Qualification Pathways For Flight-Critical PBF-LB Superalloy Parts

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PBF-LB Superalloy Technology Background and Objectives

Powder Bed Fusion-Laser Beam (PBF-LB) technology has emerged as a revolutionary manufacturing process in the aerospace industry, particularly for producing complex superalloy components with enhanced performance characteristics. The evolution of this technology spans over three decades, beginning with rudimentary selective laser sintering in the 1990s and progressing to today's sophisticated PBF-LB systems capable of producing flight-critical parts with exceptional mechanical properties and microstructural integrity.

The technological trajectory of PBF-LB for superalloys has been marked by significant advancements in laser technology, powder metallurgy, process monitoring, and computational modeling. Early applications were limited to prototyping and non-critical components due to inconsistent material properties and process reliability concerns. However, continuous refinements in process parameters, powder characterization, and in-situ monitoring have elevated this technology to a point where qualification for flight-critical applications is now within reach.

Current trends in PBF-LB superalloy development focus on expanding the processability of challenging materials such as nickel-based superalloys (Inconel 718, 625), cobalt-chrome alloys, and titanium aluminides that offer superior high-temperature performance and oxidation resistance critical for aerospace applications. The industry is witnessing a shift from empirical process development toward physics-based modeling approaches that enable predictive capabilities for microstructure and property development.

The primary technical objective for qualification pathways of flight-critical PBF-LB superalloy parts centers on establishing robust, repeatable, and verifiable processes that meet stringent aerospace requirements. This includes developing comprehensive qualification methodologies that address material-process-property relationships, defect formation mechanisms, and long-term performance reliability under extreme operating conditions.

Secondary objectives include standardizing testing protocols specific to additively manufactured superalloys, implementing advanced non-destructive evaluation techniques for in-process and post-build inspection, and creating digital twins that enable virtual qualification to reduce physical testing requirements and accelerate certification timelines.

The ultimate goal is to establish a qualification framework that balances rigorous validation with practical implementation considerations, enabling broader adoption of PBF-LB technology for flight-critical applications. This framework must accommodate the unique challenges of superalloys, including their susceptibility to cracking, residual stress development, and microstructural heterogeneity, while leveraging the design freedom and performance advantages offered by additive manufacturing.

As regulatory bodies and industry standards evolve to address these advanced manufacturing methods, the qualification pathways developed today will shape the future aerospace supply chain, potentially transforming traditional manufacturing paradigms and enabling new design possibilities previously constrained by conventional fabrication limitations.

The technological trajectory of PBF-LB for superalloys has been marked by significant advancements in laser technology, powder metallurgy, process monitoring, and computational modeling. Early applications were limited to prototyping and non-critical components due to inconsistent material properties and process reliability concerns. However, continuous refinements in process parameters, powder characterization, and in-situ monitoring have elevated this technology to a point where qualification for flight-critical applications is now within reach.

Current trends in PBF-LB superalloy development focus on expanding the processability of challenging materials such as nickel-based superalloys (Inconel 718, 625), cobalt-chrome alloys, and titanium aluminides that offer superior high-temperature performance and oxidation resistance critical for aerospace applications. The industry is witnessing a shift from empirical process development toward physics-based modeling approaches that enable predictive capabilities for microstructure and property development.

The primary technical objective for qualification pathways of flight-critical PBF-LB superalloy parts centers on establishing robust, repeatable, and verifiable processes that meet stringent aerospace requirements. This includes developing comprehensive qualification methodologies that address material-process-property relationships, defect formation mechanisms, and long-term performance reliability under extreme operating conditions.

Secondary objectives include standardizing testing protocols specific to additively manufactured superalloys, implementing advanced non-destructive evaluation techniques for in-process and post-build inspection, and creating digital twins that enable virtual qualification to reduce physical testing requirements and accelerate certification timelines.

The ultimate goal is to establish a qualification framework that balances rigorous validation with practical implementation considerations, enabling broader adoption of PBF-LB technology for flight-critical applications. This framework must accommodate the unique challenges of superalloys, including their susceptibility to cracking, residual stress development, and microstructural heterogeneity, while leveraging the design freedom and performance advantages offered by additive manufacturing.

As regulatory bodies and industry standards evolve to address these advanced manufacturing methods, the qualification pathways developed today will shape the future aerospace supply chain, potentially transforming traditional manufacturing paradigms and enabling new design possibilities previously constrained by conventional fabrication limitations.

