Directional Solidification Effects In Laser-Based Superalloy Builds

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Superalloy Solidification Background and Objectives

Directional solidification in superalloys represents a critical metallurgical process that has evolved significantly since its inception in the 1960s. Initially developed for turbine blade manufacturing in aerospace applications, this technique has become fundamental to creating components with superior high-temperature mechanical properties and creep resistance. The controlled solidification process enables the formation of aligned grain structures that dramatically enhance performance in extreme operating environments.

The emergence of laser-based additive manufacturing has revolutionized this field, offering unprecedented control over the solidification process at microscopic scales. Unlike conventional casting methods, laser-based techniques such as Selective Laser Melting (SLM) and Direct Energy Deposition (DED) create components layer by layer, allowing for complex geometries while simultaneously controlling the solidification parameters that determine microstructural development.

Recent technological advancements have focused on manipulating laser parameters—including power, scan speed, and pattern—to achieve directional solidification effects similar to those in traditional processes but with greater precision and flexibility. The ability to control thermal gradients and solidification rates at the microscale has opened new possibilities for tailoring microstructures to specific application requirements.

The global push toward more efficient aerospace engines, power generation systems, and advanced industrial applications has accelerated research in this domain. Current objectives center on understanding and controlling the fundamental mechanisms governing directional solidification during laser processing of superalloys, particularly nickel-based variants such as Inconel 718, René 80, and CMSX-4.

Key technical goals include achieving consistent columnar grain structures, minimizing defects such as stray grains and hot cracking, controlling precipitate formation, and developing predictive models that accurately capture the complex physics of rapid solidification under laser processing conditions. Additionally, there is significant interest in extending these capabilities to process new superalloy compositions specifically designed for additive manufacturing.

The intersection of computational modeling, in-situ monitoring technologies, and advanced characterization methods has created a fertile ground for innovation in this field. Machine learning approaches are increasingly being applied to optimize process parameters and predict microstructural outcomes, while high-speed imaging and thermal monitoring provide unprecedented insights into the dynamics of the melt pool during processing.

This technological convergence aims to establish robust processing-structure-property relationships that will enable the reliable production of superalloy components with directionally solidified microstructures tailored for extreme operating conditions, ultimately advancing capabilities in aerospace, energy, and other critical industries.

The emergence of laser-based additive manufacturing has revolutionized this field, offering unprecedented control over the solidification process at microscopic scales. Unlike conventional casting methods, laser-based techniques such as Selective Laser Melting (SLM) and Direct Energy Deposition (DED) create components layer by layer, allowing for complex geometries while simultaneously controlling the solidification parameters that determine microstructural development.

Recent technological advancements have focused on manipulating laser parameters—including power, scan speed, and pattern—to achieve directional solidification effects similar to those in traditional processes but with greater precision and flexibility. The ability to control thermal gradients and solidification rates at the microscale has opened new possibilities for tailoring microstructures to specific application requirements.

The global push toward more efficient aerospace engines, power generation systems, and advanced industrial applications has accelerated research in this domain. Current objectives center on understanding and controlling the fundamental mechanisms governing directional solidification during laser processing of superalloys, particularly nickel-based variants such as Inconel 718, René 80, and CMSX-4.

Key technical goals include achieving consistent columnar grain structures, minimizing defects such as stray grains and hot cracking, controlling precipitate formation, and developing predictive models that accurately capture the complex physics of rapid solidification under laser processing conditions. Additionally, there is significant interest in extending these capabilities to process new superalloy compositions specifically designed for additive manufacturing.

The intersection of computational modeling, in-situ monitoring technologies, and advanced characterization methods has created a fertile ground for innovation in this field. Machine learning approaches are increasingly being applied to optimize process parameters and predict microstructural outcomes, while high-speed imaging and thermal monitoring provide unprecedented insights into the dynamics of the melt pool during processing.

This technological convergence aims to establish robust processing-structure-property relationships that will enable the reliable production of superalloy components with directionally solidified microstructures tailored for extreme operating conditions, ultimately advancing capabilities in aerospace, energy, and other critical industries.

