Non-Destructive Evaluation Methods For Detecting Subsurface Defects

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NDE Technology Background and Objectives

Non-Destructive Evaluation (NDE) methods for subsurface defect detection have evolved significantly over the past century, transforming from rudimentary techniques to sophisticated systems that leverage advanced physics principles and computational capabilities. The journey began with simple visual inspection and tap testing in the early 20th century, progressing through radiographic testing in the 1930s-40s, ultrasonic testing in the 1950s, and electromagnetic methods in the 1960s-70s.

The technological evolution accelerated dramatically with the digital revolution of the 1980s-90s, enabling more precise data acquisition, processing, and interpretation. Recent decades have witnessed the integration of artificial intelligence, machine learning, and advanced signal processing techniques, further enhancing detection capabilities and reliability.

Today's NDE landscape encompasses a diverse array of methods including ultrasonic testing (UT), radiographic testing (RT), electromagnetic testing (ET), thermography, acoustic emission, and various hybrid approaches. Each technique offers unique advantages for specific materials, geometries, and defect types, contributing to a comprehensive toolkit for subsurface inspection.

The primary objective of modern NDE technology development is to achieve higher detection sensitivity while maintaining practical field applicability. This includes detecting smaller defects at greater depths, improving resolution in complex geometries, and enhancing reliability in challenging environmental conditions. Simultaneously, there is a growing emphasis on real-time monitoring capabilities to support predictive maintenance strategies and structural health monitoring systems.

Another critical goal is the development of more accessible and cost-effective NDE solutions. This involves miniaturization of equipment, simplification of operating procedures, and reduction of specialized training requirements, making advanced inspection capabilities available to a broader range of industries and applications.

The integration of NDE methods with digital twin technology and Industry 4.0 frameworks represents an emerging frontier, aiming to create comprehensive material and structural integrity management systems. These systems would enable continuous monitoring, predictive analytics, and risk-based inspection planning, fundamentally transforming how organizations approach asset integrity management.

Environmental considerations are also shaping technology objectives, with increasing focus on developing methods that minimize radiation exposure, reduce chemical waste, and lower energy consumption. This sustainability-oriented approach aligns with broader industrial trends toward greener technologies and processes.

The technological evolution accelerated dramatically with the digital revolution of the 1980s-90s, enabling more precise data acquisition, processing, and interpretation. Recent decades have witnessed the integration of artificial intelligence, machine learning, and advanced signal processing techniques, further enhancing detection capabilities and reliability.

Today's NDE landscape encompasses a diverse array of methods including ultrasonic testing (UT), radiographic testing (RT), electromagnetic testing (ET), thermography, acoustic emission, and various hybrid approaches. Each technique offers unique advantages for specific materials, geometries, and defect types, contributing to a comprehensive toolkit for subsurface inspection.

The primary objective of modern NDE technology development is to achieve higher detection sensitivity while maintaining practical field applicability. This includes detecting smaller defects at greater depths, improving resolution in complex geometries, and enhancing reliability in challenging environmental conditions. Simultaneously, there is a growing emphasis on real-time monitoring capabilities to support predictive maintenance strategies and structural health monitoring systems.

Another critical goal is the development of more accessible and cost-effective NDE solutions. This involves miniaturization of equipment, simplification of operating procedures, and reduction of specialized training requirements, making advanced inspection capabilities available to a broader range of industries and applications.

The integration of NDE methods with digital twin technology and Industry 4.0 frameworks represents an emerging frontier, aiming to create comprehensive material and structural integrity management systems. These systems would enable continuous monitoring, predictive analytics, and risk-based inspection planning, fundamentally transforming how organizations approach asset integrity management.

Environmental considerations are also shaping technology objectives, with increasing focus on developing methods that minimize radiation exposure, reduce chemical waste, and lower energy consumption. This sustainability-oriented approach aligns with broader industrial trends toward greener technologies and processes.

Market Analysis for Subsurface Defect Detection

The global market for Non-Destructive Evaluation (NDE) methods for subsurface defect detection is experiencing robust growth, driven by increasing quality control requirements across multiple industries. The market was valued at approximately 15.8 billion USD in 2022 and is projected to reach 24.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.4% during the forecast period.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 28% of the total market value. This dominance stems from stringent safety regulations and the critical nature of component integrity in these industries. The automotive industry follows closely at 22%, with manufacturing and oil & gas sectors representing 18% and 15% respectively.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate of 9.2% annually through 2028, primarily due to rapid industrialization in China and India, coupled with increasing adoption of advanced manufacturing technologies.