Aerospace Market Requirements Analysis

The aerospace industry maintains exceptionally stringent requirements for components used in flight-critical applications, particularly for parts manufactured using Powder Bed Fusion Laser Beam (PBF-LB) technology with superalloys. Market analysis indicates that these requirements are driven primarily by safety considerations, with regulatory compliance serving as the foundation for all aerospace manufacturing operations.

Current market demand for PBF-LB superalloy parts is experiencing significant growth, with the global aerospace additive manufacturing market projected to reach $4.7 billion by 2026, growing at a CAGR of approximately 15.7%. This growth is fueled by the industry's push toward lighter, more fuel-efficient aircraft and the need for complex geometries that traditional manufacturing methods cannot achieve.

The qualification requirements for these components are particularly demanding, as they must withstand extreme operating conditions including high temperatures, mechanical stresses, and corrosive environments. Market research shows that aerospace OEMs require parts that can operate reliably at temperatures exceeding 1000°C while maintaining structural integrity under high-stress conditions.

Regulatory bodies such as the FAA, EASA, and military standards organizations have established comprehensive certification frameworks that manufacturers must navigate. These frameworks demand extensive material characterization, process validation, and part qualification testing. The market analysis reveals that certification costs can represent up to 30% of the total development budget for new aerospace components.

Key market drivers include the need for supply chain resilience, with major aerospace manufacturers seeking to reduce dependency on traditional casting suppliers by developing in-house additive manufacturing capabilities. Additionally, the push for sustainability has created market demand for manufacturing processes that reduce material waste and energy consumption, areas where PBF-LB technology offers significant advantages.

Customer requirements analysis shows that aerospace manufacturers prioritize consistency and repeatability in the production process. Statistical process control and comprehensive quality assurance systems are non-negotiable market requirements, with zero defect tolerance being the industry standard for flight-critical components.

The aftermarket segment presents significant opportunities, with maintenance, repair, and overhaul (MRO) operations increasingly looking to additive manufacturing for rapid production of replacement parts. This market segment values reduced lead times and the ability to produce legacy components for which tooling may no longer exist.

Current market demand for PBF-LB superalloy parts is experiencing significant growth, with the global aerospace additive manufacturing market projected to reach $4.7 billion by 2026, growing at a CAGR of approximately 15.7%. This growth is fueled by the industry's push toward lighter, more fuel-efficient aircraft and the need for complex geometries that traditional manufacturing methods cannot achieve.

The qualification requirements for these components are particularly demanding, as they must withstand extreme operating conditions including high temperatures, mechanical stresses, and corrosive environments. Market research shows that aerospace OEMs require parts that can operate reliably at temperatures exceeding 1000°C while maintaining structural integrity under high-stress conditions.

Regulatory bodies such as the FAA, EASA, and military standards organizations have established comprehensive certification frameworks that manufacturers must navigate. These frameworks demand extensive material characterization, process validation, and part qualification testing. The market analysis reveals that certification costs can represent up to 30% of the total development budget for new aerospace components.

Key market drivers include the need for supply chain resilience, with major aerospace manufacturers seeking to reduce dependency on traditional casting suppliers by developing in-house additive manufacturing capabilities. Additionally, the push for sustainability has created market demand for manufacturing processes that reduce material waste and energy consumption, areas where PBF-LB technology offers significant advantages.

Customer requirements analysis shows that aerospace manufacturers prioritize consistency and repeatability in the production process. Statistical process control and comprehensive quality assurance systems are non-negotiable market requirements, with zero defect tolerance being the industry standard for flight-critical components.

The aftermarket segment presents significant opportunities, with maintenance, repair, and overhaul (MRO) operations increasingly looking to additive manufacturing for rapid production of replacement parts. This market segment values reduced lead times and the ability to produce legacy components for which tooling may no longer exist.

Current Qualification Challenges for Flight-Critical Components

The qualification of flight-critical components manufactured using Powder Bed Fusion Laser Beam (PBF-LB) technology for superalloys faces significant challenges in the aerospace industry. Current certification frameworks were primarily designed for traditional manufacturing methods and struggle to accommodate the unique characteristics of additively manufactured parts. The layer-by-layer nature of PBF-LB introduces complex thermal histories that can result in microstructural variations throughout the component, creating inconsistencies that are difficult to predict and control.