Market Analysis for Directionally Solidified Superalloy Components

The global market for directionally solidified superalloy components has experienced substantial growth over the past decade, primarily driven by increasing demand from aerospace, power generation, and industrial gas turbine sectors. Current market valuations indicate that the directionally solidified superalloy component market exceeds $5 billion annually, with projections suggesting a compound annual growth rate of 6.8% through 2030.

Aerospace applications represent the largest market segment, accounting for approximately 45% of total demand. This is attributed to the critical need for high-temperature resistant components in aircraft engines where directionally solidified superalloys provide superior creep resistance and thermal stability. The commercial aviation sector's recovery post-pandemic and increasing defense spending worldwide have further accelerated this demand.

Power generation follows as the second-largest application segment at 35% market share. The transition toward more efficient energy production systems has intensified the need for advanced materials capable of withstanding extreme operating conditions. Directionally solidified components enable higher operating temperatures in gas turbines, directly translating to improved efficiency and reduced emissions.

Regional analysis reveals that North America currently dominates the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the most significant growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid industrialization and expanding aerospace sectors are creating new demand centers. These emerging markets are expected to grow at nearly twice the global average rate.

Customer segmentation shows that OEMs constitute 65% of end-users, while maintenance, repair, and overhaul (MRO) services account for 35%. This distribution highlights the dual nature of the market: new equipment manufacturing and the substantial aftermarket for replacement components.

Pricing trends indicate premium positioning for directionally solidified components, typically commanding 30-40% higher prices than conventionally cast alternatives. This premium is justified by the superior performance characteristics and extended service life, which ultimately delivers better total cost of ownership for end-users despite higher initial investment.

Market challenges include supply chain vulnerabilities for critical raw materials like rhenium, ruthenium, and other rare elements essential for superalloy production. Additionally, the specialized manufacturing infrastructure required for directional solidification processes creates high barriers to entry and potential supply constraints during periods of peak demand.

Aerospace applications represent the largest market segment, accounting for approximately 45% of total demand. This is attributed to the critical need for high-temperature resistant components in aircraft engines where directionally solidified superalloys provide superior creep resistance and thermal stability. The commercial aviation sector's recovery post-pandemic and increasing defense spending worldwide have further accelerated this demand.

Power generation follows as the second-largest application segment at 35% market share. The transition toward more efficient energy production systems has intensified the need for advanced materials capable of withstanding extreme operating conditions. Directionally solidified components enable higher operating temperatures in gas turbines, directly translating to improved efficiency and reduced emissions.

Regional analysis reveals that North America currently dominates the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the most significant growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid industrialization and expanding aerospace sectors are creating new demand centers. These emerging markets are expected to grow at nearly twice the global average rate.

Customer segmentation shows that OEMs constitute 65% of end-users, while maintenance, repair, and overhaul (MRO) services account for 35%. This distribution highlights the dual nature of the market: new equipment manufacturing and the substantial aftermarket for replacement components.

Pricing trends indicate premium positioning for directionally solidified components, typically commanding 30-40% higher prices than conventionally cast alternatives. This premium is justified by the superior performance characteristics and extended service life, which ultimately delivers better total cost of ownership for end-users despite higher initial investment.

Market challenges include supply chain vulnerabilities for critical raw materials like rhenium, ruthenium, and other rare elements essential for superalloy production. Additionally, the specialized manufacturing infrastructure required for directional solidification processes creates high barriers to entry and potential supply constraints during periods of peak demand.

Current Challenges in Laser-Based Directional Solidification

Despite significant advancements in laser-based additive manufacturing of superalloys, directional solidification control remains a formidable challenge. The primary difficulty lies in managing the complex thermal gradients that develop during the laser melting process. Unlike traditional directional solidification methods where thermal conditions can be precisely controlled, laser-based processes create highly localized and rapidly changing thermal environments that complicate microstructure development.