Ultrasonic testing currently holds the largest technology segment share at 31%, followed by radiographic testing (24%), electromagnetic testing (18%), and visual inspection methods (15%). Emerging technologies like phased array ultrasonics and computed tomography are showing the fastest growth trajectories, with annual growth rates exceeding 10%.

Market demand is increasingly shifting toward integrated systems that combine multiple NDE methods with automated data analysis capabilities. This trend is particularly evident in high-value manufacturing sectors where the cost of undetected defects can be catastrophic. The market for AI-enhanced defect detection systems is projected to grow at 14.6% annually, significantly outpacing the overall market growth.

Key customer pain points include the need for faster inspection times, higher detection reliability for smaller defects, reduced operator dependency, and seamless integration with production lines. Industries are increasingly demanding real-time monitoring capabilities rather than periodic inspections, driving innovation in continuous monitoring technologies.

The market is also witnessing a shift toward service-based business models, with NDE-as-a-Service growing at 12.3% annually. This model is particularly attractive for smaller manufacturers who cannot justify the capital expenditure for advanced inspection equipment but still require high-quality defect detection capabilities.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 28% of the total market value. This dominance stems from stringent safety regulations and the critical nature of component integrity in these industries. The automotive industry follows closely at 22%, with manufacturing and oil & gas sectors representing 18% and 15% respectively.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate of 9.2% annually through 2028, primarily due to rapid industrialization in China and India, coupled with increasing adoption of advanced manufacturing technologies.

Ultrasonic testing currently holds the largest technology segment share at 31%, followed by radiographic testing (24%), electromagnetic testing (18%), and visual inspection methods (15%). Emerging technologies like phased array ultrasonics and computed tomography are showing the fastest growth trajectories, with annual growth rates exceeding 10%.

Market demand is increasingly shifting toward integrated systems that combine multiple NDE methods with automated data analysis capabilities. This trend is particularly evident in high-value manufacturing sectors where the cost of undetected defects can be catastrophic. The market for AI-enhanced defect detection systems is projected to grow at 14.6% annually, significantly outpacing the overall market growth.

Key customer pain points include the need for faster inspection times, higher detection reliability for smaller defects, reduced operator dependency, and seamless integration with production lines. Industries are increasingly demanding real-time monitoring capabilities rather than periodic inspections, driving innovation in continuous monitoring technologies.

The market is also witnessing a shift toward service-based business models, with NDE-as-a-Service growing at 12.3% annually. This model is particularly attractive for smaller manufacturers who cannot justify the capital expenditure for advanced inspection equipment but still require high-quality defect detection capabilities.

Current NDE Methods and Technical Challenges

Non-destructive evaluation (NDE) methods have evolved significantly over the past decades, offering diverse approaches for detecting subsurface defects without compromising material integrity. Current mainstream NDE technologies include ultrasonic testing, radiographic testing, eddy current testing, magnetic particle inspection, and thermography, each with distinct capabilities and limitations.

Ultrasonic testing utilizes high-frequency sound waves to detect internal flaws and has become increasingly sophisticated with phased array and time-of-flight diffraction advancements. This method excels in detecting discontinuities in metals and composites but faces challenges with complex geometries and highly attenuative materials. Recent developments in full matrix capture and total focusing method have improved resolution but increased computational demands.

Radiographic testing, employing X-rays or gamma rays, provides excellent visualization of internal structures but presents radiation safety concerns and struggles with planar defects oriented perpendicular to the radiation beam. Digital radiography has enhanced efficiency but requires substantial capital investment and specialized training.

Eddy current testing, while effective for surface and near-surface defects in conductive materials, has limited penetration depth and faces challenges with complex geometries. Recent innovations in multi-frequency and pulsed eddy current techniques have expanded capabilities but increased system complexity.

Magnetic particle inspection remains valuable for ferromagnetic materials but is inherently limited to surface and near-surface defects and requires direct access to inspection surfaces. The method struggles with automation and quantitative defect characterization.

