Case Study: Printing A Turbine Nozzle Inner Structure Using PBF-LB

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PBF-LB Technology Evolution for Turbine Components

The evolution of Powder Bed Fusion-Laser Beam (PBF-LB) technology for turbine components represents a significant advancement in additive manufacturing capabilities for the aerospace and power generation industries. Initially developed in the 1990s as a prototyping technology, PBF-LB has undergone substantial transformation to become a viable production method for critical turbine components.

Early iterations of PBF-LB systems in the 2000s were limited by build volume constraints, material options primarily restricted to tool steels and titanium alloys, and relatively poor surface finish. These systems operated with laser powers typically below 200W, resulting in slow build rates and limited penetration capabilities for dense metal components like turbine nozzles.

The period between 2010-2015 marked a crucial transition phase when multi-laser systems emerged, enabling faster build rates and improved thermal management. Material development accelerated during this period, with specialized nickel-based superalloys being qualified for high-temperature applications in turbine components. Parameter optimization techniques also evolved, allowing for better control of microstructure and mechanical properties.

From 2015-2020, significant breakthroughs occurred in process monitoring and control systems. In-situ monitoring capabilities were integrated into PBF-LB machines, enabling real-time quality assurance critical for aerospace certification. Laser power capabilities increased to 500-1000W, allowing for faster deposition rates and better fusion of high-temperature alloys required for turbine nozzles.

The most recent developments (2020-present) have focused on specialized parameter sets for complex internal cooling channels in turbine nozzles. Advanced scanning strategies such as contour-hatch-support combinations have been developed specifically for thin-walled structures with complex internal geometries. Multi-scale optimization approaches now enable engineers to simultaneously address macro-geometry and micro-structure considerations.

Parallel to hardware advancements, simulation capabilities have evolved from simple thermal models to comprehensive multi-physics platforms that can predict residual stress, distortion, and microstructure formation in turbine components. These tools have been crucial for reducing the empirical trial-and-error approach previously required for new component development.

The integration of machine learning algorithms for parameter optimization represents the cutting edge of PBF-LB evolution. These systems analyze vast process data sets to identify optimal parameter combinations for specific geometrical features common in turbine nozzles, such as thin overhangs, small cooling holes, and complex internal lattice structures.

Early iterations of PBF-LB systems in the 2000s were limited by build volume constraints, material options primarily restricted to tool steels and titanium alloys, and relatively poor surface finish. These systems operated with laser powers typically below 200W, resulting in slow build rates and limited penetration capabilities for dense metal components like turbine nozzles.

The period between 2010-2015 marked a crucial transition phase when multi-laser systems emerged, enabling faster build rates and improved thermal management. Material development accelerated during this period, with specialized nickel-based superalloys being qualified for high-temperature applications in turbine components. Parameter optimization techniques also evolved, allowing for better control of microstructure and mechanical properties.

From 2015-2020, significant breakthroughs occurred in process monitoring and control systems. In-situ monitoring capabilities were integrated into PBF-LB machines, enabling real-time quality assurance critical for aerospace certification. Laser power capabilities increased to 500-1000W, allowing for faster deposition rates and better fusion of high-temperature alloys required for turbine nozzles.

The most recent developments (2020-present) have focused on specialized parameter sets for complex internal cooling channels in turbine nozzles. Advanced scanning strategies such as contour-hatch-support combinations have been developed specifically for thin-walled structures with complex internal geometries. Multi-scale optimization approaches now enable engineers to simultaneously address macro-geometry and micro-structure considerations.

Parallel to hardware advancements, simulation capabilities have evolved from simple thermal models to comprehensive multi-physics platforms that can predict residual stress, distortion, and microstructure formation in turbine components. These tools have been crucial for reducing the empirical trial-and-error approach previously required for new component development.

The integration of machine learning algorithms for parameter optimization represents the cutting edge of PBF-LB evolution. These systems analyze vast process data sets to identify optimal parameter combinations for specific geometrical features common in turbine nozzles, such as thin overhangs, small cooling holes, and complex internal lattice structures.