Temperature gradient control presents a significant hurdle, as the steep thermal gradients characteristic of laser processing often lead to non-uniform cooling rates across the build. This results in inconsistent grain structures and orientations, compromising the mechanical properties that directional solidification aims to enhance. The rapid solidification inherent to laser processes further exacerbates this issue by limiting the time available for proper grain alignment.

Heat accumulation during multi-layer builds introduces additional complexity. As successive layers are processed, residual heat alters the thermal conditions for subsequent solidification, creating variability throughout the build height. This phenomenon, known as thermal history effect, makes consistent directional solidification particularly challenging in complex geometries with varying cross-sections.

Material-specific challenges further complicate the process. Superalloys, with their complex compositions including multiple alloying elements, exhibit segregation behaviors during rapid solidification that can lead to detrimental phase formations. The presence of elements like titanium and aluminum, critical for γ' precipitation strengthening, makes these alloys particularly sensitive to solidification conditions.

Process parameter optimization remains largely empirical rather than predictive. The interdependence of laser power, scan speed, hatch spacing, and layer thickness creates a vast parameter space that is difficult to navigate without comprehensive modeling tools. Current simulation capabilities struggle to accurately predict microstructural evolution during directional solidification in laser processes due to the multi-physics nature of the problem.

Monitoring and control systems lack the resolution and response time necessary for real-time adjustments to maintain directional solidification conditions. The millisecond-scale solidification events occur too rapidly for conventional feedback systems to respond effectively, limiting the ability to make dynamic corrections during the build process.

These challenges collectively hinder the widespread implementation of directional solidification in laser-based superalloy manufacturing, despite its potential benefits for high-temperature applications in aerospace and energy sectors. Overcoming these obstacles requires interdisciplinary approaches combining materials science, thermal engineering, and advanced process control methodologies.

Temperature gradient control presents a significant hurdle, as the steep thermal gradients characteristic of laser processing often lead to non-uniform cooling rates across the build. This results in inconsistent grain structures and orientations, compromising the mechanical properties that directional solidification aims to enhance. The rapid solidification inherent to laser processes further exacerbates this issue by limiting the time available for proper grain alignment.

Heat accumulation during multi-layer builds introduces additional complexity. As successive layers are processed, residual heat alters the thermal conditions for subsequent solidification, creating variability throughout the build height. This phenomenon, known as thermal history effect, makes consistent directional solidification particularly challenging in complex geometries with varying cross-sections.

Material-specific challenges further complicate the process. Superalloys, with their complex compositions including multiple alloying elements, exhibit segregation behaviors during rapid solidification that can lead to detrimental phase formations. The presence of elements like titanium and aluminum, critical for γ' precipitation strengthening, makes these alloys particularly sensitive to solidification conditions.

Process parameter optimization remains largely empirical rather than predictive. The interdependence of laser power, scan speed, hatch spacing, and layer thickness creates a vast parameter space that is difficult to navigate without comprehensive modeling tools. Current simulation capabilities struggle to accurately predict microstructural evolution during directional solidification in laser processes due to the multi-physics nature of the problem.

Monitoring and control systems lack the resolution and response time necessary for real-time adjustments to maintain directional solidification conditions. The millisecond-scale solidification events occur too rapidly for conventional feedback systems to respond effectively, limiting the ability to make dynamic corrections during the build process.

These challenges collectively hinder the widespread implementation of directional solidification in laser-based superalloy manufacturing, despite its potential benefits for high-temperature applications in aerospace and energy sectors. Overcoming these obstacles requires interdisciplinary approaches combining materials science, thermal engineering, and advanced process control methodologies.

