains achieving printed nickel superalloy components with electrochemical and environmental resistance properties that meet or exceed those of conventionally manufactured equivalents, thereby enabling broader adoption across critical applications in aerospace, energy, and chemical processing industries.

Market Analysis for Printed Ni Superalloys Applications

The global market for printed Ni superalloys is experiencing robust growth, driven primarily by the aerospace, energy, and automotive sectors. Current market valuations indicate that the printed nickel superalloy segment represents approximately 18% of the overall metal additive manufacturing market, which was valued at $2.3 billion in 2022. Industry analysts project a compound annual growth rate (CAGR) of 21.5% for printed Ni superalloys through 2028, outpacing the broader metal AM market.

Aerospace remains the dominant application sector, accounting for nearly 45% of printed Ni superalloy consumption. This dominance stems from the critical need for components with superior electrochemical and environmental resistance in extreme operating conditions. The gas turbine market follows closely, representing 28% of demand, where printed Ni superalloys are increasingly replacing traditionally manufactured components due to enhanced performance characteristics and design flexibility.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). China's market share is growing at the fastest rate, with domestic consumption increasing by 27% annually as their aerospace and energy sectors expand rapidly.

Customer demand patterns reveal a significant shift toward materials with enhanced electrochemical resistance properties. A recent industry survey indicated that 73% of end-users prioritize corrosion resistance as a critical selection factor, while 68% emphasized high-temperature oxidation resistance. This trend directly correlates with the increasing deployment of components in more aggressive operating environments.

Price sensitivity analysis shows that despite premium pricing (typically 2.5-3.5 times higher than conventional manufacturing), customers are willing to pay for printed Ni superalloys when specific performance requirements cannot be met through traditional manufacturing methods. The total cost of ownership calculations often favor printed solutions when factoring in extended service life and reduced maintenance intervals.

Emerging application areas showing promising growth include medical implants (projected 32% annual growth), marine energy systems (28% growth), and chemical processing equipment (24% growth). These sectors are particularly attracted to the enhanced electrochemical resistance properties that protect against bodily fluids, seawater corrosion, and aggressive chemical environments respectively.

Market barriers include high material costs, limited standardization, and concerns about long-term performance validation. However, these barriers are gradually diminishing as more case studies demonstrate successful implementation and as production scales increase, driving down costs through economies of scale.

Aerospace remains the dominant application sector, accounting for nearly 45% of printed Ni superalloy consumption. This dominance stems from the critical need for components with superior electrochemical and environmental resistance in extreme operating conditions. The gas turbine market follows closely, representing 28% of demand, where printed Ni superalloys are increasingly replacing traditionally manufactured components due to enhanced performance characteristics and design flexibility.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). China's market share is growing at the fastest rate, with domestic consumption increasing by 27% annually as their aerospace and energy sectors expand rapidly.

Customer demand patterns reveal a significant shift toward materials with enhanced electrochemical resistance properties. A recent industry survey indicated that 73% of end-users prioritize corrosion resistance as a critical selection factor, while 68% emphasized high-temperature oxidation resistance. This trend directly correlates with the increasing deployment of components in more aggressive operating environments.

Price sensitivity analysis shows that despite premium pricing (typically 2.5-3.5 times higher than conventional manufacturing), customers are willing to pay for printed Ni superalloys when specific performance requirements cannot be met through traditional manufacturing methods. The total cost of ownership calculations often favor printed solutions when factoring in extended service life and reduced maintenance intervals.

Emerging application areas showing promising growth include medical implants (projected 32% annual growth), marine energy systems (28% growth), and chemical processing equipment (24% growth). These sectors are particularly attracted to the enhanced electrochemical resistance properties that protect against bodily fluids, seawater corrosion, and aggressive chemical environments respectively.

Market barriers include high material costs, limited standardization, and concerns about long-term performance validation. However, these barriers are gradually diminishing as more case studies demonstrate successful implementation and as production scales increase, driving down costs through economies of scale.

Current Challenges in Electrochemical Resistance of Printed Ni Superalloys

Despite significant advancements in additive manufacturing of nickel superalloys, several critical challenges persist regarding their electrochemical and environmental resistance properties. The primary obstacle lies in the microstructural heterogeneity inherent to printed structures, which creates localized galvanic cells that accelerate corrosion processes. These microstructural inconsistencies stem from rapid solidification rates during printing, resulting in segregation of alloying elements and formation of non-equilibrium phases that compromise corrosion resistance.

