Digital Twin Approaches For PBF-LB Superalloy Production Lines

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Evolution and Objectives in PBF-LB

The concept of Digital Twin has evolved significantly since its introduction by Michael Grieves at the University of Michigan in 2002. Initially conceived as a virtual representation of physical assets, the technology has matured through several distinct phases. Early implementations focused primarily on simple visualization and basic monitoring capabilities, while contemporary Digital Twin systems incorporate real-time data integration, advanced simulation, and predictive analytics.

In the context of Powder Bed Fusion Laser Beam (PBF-LB) superalloy production, Digital Twin technology has undergone specialized development to address the unique challenges of additive manufacturing processes. The evolution began with basic process monitoring systems that captured fundamental parameters such as laser power and scan speed. This progressed to more sophisticated implementations that integrated multi-physics models to simulate complex thermal behaviors and material transformations occurring during the printing process.

Recent advancements have seen Digital Twins for PBF-LB systems incorporate machine learning algorithms that enable adaptive control mechanisms, allowing for real-time process optimization based on historical and current production data. The integration of IoT sensors throughout the production line has further enhanced the fidelity of these virtual representations, providing unprecedented visibility into previously opaque manufacturing processes.

The primary objective of Digital Twin implementation in PBF-LB superalloy production is to achieve consistent quality and reliability in manufactured components. Superalloys, with their complex microstructures and stringent performance requirements, present significant manufacturing challenges that Digital Twins aim to address through enhanced process understanding and control.

Additional objectives include reducing production costs through minimized material waste and optimized energy consumption. By accurately predicting process outcomes before physical production, manufacturers can significantly reduce the number of failed builds and iterative testing cycles. This predictive capability is particularly valuable for superalloy components, which often involve expensive raw materials and complex post-processing requirements.

Long-term strategic objectives extend to enabling mass customization capabilities while maintaining production efficiency. Digital Twins facilitate rapid virtual testing of design modifications, allowing manufacturers to assess the impact of customization requests without disrupting production workflows. Furthermore, these systems aim to support continuous improvement initiatives by creating a comprehensive digital record of production history that can be analyzed to identify optimization opportunities.

The evolution trajectory points toward increasingly autonomous production systems where Digital Twins not only monitor and predict but actively control manufacturing processes with minimal human intervention, representing the ultimate convergence of physical and digital manufacturing realms.

In the context of Powder Bed Fusion Laser Beam (PBF-LB) superalloy production, Digital Twin technology has undergone specialized development to address the unique challenges of additive manufacturing processes. The evolution began with basic process monitoring systems that captured fundamental parameters such as laser power and scan speed. This progressed to more sophisticated implementations that integrated multi-physics models to simulate complex thermal behaviors and material transformations occurring during the printing process.

Recent advancements have seen Digital Twins for PBF-LB systems incorporate machine learning algorithms that enable adaptive control mechanisms, allowing for real-time process optimization based on historical and current production data. The integration of IoT sensors throughout the production line has further enhanced the fidelity of these virtual representations, providing unprecedented visibility into previously opaque manufacturing processes.

The primary objective of Digital Twin implementation in PBF-LB superalloy production is to achieve consistent quality and reliability in manufactured components. Superalloys, with their complex microstructures and stringent performance requirements, present significant manufacturing challenges that Digital Twins aim to address through enhanced process understanding and control.

Additional objectives include reducing production costs through minimized material waste and optimized energy consumption. By accurately predicting process outcomes before physical production, manufacturers can significantly reduce the number of failed builds and iterative testing cycles. This predictive capability is particularly valuable for superalloy components, which often involve expensive raw materials and complex post-processing requirements.

Long-term strategic objectives extend to enabling mass customization capabilities while maintaining production efficiency. Digital Twins facilitate rapid virtual testing of design modifications, allowing manufacturers to assess the impact of customization requests without disrupting production workflows. Furthermore, these systems aim to support continuous improvement initiatives by creating a comprehensive digital record of production history that can be analyzed to identify optimization opportunities.

