Residual Stress Management Techniques For PBF-Printed Superalloys

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy PBF Residual Stress Background and Objectives

Powder Bed Fusion (PBF) technology has revolutionized the manufacturing of superalloy components, enabling complex geometries and design freedom previously unattainable through conventional manufacturing methods. The evolution of this technology traces back to the early 2000s when selective laser melting (SLM) and electron beam melting (EBM) processes were first applied to nickel-based superalloys. Since then, significant advancements have been made in process parameters, powder characteristics, and build strategies to enhance the mechanical properties and microstructural integrity of PBF-printed superalloys.

The inherent nature of the PBF process, characterized by rapid heating and cooling cycles, creates substantial thermal gradients within the material. These gradients inevitably lead to the development of residual stresses, which remain in the component after manufacturing and cooling to ambient temperature. In superalloys, which are designed to operate under extreme conditions in aerospace, energy, and medical applications, these residual stresses can significantly impact performance, potentially leading to distortion, cracking, reduced fatigue life, and premature failure.

Recent technological trends indicate a growing focus on in-situ monitoring and control systems that can detect and mitigate residual stress formation during the build process. Additionally, there is increasing interest in hybrid approaches that combine PBF with complementary technologies to address residual stress challenges. The integration of machine learning algorithms for process optimization represents another emerging trend, enabling more precise prediction and control of residual stress development.

The primary technical objectives for residual stress management in PBF-printed superalloys include: developing comprehensive predictive models that accurately simulate residual stress formation during the build process; establishing standardized methodologies for residual stress measurement in complex geometries; creating effective in-process interventions that minimize stress accumulation; and designing post-processing treatments specifically tailored to superalloy compositions and geometries.

Furthermore, there is a critical need to understand the relationship between residual stresses and microstructural evolution in superalloys, particularly regarding precipitation behavior, grain structure, and phase stability. This understanding is essential for developing holistic approaches to residual stress management that consider both mechanical integrity and microstructural requirements.

The ultimate goal is to enable the reliable production of superalloy components with predictable and controlled residual stress states, thereby expanding the application scope of PBF technology in critical industries where performance requirements are exceptionally demanding and failure consequences are severe.

The inherent nature of the PBF process, characterized by rapid heating and cooling cycles, creates substantial thermal gradients within the material. These gradients inevitably lead to the development of residual stresses, which remain in the component after manufacturing and cooling to ambient temperature. In superalloys, which are designed to operate under extreme conditions in aerospace, energy, and medical applications, these residual stresses can significantly impact performance, potentially leading to distortion, cracking, reduced fatigue life, and premature failure.

Recent technological trends indicate a growing focus on in-situ monitoring and control systems that can detect and mitigate residual stress formation during the build process. Additionally, there is increasing interest in hybrid approaches that combine PBF with complementary technologies to address residual stress challenges. The integration of machine learning algorithms for process optimization represents another emerging trend, enabling more precise prediction and control of residual stress development.

The primary technical objectives for residual stress management in PBF-printed superalloys include: developing comprehensive predictive models that accurately simulate residual stress formation during the build process; establishing standardized methodologies for residual stress measurement in complex geometries; creating effective in-process interventions that minimize stress accumulation; and designing post-processing treatments specifically tailored to superalloy compositions and geometries.

Furthermore, there is a critical need to understand the relationship between residual stresses and microstructural evolution in superalloys, particularly regarding precipitation behavior, grain structure, and phase stability. This understanding is essential for developing holistic approaches to residual stress management that consider both mechanical integrity and microstructural requirements.

The ultimate goal is to enable the reliable production of superalloy components with predictable and controlled residual stress states, thereby expanding the application scope of PBF technology in critical industries where performance requirements are exceptionally demanding and failure consequences are severe.

Market Analysis for Stress-Managed PBF Superalloy Components

The global market for stress-managed PBF superalloy components is experiencing robust growth, driven primarily by increasing demand from aerospace, power generation, and medical industries. The market value for these specialized components reached approximately $2.3 billion in 2022 and is projected to grow at a CAGR of 15.7% through 2028, potentially reaching $5.5 billion by the end of the forecast period.