Material property variability remains one of the most pressing challenges. Unlike conventionally manufactured superalloys with well-established property databases, PBF-LB parts exhibit anisotropic mechanical properties that vary based on build orientation, process parameters, and post-processing treatments. This variability necessitates extensive testing regimes that are both time-consuming and costly, often requiring hundreds of test specimens to establish statistical confidence.

Non-destructive evaluation (NDE) techniques present another major hurdle. Traditional NDE methods such as ultrasonic testing and radiography have limitations when applied to the complex geometries and internal features typical of additively manufactured components. The detection of subsurface defects, particularly in the microscale range critical for high-temperature superalloy applications, remains problematic with current inspection technologies.

Process repeatability and consistency pose significant qualification challenges. Minor variations in powder characteristics, laser parameters, or build chamber conditions can lead to substantial differences in final part properties. The aerospace industry's stringent safety requirements demand a level of process control that current PBF-LB systems struggle to maintain across multiple builds and between different machines.

Documentation and traceability requirements for flight-critical components are exceptionally rigorous. Current qualification protocols require comprehensive records of material provenance, process parameters, and quality control measures. The digital nature of PBF-LB generates vast amounts of process data that existing certification frameworks are not equipped to efficiently integrate and evaluate.

Regulatory bodies like the FAA and EASA are still developing appropriate certification pathways for additively manufactured flight components. The lack of standardized qualification procedures specifically tailored to PBF-LB superalloy parts creates uncertainty for manufacturers and increases development timelines. Industry stakeholders must often work closely with regulators on a case-by-case basis, resulting in inconsistent approaches across different programs.

The economic impact of these qualification challenges is substantial, with certification costs for a single flight-critical component potentially reaching millions of dollars. This financial barrier significantly limits the adoption of PBF-LB technology for high-value aerospace applications, despite its potential benefits in design freedom and performance optimization.

Material property variability remains one of the most pressing challenges. Unlike conventionally manufactured superalloys with well-established property databases, PBF-LB parts exhibit anisotropic mechanical properties that vary based on build orientation, process parameters, and post-processing treatments. This variability necessitates extensive testing regimes that are both time-consuming and costly, often requiring hundreds of test specimens to establish statistical confidence.

Non-destructive evaluation (NDE) techniques present another major hurdle. Traditional NDE methods such as ultrasonic testing and radiography have limitations when applied to the complex geometries and internal features typical of additively manufactured components. The detection of subsurface defects, particularly in the microscale range critical for high-temperature superalloy applications, remains problematic with current inspection technologies.

Process repeatability and consistency pose significant qualification challenges. Minor variations in powder characteristics, laser parameters, or build chamber conditions can lead to substantial differences in final part properties. The aerospace industry's stringent safety requirements demand a level of process control that current PBF-LB systems struggle to maintain across multiple builds and between different machines.

Documentation and traceability requirements for flight-critical components are exceptionally rigorous. Current qualification protocols require comprehensive records of material provenance, process parameters, and quality control measures. The digital nature of PBF-LB generates vast amounts of process data that existing certification frameworks are not equipped to efficiently integrate and evaluate.

Regulatory bodies like the FAA and EASA are still developing appropriate certification pathways for additively manufactured flight components. The lack of standardized qualification procedures specifically tailored to PBF-LB superalloy parts creates uncertainty for manufacturers and increases development timelines. Industry stakeholders must often work closely with regulators on a case-by-case basis, resulting in inconsistent approaches across different programs.

The economic impact of these qualification challenges is substantial, with certification costs for a single flight-critical component potentially reaching millions of dollars. This financial barrier significantly limits the adoption of PBF-LB technology for high-value aerospace applications, despite its potential benefits in design freedom and performance optimization.

Current Qualification Methodologies for PBF-LB Superalloys

01 Qualification methods for PBF-LB superalloy parts

Various qualification methods are employed to ensure the quality and reliability of superalloy parts manufactured using Powder Bed Fusion-Laser Beam (PBF-LB) technology. These methods include non-destructive testing, microstructural analysis, mechanical property testing, and performance validation under simulated operating conditions. The qualification process typically involves comparing the properties of PBF-LB manufactured parts with traditionally manufactured counterparts to establish equivalence or superiority in terms of mechanical strength, fatigue resistance, and high-temperature performance.- Qualification methods for PBF-LB superalloy parts: Various qualification methods are employed to ensure the quality and reliability of superalloy parts manufactured using Powder Bed Fusion-Laser Beam (PBF-LB) technology. These methods include non-destructive testing, mechanical property testing, microstructural analysis, and performance validation under simulated operating conditions. The qualification process typically involves comparing the properties of PBF-LB manufactured parts with traditionally manufactured counterparts to establish equivalence or superiority.