The evolution trajectory points toward increasingly autonomous production systems where Digital Twins not only monitor and predict but actively control manufacturing processes with minimal human intervention, representing the ultimate convergence of physical and digital manufacturing realms.

Market Analysis for Digital Twin in Superalloy Manufacturing

The digital twin market in superalloy manufacturing is experiencing significant growth, driven by the increasing adoption of Industry 4.0 technologies across aerospace, energy, and automotive sectors. The global digital twin market was valued at approximately $7.1 billion in 2022 and is projected to reach $96.5 billion by 2030, growing at a CAGR of 38.2%. Within this broader market, the segment dedicated to superalloy manufacturing represents a specialized but rapidly expanding niche.

Powder Bed Fusion Laser Beam (PBF-LB) technology has emerged as a critical additive manufacturing process for superalloys, particularly in high-value industries requiring complex geometries and superior material properties. The market demand for digital twin solutions in this specific application is primarily driven by the need to optimize production efficiency, reduce material waste, and ensure consistent quality in components that often operate in extreme conditions.

Aerospace remains the dominant market segment, accounting for approximately 35% of the digital twin implementation in superalloy manufacturing. This sector's stringent quality requirements and high-value components justify the investment in advanced monitoring and simulation technologies. The energy sector follows closely at 28%, with particular interest from gas turbine manufacturers seeking to improve component performance and longevity.

Market research indicates that manufacturers implementing digital twin technologies in PBF-LB superalloy production lines have reported defect reduction rates of up to 25% and production efficiency improvements averaging 18%. These tangible benefits are accelerating adoption despite the significant initial investment required for comprehensive digital twin implementation.

Regional analysis shows North America leading the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 42% annually, primarily driven by China's and India's expanding aerospace and energy sectors.

Customer demand patterns reveal a clear preference for end-to-end solutions that integrate multiple aspects of the production process rather than standalone monitoring tools. Approximately 76% of surveyed manufacturers expressed interest in digital twins that could provide predictive maintenance capabilities alongside process optimization and quality control functionalities.

The market is also witnessing increased demand for cloud-based digital twin solutions, which offer greater flexibility and reduced infrastructure requirements. This trend is particularly pronounced among mid-sized manufacturers seeking to adopt advanced technologies without prohibitive capital expenditure.

Powder Bed Fusion Laser Beam (PBF-LB) technology has emerged as a critical additive manufacturing process for superalloys, particularly in high-value industries requiring complex geometries and superior material properties. The market demand for digital twin solutions in this specific application is primarily driven by the need to optimize production efficiency, reduce material waste, and ensure consistent quality in components that often operate in extreme conditions.

Aerospace remains the dominant market segment, accounting for approximately 35% of the digital twin implementation in superalloy manufacturing. This sector's stringent quality requirements and high-value components justify the investment in advanced monitoring and simulation technologies. The energy sector follows closely at 28%, with particular interest from gas turbine manufacturers seeking to improve component performance and longevity.

Market research indicates that manufacturers implementing digital twin technologies in PBF-LB superalloy production lines have reported defect reduction rates of up to 25% and production efficiency improvements averaging 18%. These tangible benefits are accelerating adoption despite the significant initial investment required for comprehensive digital twin implementation.

Regional analysis shows North America leading the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 42% annually, primarily driven by China's and India's expanding aerospace and energy sectors.

Customer demand patterns reveal a clear preference for end-to-end solutions that integrate multiple aspects of the production process rather than standalone monitoring tools. Approximately 76% of surveyed manufacturers expressed interest in digital twins that could provide predictive maintenance capabilities alongside process optimization and quality control functionalities.

The market is also witnessing increased demand for cloud-based digital twin solutions, which offer greater flexibility and reduced infrastructure requirements. This trend is particularly pronounced among mid-sized manufacturers seeking to adopt advanced technologies without prohibitive capital expenditure.

Current Challenges in PBF-LB Digital Twin Implementation

Despite the promising potential of digital twins for Powder Bed Fusion-Laser Beam (PBF-LB) superalloy production lines, several significant challenges impede their widespread implementation. The complexity of real-time data acquisition presents a formidable obstacle, as PBF-LB processes generate massive amounts of heterogeneous data from multiple sensors monitoring temperature, melt pool dynamics, powder distribution, and laser parameters. Integrating these diverse data streams into a coherent digital representation remains technically demanding.