Thermography has gained prominence for composite materials inspection but faces challenges in detecting deep defects and requires careful control of environmental conditions. Active thermography methods have improved detection capabilities but increased equipment costs and complexity.

The technical challenges across these methods include detection reliability in complex geometries, characterization of defect morphology, inspection speed versus resolution trade-offs, and data interpretation complexity. Material-specific challenges persist, particularly with advanced composites, additively manufactured components, and multi-material structures where traditional NDE approaches often prove inadequate.

Automation and real-time inspection capabilities remain underdeveloped, with many methods still requiring significant human interpretation. Additionally, the industry faces challenges in standardization and qualification of new NDE techniques, creating barriers to adoption despite technological advancements.

Emerging computational approaches, including artificial intelligence and machine learning algorithms, show promise in addressing interpretation challenges but require extensive validated datasets and face implementation hurdles in safety-critical applications.

Ultrasonic testing utilizes high-frequency sound waves to detect internal flaws and has become increasingly sophisticated with phased array and time-of-flight diffraction advancements. This method excels in detecting discontinuities in metals and composites but faces challenges with complex geometries and highly attenuative materials. Recent developments in full matrix capture and total focusing method have improved resolution but increased computational demands.

Radiographic testing, employing X-rays or gamma rays, provides excellent visualization of internal structures but presents radiation safety concerns and struggles with planar defects oriented perpendicular to the radiation beam. Digital radiography has enhanced efficiency but requires substantial capital investment and specialized training.

Eddy current testing, while effective for surface and near-surface defects in conductive materials, has limited penetration depth and faces challenges with complex geometries. Recent innovations in multi-frequency and pulsed eddy current techniques have expanded capabilities but increased system complexity.

Magnetic particle inspection remains valuable for ferromagnetic materials but is inherently limited to surface and near-surface defects and requires direct access to inspection surfaces. The method struggles with automation and quantitative defect characterization.

Thermography has gained prominence for composite materials inspection but faces challenges in detecting deep defects and requires careful control of environmental conditions. Active thermography methods have improved detection capabilities but increased equipment costs and complexity.

The technical challenges across these methods include detection reliability in complex geometries, characterization of defect morphology, inspection speed versus resolution trade-offs, and data interpretation complexity. Material-specific challenges persist, particularly with advanced composites, additively manufactured components, and multi-material structures where traditional NDE approaches often prove inadequate.

Automation and real-time inspection capabilities remain underdeveloped, with many methods still requiring significant human interpretation. Additionally, the industry faces challenges in standardization and qualification of new NDE techniques, creating barriers to adoption despite technological advancements.

Emerging computational approaches, including artificial intelligence and machine learning algorithms, show promise in addressing interpretation challenges but require extensive validated datasets and face implementation hurdles in safety-critical applications.

Existing Subsurface Defect Detection Solutions

01 Ultrasonic Testing Methods

Ultrasonic testing is a widely used non-destructive evaluation method for detecting subsurface defects in various materials. This technique uses high-frequency sound waves that penetrate the material and reflect back when encountering discontinuities. Advanced ultrasonic methods include phased array technology, which allows for more precise detection and characterization of defects. These methods are particularly effective for detecting cracks, voids, and inclusions in metals, composites, and other solid materials.- Ultrasonic testing methods for subsurface defect detection: Ultrasonic testing is a widely used non-destructive evaluation method for detecting subsurface defects in various materials. This technique uses high-frequency sound waves that penetrate the material and reflect back when encountering discontinuities or defects. The reflected signals are analyzed to determine the location, size, and nature of subsurface defects. Advanced ultrasonic techniques include phased array ultrasonics, which allows for electronic beam steering and focusing, improving detection capabilities for complex geometries and orientations of defects.

- Electromagnetic and eddy current inspection techniques: Electromagnetic methods, particularly eddy current testing, are effective non-destructive evaluation techniques for detecting subsurface defects in conductive materials. These methods involve inducing electromagnetic fields in the test material and measuring changes in the field caused by defects. Eddy current techniques are especially useful for detecting cracks, corrosion, and other discontinuities near the surface of metallic components. Advanced electromagnetic methods incorporate multiple frequencies and sophisticated signal processing algorithms to improve detection depth and resolution.