Market Analysis for Additive Manufactured Turbine Nozzles

The global market for additively manufactured turbine nozzles is experiencing significant growth, driven by the aerospace, power generation, and industrial gas turbine sectors. Current market valuations indicate that the aerospace turbine components manufactured using additive manufacturing techniques represent approximately 12% of the total aerospace AM market, which reached $2.7 billion in 2022. Within this segment, turbine nozzles are becoming increasingly important due to their complex geometries and critical performance requirements.

Market demand for AM turbine nozzles is primarily fueled by the need for improved fuel efficiency, reduced emissions, and enhanced performance in modern turbine engines. The commercial aviation sector, with its push toward more sustainable operations, represents the largest market segment, followed by military aerospace applications and land-based power generation systems. Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%), with the latter showing the fastest growth rate at 18% annually.

The PBF-LB (Powder Bed Fusion - Laser Beam) technology specifically for turbine nozzle inner structures has demonstrated compelling market advantages. End-users report 30-40% weight reduction in components, 15-25% improvement in cooling efficiency, and production lead time reductions of up to 60% compared to conventional manufacturing methods. These benefits translate directly to operational cost savings for airlines and power generation companies, estimated at $3-5 million annually per fleet for major operators.

Market segmentation reveals distinct customer profiles: OEMs seeking design innovation and performance improvements; MRO (Maintenance, Repair, and Overhaul) providers looking for faster turnaround times and cost-effective replacement parts; and aftermarket suppliers targeting the growing retrofit market. Each segment presents unique requirements and growth opportunities, with the MRO segment showing the highest projected CAGR of 22% through 2028.

Pricing analysis indicates that while initial costs for AM turbine nozzles remain 30-45% higher than traditionally manufactured counterparts, the total cost of ownership over the component lifecycle is approximately 20% lower due to extended service life, reduced maintenance requirements, and fuel savings. This value proposition is driving adoption despite higher upfront investments.

Market forecasts project the global AM turbine nozzle market to grow at a CAGR of 17.5% from 2023 to 2030, reaching a market value of $1.2 billion by 2030. The PBF-LB technology segment specifically is expected to maintain a dominant position with 65% market share due to its superior capability in producing the complex inner cooling structures essential for high-performance turbine nozzles.

Market demand for AM turbine nozzles is primarily fueled by the need for improved fuel efficiency, reduced emissions, and enhanced performance in modern turbine engines. The commercial aviation sector, with its push toward more sustainable operations, represents the largest market segment, followed by military aerospace applications and land-based power generation systems. Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%), with the latter showing the fastest growth rate at 18% annually.

The PBF-LB (Powder Bed Fusion - Laser Beam) technology specifically for turbine nozzle inner structures has demonstrated compelling market advantages. End-users report 30-40% weight reduction in components, 15-25% improvement in cooling efficiency, and production lead time reductions of up to 60% compared to conventional manufacturing methods. These benefits translate directly to operational cost savings for airlines and power generation companies, estimated at $3-5 million annually per fleet for major operators.

Market segmentation reveals distinct customer profiles: OEMs seeking design innovation and performance improvements; MRO (Maintenance, Repair, and Overhaul) providers looking for faster turnaround times and cost-effective replacement parts; and aftermarket suppliers targeting the growing retrofit market. Each segment presents unique requirements and growth opportunities, with the MRO segment showing the highest projected CAGR of 22% through 2028.

Pricing analysis indicates that while initial costs for AM turbine nozzles remain 30-45% higher than traditionally manufactured counterparts, the total cost of ownership over the component lifecycle is approximately 20% lower due to extended service life, reduced maintenance requirements, and fuel savings. This value proposition is driving adoption despite higher upfront investments.