The extreme operating conditions of PBF-LB systems further complicate sensor deployment and reliability. High temperatures, metal vapors, and powder particles can damage or interfere with sensing equipment, creating gaps in the data necessary for accurate digital twin operation. Additionally, the specialized sensors capable of withstanding these harsh environments often come with prohibitive costs, limiting their industrial adoption.

Computational demands pose another substantial challenge. Simulating the complex physics of laser-powder interactions, heat transfer, solidification, and microstructure evolution requires immense computational resources. Current models must balance accuracy with computational efficiency, often resulting in oversimplifications that reduce the digital twin's predictive capabilities for superalloy components where precision is paramount.

Interoperability issues between different software platforms and hardware systems create integration bottlenecks. The lack of standardized protocols for data exchange between CAD/CAM systems, simulation software, monitoring equipment, and production management systems hinders the creation of comprehensive digital twins spanning the entire production line.

For superalloy applications specifically, material behavior modeling presents unique difficulties. The complex phase transformations, precipitation kinetics, and anisotropic properties of superalloys are challenging to capture in real-time simulations. Current models often fail to accurately predict defect formation or microstructural evolution during the PBF-LB process for these sophisticated alloys.

Validation methodologies for digital twins remain underdeveloped. Establishing the fidelity of a digital twin requires extensive experimental validation, which is time-consuming and expensive, particularly for superalloy components with stringent quality requirements. The lack of standardized validation approaches creates uncertainty about the reliability of digital twin predictions.

Finally, workforce expertise gaps present a human-centered challenge. Implementing digital twins requires interdisciplinary knowledge spanning materials science, computer simulation, data analytics, and manufacturing engineering. The scarcity of professionals with this multidisciplinary expertise limits the development and maintenance of sophisticated digital twins for PBF-LB superalloy production.

The extreme operating conditions of PBF-LB systems further complicate sensor deployment and reliability. High temperatures, metal vapors, and powder particles can damage or interfere with sensing equipment, creating gaps in the data necessary for accurate digital twin operation. Additionally, the specialized sensors capable of withstanding these harsh environments often come with prohibitive costs, limiting their industrial adoption.

Computational demands pose another substantial challenge. Simulating the complex physics of laser-powder interactions, heat transfer, solidification, and microstructure evolution requires immense computational resources. Current models must balance accuracy with computational efficiency, often resulting in oversimplifications that reduce the digital twin's predictive capabilities for superalloy components where precision is paramount.

Interoperability issues between different software platforms and hardware systems create integration bottlenecks. The lack of standardized protocols for data exchange between CAD/CAM systems, simulation software, monitoring equipment, and production management systems hinders the creation of comprehensive digital twins spanning the entire production line.

For superalloy applications specifically, material behavior modeling presents unique difficulties. The complex phase transformations, precipitation kinetics, and anisotropic properties of superalloys are challenging to capture in real-time simulations. Current models often fail to accurately predict defect formation or microstructural evolution during the PBF-LB process for these sophisticated alloys.

Validation methodologies for digital twins remain underdeveloped. Establishing the fidelity of a digital twin requires extensive experimental validation, which is time-consuming and expensive, particularly for superalloy components with stringent quality requirements. The lack of standardized validation approaches creates uncertainty about the reliability of digital twin predictions.

Finally, workforce expertise gaps present a human-centered challenge. Implementing digital twins requires interdisciplinary knowledge spanning materials science, computer simulation, data analytics, and manufacturing engineering. The scarcity of professionals with this multidisciplinary expertise limits the development and maintenance of sophisticated digital twins for PBF-LB superalloy production.