- Radiographic and X-ray based inspection systems: Radiographic inspection methods use penetrating radiation, such as X-rays or gamma rays, to detect internal defects in materials. These techniques create images of the internal structure of components, revealing subsurface defects like voids, inclusions, and cracks. Digital radiography and computed tomography (CT) scanning provide enhanced capabilities for three-dimensional visualization of defects. These methods are particularly valuable for inspecting complex assemblies and components where other non-destructive techniques may have limitations.

- Thermal and infrared imaging techniques: Thermal imaging techniques, including active thermography and infrared imaging, detect subsurface defects by measuring temperature differences or thermal patterns on the surface of materials. These methods involve heating or cooling the test object and monitoring the thermal response, which is affected by subsurface defects that alter heat flow. Pulse thermography, lock-in thermography, and vibrothermography are specialized techniques that enhance detection capabilities for different types of defects and materials. These methods are particularly effective for composite materials and thin structures.

- Advanced signal processing and AI-based defect analysis: Modern non-destructive evaluation methods incorporate advanced signal processing techniques and artificial intelligence to enhance defect detection and characterization. Machine learning algorithms analyze complex data patterns from various inspection methods to identify and classify defects with greater accuracy and reliability. These computational approaches enable automated inspection systems that can detect subtle indications of subsurface defects that might be missed by conventional analysis. Integration of multiple non-destructive testing modalities with sophisticated data fusion techniques provides comprehensive assessment of material integrity.

02 Electromagnetic and Eddy Current Techniques

Electromagnetic testing methods, including eddy current techniques, are effective for detecting subsurface defects in conductive materials. These methods involve inducing electromagnetic fields in the test material and measuring changes in the field caused by defects. Advanced techniques include pulsed eddy current testing and remote field testing, which can detect defects at greater depths. These methods are particularly useful for inspecting pipelines, aircraft components, and other critical infrastructure where subsurface defects could lead to catastrophic failures.Expand Specific Solutions03 Radiographic Inspection Systems

Radiographic inspection uses penetrating radiation (X-rays or gamma rays) to detect internal defects in materials. Digital radiography and computed tomography (CT) scanning provide enhanced capabilities for visualizing and analyzing subsurface defects in three dimensions. These techniques can detect voids, inclusions, and cracks that might not be visible using other methods. Advanced image processing algorithms improve defect detection accuracy and allow for automated inspection of complex components.Expand Specific Solutions04 Thermal and Infrared Imaging Methods

Thermal imaging methods, including active thermography and infrared testing, detect subsurface defects by measuring temperature differences or thermal conductivity variations in materials. These techniques involve heating the test material and monitoring how heat flows through it, with anomalies indicating potential defects. Pulse thermography and lock-in thermography are advanced variations that enhance detection capabilities. These methods are particularly effective for composite materials, adhesive bonds, and thin coatings where traditional methods may be less effective.Expand Specific Solutions05 Machine Learning and AI-Enhanced Defect Detection

Artificial intelligence and machine learning algorithms are increasingly being integrated with non-destructive evaluation methods to improve defect detection accuracy and efficiency. These systems can automatically analyze data from various inspection methods, identify patterns indicating defects, and reduce false positives. Deep learning models trained on large datasets of known defects can detect subtle anomalies that might be missed by human inspectors. This approach is particularly valuable for automated inspection systems in manufacturing environments where consistency and speed are critical.Expand Specific Solutions

Leading Companies and Research Institutions in NDE

The non-destructive evaluation (NDE) market for subsurface defect detection is currently in a growth phase, with increasing adoption across aerospace, automotive, and infrastructure sectors. The market size is projected to reach significant expansion due to aging infrastructure and stringent safety regulations. Technologically, the field shows varying maturity levels, with established players like General Electric, Boeing, and Siemens leading with comprehensive solutions integrating advanced imaging and AI. Academic institutions including Dalian University of Technology and Zhejiang University contribute fundamental research, while specialized companies like Prime Photonics and ISRA VISION drive innovation in optical and sensor-based detection methods. The competitive landscape features both diversified industrial conglomerates and niche technology providers developing complementary approaches to address complex inspection challenges across different materials and environments.