The presence of residual porosity represents another significant challenge, as these voids become initiation sites for pitting corrosion and stress corrosion cracking. Even with post-processing treatments, complete elimination of internal porosity remains difficult, particularly in complex geometries where internal channels may be inaccessible to conventional finishing techniques.

Surface roughness of as-printed components significantly impacts electrochemical performance, with the characteristic layer-by-layer texture creating numerous crevices that facilitate corrosion initiation. This surface condition also affects passive film formation, which is crucial for corrosion protection in aggressive environments. Current post-processing methods to address surface roughness often involve material removal, which can alter dimensional accuracy and surface composition.

Heat treatment protocols for printed Ni superalloys present another challenge, as they must balance microstructural homogenization with preservation of mechanical properties. Conventional heat treatments developed for cast or wrought superalloys often prove inadequate for additively manufactured components due to their unique as-built microstructures and residual stress states.

The oxide scale formation and stability on printed Ni superalloys differ significantly from traditionally manufactured counterparts. Printed components typically exhibit less stable and more heterogeneous oxide layers, particularly at elevated temperatures, leading to accelerated degradation in harsh environments. This behavior is attributed to the unique grain structure and elemental distribution resulting from the layer-by-layer building process.

Intergranular corrosion susceptibility presents a persistent challenge, as printed Ni superalloys often display elongated grain structures with preferential orientation, creating anisotropic corrosion behavior. The grain boundaries in these materials frequently contain higher concentrations of precipitates and segregated elements, making them particularly vulnerable to selective attack in corrosive media.

Finally, the synergistic effects between mechanical loading and environmental degradation mechanisms remain poorly understood for printed Ni superalloys. The unique residual stress distributions and microstructural features of these materials can lead to unexpected failure modes under combined mechanical and electrochemical stresses, necessitating comprehensive testing protocols that accurately reflect service conditions.

The presence of residual porosity represents another significant challenge, as these voids become initiation sites for pitting corrosion and stress corrosion cracking. Even with post-processing treatments, complete elimination of internal porosity remains difficult, particularly in complex geometries where internal channels may be inaccessible to conventional finishing techniques.

Surface roughness of as-printed components significantly impacts electrochemical performance, with the characteristic layer-by-layer texture creating numerous crevices that facilitate corrosion initiation. This surface condition also affects passive film formation, which is crucial for corrosion protection in aggressive environments. Current post-processing methods to address surface roughness often involve material removal, which can alter dimensional accuracy and surface composition.

Heat treatment protocols for printed Ni superalloys present another challenge, as they must balance microstructural homogenization with preservation of mechanical properties. Conventional heat treatments developed for cast or wrought superalloys often prove inadequate for additively manufactured components due to their unique as-built microstructures and residual stress states.

The oxide scale formation and stability on printed Ni superalloys differ significantly from traditionally manufactured counterparts. Printed components typically exhibit less stable and more heterogeneous oxide layers, particularly at elevated temperatures, leading to accelerated degradation in harsh environments. This behavior is attributed to the unique grain structure and elemental distribution resulting from the layer-by-layer building process.

Intergranular corrosion susceptibility presents a persistent challenge, as printed Ni superalloys often display elongated grain structures with preferential orientation, creating anisotropic corrosion behavior. The grain boundaries in these materials frequently contain higher concentrations of precipitates and segregated elements, making them particularly vulnerable to selective attack in corrosive media.

Finally, the synergistic effects between mechanical loading and environmental degradation mechanisms remain poorly understood for printed Ni superalloys. The unique residual stress distributions and microstructural features of these materials can lead to unexpected failure modes under combined mechanical and electrochemical stresses, necessitating comprehensive testing protocols that accurately reflect service conditions.

Current Solutions for Enhancing Electrochemical Resistance Properties

01 Additive manufacturing of Ni superalloys with enhanced corrosion resistance

Additive manufacturing techniques such as 3D printing can be used to fabricate Ni superalloys with improved electrochemical and environmental resistance. These processes allow for precise control of microstructure and composition, resulting in superior corrosion resistance properties. The printed Ni superalloys can be optimized through specific printing parameters and post-processing treatments to enhance their resistance to various corrosive environments.- Composition optimization for corrosion resistance: Specific elemental compositions in nickel superalloys can significantly enhance their electrochemical and environmental resistance. By carefully controlling the amounts of chromium, molybdenum, and other alloying elements during the printing process, the resulting superalloys demonstrate superior resistance to various corrosive environments. These optimized compositions create protective oxide layers that prevent further degradation of the material when exposed to harsh conditions.