Existing Digital Twin Frameworks for Superalloy Production

01 Digital Twin for Industrial Systems and Manufacturing

Digital twin technology enables the creation of virtual replicas of physical industrial systems and manufacturing processes. These digital models simulate real-world operations, allowing for monitoring, analysis, and optimization of production systems. By creating a digital counterpart of physical assets, manufacturers can predict maintenance needs, optimize performance, and reduce downtime. The technology integrates with IoT sensors to collect real-time data, enabling continuous improvement of manufacturing processes and equipment lifecycle management.- Digital Twin for Industrial Systems and Manufacturing: Digital twins are virtual replicas of physical industrial systems and manufacturing processes that enable real-time monitoring, simulation, and optimization. These digital models collect data from sensors embedded in physical equipment to create accurate representations that can predict performance, identify maintenance needs, and optimize operations. By implementing digital twins in manufacturing environments, companies can reduce downtime, improve product quality, and enhance overall operational efficiency.

- Digital Twin for Healthcare and Medical Applications: Digital twin technology is being applied in healthcare to create virtual models of patients, medical devices, and treatment processes. These digital representations enable personalized medicine approaches by simulating patient responses to treatments, optimizing medical device performance, and improving clinical decision-making. Healthcare digital twins integrate patient data from various sources to provide comprehensive views of health status and predict potential health issues before they become critical.

- Digital Twin for Smart Cities and Infrastructure: Digital twins for urban environments and infrastructure create virtual replicas of cities, buildings, and utility networks to improve planning, management, and sustainability. These models integrate data from IoT sensors, geographic information systems, and other sources to simulate traffic patterns, energy consumption, and environmental impacts. By implementing digital twins for infrastructure, city planners and operators can optimize resource allocation, improve emergency response, and enhance the quality of urban life.

- Digital Twin Integration with AI and Machine Learning: The integration of artificial intelligence and machine learning with digital twin technology enhances predictive capabilities and autonomous decision-making. These advanced digital twins can learn from historical data, identify patterns, and make intelligent recommendations without human intervention. AI-powered digital twins enable more sophisticated simulations, anomaly detection, and optimization scenarios across various domains, creating self-improving systems that become more accurate and valuable over time.

- Digital Twin for Product Development and Lifecycle Management: Digital twins support the entire product lifecycle from design and development through manufacturing, operation, and maintenance. By creating virtual prototypes, companies can test and validate designs before physical production, reducing development time and costs. Throughout the product lifecycle, digital twins collect operational data to inform future designs and enable predictive maintenance. This approach facilitates continuous improvement and innovation while extending product lifespan and enhancing customer satisfaction.

02 Digital Twin in Healthcare and Medical Applications

Digital twin technology is being applied in healthcare to create virtual models of patients, medical devices, and healthcare systems. These digital replicas enable personalized medicine approaches by simulating patient responses to treatments, predicting health outcomes, and optimizing medical interventions. The technology allows healthcare providers to test various scenarios virtually before implementing them in real-world settings, improving patient care and treatment efficacy. Digital twins also facilitate remote monitoring of patients and medical equipment, enhancing healthcare delivery and management.Expand Specific Solutions03 Digital Twin for Smart Cities and Infrastructure

Digital twin technology is revolutionizing urban planning and infrastructure management by creating virtual replicas of cities, buildings, and utility networks. These comprehensive digital models integrate data from various sources including IoT sensors, geographic information systems, and building information modeling. Smart city digital twins enable simulation of urban scenarios, optimization of resource allocation, and improvement of city services. The technology supports sustainable urban development by facilitating better energy management, traffic flow optimization, and emergency response planning in complex urban environments.Expand Specific Solutions04 Digital Twin Integration with AI and Machine Learning

The integration of artificial intelligence and machine learning with digital twin technology creates advanced predictive capabilities. These AI-enhanced digital twins can analyze patterns, predict outcomes, and recommend optimizations based on historical and real-time data. The combination enables autonomous decision-making processes where digital twins can self-adjust parameters based on changing conditions. Machine learning algorithms continuously improve the accuracy of digital twin models by learning from discrepancies between predicted and actual behaviors, creating increasingly sophisticated simulation capabilities for complex systems.Expand Specific Solutions05 Digital Twin for Product Development and Lifecycle Management