General Electric Company

Technical Solution: General Electric has developed advanced phased array ultrasonic testing (PAUT) systems for subsurface defect detection in critical components. Their technology utilizes multi-element transducer arrays that can electronically steer, focus, and scan ultrasonic beams without mechanical movement. GE's systems incorporate sophisticated signal processing algorithms that enhance defect detection capabilities through improved signal-to-noise ratios and automated defect recognition. Their proprietary Mentor UT platform combines portable hardware with cloud-connected software for real-time data analysis and remote collaboration[1]. GE has also pioneered the integration of computed tomography (CT) with digital radiography, allowing for comprehensive 3D visualization of internal structures at resolutions down to micrometers, particularly valuable for complex aerospace and power generation components[3].

Strengths: Industry-leading integration of multiple NDT technologies into unified inspection platforms; extensive material databases for accurate defect characterization; strong digital connectivity enabling remote expert analysis. Weaknesses: Higher initial equipment costs compared to conventional NDT methods; requires specialized operator training; some systems have limitations in high-temperature environments.

The Boeing Co.

Technical Solution: Boeing has developed a comprehensive suite of non-destructive evaluation technologies specifically optimized for aerospace composite structures. Their approach combines traditional ultrasonic inspection with advanced laser shearography and thermography systems. Boeing's proprietary Mobile Automated Scanner (MAUS) technology employs ultrasonic C-scan capabilities with automated movement systems that can conform to complex aircraft geometries, enabling precise mapping of subsurface defects in composite materials[2]. Their thermal inspection systems utilize both active and passive thermography with sophisticated image processing algorithms to detect delaminations, disbonds, and moisture ingress. Boeing has also pioneered the use of terahertz imaging for inspection of non-conductive materials and radome structures, allowing detection of defects that are challenging for conventional methods[4].

Strengths: Highly specialized systems optimized for aerospace composite structures; extensive validation through fleet service data; excellent detection capabilities for critical defect types in multi-layer composites. Weaknesses: Systems often require significant capital investment; some technologies have limited penetration depth in certain material configurations; specialized operator training requirements.

Key Patents and Technical Innovations in NDE

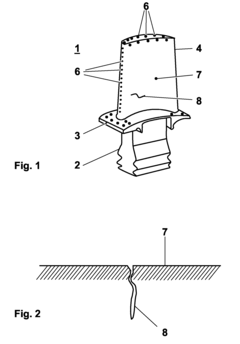

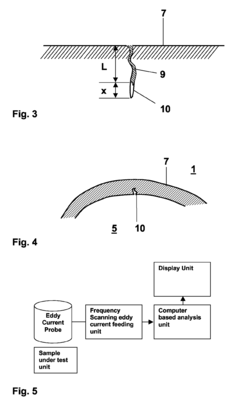

A non-destructive method of detecting defects in braze-repaired cracks

PatentInactiveEP1416269A1

Innovation

- A multifrequency scanning eddy current system is used to detect and quantify subsurface defects by analyzing changes in electrical conductivity, allowing for the determination of defect depth and distance from the surface, without the need for calibration on specific samples, and incorporating surface cleaning methods like Fluoride Ion Cleaning to prepare the surface for brazing.