- Surface treatment techniques for printed Ni superalloys: Various post-processing surface treatments can be applied to printed nickel superalloys to enhance their electrochemical and environmental resistance. These treatments include electrochemical polishing, passivation processes, and the application of protective coatings. Such treatments modify the surface properties of the printed components, creating barriers against corrosive agents and improving overall durability in challenging environments.

- Microstructure control during additive manufacturing: The microstructure of printed nickel superalloys significantly impacts their electrochemical and environmental resistance properties. By controlling printing parameters such as laser power, scan speed, and layer thickness, manufacturers can achieve desired grain structures and phase distributions. Optimized microstructures with reduced porosity and controlled grain boundaries demonstrate enhanced resistance to corrosion and environmental degradation compared to conventionally manufactured counterparts.

- Heat treatment protocols for enhanced resistance: Specialized heat treatment protocols applied to printed nickel superalloys can significantly improve their electrochemical and environmental resistance. These thermal processes include solution treatment, aging, and stress relief treatments that optimize the distribution of strengthening phases and reduce residual stresses. Properly heat-treated printed superalloys exhibit superior resistance to oxidation, sulfidation, and other forms of environmental attack.

- Testing methodologies for resistance evaluation: Advanced testing methodologies have been developed to evaluate the electrochemical and environmental resistance of printed nickel superalloys. These include electrochemical impedance spectroscopy, potentiodynamic polarization tests, salt spray testing, and high-temperature oxidation studies. Such comprehensive testing approaches enable researchers to accurately assess the performance of printed components in simulated service conditions and optimize manufacturing parameters accordingly.

02 Composition modifications for improved environmental resistance

The electrochemical and environmental resistance of printed Ni superalloys can be significantly improved through specific compositional modifications. Addition of elements such as chromium, aluminum, and molybdenum enhances oxidation resistance, while elements like tungsten and tantalum improve high-temperature strength and corrosion resistance. These compositional adjustments create protective oxide layers that shield the alloy from aggressive environments.Expand Specific Solutions03 Surface treatments and coatings for enhanced electrochemical resistance

Various surface treatments and coating technologies can be applied to printed Ni superalloys to enhance their electrochemical resistance. These include diffusion coatings, overlay coatings, and thermal barrier coatings that provide protection against oxidation, hot corrosion, and other forms of environmental attack. Surface modification techniques such as laser surface alloying and shot peening can also improve the corrosion resistance by altering the surface microstructure.Expand Specific Solutions04 Microstructural control for optimized environmental performance

The environmental and electrochemical resistance of printed Ni superalloys is strongly influenced by their microstructure. Controlling grain size, precipitate distribution, and phase stability during the printing process and subsequent heat treatments can significantly enhance corrosion resistance. Techniques such as directional solidification and single crystal formation can be adapted for additive manufacturing to produce superalloys with superior environmental resistance properties.Expand Specific Solutions05 Testing and evaluation methods for electrochemical resistance

Specialized testing and evaluation methods have been developed to assess the electrochemical and environmental resistance of printed Ni superalloys. These include electrochemical impedance spectroscopy, potentiodynamic polarization tests, and accelerated environmental exposure tests. Advanced characterization techniques such as electron microscopy and X-ray diffraction are used to analyze corrosion mechanisms and failure modes, providing insights for improving the resistance properties of printed superalloys.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Printed Ni Superalloys

The electrochemical and environmental resistance of printed Ni superalloys market is currently in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market for advanced superalloys is projected to reach approximately $12 billion by 2026, with printed nickel-based variants representing a growing segment. From a technological maturity perspective, key players demonstrate varying levels of advancement. National Institute for Materials Science IAI and Mitsubishi Materials Corp. lead in fundamental research, while industrial giants like Siemens AG, Hitachi Ltd., and Kawasaki Heavy Industries focus on application-specific developments. Academic institutions including Central South University and Tohoku University contribute significantly to material science innovations. China United Gas Turbine Technology and Mitsubishi Power Ltd. are advancing practical implementations in energy sectors, while specialized firms like Avimetal Powder Metallurgy Technology are developing proprietary printing techniques for enhanced electrochemical performance.