Market forecasts project the global AM turbine nozzle market to grow at a CAGR of 17.5% from 2023 to 2030, reaching a market value of $1.2 billion by 2030. The PBF-LB technology segment specifically is expected to maintain a dominant position with 65% market share due to its superior capability in producing the complex inner cooling structures essential for high-performance turbine nozzles.

Technical Challenges in PBF-LB Turbine Nozzle Fabrication

The fabrication of turbine nozzle inner structures using Powder Bed Fusion-Laser Beam (PBF-LB) technology presents numerous technical challenges that must be overcome to achieve high-quality components. One of the primary difficulties lies in the complex geometry of turbine nozzles, which often feature intricate internal cooling channels, thin walls, and variable cross-sections. These geometrical complexities create significant challenges for the PBF-LB process, particularly in maintaining dimensional accuracy and surface quality.

Material selection poses another substantial challenge. Turbine nozzles typically require superalloys such as Inconel 718 or CM247LC, which exhibit excellent high-temperature properties but are notoriously difficult to process using PBF-LB. These materials tend to develop thermal stresses and cracking during fabrication due to their low thermal conductivity and high thermal expansion coefficients.

The thermal management during the PBF-LB process represents a critical challenge. The localized high-energy laser input creates steep thermal gradients that can lead to residual stresses, distortion, and potentially part failure. For turbine nozzle components with thin walls and complex internal features, these thermal effects are particularly problematic and can compromise the structural integrity of the final part.

Support structure design and removal present unique difficulties for internal nozzle geometries. The internal channels and cavities often require supports during fabrication, yet these supports must be accessible for removal post-processing. This creates a design paradox where supports are necessary for successful printing but may be impossible to remove from internal structures without compromising the component.

Powder removal from internal channels represents another significant technical hurdle. The complex internal geometries of turbine nozzles often include narrow passages and blind holes where unfused powder can become trapped. Complete powder removal is essential for proper functionality, yet achieving this in complex internal structures remains challenging.

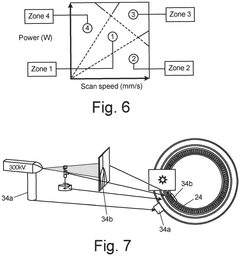

Process parameter optimization for PBF-LB turbine nozzle fabrication requires extensive experimentation. Parameters such as laser power, scan speed, hatch spacing, and layer thickness must be precisely calibrated to achieve the desired microstructure and mechanical properties while minimizing defects such as porosity, lack of fusion, and cracking.

Post-processing operations add another layer of complexity. Heat treatments are necessary to relieve residual stresses and achieve the required microstructure, but these treatments must be carefully designed to prevent distortion. Surface finishing of internal channels presents particular difficulties due to limited accessibility, yet is crucial for aerodynamic performance and durability of the nozzle.

Quality control and inspection of internal features remain challenging with conventional non-destructive testing methods often proving inadequate for complex internal geometries. Advanced techniques such as X-ray computed tomography are necessary but add significant cost and complexity to the manufacturing process.

Material selection poses another substantial challenge. Turbine nozzles typically require superalloys such as Inconel 718 or CM247LC, which exhibit excellent high-temperature properties but are notoriously difficult to process using PBF-LB. These materials tend to develop thermal stresses and cracking during fabrication due to their low thermal conductivity and high thermal expansion coefficients.

The thermal management during the PBF-LB process represents a critical challenge. The localized high-energy laser input creates steep thermal gradients that can lead to residual stresses, distortion, and potentially part failure. For turbine nozzle components with thin walls and complex internal features, these thermal effects are particularly problematic and can compromise the structural integrity of the final part.

Support structure design and removal present unique difficulties for internal nozzle geometries. The internal channels and cavities often require supports during fabrication, yet these supports must be accessible for removal post-processing. This creates a design paradox where supports are necessary for successful printing but may be impossible to remove from internal structures without compromising the component.

Powder removal from internal channels represents another significant technical hurdle. The complex internal geometries of turbine nozzles often include narrow passages and blind holes where unfused powder can become trapped. Complete powder removal is essential for proper functionality, yet achieving this in complex internal structures remains challenging.