Existing Methodologies for Controlling Solidification Microstructure

01 Laser parameters control for directional solidification

Controlling laser parameters such as power, scan speed, and beam diameter is crucial for achieving directional solidification in superalloy builds. These parameters influence the thermal gradient and solidification rate, which directly affect the microstructure development. By optimizing these parameters, manufacturers can promote columnar grain growth in the build direction, enhancing the mechanical properties of the final component.- Laser parameters for directional solidification: Controlling laser parameters such as power, scan speed, and beam diameter is crucial for achieving directional solidification in superalloy builds. These parameters influence the thermal gradient and solidification rate, which directly affect the microstructure development. By optimizing these parameters, it's possible to create a controlled directional solidification front that promotes columnar grain growth and preferred crystallographic orientation, enhancing the mechanical properties of the superalloy components.

- Thermal gradient control techniques: Various techniques can be employed to control thermal gradients during laser-based processing of superalloys. These include substrate preheating, secondary heat sources, cooling systems, and thermal barriers. By manipulating the thermal gradient, the solidification direction can be controlled, resulting in desired microstructural features such as columnar grains or single crystals. Proper thermal gradient control is essential for minimizing defects and achieving consistent directional solidification throughout the build.

- Alloy composition effects on solidification: The chemical composition of superalloys significantly influences their solidification behavior during laser-based processes. Elements such as aluminum, titanium, tantalum, and rhenium affect dendrite growth, segregation patterns, and phase formation. Tailoring the alloy composition can modify the solidification range, promote columnar grain growth, and enhance high-temperature properties. Understanding these compositional effects is crucial for designing superalloys specifically optimized for directional solidification in laser-based manufacturing processes.

- Microstructure development and control: Directional solidification in laser-based superalloy builds results in distinctive microstructural features that directly influence mechanical properties. These include dendritic structures, primary and secondary arm spacing, grain boundaries, and precipitate formation. Controlling these microstructural elements through process parameters enables the tailoring of mechanical properties such as creep resistance, fatigue strength, and high-temperature stability. Advanced characterization techniques help in understanding and optimizing the relationship between processing conditions and resultant microstructures.

- Novel equipment and process innovations: Innovative equipment designs and process modifications have been developed to enhance directional solidification in laser-based superalloy manufacturing. These include specialized build chambers with controlled atmospheres, multi-laser systems, advanced monitoring and control systems, and hybrid manufacturing approaches. Such innovations enable precise control over solidification conditions, resulting in improved microstructural uniformity, reduced defects, and enhanced mechanical properties in the final components.

02 Substrate heating and temperature gradient management

Maintaining appropriate temperature gradients through substrate preheating and controlled cooling is essential for directional solidification in laser-based processes. This approach creates favorable conditions for columnar grain growth by establishing a unidirectional heat flow. The controlled temperature gradient helps minimize defects and ensures consistent microstructural development throughout the build, resulting in superior mechanical properties.Expand Specific Solutions03 Alloy composition modification for improved solidification

Tailoring the chemical composition of superalloys can significantly influence their solidification behavior during laser-based manufacturing. The addition of specific elements can promote columnar grain growth, refine grain structure, or modify the solidification path. These compositional adjustments can help control segregation, prevent unwanted phases, and enhance the overall directional solidification process in laser-built superalloy components.Expand Specific Solutions04 Post-processing heat treatments for microstructure optimization

Post-build heat treatments are critical for optimizing the microstructure of directionally solidified laser-built superalloys. These treatments can homogenize the composition, relieve residual stresses, and promote desired phase transformations. Carefully designed heat treatment protocols can enhance the directional characteristics of the solidified structure, improving the mechanical properties and performance of the final components.Expand Specific Solutions05 Novel equipment designs for enhanced directional solidification

Specialized equipment designs and modifications can significantly improve directional solidification in laser-based superalloy manufacturing. These innovations include customized build chambers, advanced cooling systems, and integrated monitoring technologies. Such equipment enhancements enable better control over the solidification process, resulting in more consistent directional grain structures and improved component quality.Expand Specific Solutions

Leading Organizations in Laser Superalloy Manufacturing

The directional solidification in laser-based superalloy builds market is currently in a growth phase, with increasing adoption across aerospace and energy sectors. The global market is expanding rapidly, driven by demand for high-performance components in extreme environments. Technologically, the field shows varying maturity levels among key players. Leading companies like Siemens Energy, GE, and Rolls-Royce have achieved significant advancements in controlling microstructure development during solidification processes. Research institutions including Northwestern Polytechnical University, MIT, and Fraunhofer-Gesellschaft are pioneering fundamental research. Meanwhile, specialized manufacturers such as Renishaw and IHI Corp are developing application-specific solutions. The competitive landscape features strong collaboration between academic institutions and industrial partners, with aerospace companies increasingly investing in proprietary technologies to secure competitive advantages.