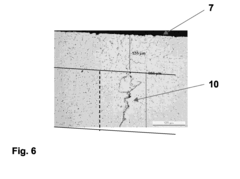

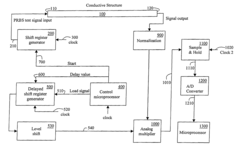

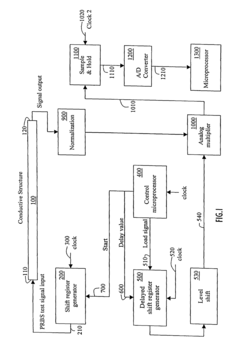

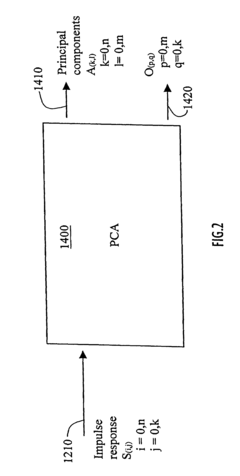

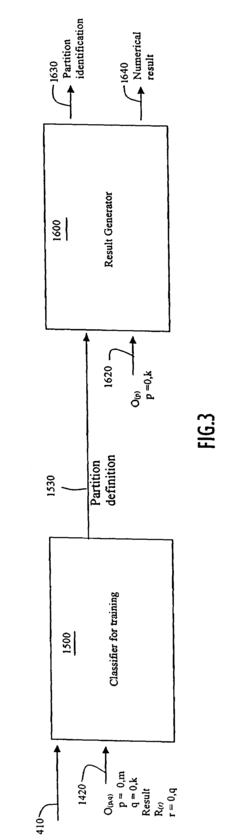

Method and system for non-destructive evaluation of conducting structures

PatentInactiveUS7427867B2

Innovation

- The use of a high-frequency, wideband pseudo-random binary sequence (PRBS) test signal with an analog multiplier and asynchronous sampling to measure the electrical impulse response of conducting structures, allowing for the detection of subtle changes and defects like cracks or corrosion, and enabling on-line testing with simple hardware.

Industry Standards and Certification Requirements

The landscape of Non-Destructive Evaluation (NDE) methods is heavily regulated by a comprehensive framework of industry standards and certification requirements that ensure reliability, safety, and consistency across various sectors. Organizations such as the American Society for Nondestructive Testing (ASNT), the International Organization for Standardization (ISO), and the American Society for Testing and Materials (ASTM) have established pivotal guidelines that govern the implementation of subsurface defect detection technologies.

ASNT's Recommended Practice No. SNT-TC-1A provides the foundation for personnel qualification and certification in NDE methods, establishing three levels of expertise that practitioners must achieve through rigorous training and examination. This tiered approach ensures that professionals conducting subsurface defect evaluations possess the requisite knowledge and skills to accurately interpret results and make critical decisions regarding structural integrity.

ISO 9712 represents the international standard for qualification and certification of NDE personnel, harmonizing requirements across global markets and facilitating cross-border recognition of professional credentials. This standard is particularly significant for multinational corporations operating in diverse regulatory environments, as it establishes a common framework for competency assessment.

Sector-specific standards further refine NDE requirements based on industry needs. In aerospace, the AS9100 quality management system incorporates specialized NDE protocols for critical components, while the Federal Aviation Administration (FAA) mandates specific inspection methodologies through Advisory Circulars. Similarly, the nuclear industry adheres to ASME Section XI guidelines for in-service inspection of nuclear power plant components, with additional oversight from regulatory bodies like the Nuclear Regulatory Commission.

Equipment calibration standards, such as those outlined in ASTM E1316, ensure measurement accuracy and repeatability across different NDE systems and operators. These standards typically specify reference blocks, calibration procedures, and verification methods that must be employed before conducting subsurface defect evaluations.

Emerging technologies in NDE face additional certification challenges, requiring new standards development to address novel inspection methodologies. Organizations like the National Institute of Standards and Technology (NIST) play crucial roles in validating these technologies through interlaboratory studies and reference material development, accelerating their adoption in regulated industries.

Compliance with these standards is increasingly verified through third-party certification programs that assess both personnel competency and organizational quality management systems. These certifications have become de facto requirements for companies seeking to participate in high-value supply chains where component reliability is paramount.

ASNT's Recommended Practice No. SNT-TC-1A provides the foundation for personnel qualification and certification in NDE methods, establishing three levels of expertise that practitioners must achieve through rigorous training and examination. This tiered approach ensures that professionals conducting subsurface defect evaluations possess the requisite knowledge and skills to accurately interpret results and make critical decisions regarding structural integrity.

ISO 9712 represents the international standard for qualification and certification of NDE personnel, harmonizing requirements across global markets and facilitating cross-border recognition of professional credentials. This standard is particularly significant for multinational corporations operating in diverse regulatory environments, as it establishes a common framework for competency assessment.

Sector-specific standards further refine NDE requirements based on industry needs. In aerospace, the AS9100 quality management system incorporates specialized NDE protocols for critical components, while the Federal Aviation Administration (FAA) mandates specific inspection methodologies through Advisory Circulars. Similarly, the nuclear industry adheres to ASME Section XI guidelines for in-service inspection of nuclear power plant components, with additional oversight from regulatory bodies like the Nuclear Regulatory Commission.

Equipment calibration standards, such as those outlined in ASTM E1316, ensure measurement accuracy and repeatability across different NDE systems and operators. These standards typically specify reference blocks, calibration procedures, and verification methods that must be employed before conducting subsurface defect evaluations.