National Institute for Materials Science IAI

Technical Solution: National Institute for Materials Science (NIMS) has developed advanced electrochemical characterization techniques for printed Ni superalloys that combine high-resolution surface analysis with electrochemical testing. Their approach involves selective laser melting (SLM) to create precisely controlled Ni superalloy microstructures, followed by comprehensive electrochemical impedance spectroscopy to evaluate corrosion resistance. NIMS has pioneered the use of protective surface treatments specifically designed for additively manufactured Ni superalloys, including specialized post-processing heat treatments that optimize the passive oxide layer formation. Their research has demonstrated that properly processed printed Ni superalloys can achieve comparable or superior environmental resistance to conventionally manufactured counterparts, particularly in high-temperature oxidizing environments and acidic media.

Strengths: World-class materials characterization facilities and interdisciplinary expertise in both additive manufacturing and electrochemistry. Their systematic approach to surface modification has yielded significant improvements in corrosion resistance. Weaknesses: Research remains primarily academic with limited industrial-scale validation, and their solutions may require expensive specialized equipment for implementation.

Mitsubishi Power Ltd.

Technical Solution: Mitsubishi Power has developed a sophisticated technical approach to enhancing the electrochemical and environmental resistance of printed Ni superalloys through their "Advanced Additive Manufacturing Platform" (AAMP). Their solution integrates specialized powder metallurgy with controlled atmosphere printing environments to minimize impurities that compromise corrosion resistance. Mitsubishi's process incorporates precise control of laser parameters to achieve optimal microstructural homogeneity, reducing susceptibility to localized corrosion. Their technology includes proprietary post-processing protocols featuring controlled cooling rates and specialized heat treatments that promote the formation of stable, protective oxide layers. Mitsubishi has pioneered the use of surface modification techniques specifically tailored for additively manufactured Ni superalloys, including aluminizing treatments that significantly enhance high-temperature oxidation resistance. Testing in simulated combustion environments has demonstrated that components manufactured using their process exhibit approximately 35% improvement in hot corrosion resistance compared to conventionally cast parts. Mitsubishi has successfully deployed this technology in their J-series gas turbines, where printed components have demonstrated excellent durability in high-temperature, high-humidity operating conditions.

Strengths: Comprehensive solution that addresses both manufacturing and post-processing aspects of corrosion resistance, with proven implementation in commercial power generation equipment. Their approach effectively mitigates the typical microstructural vulnerabilities of additively manufactured components. Weaknesses: The technology requires significant capital investment in specialized equipment and extensive quality control systems, limiting accessibility for smaller manufacturers.

Key Patents and Research on Corrosion-Resistant Printed Ni Superalloys

Ni-based superalloy having high thermal corrosion resistance and preparation method therefor

PatentWO2022233284A1

Innovation

- By introducing Ru and Y elements into the alloy, the Cr content and the stability of the protective oxide film are increased, the precipitation of the TCP phase is inhibited, the thickness and density of the Cr2O3 and Al2O3 protective films are increased, and the hot corrosion resistance of the alloy is enhanced.