Siemens AG

Technical Solution: Siemens has developed an integrated approach to directional solidification in laser-based additive manufacturing of superalloys, focusing on precise thermal management throughout the build process. Their technology employs sophisticated thermal modeling coupled with adaptive laser control systems to maintain optimal temperature gradients for columnar grain growth. Siemens' process utilizes a combination of preheating strategies and carefully designed scan patterns to control solidification rates and directions. Their system incorporates multi-sensor monitoring that tracks both thermal conditions and resulting microstructural development in real-time, allowing for dynamic adjustments to process parameters. This approach has been successfully implemented in the production of gas turbine components, demonstrating improved high-temperature mechanical properties and extended service life compared to conventionally manufactured parts.

Strengths: Advanced thermal modeling capabilities integrated with process control; comprehensive multi-sensor monitoring system; successful implementation in power generation applications. Weaknesses: Complex system requiring significant computational resources; challenging to scale for mass production; requires specialized operator training and expertise.

Renishaw Plc

Technical Solution: Renishaw has developed a precision-focused approach to directional solidification in laser-based superalloy builds, emphasizing microstructural control through advanced laser parameter optimization. Their technology utilizes high-precision galvanometer systems coupled with sophisticated beam shaping optics to create highly controlled melt pool geometries and thermal gradients. Renishaw's process incorporates variable laser power and spot size modulation synchronized with scan speed adjustments to maintain consistent solidification conditions throughout complex geometries. Their system features in-process monitoring capabilities that track melt pool dynamics and correlate them with resulting microstructural features. Renishaw has demonstrated successful implementation of their technology in aerospace and medical applications, achieving directionally solidified structures with minimal defects and highly consistent mechanical properties across build volumes.

Strengths: Exceptional precision in laser control and beam shaping; excellent repeatability across builds; sophisticated in-process monitoring capabilities. Weaknesses: Limited build volume compared to some competitors; higher capital equipment costs; requires extensive parameter development for new materials.

Critical Patents in Laser-Based Directional Solidification

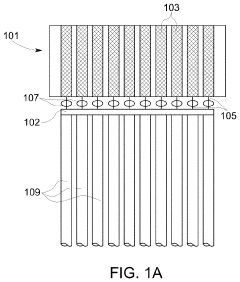

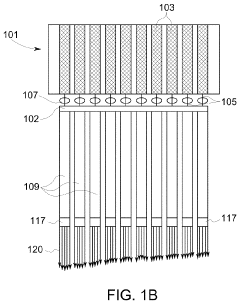

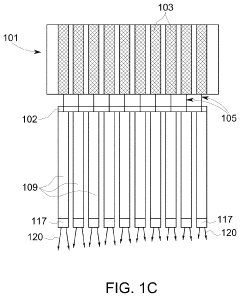

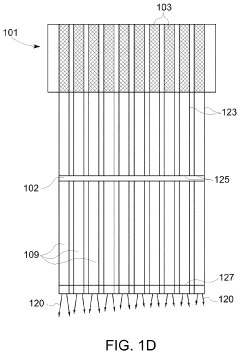

Control of solidification in laser powder bed fusion additive manufacturing using a diode laser fiber array

PatentActiveUS20200180297A1

Innovation

- A diode laser fiber array is used to emit multiple laser beams onto a powder bed, controlling temperature gradients and solidification velocities to form columnar or single crystal microstructures, allowing for simultaneous melting and precise control of cooling rates to prevent cracking and achieve desired grain structures.