Process parameter optimization for PBF-LB turbine nozzle fabrication requires extensive experimentation. Parameters such as laser power, scan speed, hatch spacing, and layer thickness must be precisely calibrated to achieve the desired microstructure and mechanical properties while minimizing defects such as porosity, lack of fusion, and cracking.

Post-processing operations add another layer of complexity. Heat treatments are necessary to relieve residual stresses and achieve the required microstructure, but these treatments must be carefully designed to prevent distortion. Surface finishing of internal channels presents particular difficulties due to limited accessibility, yet is crucial for aerodynamic performance and durability of the nozzle.

Quality control and inspection of internal features remain challenging with conventional non-destructive testing methods often proving inadequate for complex internal geometries. Advanced techniques such as X-ray computed tomography are necessary but add significant cost and complexity to the manufacturing process.

Current PBF-LB Solutions for Turbine Nozzle Inner Structures

01 Lattice and cellular structures in PBF-LB

Powder Bed Fusion - Laser Beam technology enables the creation of complex lattice and cellular internal structures that provide lightweight yet strong components. These structures can be designed with varying densities, cell sizes, and geometries to optimize mechanical properties such as strength-to-weight ratio, energy absorption, and thermal conductivity. Advanced algorithms allow for the generation of biomimetic lattices that can be tailored for specific load cases and functional requirements.- Lattice and cellular inner structures in PBF-LB: Powder Bed Fusion-Laser Beam technology enables the creation of complex lattice and cellular inner structures that provide lightweight yet strong components. These structures can be designed with varying densities, cell sizes, and geometries to optimize mechanical properties such as strength-to-weight ratio, energy absorption, and thermal conductivity. Advanced algorithms allow for the generation of topology-optimized lattice structures that can be tailored for specific loading conditions and functional requirements.

- Support structures and build orientation optimization: Internal support structures are critical in PBF-LB processes to manage thermal stresses and prevent distortion during fabrication. These structures must be strategically designed and positioned to support overhanging features while being removable post-processing. Build orientation optimization algorithms analyze part geometry to determine the optimal positioning that minimizes the need for supports while maintaining structural integrity. Advanced software tools can automatically generate optimized support structures based on thermal simulation and mechanical stress analysis.

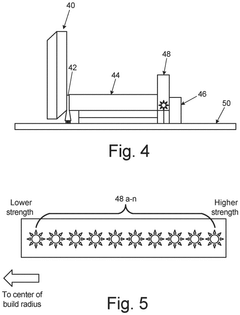

- Functionally graded materials and structures: PBF-LB technology enables the creation of functionally graded inner structures where material composition, density, or microstructure gradually changes throughout the part. This approach allows for tailored mechanical, thermal, or electrical properties in different regions of the same component. By controlling laser parameters, scan strategies, and powder distribution, engineers can create components with varying porosity levels, hardness gradients, or thermal expansion characteristics to meet specific application requirements.

- Internal cooling channels and fluid flow optimization: Advanced PBF-LB processes enable the fabrication of complex internal cooling channels and fluid pathways that would be impossible to create using conventional manufacturing methods. These conformal cooling designs can follow the contours of the part, optimizing heat transfer efficiency. Computational fluid dynamics simulations guide the design of these internal structures to enhance thermal management in applications such as injection molds, heat exchangers, and high-performance components for aerospace and automotive industries.

- Process monitoring and quality control for inner structures: Ensuring the quality of internal structures in PBF-LB manufactured parts requires advanced monitoring and control systems. In-situ monitoring technologies such as thermal imaging, optical tomography, and acoustic sensors can detect defects during the build process. Machine learning algorithms analyze this data to identify anomalies like porosity, lack of fusion, or cracks within the internal structure. Post-processing techniques including heat treatment and hot isostatic pressing can be applied to improve the density and mechanical properties of the inner structures.