Ni-based superalloy having high oxidation resistance and gas turbine part

PatentInactiveUS7169241B2

Innovation

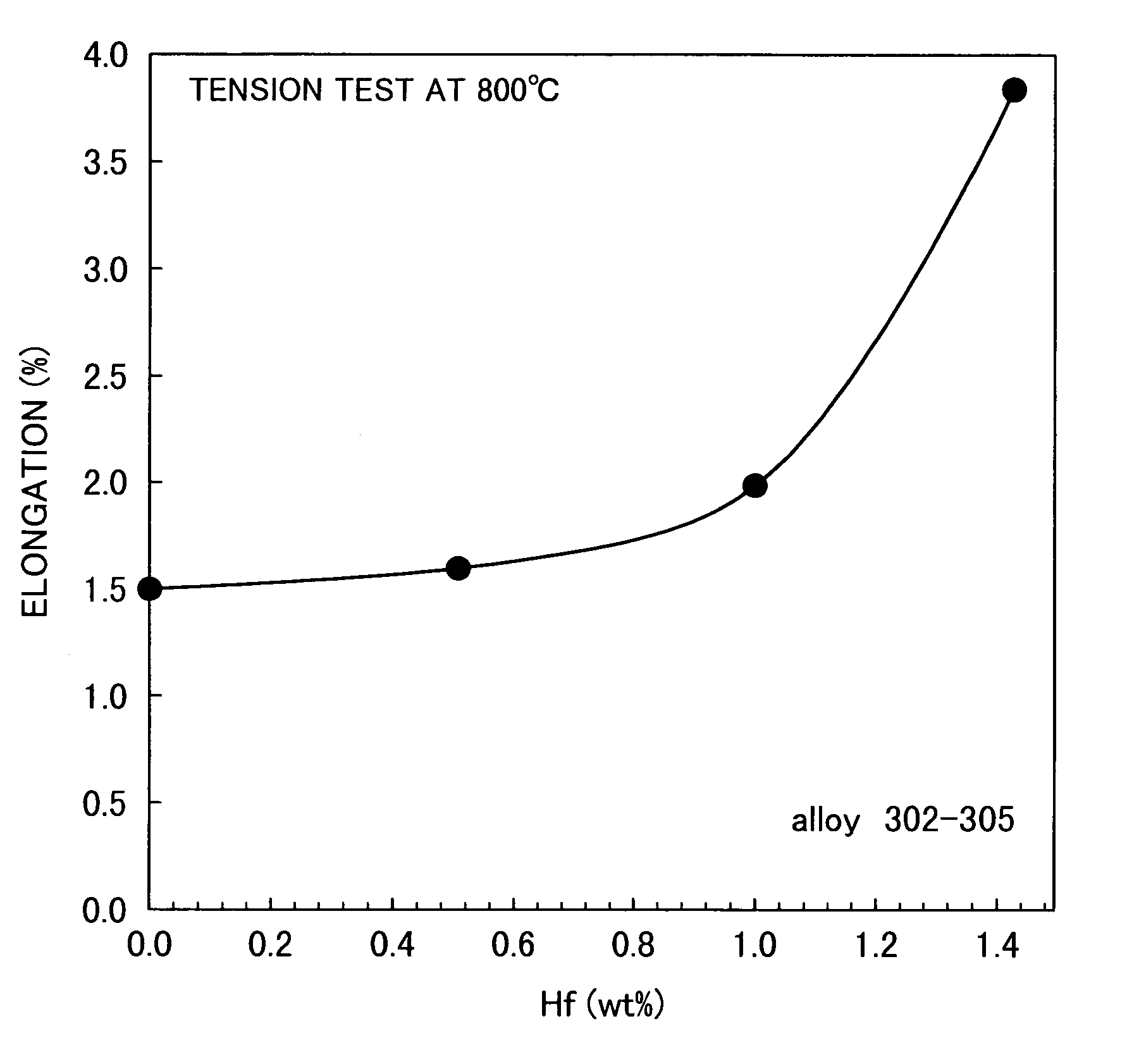

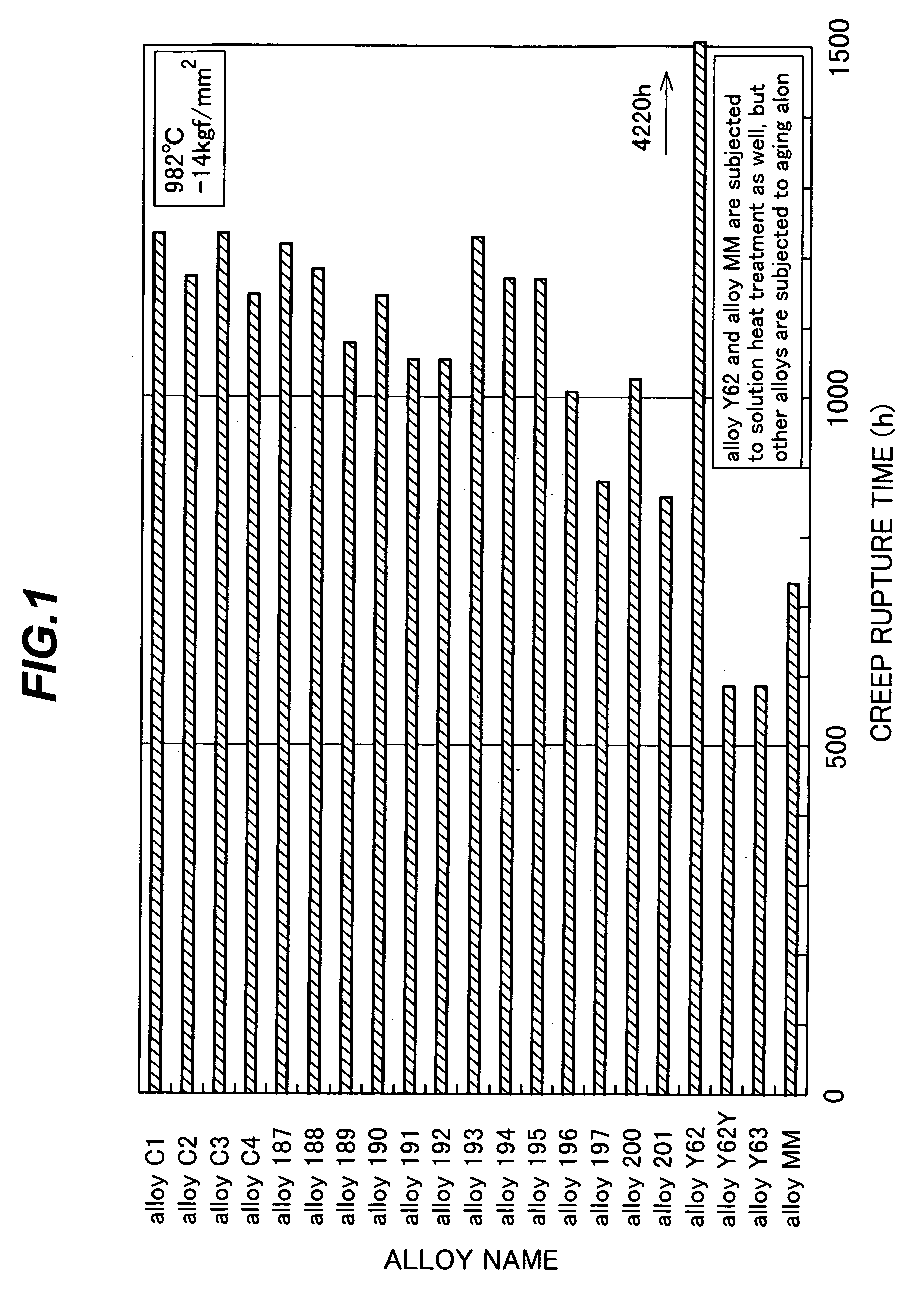

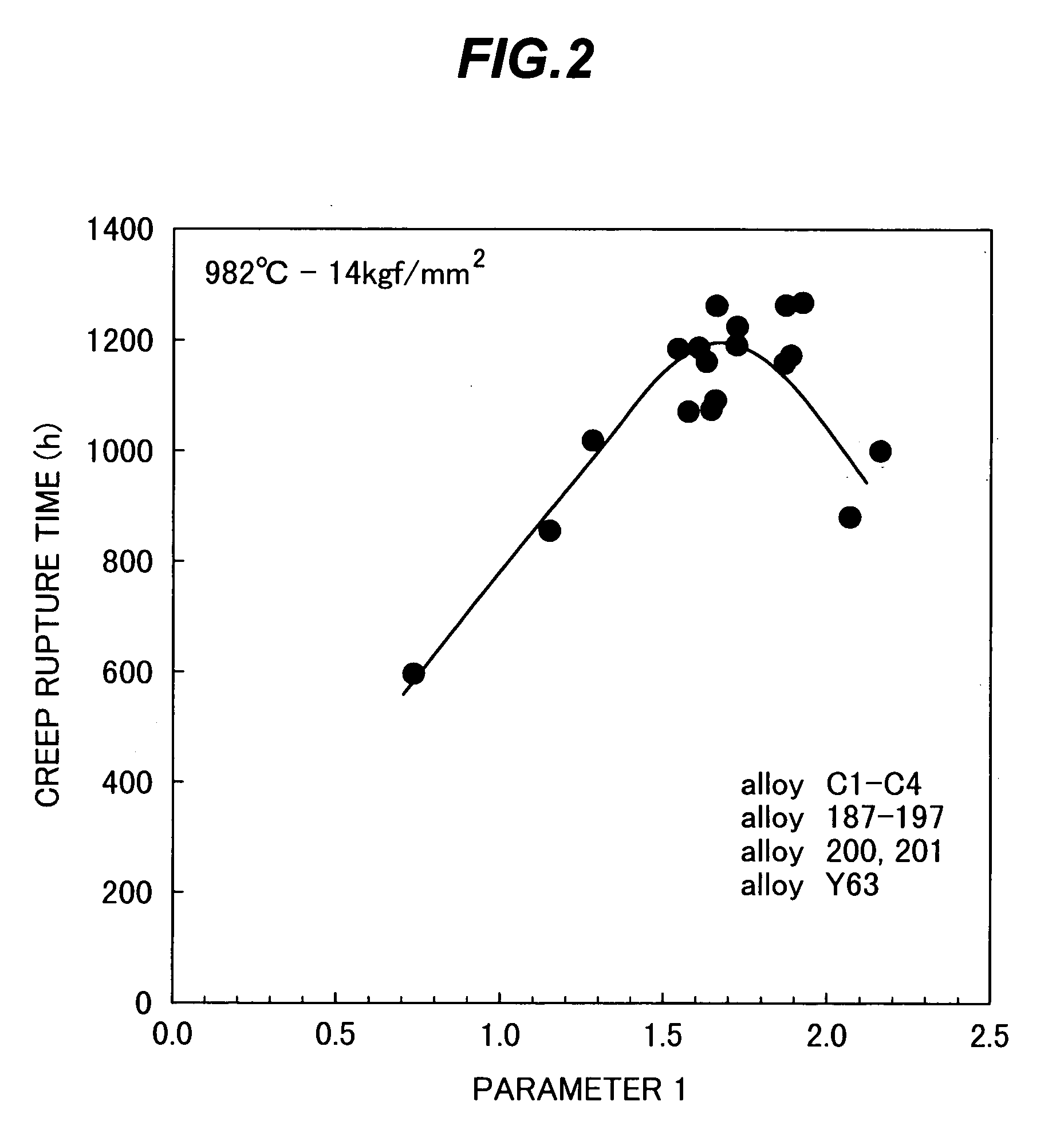

- A Ni-based superalloy with optimized elemental balances, including Cr, Mo, W, Ta, Ti, Nb, C, B, Hf, Co, and rare earth elements, dispersed γ′ phases in a γ-phase matrix, without significant Re content, to enhance strength, corrosion resistance, and oxidation resistance, and employing specific heat treatment processes to maintain alloy stability and reduce costs.

Material Characterization and Testing Standards for Printed Ni Superalloys

The characterization and testing of printed Ni superalloys require standardized methodologies to ensure consistent evaluation of their electrochemical and environmental resistance properties. ASTM International and ISO have established several key standards specifically applicable to these advanced materials, including ASTM G5 for potentiodynamic anodic polarization measurements and ASTM G61 for cyclic polarization testing in chloride environments.

Material characterization begins with microstructural analysis using scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) to evaluate elemental distribution and identify potential segregation that might affect corrosion resistance. X-ray diffraction (XRD) analysis is essential for phase identification and determination of crystallographic texture, which significantly influences electrochemical behavior.