Emerging technologies in NDE face additional certification challenges, requiring new standards development to address novel inspection methodologies. Organizations like the National Institute of Standards and Technology (NIST) play crucial roles in validating these technologies through interlaboratory studies and reference material development, accelerating their adoption in regulated industries.

Compliance with these standards is increasingly verified through third-party certification programs that assess both personnel competency and organizational quality management systems. These certifications have become de facto requirements for companies seeking to participate in high-value supply chains where component reliability is paramount.

Material-Specific NDE Application Considerations

The selection of appropriate Non-Destructive Evaluation (NDE) methods for subsurface defect detection must be carefully tailored to the specific material properties under examination. Metallic materials typically respond well to electromagnetic techniques such as eddy current testing and magnetic particle inspection, with penetration depth varying based on conductivity and permeability characteristics. For ferromagnetic metals, magnetic flux leakage offers superior sensitivity to subsurface cracks, while non-ferrous metals may require alternative approaches like ultrasonic testing.

Composite materials present unique challenges due to their anisotropic nature and heterogeneous composition. Ultrasonic techniques must be modified to account for varying acoustic impedance between layers, often necessitating specialized transducers and signal processing algorithms. Thermography has proven particularly effective for laminated composites, as delaminations create distinctive thermal barriers that can be detected through temperature gradient analysis.

Concrete and civil infrastructure materials require NDE methods capable of penetrating significant depths while maintaining resolution. Ground Penetrating Radar (GPR) has emerged as a preferred technique, with frequency selection determined by the required penetration depth versus resolution trade-off. Lower frequencies (100-500 MHz) provide greater penetration but reduced resolution, while higher frequencies (1-2 GHz) offer enhanced detail at shallower depths.

Ceramic materials present particular difficulties due to their brittle nature and high acoustic impedance. Advanced ultrasonic techniques utilizing higher frequencies and specialized coupling methods have been developed to address these challenges. For critical ceramic components in aerospace and medical applications, micro-CT scanning offers exceptional resolution but with limitations in component size and inspection throughput.

Polymeric materials exhibit viscoelastic behavior that can complicate ultrasonic wave propagation. Temperature-controlled testing environments are often necessary to ensure consistent results, as material properties can vary significantly with thermal conditions. Additionally, specialized NDE approaches like terahertz imaging have shown promise for polymer inspection, particularly for detecting water ingress and internal voids.

Material thickness represents another critical consideration, with thin materials often requiring surface-sensitive techniques like guided wave ultrasonics, while thick sections may necessitate radiographic methods with higher energy sources. The presence of coatings, surface treatments, or multi-material interfaces further complicates inspection strategies, requiring careful calibration and reference standards specific to the material system under evaluation.

Composite materials present unique challenges due to their anisotropic nature and heterogeneous composition. Ultrasonic techniques must be modified to account for varying acoustic impedance between layers, often necessitating specialized transducers and signal processing algorithms. Thermography has proven particularly effective for laminated composites, as delaminations create distinctive thermal barriers that can be detected through temperature gradient analysis.

Concrete and civil infrastructure materials require NDE methods capable of penetrating significant depths while maintaining resolution. Ground Penetrating Radar (GPR) has emerged as a preferred technique, with frequency selection determined by the required penetration depth versus resolution trade-off. Lower frequencies (100-500 MHz) provide greater penetration but reduced resolution, while higher frequencies (1-2 GHz) offer enhanced detail at shallower depths.

Ceramic materials present particular difficulties due to their brittle nature and high acoustic impedance. Advanced ultrasonic techniques utilizing higher frequencies and specialized coupling methods have been developed to address these challenges. For critical ceramic components in aerospace and medical applications, micro-CT scanning offers exceptional resolution but with limitations in component size and inspection throughput.

Polymeric materials exhibit viscoelastic behavior that can complicate ultrasonic wave propagation. Temperature-controlled testing environments are often necessary to ensure consistent results, as material properties can vary significantly with thermal conditions. Additionally, specialized NDE approaches like terahertz imaging have shown promise for polymer inspection, particularly for detecting water ingress and internal voids.

Material thickness represents another critical consideration, with thin materials often requiring surface-sensitive techniques like guided wave ultrasonics, while thick sections may necessitate radiographic methods with higher energy sources. The presence of coatings, surface treatments, or multi-material interfaces further complicates inspection strategies, requiring careful calibration and reference standards specific to the material system under evaluation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!