Digital twin technology transforms product development and lifecycle management by creating virtual representations of products throughout their entire lifecycle. These digital models enable designers and engineers to test and validate product designs virtually before physical prototyping, reducing development time and costs. The technology supports continuous product improvement by collecting and analyzing performance data from deployed products, identifying optimization opportunities, and facilitating predictive maintenance. Digital twins also enhance sustainability efforts by enabling simulation of product end-of-life scenarios and recycling processes.Expand Specific Solutions

Leading Companies in PBF-LB Digital Twin Solutions

The digital twin market for PBF-LB superalloy production is in its growth phase, characterized by increasing adoption across aerospace and energy sectors. The market is projected to expand significantly as manufacturers seek to optimize complex additive manufacturing processes for high-value superalloy components. Leading academic institutions (MIT, Beihang University) are driving fundamental research, while industrial players demonstrate varying levels of technological maturity. Applied Materials and Lam Research lead in equipment integration, IBM and Siemens offer advanced simulation platforms, while specialized firms like Simacro provide tailored digital twin solutions. Material specialists such as NIMS and VSMPO-AVISMA contribute critical superalloy expertise, creating a competitive ecosystem balancing research innovation with industrial implementation.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an integrated Digital Twin solution for PBF-LB superalloy production that focuses on process control and material quality optimization. Their approach combines in-situ monitoring technologies with physics-based modeling to create accurate virtual representations of the powder bed fusion process. The system utilizes high-resolution thermal imaging and layer-wise optical inspection to capture real-time data during fabrication, which is then fed into their proprietary simulation environment[7]. Applied Materials' digital twin implementation features advanced powder spreading dynamics modeling that accounts for particle size distribution, flowability, and packing density to predict and mitigate defects before they occur. Their solution incorporates machine learning algorithms that continuously analyze the correlation between process parameters and material properties, enabling adaptive control strategies that can respond to variations in raw material characteristics or environmental conditions. The company has demonstrated significant improvements in superalloy component quality, with up to 50% reduction in porosity and 35% enhancement in fatigue resistance compared to conventional manufacturing approaches[8].

Strengths: Exceptional materials science expertise; superior in-situ monitoring capabilities; strong focus on powder characteristics and behavior modeling. Weaknesses: Less comprehensive end-to-end workflow integration compared to competitors; more focused on process optimization than full production line simulation; requires significant materials characterization investment.

International Business Machines Corp.

Technical Solution: IBM has developed an advanced Digital Twin framework specifically for Powder Bed Fusion Laser-Based (PBF-LB) superalloy production lines that integrates multi-physics simulation with real-time data analytics. Their approach combines high-fidelity computational models with machine learning algorithms to create accurate virtual representations of physical manufacturing processes. IBM's solution incorporates thermal modeling, microstructure prediction, and mechanical property simulation to predict material behavior during the PBF-LB process[1]. The system utilizes IBM's quantum-inspired optimization algorithms to enhance computational efficiency while maintaining accuracy. Their digital twin implementation features a closed-loop feedback system that continuously updates the virtual model based on sensor data from the physical production line, enabling real-time process optimization and quality control[3]. IBM has also integrated their Watson AI platform to provide predictive maintenance capabilities, reducing downtime in superalloy manufacturing facilities.

Strengths: Superior computational capabilities leveraging IBM's expertise in high-performance computing and AI; comprehensive integration with existing manufacturing execution systems; strong data security protocols. Weaknesses: Higher implementation costs compared to competitors; requires significant customization for specific superalloy applications; steeper learning curve for operators without advanced technical training.