- Material characterization for PBF-LB superalloys: Comprehensive material characterization is essential for qualifying PBF-LB superalloy parts. This includes analysis of chemical composition, grain structure, phase distribution, porosity levels, and surface finish. Advanced techniques such as electron microscopy, X-ray diffraction, and computed tomography are used to evaluate the microstructural features that influence the mechanical properties and performance of the superalloy parts. Understanding the relationship between processing parameters and material characteristics is crucial for establishing reliable qualification pathways.

- Process parameter optimization for PBF-LB superalloys: Optimizing process parameters is critical for producing high-quality PBF-LB superalloy parts. Parameters such as laser power, scan speed, hatch spacing, layer thickness, and build chamber atmosphere significantly affect the final part properties. Systematic approaches to parameter optimization involve design of experiments, statistical analysis, and machine learning techniques to identify the optimal processing window. Establishing standardized parameter sets for specific superalloy compositions helps ensure reproducibility and reliability in the qualification process.

- Post-processing treatments for PBF-LB superalloy parts: Post-processing treatments play a crucial role in the qualification pathway for PBF-LB superalloy parts. These treatments include heat treatment for stress relief and microstructure optimization, hot isostatic pressing to eliminate porosity, surface finishing to improve fatigue performance, and machining to achieve dimensional accuracy. The selection and optimization of post-processing methods depend on the specific superalloy composition and the intended application of the part. Properly executed post-processing can significantly enhance the mechanical properties and performance reliability of PBF-LB superalloy components.

- Standardization and certification frameworks for PBF-LB superalloys: Standardization and certification frameworks provide structured approaches for qualifying PBF-LB superalloy parts across different industries. These frameworks include industry-specific standards, testing protocols, and acceptance criteria that ensure consistency and reliability in the qualification process. Certification may involve third-party validation, documentation of the entire manufacturing process, and traceability of materials and processing conditions. Establishing robust standardization and certification frameworks facilitates the adoption of PBF-LB technology for critical applications in aerospace, energy, and medical sectors.

02 Material characterization for PBF-LB superalloy processing

Material characterization plays a crucial role in qualifying PBF-LB superalloy parts. This involves analyzing powder characteristics, microstructure evolution during processing, phase formation, and compositional homogeneity. Advanced techniques such as electron microscopy, X-ray diffraction, and thermal analysis are used to understand the relationship between processing parameters and resultant material properties. Characterization helps in establishing process-structure-property relationships that are essential for consistent production of high-quality superalloy components with predictable performance.Expand Specific Solutions03 Process parameter optimization for PBF-LB superalloy manufacturing

Optimizing process parameters is critical for successful qualification of PBF-LB superalloy parts. This involves systematic investigation of laser power, scan speed, hatch spacing, layer thickness, and build orientation to achieve desired microstructure and properties. Statistical methods and design of experiments are employed to establish robust processing windows that ensure repeatability and reliability. Process monitoring and control systems are implemented to maintain consistency throughout the manufacturing process, which is essential for qualification and certification of aerospace and industrial components.Expand Specific Solutions04 Post-processing treatments for PBF-LB superalloy parts

Post-processing treatments are integral to the qualification pathway for PBF-LB superalloy parts. These treatments include heat treatment for stress relief and microstructure optimization, hot isostatic pressing to eliminate porosity, surface finishing to improve fatigue performance, and machining to achieve dimensional accuracy. The selection and optimization of post-processing methods significantly influence the final properties of the components and are tailored according to specific application requirements. Proper post-processing can mitigate the inherent limitations of the PBF-LB process and enhance the overall quality and performance of superalloy parts.Expand Specific Solutions05 Standardization and certification frameworks for PBF-LB superalloy components