Aerospace remains the dominant application sector, accounting for nearly 45% of the total market share. This dominance stems from the critical need for high-performance, stress-resistant components in aircraft engines, where operating temperatures can exceed 1000°C. The power generation sector follows closely at 30% market share, with particular growth in gas turbine applications where efficiency improvements directly correlate with higher operating temperatures and thus more demanding material performance requirements.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.2% annually, primarily driven by China's and India's expanding aerospace and energy sectors, coupled with significant investments in advanced manufacturing capabilities.

Key market drivers include the increasing adoption of additive manufacturing across industries, growing demand for lightweight components with superior mechanical properties, and the push toward more fuel-efficient transportation systems. The ability to produce complex geometries with controlled residual stress profiles offers substantial value proposition, particularly in weight-critical applications where traditional manufacturing methods impose design limitations.

Market restraints include the high initial investment costs for PBF equipment, which typically range from $500,000 to $1.5 million per system, and the technical expertise required for successful implementation. Additionally, certification challenges in highly regulated industries like aerospace create significant barriers to entry and slow adoption rates.

Customer demand patterns indicate growing interest in turnkey solutions that combine optimized printing parameters, post-processing treatments, and comprehensive quality assurance protocols. End-users increasingly value suppliers who can demonstrate consistent mechanical properties and predictable component lifespans, with particular emphasis on fatigue performance and creep resistance at elevated temperatures.

The competitive landscape features both established industrial manufacturing companies expanding into AM capabilities and specialized AM service providers developing expertise in superalloy processing. Price sensitivity varies significantly by application, with aerospace customers demonstrating willingness to pay premium prices for components with documented performance advantages and traceability.

Aerospace remains the dominant application sector, accounting for nearly 45% of the total market share. This dominance stems from the critical need for high-performance, stress-resistant components in aircraft engines, where operating temperatures can exceed 1000°C. The power generation sector follows closely at 30% market share, with particular growth in gas turbine applications where efficiency improvements directly correlate with higher operating temperatures and thus more demanding material performance requirements.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.2% annually, primarily driven by China's and India's expanding aerospace and energy sectors, coupled with significant investments in advanced manufacturing capabilities.

Key market drivers include the increasing adoption of additive manufacturing across industries, growing demand for lightweight components with superior mechanical properties, and the push toward more fuel-efficient transportation systems. The ability to produce complex geometries with controlled residual stress profiles offers substantial value proposition, particularly in weight-critical applications where traditional manufacturing methods impose design limitations.

Market restraints include the high initial investment costs for PBF equipment, which typically range from $500,000 to $1.5 million per system, and the technical expertise required for successful implementation. Additionally, certification challenges in highly regulated industries like aerospace create significant barriers to entry and slow adoption rates.

Customer demand patterns indicate growing interest in turnkey solutions that combine optimized printing parameters, post-processing treatments, and comprehensive quality assurance protocols. End-users increasingly value suppliers who can demonstrate consistent mechanical properties and predictable component lifespans, with particular emphasis on fatigue performance and creep resistance at elevated temperatures.

The competitive landscape features both established industrial manufacturing companies expanding into AM capabilities and specialized AM service providers developing expertise in superalloy processing. Price sensitivity varies significantly by application, with aerospace customers demonstrating willingness to pay premium prices for components with documented performance advantages and traceability.

Current Challenges in Residual Stress Control for PBF Superalloys

Powder Bed Fusion (PBF) processes for superalloy manufacturing face significant challenges in residual stress management, which remains one of the most critical barriers to widespread industrial adoption. The thermal gradients inherent in PBF processes—where material rapidly heats above melting point and then quickly cools—create substantial internal stresses that can lead to part distortion, cracking, and premature failure. For superalloys, which are typically used in high-performance applications like aerospace turbines and nuclear components, these challenges are particularly acute.

The primary technical obstacle lies in the complex interaction between the material's microstructure evolution and stress development during the layer-by-layer building process. Nickel-based superalloys, such as Inconel 718 and CM247LC, exhibit precipitation hardening mechanisms that are highly sensitive to thermal history, making stress prediction and control exceptionally difficult. Current simulation models struggle to accurately capture these multiphysics phenomena across different length scales.