02 Support structures and build orientation optimization

Internal support structures are critical in PBF-LB processes to manage thermal stresses and prevent distortion during fabrication. Innovative approaches include self-supporting geometries, dissolvable internal supports, and orientation optimization algorithms that minimize the need for supports while maintaining structural integrity. These techniques reduce post-processing requirements and material waste while enabling the production of complex internal features that would be impossible with conventional manufacturing methods.Expand Specific Solutions03 Functionally graded materials and structures

PBF-LB technology allows for the creation of functionally graded internal structures where material composition, density, or microstructure can be varied throughout a component. This enables optimization of mechanical properties, thermal management, and weight distribution within a single part. By strategically controlling laser parameters, scan strategies, and powder distribution, engineers can design components with tailored properties in specific regions to meet complex performance requirements.Expand Specific Solutions04 Internal cooling channels and thermal management

Advanced PBF-LB processes enable the fabrication of complex internal cooling channels and heat exchangers that cannot be produced using conventional manufacturing methods. These conformal cooling structures can follow the contours of the part, featuring optimized geometries such as helical passages, pin-fin arrays, and micro-channels. Such designs enhance heat transfer efficiency, reduce thermal gradients, and improve overall performance in applications like injection molds, turbine components, and heat exchangers.Expand Specific Solutions05 Process monitoring and quality control for internal features

Ensuring the quality of internal structures in PBF-LB parts requires advanced monitoring and control systems. In-situ monitoring technologies such as melt pool monitoring, layer-wise imaging, and acoustic emission analysis help detect defects during the build process. Post-build inspection methods including CT scanning, ultrasonic testing, and eddy current analysis enable verification of internal feature integrity. These quality control approaches are essential for critical applications where internal defects could lead to catastrophic failure.Expand Specific Solutions

Leading Manufacturers in PBF-LB Turbine Component Production

The additive manufacturing market for turbine nozzle inner structures using Powder Bed Fusion-Laser Beam (PBF-LB) technology is in a growth phase, with increasing adoption across aerospace and energy sectors. The global market size for this application is expanding rapidly, driven by demands for higher efficiency and performance in turbine systems. Leading players include General Electric, Safran Aircraft Engines, and Rolls-Royce, who have achieved high technical maturity in implementing PBF-LB for critical turbine components. Companies like IHI Corp, Ansaldo Energia, and Hitachi are advancing their capabilities, while research institutions such as King Abdullah University of Science & Technology contribute to technological innovation. The technology maturity varies across players, with aerospace OEMs generally leading implementation while industrial equipment manufacturers are rapidly closing the gap.

General Electric Company

Technical Solution: GE has developed advanced Powder Bed Fusion-Laser Beam (PBF-LB) technology specifically for manufacturing complex turbine nozzle inner structures. Their approach utilizes high-powered fiber lasers (400-1000W) with precise beam control systems to selectively melt metal powder layers as thin as 20-60 microns. GE's proprietary parameter optimization includes specialized scanning strategies that address the complex cooling channels and internal geometries of turbine nozzles. Their process incorporates in-situ monitoring with thermal imaging cameras and photodiodes to detect anomalies during printing, ensuring consistent quality. GE has also developed specialized post-processing techniques including Hot Isostatic Pressing (HIP) to eliminate internal porosity and specialized heat treatments to optimize the microstructure of nickel-based superalloys commonly used in turbine applications. Their integrated digital workflow connects design, simulation, and manufacturing to predict and compensate for distortion during the build process.

Strengths: Industry-leading expertise in aviation-grade components with proven implementation in commercial engines; comprehensive vertical integration from powder development to final part qualification; proprietary parameter sets for nickel-based superalloys. Weaknesses: Higher capital investment requirements; longer development cycles for parameter optimization; process can be material-specific requiring extensive validation for each new alloy.

IHI Corp.