Standardization and certification frameworks provide structured approaches for qualifying PBF-LB superalloy parts across different industries. These frameworks include industry-specific standards, testing protocols, and quality assurance systems that ensure consistency and reliability. Certification processes typically involve material qualification, process qualification, and part qualification stages, with documentation requirements at each level. Regulatory bodies and industry consortia are actively developing and refining these frameworks to address the unique challenges of additive manufacturing technologies and facilitate wider adoption of PBF-LB superalloy components in critical applications.Expand Specific Solutions

Key Industry Players in Aerospace Additive Manufacturing

The qualification pathways for flight-critical PBF-LB superalloy parts are currently in an emerging growth phase, with the market expanding as aerospace manufacturers seek to leverage additive manufacturing advantages. The technology maturity varies significantly across key players, with established aerospace OEMs like Rolls-Royce, GE, and Safran leading commercial implementation efforts. Research institutions such as Central South University and Beihang University are advancing fundamental understanding, while aircraft manufacturers including Boeing, Airbus, and COMAC are developing certification frameworks. The competitive landscape shows traditional aerospace companies collaborating with research organizations to overcome technical challenges in material qualification, process control, and regulatory approval, creating a complex ecosystem where both technical expertise and regulatory experience provide competitive advantages.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a comprehensive qualification pathway for flight-critical PBF-LB (Powder Bed Fusion - Laser Beam) superalloy parts that integrates digital twins with physical testing. Their approach includes a multi-stage validation process starting with powder characterization using advanced spectroscopy techniques to ensure consistent material properties. The company employs in-situ monitoring systems during the PBF-LB process that capture layer-by-layer data to detect anomalies in real-time[1]. Post-build, Rolls-Royce utilizes non-destructive testing methods including CT scanning and ultrasonic inspection combined with machine learning algorithms to identify potential defects. Their qualification pathway also incorporates accelerated life testing protocols that simulate extreme operating conditions experienced in aerospace applications, with particular focus on high-temperature fatigue and creep resistance testing for superalloy components[3].

Strengths: Industry-leading digital twin integration allows for comprehensive virtual testing before physical validation, reducing development cycles. Their in-situ monitoring capabilities provide superior quality assurance during manufacturing. Weaknesses: The extensive testing protocols increase qualification time and costs compared to conventional manufacturing methods, and their proprietary qualification standards may limit broader industry adoption.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered a qualification pathway for PBF-LB superalloy parts focused on standardization and repeatability across global manufacturing sites. Their approach centers on a proprietary "Digital Material Qualification" framework that establishes statistical correlations between process parameters, microstructure development, and mechanical properties of superalloys. Honeywell employs advanced thermal modeling to predict and control residual stresses during the PBF-LB process, which is critical for flight-critical components[2]. Their qualification pathway includes specialized hot isostatic pressing (HIP) protocols optimized for different superalloy compositions to eliminate internal porosity. The company has developed customized post-processing heat treatments that ensure consistent microstructural homogeneity across complex geometries. Additionally, Honeywell implements rigorous traceability systems that track each component from powder batch through manufacturing to final installation, meeting stringent aerospace certification requirements[4].

Strengths: Exceptional process standardization enables consistent quality across global manufacturing facilities. Their specialized post-processing techniques effectively address common PBF-LB defects in superalloys. Weaknesses: Their qualification pathway requires significant capital investment in specialized equipment and may have limitations with certain novel superalloy compositions that haven't been extensively characterized in their database.

Critical Technical Standards and Certification Protocols

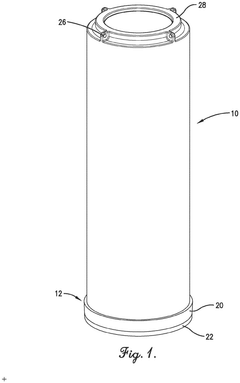

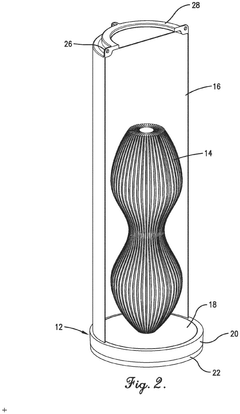

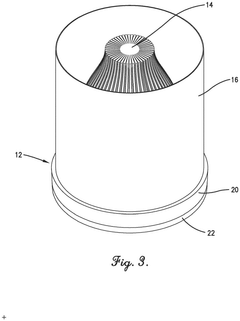

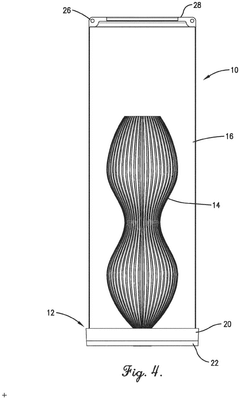

Method for three-dimensional printed powder containment

PatentPendingEP4509249A2

Innovation

- A method involving the simultaneous 3D printing of a canister with the printed part using a single additive manufacturing process, allowing for the containment of powder within the canister, which can then be transported and processed separately for powder removal and recycling.