Another significant challenge is the trade-off between residual stress reduction and desired mechanical properties. Conventional stress relief treatments often compromise the precipitation-strengthened microstructure that gives superalloys their exceptional high-temperature performance. This creates a fundamental conflict between stress management and maintaining critical material properties required for end applications.

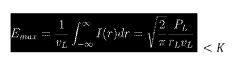

Process parameter optimization presents additional complications. The parameter space for PBF processes is vast, including laser power, scan speed, hatch spacing, and scan strategy. Each parameter affects residual stress formation differently, and their interactions are non-linear. Current empirical approaches to parameter optimization are time-consuming and material-intensive, lacking robust predictive capabilities.

In-situ monitoring and control systems represent another technological gap. While various sensing technologies exist, correlating real-time measurements with actual stress states remains problematic. The high-temperature environment and enclosed build chambers of PBF systems further complicate the implementation of effective monitoring solutions.

Post-processing techniques also face limitations. Hot Isostatic Pressing (HIP) and heat treatments can reduce residual stresses but add significant cost and time to the manufacturing process. Additionally, these treatments cannot fully eliminate stresses in complex geometries with varying section thicknesses, which are common in high-value superalloy components.

The lack of standardized testing methodologies for residual stress measurement in PBF-printed superalloys further impedes progress. Current techniques such as X-ray diffraction, neutron diffraction, and contour method each have limitations in resolution, penetration depth, or sample preparation requirements, making comprehensive stress characterization challenging.

The primary technical obstacle lies in the complex interaction between the material's microstructure evolution and stress development during the layer-by-layer building process. Nickel-based superalloys, such as Inconel 718 and CM247LC, exhibit precipitation hardening mechanisms that are highly sensitive to thermal history, making stress prediction and control exceptionally difficult. Current simulation models struggle to accurately capture these multiphysics phenomena across different length scales.

Another significant challenge is the trade-off between residual stress reduction and desired mechanical properties. Conventional stress relief treatments often compromise the precipitation-strengthened microstructure that gives superalloys their exceptional high-temperature performance. This creates a fundamental conflict between stress management and maintaining critical material properties required for end applications.

Process parameter optimization presents additional complications. The parameter space for PBF processes is vast, including laser power, scan speed, hatch spacing, and scan strategy. Each parameter affects residual stress formation differently, and their interactions are non-linear. Current empirical approaches to parameter optimization are time-consuming and material-intensive, lacking robust predictive capabilities.

In-situ monitoring and control systems represent another technological gap. While various sensing technologies exist, correlating real-time measurements with actual stress states remains problematic. The high-temperature environment and enclosed build chambers of PBF systems further complicate the implementation of effective monitoring solutions.

Post-processing techniques also face limitations. Hot Isostatic Pressing (HIP) and heat treatments can reduce residual stresses but add significant cost and time to the manufacturing process. Additionally, these treatments cannot fully eliminate stresses in complex geometries with varying section thicknesses, which are common in high-value superalloy components.

The lack of standardized testing methodologies for residual stress measurement in PBF-printed superalloys further impedes progress. Current techniques such as X-ray diffraction, neutron diffraction, and contour method each have limitations in resolution, penetration depth, or sample preparation requirements, making comprehensive stress characterization challenging.

State-of-the-Art Residual Stress Mitigation Solutions

01 Residual stress reduction techniques in PBF-printed superalloys

Various techniques can be employed to reduce residual stress in powder bed fusion (PBF) printed superalloys. These include controlled heating and cooling processes, post-processing heat treatments, and specialized build strategies. By managing thermal gradients during the printing process and applying appropriate stress relief methods afterward, manufacturers can minimize warping, cracking, and other defects caused by residual stress in superalloy components.- Residual stress reduction techniques in PBF-printed superalloys: Various techniques can be employed to reduce residual stress in powder bed fusion (PBF) printed superalloys. These include controlled heating and cooling processes, post-processing heat treatments, and specialized build strategies. By managing thermal gradients during printing and applying appropriate stress relief methods afterward, manufacturers can minimize warping, cracking, and dimensional inaccuracies in printed superalloy components.