Technical Solution: IHI has developed a specialized PBF-LB approach for turbine nozzle inner structures that focuses on optimizing internal cooling channel geometries. Their technology utilizes medium-powered fiber lasers (300-500W) with specialized beam shaping optics to achieve consistent melt pool characteristics across varying feature sizes. IHI's process incorporates advanced powder spreading mechanisms with ultrasonic assistance to achieve uniform powder beds even with challenging superalloy powders that tend to agglomerate. Their manufacturing methodology includes specialized parameter sets for thin-walled structures (down to 0.3mm) that maintain mechanical integrity while maximizing heat transfer efficiency. IHI has developed proprietary build strategies that minimize the need for internal supports within cooling channels, reducing post-processing complexity and improving surface finish in areas inaccessible to conventional finishing techniques. Their quality control system incorporates specialized fluid flow testing and thermal imaging to validate cooling effectiveness before final assembly. IHI's approach includes integrated stress relief heat treatments performed in-situ during the build process to minimize distortion in complex geometries.

Strengths: Specialized expertise in gas turbine cooling technologies; proven implementation in industrial power generation systems; advanced capabilities in thin-walled structures with complex internal geometries. Weaknesses: More limited global support infrastructure compared to larger competitors; process optimization primarily focused on specific alloy systems; higher unit costs for smaller production volumes.

Key Patents and Research in PBF-LB Turbine Applications

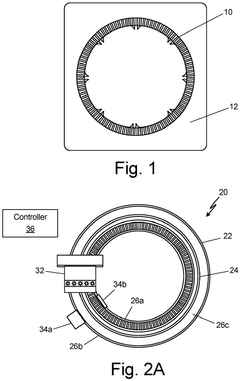

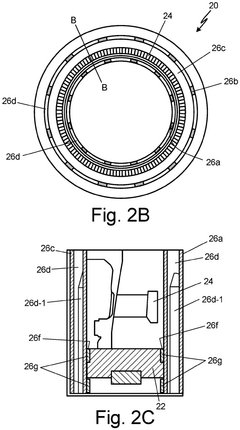

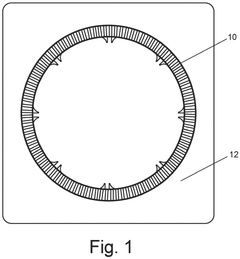

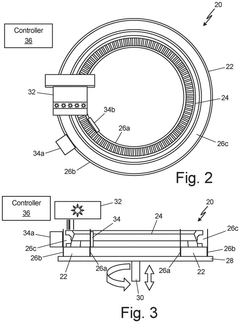

Shrouded build plate for powder bed fusion additive printer

PatentPendingEP4484130A1

Innovation

- An annular build plate with inner and outer radius walls featuring apertures to collect and direct excess powder to a reservoir, combined with a rotating and translating build piston, allows for continuous, helical layer formation and efficient powder utilization.

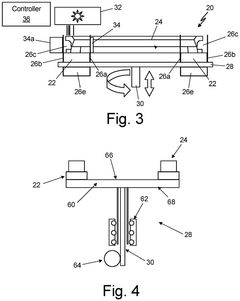

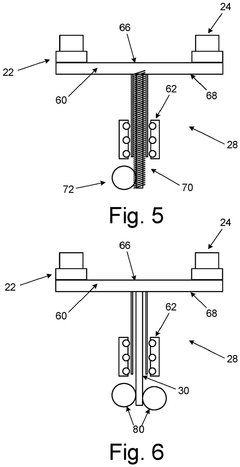

Powder bed fusion additive printer with integrated inspection

PatentPendingEP4484127A1

Innovation

- A PBF additive manufacturing system with an annular build plate and a rotating build piston that translates and rotates continuously, combined with an integrated X-ray CT system for in-situ inspection, and a multi-function build head featuring a powder delivery mechanism, recoater, and optical array for even energy distribution and consolidation.