For electrochemical resistance testing, electrochemical impedance spectroscopy (EIS) provides critical insights into the passive film formation and stability on printed Ni superalloys. The test parameters typically include frequency ranges from 100 kHz to 10 mHz and potential amplitudes of 10-20 mV. Tafel extrapolation methods following ASTM G102 enable the determination of corrosion rates under various environmental conditions.

Environmental resistance testing standards include ASTM G85 for salt spray (fog) testing, which has been modified specifically for additive manufactured alloys to account for their unique layer-by-layer structure. High-temperature oxidation resistance is evaluated according to ASTM G54, with testing temperatures ranging from 650°C to 1100°C to simulate extreme service conditions.

The mechanical properties of printed Ni superalloys after environmental exposure are assessed using ASTM E8 for tensile testing and ASTM E399 for fracture toughness evaluation. These tests provide critical data on how environmental factors affect the structural integrity of these materials over time.

Recent developments in testing standards include specialized protocols for evaluating the resistance of printed Ni superalloys to molten salt environments, particularly relevant for concentrated solar power applications. These tests typically involve exposure to binary and ternary salt mixtures at temperatures between 500-800°C for periods ranging from 100 to 1000 hours.

Intergranular corrosion susceptibility, a particular concern for printed Ni superalloys due to their unique solidification patterns, is evaluated using ASTM G28 methods, which have been adapted to account for the directional grain structures common in additively manufactured components.

Material characterization begins with microstructural analysis using scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) to evaluate elemental distribution and identify potential segregation that might affect corrosion resistance. X-ray diffraction (XRD) analysis is essential for phase identification and determination of crystallographic texture, which significantly influences electrochemical behavior.

For electrochemical resistance testing, electrochemical impedance spectroscopy (EIS) provides critical insights into the passive film formation and stability on printed Ni superalloys. The test parameters typically include frequency ranges from 100 kHz to 10 mHz and potential amplitudes of 10-20 mV. Tafel extrapolation methods following ASTM G102 enable the determination of corrosion rates under various environmental conditions.

Environmental resistance testing standards include ASTM G85 for salt spray (fog) testing, which has been modified specifically for additive manufactured alloys to account for their unique layer-by-layer structure. High-temperature oxidation resistance is evaluated according to ASTM G54, with testing temperatures ranging from 650°C to 1100°C to simulate extreme service conditions.