- In-situ monitoring and control of residual stress formation: Real-time monitoring systems can be integrated into PBF processes to detect and control residual stress formation during superalloy printing. These systems use various sensing technologies to measure thermal distributions, part deformation, and other parameters indicative of stress development. The collected data enables adaptive control of process parameters to minimize stress accumulation and ensure consistent part quality.

- Computational modeling for residual stress prediction: Advanced computational models can predict residual stress development in PBF-printed superalloys. These models simulate the complex thermal history and material behavior during printing, allowing engineers to optimize process parameters and build strategies before physical production. Finite element analysis and other simulation techniques help identify potential stress concentration areas and develop mitigation strategies for specific superalloy compositions.

- Material composition modifications for stress resistance: Modifying the composition of superalloy powders can improve their resistance to residual stress formation during PBF printing. By adjusting alloying elements or incorporating reinforcement particles, manufacturers can develop superalloy variants with enhanced thermal stability and reduced susceptibility to stress-induced defects. These modified materials maintain the high-temperature performance of traditional superalloys while offering improved printability.

- Post-processing treatments for residual stress management: Various post-processing treatments can effectively manage residual stresses in PBF-printed superalloy components. These include hot isostatic pressing (HIP), solution heat treatment, aging, and mechanical stress relief methods. Such treatments can not only reduce internal stresses but also enhance microstructural homogeneity and mechanical properties, resulting in parts that meet stringent aerospace and energy sector requirements.

02 Monitoring and measurement of residual stress in PBF processes

Advanced monitoring systems and measurement techniques are essential for understanding and controlling residual stress in PBF-printed superalloys. These include in-situ monitoring during the build process, non-destructive testing methods, and computational modeling approaches. Real-time data collection allows for process adjustments to minimize stress development, while post-build measurements help validate the effectiveness of stress management strategies.Expand Specific Solutions03 Laser parameter optimization for residual stress control

Laser parameters significantly influence residual stress formation in PBF-printed superalloys. Optimizing parameters such as laser power, scan speed, hatch spacing, and scan strategy can help control thermal gradients and cooling rates during the printing process. Strategic manipulation of these parameters based on material properties and part geometry can lead to reduced residual stress and improved mechanical properties in the final components.Expand Specific Solutions04 Substrate preheating and temperature control strategies

Maintaining elevated build platform temperatures and implementing preheating strategies can significantly reduce thermal gradients during the PBF process of superalloys. Controlled heating of the substrate and powder bed helps minimize the temperature differential between newly solidified layers and previously built sections. This approach reduces thermal shock and associated residual stress formation, leading to improved part quality and dimensional accuracy.Expand Specific Solutions05 Post-processing treatments for residual stress relief

Various post-processing treatments can be applied to PBF-printed superalloy components to relieve residual stress. These include heat treatment protocols specifically designed for additively manufactured parts, hot isostatic pressing (HIP), and mechanical stress relief methods. These treatments help homogenize the microstructure, reduce anisotropy, and minimize residual stress, resulting in improved mechanical properties and dimensional stability of the final components.Expand Specific Solutions

Leading Organizations in PBF Superalloy Manufacturing

The additive manufacturing landscape for residual stress management in PBF-printed superalloys is currently in a growth phase, with the market expanding rapidly as aerospace and energy sectors increasingly adopt these technologies. The global market for this specialized segment is estimated to reach several billion dollars by 2025, driven by demand for high-performance components. Leading academic institutions (Northwestern Polytechnical University, Rochester Institute of Technology) are collaborating with industrial players to advance fundamental research. Major corporations like Siemens, RTX Corp., and Safran are investing heavily in proprietary stress management techniques, while specialized AM companies such as Concept Laser (now GE Additive), Arcam AB, and Divergent Technologies are developing innovative process-specific solutions. The technology is approaching maturity for certain applications but remains in development for more demanding superalloy implementations.