Regulatory Framework for Flight-Critical AM Components

The regulatory landscape for flight-critical additive manufacturing (AM) components represents a complex framework of standards, guidelines, and certification processes established by aviation authorities worldwide. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have developed specific pathways for qualifying PBF-LB (Powder Bed Fusion - Laser Beam) superalloy parts intended for critical aerospace applications.

These regulatory bodies have established a multi-tiered approach to qualification, beginning with material property validation through standardized testing protocols. ASTM F3055 and AMS7003 serve as foundational standards specifically addressing the requirements for powder bed fusion processes using nickel-based superalloys in aerospace applications. These standards outline the minimum requirements for chemical composition, mechanical properties, and microstructural characteristics.

Process qualification represents the second major regulatory hurdle, requiring manufacturers to demonstrate consistent production capabilities through statistical process control methodologies. The SAE AMS7000 series provides detailed specifications for process control parameters, including laser power, scan strategy, and thermal management during the PBF-LB process. Manufacturers must establish process windows that consistently yield parts meeting predetermined quality thresholds.

Part qualification frameworks typically follow the building block approach outlined in the FAA Advisory Circular AC 20-107B, adapted specifically for additively manufactured components. This involves progressive testing from coupon-level specimens to sub-components and finally full-scale parts. The qualification process must address the unique challenges of AM technologies, including anisotropic material properties and potential defect formation mechanisms specific to PBF-LB processes.

Quality assurance systems for flight-critical AM components must comply with AS9100D requirements, with additional considerations for AM-specific process controls. The regulatory framework mandates comprehensive documentation of the entire manufacturing process chain, from powder feedstock characterization to post-processing treatments and non-destructive evaluation techniques.

Recent regulatory developments have introduced risk-based certification approaches, allowing manufacturers to tailor qualification efforts based on the criticality of specific components. The FAA's Additive Manufacturing Strategic Roadmap and EASA's Additive Manufacturing Roadmap both emphasize the need for performance-based standards rather than prescriptive requirements, enabling innovation while maintaining safety margins.

International harmonization efforts, led by organizations such as the International Aerospace Quality Group (IAQG), aim to standardize qualification requirements across different regulatory jurisdictions, reducing compliance burdens for global aerospace manufacturers utilizing PBF-LB technologies for superalloy components in flight-critical applications.

These regulatory bodies have established a multi-tiered approach to qualification, beginning with material property validation through standardized testing protocols. ASTM F3055 and AMS7003 serve as foundational standards specifically addressing the requirements for powder bed fusion processes using nickel-based superalloys in aerospace applications. These standards outline the minimum requirements for chemical composition, mechanical properties, and microstructural characteristics.

Process qualification represents the second major regulatory hurdle, requiring manufacturers to demonstrate consistent production capabilities through statistical process control methodologies. The SAE AMS7000 series provides detailed specifications for process control parameters, including laser power, scan strategy, and thermal management during the PBF-LB process. Manufacturers must establish process windows that consistently yield parts meeting predetermined quality thresholds.

Part qualification frameworks typically follow the building block approach outlined in the FAA Advisory Circular AC 20-107B, adapted specifically for additively manufactured components. This involves progressive testing from coupon-level specimens to sub-components and finally full-scale parts. The qualification process must address the unique challenges of AM technologies, including anisotropic material properties and potential defect formation mechanisms specific to PBF-LB processes.

Quality assurance systems for flight-critical AM components must comply with AS9100D requirements, with additional considerations for AM-specific process controls. The regulatory framework mandates comprehensive documentation of the entire manufacturing process chain, from powder feedstock characterization to post-processing treatments and non-destructive evaluation techniques.