Key Technologies Enabling PBF-LB Process Simulation

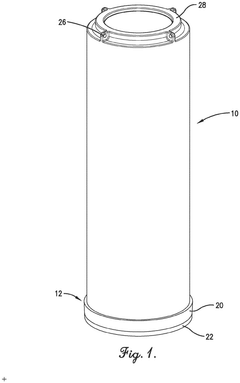

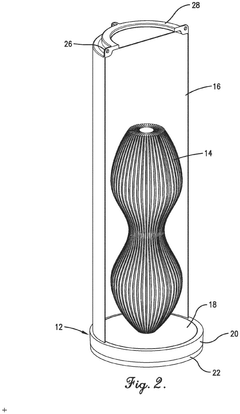

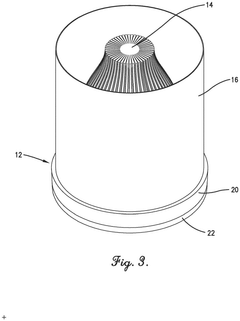

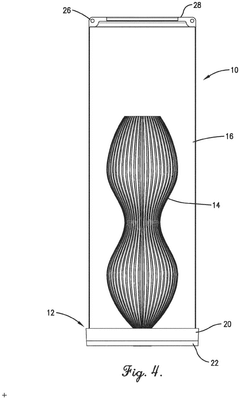

Method for three-dimensional printed powder containment

PatentPendingEP4509249A2

Innovation

- A method involving the simultaneous 3D printing of a canister with the printed part using a single additive manufacturing process, allowing for the containment of powder within the canister, which can then be transported and processed separately for powder removal and recycling.

Cybersecurity Considerations for Industrial Digital Twins

The integration of Digital Twin technology in PBF-LB (Powder Bed Fusion - Laser Beam) superalloy production lines introduces significant cybersecurity vulnerabilities that must be addressed comprehensively. As these digital replicas collect, process, and transmit sensitive operational data, they become potential entry points for malicious actors seeking to compromise industrial systems.

Primary security concerns include unauthorized access to proprietary manufacturing parameters, which could lead to intellectual property theft of critical superalloy formulations and processing techniques. The real-time monitoring capabilities of Digital Twins also create potential attack surfaces where threat actors could intercept data streams to extract valuable insights about production capabilities or introduce falsified sensor readings.

Supply chain vulnerabilities present another significant risk vector. PBF-LB superalloy production typically involves multiple stakeholders, each potentially contributing to the Digital Twin ecosystem. Without proper security protocols, these interconnections can create cascading vulnerabilities where a compromise in one system component affects the entire production line integrity.

The bidirectional communication between physical assets and their digital counterparts requires robust authentication mechanisms. Implementation of zero-trust architecture principles is essential, where every access request is fully authenticated, authorized, and encrypted regardless of the request's origin. This approach is particularly crucial for protecting the simulation models that predict superalloy microstructure development during the PBF-LB process.

Data integrity protection must extend across the entire Digital Twin lifecycle. Cryptographic validation of sensor data helps ensure that the virtual model accurately represents the physical state of the production line. Additionally, implementing blockchain technology can create tamper-evident logs of manufacturing parameters and material certifications, which is particularly valuable for aerospace and defense applications of superalloys.

Resilience planning should include air-gapped backup systems that can maintain basic production capabilities even during cybersecurity incidents. Regular penetration testing specifically targeting the Digital Twin infrastructure helps identify vulnerabilities before they can be exploited. These tests should simulate sophisticated attacks that might target the proprietary algorithms governing laser parameters and powder distribution in the PBF-LB process.

Regulatory compliance adds another layer of complexity, as superalloy components often serve critical applications subject to stringent certification requirements. Digital Twin security measures must therefore be documented and validated according to relevant industry standards such as IEC 62443 for industrial automation and control systems.

Primary security concerns include unauthorized access to proprietary manufacturing parameters, which could lead to intellectual property theft of critical superalloy formulations and processing techniques. The real-time monitoring capabilities of Digital Twins also create potential attack surfaces where threat actors could intercept data streams to extract valuable insights about production capabilities or introduce falsified sensor readings.

Supply chain vulnerabilities present another significant risk vector. PBF-LB superalloy production typically involves multiple stakeholders, each potentially contributing to the Digital Twin ecosystem. Without proper security protocols, these interconnections can create cascading vulnerabilities where a compromise in one system component affects the entire production line integrity.

The bidirectional communication between physical assets and their digital counterparts requires robust authentication mechanisms. Implementation of zero-trust architecture principles is essential, where every access request is fully authenticated, authorized, and encrypted regardless of the request's origin. This approach is particularly crucial for protecting the simulation models that predict superalloy microstructure development during the PBF-LB process.