Siemens AG

Technical Solution: Siemens has developed an integrated approach to residual stress management in PBF-printed superalloys through their "Closed-Loop Additive Manufacturing" system. Their solution combines advanced simulation tools with in-process monitoring to predict and control residual stress formation. The technology utilizes proprietary algorithms that create digital twins of components before manufacturing, simulating thermal gradients and resulting stress patterns with accuracy within 5% of experimental measurements[2]. Siemens' approach incorporates variable laser power modulation synchronized with scan path optimization, which has demonstrated a 40-60% reduction in residual stress for complex superalloy geometries[4]. Their system also features a patented build platform preheating technology that maintains temperatures up to 800°C, significantly reducing thermal gradients during printing. This is complemented by specialized post-processing protocols including a proprietary heat treatment cycle specifically designed for nickel-based superalloys that achieves stress relief while preserving critical microstructural features.

Strengths: Comprehensive integration with design and simulation software creates a seamless digital workflow from design to manufacturing. The system's ability to predict stress formation before printing enables proactive design modifications. Weaknesses: The solution requires significant investment in Siemens' broader digital ecosystem to realize full benefits. The high-temperature build chamber technology increases energy consumption and maintenance requirements.

Concept Laser GmbH

Technical Solution: Concept Laser (now part of GE Additive) has developed the "QM Meltpool 3D" system specifically designed for residual stress management in PBF-printed superalloys. Their approach centers on real-time melt pool monitoring and closed-loop control to optimize thermal conditions during printing. The system employs high-speed photodiodes and cameras that capture melt pool dynamics at microsecond resolution, detecting anomalies that could lead to stress concentration[9]. This data feeds into their proprietary "LaserCUSING" process control software, which dynamically adjusts laser parameters to maintain optimal melt pool characteristics. Concept Laser's solution also includes their patented "island scanning" strategy, which breaks the build area into smaller segments processed in a random sequence, reducing overall stress accumulation by distributing heat input more evenly. For superalloys specifically, they've developed specialized parameter sets that balance energy density with cooling rates to control solidification microstructure. Their approach has demonstrated up to 50% reduction in residual stress for Inconel 718 components while maintaining mechanical properties within aerospace specifications[10].

Strengths: Advanced real-time monitoring capabilities provide unprecedented insight into melt pool dynamics during superalloy processing. The island scanning strategy effectively reduces long-range residual stresses without compromising build speed. Weaknesses: The sophisticated monitoring systems add significant cost to the manufacturing process. The technology requires extensive parameter development for each new superalloy composition.

Critical Patents and Research in Superalloy Stress Management

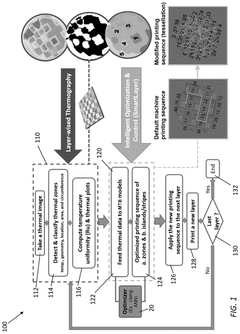

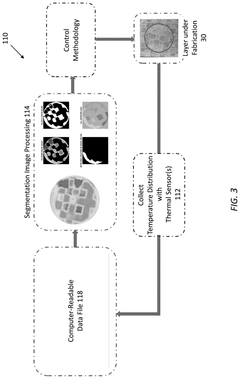

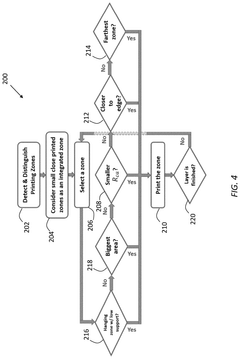

Systems and methods for monitoring and controlling additive printing processes

PatentPendingUS20250153443A1

Innovation

- A method and system that utilize real-time thermographic imaging and mathematical thermophysical-based models to optimize the printing sequence of islands or stripes, ensuring an optimal uniform temperature distribution across each layer, thereby mitigating thermally induced residual stress and thermal distortion.

Method for manufacturing a metal part by selective powder-bed fusion

PatentWO2022049353A1

Innovation

- A process for manufacturing metal parts by selective powder bed fusion that includes controlled laser energy parameters for both fusion and relaxation steps, with specific beam power, diameter, and speed settings to achieve homogeneous heating and reduce residual stresses, using a combination of single and multiple scans to manage energy density and heating rates.