The mechanical properties of printed Ni superalloys after environmental exposure are assessed using ASTM E8 for tensile testing and ASTM E399 for fracture toughness evaluation. These tests provide critical data on how environmental factors affect the structural integrity of these materials over time.

Recent developments in testing standards include specialized protocols for evaluating the resistance of printed Ni superalloys to molten salt environments, particularly relevant for concentrated solar power applications. These tests typically involve exposure to binary and ternary salt mixtures at temperatures between 500-800°C for periods ranging from 100 to 1000 hours.

Intergranular corrosion susceptibility, a particular concern for printed Ni superalloys due to their unique solidification patterns, is evaluated using ASTM G28 methods, which have been adapted to account for the directional grain structures common in additively manufactured components.

Sustainability and Lifecycle Assessment of Printed Ni Superalloy Components

The sustainability assessment of printed Ni superalloy components reveals significant environmental advantages compared to traditional manufacturing methods. Life cycle analysis indicates that additive manufacturing processes for nickel superalloys can reduce material waste by 30-45% compared to conventional subtractive manufacturing techniques. This waste reduction translates directly to lower environmental impact across the entire production chain, from raw material extraction to final component disposal.

Energy consumption patterns during the manufacturing phase show that while 3D printing technologies require substantial energy input during the printing process, the overall energy footprint is often lower when considering the complete product lifecycle. This is particularly evident in aerospace and energy sector applications, where the lightweight optimized designs enabled by printing technologies lead to operational fuel savings that offset initial manufacturing energy investments.

Raw material utilization efficiency represents another critical sustainability factor. Printed Ni superalloys demonstrate superior material efficiency ratios, with powder recycling rates reaching up to 95% in closed-loop systems. The ability to reuse unmelted powder significantly reduces the environmental burden associated with mining and processing virgin nickel alloy materials, which are energy-intensive and generate substantial greenhouse gas emissions.

Environmental impact assessments of printed Ni superalloy components must also consider end-of-life scenarios. Research indicates that these components offer enhanced recyclability potential due to their controlled composition and reduced contamination compared to conventionally manufactured parts. The homogeneous microstructure achieved through printing processes facilitates material recovery and reprocessing, creating opportunities for circular economy approaches.

Water usage metrics reveal that additive manufacturing of Ni superalloys typically requires 40-60% less water compared to traditional casting and machining operations. This reduction stems primarily from the elimination of multiple cooling and cleaning steps inherent in conventional manufacturing processes, contributing to overall resource conservation.

Carbon footprint calculations across the entire lifecycle demonstrate that printed Ni superalloy components can achieve carbon emission reductions of 15-25% compared to their conventionally manufactured counterparts. These reductions become even more significant when factoring in the extended service life and improved performance characteristics of printed components, which delay replacement cycles and associated environmental impacts.

Energy consumption patterns during the manufacturing phase show that while 3D printing technologies require substantial energy input during the printing process, the overall energy footprint is often lower when considering the complete product lifecycle. This is particularly evident in aerospace and energy sector applications, where the lightweight optimized designs enabled by printing technologies lead to operational fuel savings that offset initial manufacturing energy investments.

Raw material utilization efficiency represents another critical sustainability factor. Printed Ni superalloys demonstrate superior material efficiency ratios, with powder recycling rates reaching up to 95% in closed-loop systems. The ability to reuse unmelted powder significantly reduces the environmental burden associated with mining and processing virgin nickel alloy materials, which are energy-intensive and generate substantial greenhouse gas emissions.

Environmental impact assessments of printed Ni superalloy components must also consider end-of-life scenarios. Research indicates that these components offer enhanced recyclability potential due to their controlled composition and reduced contamination compared to conventionally manufactured parts. The homogeneous microstructure achieved through printing processes facilitates material recovery and reprocessing, creating opportunities for circular economy approaches.

Water usage metrics reveal that additive manufacturing of Ni superalloys typically requires 40-60% less water compared to traditional casting and machining operations. This reduction stems primarily from the elimination of multiple cooling and cleaning steps inherent in conventional manufacturing processes, contributing to overall resource conservation.

Carbon footprint calculations across the entire lifecycle demonstrate that printed Ni superalloy components can achieve carbon emission reductions of 15-25% compared to their conventionally manufactured counterparts. These reductions become even more significant when factoring in the extended service life and improved performance characteristics of printed components, which delay replacement cycles and associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!