Data integrity protection must extend across the entire Digital Twin lifecycle. Cryptographic validation of sensor data helps ensure that the virtual model accurately represents the physical state of the production line. Additionally, implementing blockchain technology can create tamper-evident logs of manufacturing parameters and material certifications, which is particularly valuable for aerospace and defense applications of superalloys.

Resilience planning should include air-gapped backup systems that can maintain basic production capabilities even during cybersecurity incidents. Regular penetration testing specifically targeting the Digital Twin infrastructure helps identify vulnerabilities before they can be exploited. These tests should simulate sophisticated attacks that might target the proprietary algorithms governing laser parameters and powder distribution in the PBF-LB process.

Regulatory compliance adds another layer of complexity, as superalloy components often serve critical applications subject to stringent certification requirements. Digital Twin security measures must therefore be documented and validated according to relevant industry standards such as IEC 62443 for industrial automation and control systems.

ROI Assessment for Digital Twin Implementation

Implementing digital twins for Powder Bed Fusion Laser Beam (PBF-LB) superalloy production lines requires significant investment, making ROI assessment critical for decision-makers. The financial analysis indicates that initial implementation costs range from $500,000 to $2 million, depending on production line complexity and the sophistication of the digital twin solution. These costs encompass hardware sensors, computing infrastructure, software development, and specialized staff training.

Return on investment typically materializes through multiple value streams. Production efficiency improvements of 15-25% have been documented in case studies, primarily through reduced material waste and optimized process parameters. Quality control enhancements result in defect reduction rates of 30-40%, significantly decreasing costly rework and scrap in high-value superalloy components.

Maintenance cost reduction represents another substantial ROI factor, with predictive maintenance capabilities reducing unplanned downtime by 25-35%. For superalloy production facilities operating 24/7, each hour of avoided downtime translates to approximately $10,000-$15,000 in preserved production value.

Time-to-market acceleration provides competitive advantages difficult to quantify but critically important. Digital twins enable virtual testing of new superalloy formulations and process parameters, reducing physical testing iterations by 40-60%. This acceleration can represent millions in additional revenue when bringing novel superalloy components to market ahead of competitors.

The ROI timeline analysis reveals that most implementations achieve break-even within 12-24 months. Early returns typically come from quality improvements and waste reduction, while more substantial benefits from process optimization and predictive capabilities materialize in years 2-3. Organizations implementing comprehensive digital twins report 300-400% ROI over a five-year period.

Risk factors affecting ROI include integration challenges with legacy systems, data quality issues, and staff adaptation curves. Companies that implement change management programs alongside technical implementation report 30% faster ROI realization. Additionally, scalability considerations significantly impact long-term returns, with modular approaches allowing for incremental investment aligned with validated returns from initial implementations.

Return on investment typically materializes through multiple value streams. Production efficiency improvements of 15-25% have been documented in case studies, primarily through reduced material waste and optimized process parameters. Quality control enhancements result in defect reduction rates of 30-40%, significantly decreasing costly rework and scrap in high-value superalloy components.

Maintenance cost reduction represents another substantial ROI factor, with predictive maintenance capabilities reducing unplanned downtime by 25-35%. For superalloy production facilities operating 24/7, each hour of avoided downtime translates to approximately $10,000-$15,000 in preserved production value.

Time-to-market acceleration provides competitive advantages difficult to quantify but critically important. Digital twins enable virtual testing of new superalloy formulations and process parameters, reducing physical testing iterations by 40-60%. This acceleration can represent millions in additional revenue when bringing novel superalloy components to market ahead of competitors.

The ROI timeline analysis reveals that most implementations achieve break-even within 12-24 months. Early returns typically come from quality improvements and waste reduction, while more substantial benefits from process optimization and predictive capabilities materialize in years 2-3. Organizations implementing comprehensive digital twins report 300-400% ROI over a five-year period.

Risk factors affecting ROI include integration challenges with legacy systems, data quality issues, and staff adaptation curves. Companies that implement change management programs alongside technical implementation report 30% faster ROI realization. Additionally, scalability considerations significantly impact long-term returns, with modular approaches allowing for incremental investment aligned with validated returns from initial implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!