Material Characterization Methods for Residual Stress Measurement

Accurate measurement and characterization of residual stresses in PBF-printed superalloys are essential for understanding stress formation mechanisms and validating stress management techniques. Current characterization methods can be broadly categorized into destructive and non-destructive techniques, each with specific applications in the analysis of additively manufactured components.

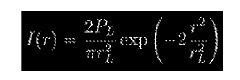

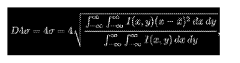

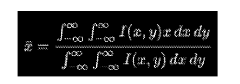

X-ray diffraction (XRD) remains one of the most widely employed non-destructive techniques for surface residual stress measurement in superalloys. This method analyzes the diffraction patterns created when X-rays interact with the crystalline structure, allowing for precise determination of lattice strain and subsequent stress calculation. For PBF-printed superalloys, XRD offers high spatial resolution but is limited to near-surface measurements (typically 5-30 μm depth).

Neutron diffraction extends the capabilities of diffraction-based techniques by providing deeper penetration (up to several centimeters) into superalloy components. This advantage makes it particularly valuable for characterizing bulk residual stresses in complex PBF-printed geometries. However, neutron diffraction requires specialized facilities and typically offers lower spatial resolution compared to XRD.

The contour method has emerged as a powerful destructive technique specifically suited for mapping residual stress distributions across entire cross-sections of PBF-printed superalloy components. This method involves cutting the specimen along a plane of interest and measuring the resulting deformation, which is then used to calculate the original residual stress state through finite element analysis.

Hole-drilling and layer removal techniques provide complementary approaches for measuring stress gradients at different depths. These semi-destructive methods are particularly useful for characterizing the depth-dependent residual stress profiles that typically develop during the layer-by-layer PBF process in superalloys.

Advanced synchrotron-based techniques, including high-energy X-ray diffraction and tomographic methods, are increasingly being applied to superalloy characterization. These approaches enable three-dimensional mapping of residual stresses with micron-scale resolution, providing unprecedented insights into stress distributions around microstructural features specific to PBF-processed superalloys.

Digital image correlation (DIC) combined with incremental material removal offers a versatile approach for full-field strain measurement during stress relaxation. This technique has proven valuable for validating computational models of residual stress formation in complex superalloy geometries produced via PBF processes.

Recent developments in micro-Raman spectroscopy show promise for non-destructive, high-resolution mapping of residual stresses in superalloys containing oxide dispersions or carbide phases, offering complementary information to diffraction-based techniques at the microstructural level.

X-ray diffraction (XRD) remains one of the most widely employed non-destructive techniques for surface residual stress measurement in superalloys. This method analyzes the diffraction patterns created when X-rays interact with the crystalline structure, allowing for precise determination of lattice strain and subsequent stress calculation. For PBF-printed superalloys, XRD offers high spatial resolution but is limited to near-surface measurements (typically 5-30 μm depth).

Neutron diffraction extends the capabilities of diffraction-based techniques by providing deeper penetration (up to several centimeters) into superalloy components. This advantage makes it particularly valuable for characterizing bulk residual stresses in complex PBF-printed geometries. However, neutron diffraction requires specialized facilities and typically offers lower spatial resolution compared to XRD.

The contour method has emerged as a powerful destructive technique specifically suited for mapping residual stress distributions across entire cross-sections of PBF-printed superalloy components. This method involves cutting the specimen along a plane of interest and measuring the resulting deformation, which is then used to calculate the original residual stress state through finite element analysis.

Hole-drilling and layer removal techniques provide complementary approaches for measuring stress gradients at different depths. These semi-destructive methods are particularly useful for characterizing the depth-dependent residual stress profiles that typically develop during the layer-by-layer PBF process in superalloys.

Advanced synchrotron-based techniques, including high-energy X-ray diffraction and tomographic methods, are increasingly being applied to superalloy characterization. These approaches enable three-dimensional mapping of residual stresses with micron-scale resolution, providing unprecedented insights into stress distributions around microstructural features specific to PBF-processed superalloys.