Method for welding depending on a preferred direction of the substrate

PatentInactiveEP2262608A1

Innovation

- The method involves selecting the direction of travel for the substrate during laser welding to align the crystallographic directions of the solidification front with the surface normal, ensuring that the dendrite growth direction is initialized in a manner that maintains the preferred crystal orientation, thereby preventing the loss of epitaxy.

Material Property Optimization Through Process Parameters

The optimization of material properties in laser-based superalloy builds requires a systematic approach to process parameter selection. Laser power, scan speed, hatch spacing, and layer thickness constitute the primary variables that directly influence the directional solidification behavior. These parameters determine the thermal gradient and solidification rate, which in turn affect the microstructure development and resultant mechanical properties.

Research indicates that higher laser power combined with moderate scan speeds promotes columnar grain growth parallel to the build direction, enhancing high-temperature creep resistance. Conversely, faster scan speeds with lower power settings tend to produce more equiaxed grain structures, which may improve fatigue performance at the expense of directional properties. The energy density equation (E = P/(v×h×t), where P is laser power, v is scan speed, h is hatch spacing, and t is layer thickness) provides a useful framework for parameter optimization.

Recent studies have demonstrated that pulsed laser modes offer superior control over the solidification front compared to continuous wave operation. By manipulating pulse duration and frequency, researchers have achieved more consistent directional solidification with reduced defect formation. The cooling rate between pulses allows for controlled nucleation and growth of precipitate phases critical to superalloy performance.

Pre-heating the build platform to temperatures between 800-1000°C has shown significant improvements in maintaining directional solidification throughout the build process. This reduces thermal gradients between layers and minimizes residual stress accumulation, which can disrupt the preferred crystallographic orientation. Platform rotation during the build process has also emerged as an innovative approach to enhance directional properties in complex geometries.

Post-process heat treatments must be carefully integrated with the initial build parameters. The as-built microstructure, determined by the laser parameters, significantly influences the response to subsequent heat treatments. Optimized solution and aging cycles can enhance the γ' precipitate distribution while maintaining the directional grain structure established during the build process.

Computational modeling has become essential for parameter optimization, with high-fidelity thermal-mechanical models now capable of predicting grain structure evolution based on process parameters. These models incorporate Cellular Automata and Phase Field approaches to simulate competitive grain growth during directional solidification, enabling more efficient parameter selection without extensive experimental trials.

Research indicates that higher laser power combined with moderate scan speeds promotes columnar grain growth parallel to the build direction, enhancing high-temperature creep resistance. Conversely, faster scan speeds with lower power settings tend to produce more equiaxed grain structures, which may improve fatigue performance at the expense of directional properties. The energy density equation (E = P/(v×h×t), where P is laser power, v is scan speed, h is hatch spacing, and t is layer thickness) provides a useful framework for parameter optimization.

Recent studies have demonstrated that pulsed laser modes offer superior control over the solidification front compared to continuous wave operation. By manipulating pulse duration and frequency, researchers have achieved more consistent directional solidification with reduced defect formation. The cooling rate between pulses allows for controlled nucleation and growth of precipitate phases critical to superalloy performance.

Pre-heating the build platform to temperatures between 800-1000°C has shown significant improvements in maintaining directional solidification throughout the build process. This reduces thermal gradients between layers and minimizes residual stress accumulation, which can disrupt the preferred crystallographic orientation. Platform rotation during the build process has also emerged as an innovative approach to enhance directional properties in complex geometries.

Post-process heat treatments must be carefully integrated with the initial build parameters. The as-built microstructure, determined by the laser parameters, significantly influences the response to subsequent heat treatments. Optimized solution and aging cycles can enhance the γ' precipitate distribution while maintaining the directional grain structure established during the build process.

Computational modeling has become essential for parameter optimization, with high-fidelity thermal-mechanical models now capable of predicting grain structure evolution based on process parameters. These models incorporate Cellular Automata and Phase Field approaches to simulate competitive grain growth during directional solidification, enabling more efficient parameter selection without extensive experimental trials.