Material Selection Considerations for Turbine Nozzle Printing

Material selection for turbine nozzle components in Powder Bed Fusion Laser Beam (PBF-LB) processes requires careful consideration of multiple factors due to the extreme operating conditions these components face. High-performance nickel-based superalloys, particularly Inconel 718 and Inconel 625, have emerged as primary candidates due to their exceptional high-temperature strength, oxidation resistance, and thermal stability up to 700°C.

These superalloys maintain mechanical integrity under the severe thermal cycling and stress conditions typical in turbine environments. Their composition, featuring nickel matrices strengthened by precipitates of niobium, titanium, and aluminum, creates microstructures that resist creep deformation at elevated temperatures - a critical requirement for turbine nozzle applications.

When implementing PBF-LB for turbine nozzle manufacturing, powder characteristics significantly impact print quality. Optimal particle size distribution (typically 15-45 μm) ensures proper flowability and packing density. Spherical morphology and minimal satellite formations are essential for achieving consistent layer deposition and reducing defect formation during the printing process.

The thermal conductivity of selected materials directly influences the laser parameter optimization. Materials with lower thermal conductivity, like nickel superalloys, require careful calibration of laser power, scan speed, and hatch spacing to prevent overheating while ensuring adequate fusion between layers. This balance is crucial for achieving the complex internal cooling channels characteristic of advanced turbine nozzle designs.

Post-processing heat treatments are indispensable for optimizing the microstructure of printed components. Solution annealing followed by aging treatments helps homogenize the microstructure, relieve residual stresses, and develop the strengthening precipitates necessary for high-temperature performance. Hot Isostatic Pressing (HIP) is frequently employed to eliminate internal porosity that could otherwise serve as crack initiation sites during service.

Surface finishing considerations cannot be overlooked, as turbine nozzles require specific surface roughness values to maintain aerodynamic efficiency. Techniques such as chemical etching, electropolishing, or abrasive flow machining may be necessary to achieve the required surface quality, particularly for internal cooling passages that are inaccessible to conventional machining methods.

Recent research has explored the potential of refractory metal additions and oxide dispersion strengthened (ODS) variants to push temperature capabilities beyond current limitations. These advanced material systems may enable next-generation turbine designs operating at even higher temperatures, further improving engine efficiency and performance.

These superalloys maintain mechanical integrity under the severe thermal cycling and stress conditions typical in turbine environments. Their composition, featuring nickel matrices strengthened by precipitates of niobium, titanium, and aluminum, creates microstructures that resist creep deformation at elevated temperatures - a critical requirement for turbine nozzle applications.

When implementing PBF-LB for turbine nozzle manufacturing, powder characteristics significantly impact print quality. Optimal particle size distribution (typically 15-45 μm) ensures proper flowability and packing density. Spherical morphology and minimal satellite formations are essential for achieving consistent layer deposition and reducing defect formation during the printing process.

The thermal conductivity of selected materials directly influences the laser parameter optimization. Materials with lower thermal conductivity, like nickel superalloys, require careful calibration of laser power, scan speed, and hatch spacing to prevent overheating while ensuring adequate fusion between layers. This balance is crucial for achieving the complex internal cooling channels characteristic of advanced turbine nozzle designs.

Post-processing heat treatments are indispensable for optimizing the microstructure of printed components. Solution annealing followed by aging treatments helps homogenize the microstructure, relieve residual stresses, and develop the strengthening precipitates necessary for high-temperature performance. Hot Isostatic Pressing (HIP) is frequently employed to eliminate internal porosity that could otherwise serve as crack initiation sites during service.

Surface finishing considerations cannot be overlooked, as turbine nozzles require specific surface roughness values to maintain aerodynamic efficiency. Techniques such as chemical etching, electropolishing, or abrasive flow machining may be necessary to achieve the required surface quality, particularly for internal cooling passages that are inaccessible to conventional machining methods.

Recent research has explored the potential of refractory metal additions and oxide dispersion strengthened (ODS) variants to push temperature capabilities beyond current limitations. These advanced material systems may enable next-generation turbine designs operating at even higher temperatures, further improving engine efficiency and performance.