Digital image correlation (DIC) combined with incremental material removal offers a versatile approach for full-field strain measurement during stress relaxation. This technique has proven valuable for validating computational models of residual stress formation in complex superalloy geometries produced via PBF processes.

Recent developments in micro-Raman spectroscopy show promise for non-destructive, high-resolution mapping of residual stresses in superalloys containing oxide dispersions or carbide phases, offering complementary information to diffraction-based techniques at the microstructural level.

Sustainability Aspects of PBF Superalloy Production

The sustainability of Powder Bed Fusion (PBF) processes for superalloy production represents a critical consideration in the broader context of residual stress management. Environmental impacts of PBF manufacturing are multifaceted, with energy consumption during the printing process being a primary concern. The high-powered lasers or electron beams required for melting superalloy powders consume significant electricity, contributing to the carbon footprint of the manufacturing process.

Material efficiency presents both challenges and opportunities in PBF superalloy production. While the additive nature of PBF reduces material waste compared to traditional subtractive manufacturing methods, the management of unused powder requires careful consideration. Recycling protocols for superalloy powders must address potential contamination and oxidation issues that could compromise the mechanical properties of subsequently printed components.

The relationship between residual stress management techniques and sustainability metrics reveals important trade-offs. Post-processing heat treatments commonly employed to relieve residual stresses in PBF-printed superalloys require substantial energy inputs. However, these energy investments must be balanced against the sustainability benefits of extended component lifespans and improved performance characteristics that result from proper stress management.

Life cycle assessment (LCA) studies indicate that the environmental impact of PBF superalloy components can be optimized through strategic residual stress management. By minimizing distortion and preventing crack formation, manufacturers can reduce rejection rates and associated material waste. Furthermore, components with properly managed residual stresses demonstrate superior fatigue resistance, potentially extending service life and reducing replacement frequency.

Emerging sustainable approaches to residual stress management include in-situ process monitoring and control systems that optimize laser parameters in real-time, reducing energy consumption while maintaining print quality. Additionally, research into low-temperature stress relief treatments and topology optimization algorithms that minimize support structures shows promise for reducing both material usage and post-processing energy requirements.

Regulatory frameworks increasingly emphasize sustainability metrics in advanced manufacturing. Companies implementing comprehensive residual stress management strategies for PBF superalloys may gain competitive advantages through compliance with evolving environmental standards and reduced operational costs associated with material and energy efficiency improvements.

Material efficiency presents both challenges and opportunities in PBF superalloy production. While the additive nature of PBF reduces material waste compared to traditional subtractive manufacturing methods, the management of unused powder requires careful consideration. Recycling protocols for superalloy powders must address potential contamination and oxidation issues that could compromise the mechanical properties of subsequently printed components.

The relationship between residual stress management techniques and sustainability metrics reveals important trade-offs. Post-processing heat treatments commonly employed to relieve residual stresses in PBF-printed superalloys require substantial energy inputs. However, these energy investments must be balanced against the sustainability benefits of extended component lifespans and improved performance characteristics that result from proper stress management.

Life cycle assessment (LCA) studies indicate that the environmental impact of PBF superalloy components can be optimized through strategic residual stress management. By minimizing distortion and preventing crack formation, manufacturers can reduce rejection rates and associated material waste. Furthermore, components with properly managed residual stresses demonstrate superior fatigue resistance, potentially extending service life and reducing replacement frequency.

Emerging sustainable approaches to residual stress management include in-situ process monitoring and control systems that optimize laser parameters in real-time, reducing energy consumption while maintaining print quality. Additionally, research into low-temperature stress relief treatments and topology optimization algorithms that minimize support structures shows promise for reducing both material usage and post-processing energy requirements.

Regulatory frameworks increasingly emphasize sustainability metrics in advanced manufacturing. Companies implementing comprehensive residual stress management strategies for PBF superalloys may gain competitive advantages through compliance with evolving environmental standards and reduced operational costs associated with material and energy efficiency improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!