Recent regulatory developments have introduced risk-based certification approaches, allowing manufacturers to tailor qualification efforts based on the criticality of specific components. The FAA's Additive Manufacturing Strategic Roadmap and EASA's Additive Manufacturing Roadmap both emphasize the need for performance-based standards rather than prescriptive requirements, enabling innovation while maintaining safety margins.

International harmonization efforts, led by organizations such as the International Aerospace Quality Group (IAQG), aim to standardize qualification requirements across different regulatory jurisdictions, reducing compliance burdens for global aerospace manufacturers utilizing PBF-LB technologies for superalloy components in flight-critical applications.

Material Traceability and Digital Thread Implementation

Material traceability and digital thread implementation represent critical components in the qualification pathway for flight-critical PBF-LB superalloy parts. The aerospace industry demands comprehensive documentation of material provenance and processing history to ensure compliance with stringent safety regulations. Current traceability systems for powder bed fusion laser beam (PBF-LB) manufactured superalloy components typically employ a combination of physical marking techniques and digital documentation.

Advanced digital thread implementations connect all stages of the manufacturing process, from powder production to final part qualification. These systems integrate data from powder characterization, build process monitoring, post-processing treatments, and final inspection into a unified digital record. Leading aerospace manufacturers have developed proprietary digital thread architectures that maintain unbroken chains of custody and processing parameters throughout the part lifecycle.

Material traceability begins with powder lot certification and extends through the entire manufacturing workflow. Each batch of superalloy powder receives unique identifiers that follow the material through atomization, sieving, storage, and printing processes. Modern systems employ blockchain technology to create tamper-proof records of material handling and processing conditions, addressing concerns about data integrity in qualification documentation.

In-situ monitoring systems generate massive datasets during PBF-LB builds, capturing layer-by-layer information about melt pool characteristics, thermal gradients, and potential anomalies. These datasets become integral components of the digital thread, enabling correlation between process parameters and final part properties. Machine learning algorithms increasingly analyze these datasets to identify patterns predictive of part quality, enhancing the robustness of qualification pathways.

Post-build traceability continues through heat treatment, machining, and surface finishing operations. Each process step adds data to the digital thread, documenting parameters such as temperature profiles, machining tool paths, and surface treatment specifications. Emerging standards from organizations like ASTM International and SAE are establishing protocols for digital thread implementation specific to additive manufacturing of flight-critical components.

The integration of digital thread data with traditional quality management systems presents significant challenges. Legacy aerospace quality systems often rely on document-based workflows that must be adapted to accommodate the data-rich nature of additive manufacturing processes. Industry leaders are developing hybrid approaches that satisfy regulatory requirements while leveraging the advantages of comprehensive digital traceability.

Advanced digital thread implementations connect all stages of the manufacturing process, from powder production to final part qualification. These systems integrate data from powder characterization, build process monitoring, post-processing treatments, and final inspection into a unified digital record. Leading aerospace manufacturers have developed proprietary digital thread architectures that maintain unbroken chains of custody and processing parameters throughout the part lifecycle.

Material traceability begins with powder lot certification and extends through the entire manufacturing workflow. Each batch of superalloy powder receives unique identifiers that follow the material through atomization, sieving, storage, and printing processes. Modern systems employ blockchain technology to create tamper-proof records of material handling and processing conditions, addressing concerns about data integrity in qualification documentation.

In-situ monitoring systems generate massive datasets during PBF-LB builds, capturing layer-by-layer information about melt pool characteristics, thermal gradients, and potential anomalies. These datasets become integral components of the digital thread, enabling correlation between process parameters and final part properties. Machine learning algorithms increasingly analyze these datasets to identify patterns predictive of part quality, enhancing the robustness of qualification pathways.

Post-build traceability continues through heat treatment, machining, and surface finishing operations. Each process step adds data to the digital thread, documenting parameters such as temperature profiles, machining tool paths, and surface treatment specifications. Emerging standards from organizations like ASTM International and SAE are establishing protocols for digital thread implementation specific to additive manufacturing of flight-critical components.

The integration of digital thread data with traditional quality management systems presents significant challenges. Legacy aerospace quality systems often rely on document-based workflows that must be adapted to accommodate the data-rich nature of additive manufacturing processes. Industry leaders are developing hybrid approaches that satisfy regulatory requirements while leveraging the advantages of comprehensive digital traceability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!