Post-Processing Requirements for PBF-LB Turbine Components

Post-processing is a critical phase in the manufacturing of turbine nozzle inner structures using Powder Bed Fusion-Laser Beam (PBF-LB) technology. The complex geometries and demanding performance requirements of turbine components necessitate meticulous post-processing procedures to ensure functional integrity and operational reliability.

Support structure removal represents the initial post-processing challenge for PBF-LB turbine nozzles. These structures, essential during printing to prevent distortion and provide thermal management, must be carefully removed without compromising the delicate internal passages that characterize turbine nozzle designs. Advanced techniques including wire Electrical Discharge Machining (EDM) and precision mechanical methods are typically employed for this purpose.

Surface finishing requirements for turbine components are exceptionally stringent due to their aerodynamic functionality. The as-built surface roughness from PBF-LB processes (typically Ra 5-15μm) must be reduced to Ra 0.8-1.6μm for optimal fluid dynamics within the nozzle passages. Techniques such as abrasive flow machining, chemical polishing, and vibratory finishing are commonly utilized, with particular attention paid to maintaining dimensional accuracy of internal cooling channels.

Heat treatment constitutes another essential post-processing step for PBF-LB turbine nozzles. Stress relief treatments (typically 650-700°C for nickel superalloys) are mandatory to address residual stresses from the rapid heating and cooling cycles inherent to the PBF-LB process. Additionally, solution treatment and aging processes are often required to optimize the microstructure and mechanical properties for high-temperature applications.

Dimensional verification and quality control represent the final critical post-processing requirements. Advanced metrology techniques including computed tomography (CT) scanning and coordinate measuring machines (CMM) are employed to verify that internal passages maintain design specifications after all post-processing operations. Non-destructive testing methods such as X-ray inspection and penetrant testing are also essential to identify any subsurface defects or cracks that could lead to premature failure.

The economic implications of these post-processing requirements are significant, often accounting for 40-60% of the total manufacturing cost for PBF-LB turbine components. This cost factor drives ongoing research into in-situ process monitoring and control systems that could potentially reduce post-processing requirements while maintaining component integrity and performance characteristics.

Support structure removal represents the initial post-processing challenge for PBF-LB turbine nozzles. These structures, essential during printing to prevent distortion and provide thermal management, must be carefully removed without compromising the delicate internal passages that characterize turbine nozzle designs. Advanced techniques including wire Electrical Discharge Machining (EDM) and precision mechanical methods are typically employed for this purpose.

Surface finishing requirements for turbine components are exceptionally stringent due to their aerodynamic functionality. The as-built surface roughness from PBF-LB processes (typically Ra 5-15μm) must be reduced to Ra 0.8-1.6μm for optimal fluid dynamics within the nozzle passages. Techniques such as abrasive flow machining, chemical polishing, and vibratory finishing are commonly utilized, with particular attention paid to maintaining dimensional accuracy of internal cooling channels.

Heat treatment constitutes another essential post-processing step for PBF-LB turbine nozzles. Stress relief treatments (typically 650-700°C for nickel superalloys) are mandatory to address residual stresses from the rapid heating and cooling cycles inherent to the PBF-LB process. Additionally, solution treatment and aging processes are often required to optimize the microstructure and mechanical properties for high-temperature applications.

Dimensional verification and quality control represent the final critical post-processing requirements. Advanced metrology techniques including computed tomography (CT) scanning and coordinate measuring machines (CMM) are employed to verify that internal passages maintain design specifications after all post-processing operations. Non-destructive testing methods such as X-ray inspection and penetrant testing are also essential to identify any subsurface defects or cracks that could lead to premature failure.

The economic implications of these post-processing requirements are significant, often accounting for 40-60% of the total manufacturing cost for PBF-LB turbine components. This cost factor drives ongoing research into in-situ process monitoring and control systems that could potentially reduce post-processing requirements while maintaining component integrity and performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!