Environmental Impact of Laser Superalloy Manufacturing Processes

The environmental impact of laser-based superalloy manufacturing processes represents a critical consideration in the broader adoption of these advanced technologies. Directional solidification in laser-based superalloy builds, while offering superior mechanical properties, introduces specific environmental challenges that must be addressed for sustainable implementation.

Energy consumption stands as a primary environmental concern, with laser-based manufacturing processes requiring significant electrical power for operation. The high-energy lasers needed to achieve directional solidification in superalloys typically consume between 1-10 kW of power, contributing substantially to the carbon footprint of manufacturing operations. This energy intensity is particularly pronounced during the precise thermal control required for directional grain growth.

Material efficiency presents both challenges and opportunities. While laser-based processes can achieve near-net-shape components, reducing material waste compared to traditional subtractive manufacturing, the production of superalloy powders involves energy-intensive atomization processes. The environmental impact of powder production must be factored into lifecycle assessments, especially considering the rare and strategic elements often incorporated in superalloys.

Emissions from laser-based superalloy manufacturing include metal vapors, nanoparticles, and process gases that require sophisticated filtration systems. The directional solidification process can generate volatile compounds from alloying elements such as chromium, cobalt, and nickel, which present potential environmental and health hazards if not properly contained and treated.

Water usage for cooling systems represents another environmental consideration. The precise thermal management required for directional solidification necessitates efficient cooling systems, which traditionally consume significant water resources. Closed-loop cooling technologies are increasingly being implemented to mitigate this impact.

Waste management challenges include the handling of unused powder materials, which may contain environmentally sensitive elements. Recycling protocols for these materials are advancing but remain technically challenging due to potential contamination and oxidation issues that can affect the directional solidification behavior in subsequent builds.

Comparative lifecycle analyses indicate that despite these challenges, laser-based processes with directional solidification capabilities often demonstrate lower overall environmental impacts than conventional manufacturing when considering the entire product lifecycle. The improved performance and longevity of components with directionally solidified microstructures can offset initial manufacturing impacts through extended service life and improved efficiency in high-temperature applications.

Energy consumption stands as a primary environmental concern, with laser-based manufacturing processes requiring significant electrical power for operation. The high-energy lasers needed to achieve directional solidification in superalloys typically consume between 1-10 kW of power, contributing substantially to the carbon footprint of manufacturing operations. This energy intensity is particularly pronounced during the precise thermal control required for directional grain growth.

Material efficiency presents both challenges and opportunities. While laser-based processes can achieve near-net-shape components, reducing material waste compared to traditional subtractive manufacturing, the production of superalloy powders involves energy-intensive atomization processes. The environmental impact of powder production must be factored into lifecycle assessments, especially considering the rare and strategic elements often incorporated in superalloys.

Emissions from laser-based superalloy manufacturing include metal vapors, nanoparticles, and process gases that require sophisticated filtration systems. The directional solidification process can generate volatile compounds from alloying elements such as chromium, cobalt, and nickel, which present potential environmental and health hazards if not properly contained and treated.

Water usage for cooling systems represents another environmental consideration. The precise thermal management required for directional solidification necessitates efficient cooling systems, which traditionally consume significant water resources. Closed-loop cooling technologies are increasingly being implemented to mitigate this impact.

Waste management challenges include the handling of unused powder materials, which may contain environmentally sensitive elements. Recycling protocols for these materials are advancing but remain technically challenging due to potential contamination and oxidation issues that can affect the directional solidification behavior in subsequent builds.

Comparative lifecycle analyses indicate that despite these challenges, laser-based processes with directional solidification capabilities often demonstrate lower overall environmental impacts than conventional manufacturing when considering the entire product lifecycle. The improved performance and longevity of components with directionally solidified microstructures can offset initial manufacturing impacts through extended service life and improved efficiency in high-temperature applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!