Comparing PBF-LB With DED For Producing Repair And Near-Net Shapes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM Technology Evolution and Objectives

Additive Manufacturing (AM) has evolved significantly since its inception in the 1980s, transforming from a prototyping technology to a viable manufacturing process for functional parts. The evolution of AM technologies has been marked by continuous improvements in precision, material compatibility, and production efficiency. Among these technologies, Powder Bed Fusion-Laser Beam (PBF-LB) and Directed Energy Deposition (DED) have emerged as prominent methods with distinct capabilities and applications.

PBF-LB technology, developed in the early 1990s, has undergone substantial refinement over the past three decades. Initially limited to polymer materials, it has expanded to process various metals, including titanium alloys, nickel-based superalloys, and stainless steels. The evolution of PBF-LB has been characterized by increasing laser power, improved scanning strategies, and enhanced process monitoring capabilities, resulting in parts with superior mechanical properties and dimensional accuracy.

Concurrently, DED technology has evolved from its roots in laser cladding processes. The technology has progressed from simple single-bead deposition to sophisticated multi-axis systems capable of producing complex geometries. Significant advancements in powder feeding mechanisms, energy source control, and path planning algorithms have expanded DED's applications beyond simple repairs to the production of near-net shape components with functionally graded materials.

The primary objective of comparing PBF-LB and DED technologies is to establish optimal application scenarios for each method in repair operations and near-net shape manufacturing. This comparison aims to identify the technical boundaries, material compatibility, economic viability, and quality assurance parameters for both technologies. Understanding these factors is crucial for industries seeking to implement the most appropriate AM solution for specific manufacturing challenges.

Another key objective is to evaluate the potential for hybrid manufacturing approaches that combine the strengths of both technologies. By integrating PBF-LB's precision with DED's flexibility, manufacturers could potentially overcome the limitations inherent to each individual process. This evaluation includes assessing the technical feasibility, process integration challenges, and economic implications of such hybrid approaches.

Furthermore, this technological comparison seeks to establish a roadmap for future research and development efforts. By identifying current technological gaps and limitations, stakeholders can prioritize innovation initiatives to enhance the capabilities of both PBF-LB and DED for repair applications and near-net shape production, ultimately advancing the state of additive manufacturing technology.

PBF-LB technology, developed in the early 1990s, has undergone substantial refinement over the past three decades. Initially limited to polymer materials, it has expanded to process various metals, including titanium alloys, nickel-based superalloys, and stainless steels. The evolution of PBF-LB has been characterized by increasing laser power, improved scanning strategies, and enhanced process monitoring capabilities, resulting in parts with superior mechanical properties and dimensional accuracy.

Concurrently, DED technology has evolved from its roots in laser cladding processes. The technology has progressed from simple single-bead deposition to sophisticated multi-axis systems capable of producing complex geometries. Significant advancements in powder feeding mechanisms, energy source control, and path planning algorithms have expanded DED's applications beyond simple repairs to the production of near-net shape components with functionally graded materials.

The primary objective of comparing PBF-LB and DED technologies is to establish optimal application scenarios for each method in repair operations and near-net shape manufacturing. This comparison aims to identify the technical boundaries, material compatibility, economic viability, and quality assurance parameters for both technologies. Understanding these factors is crucial for industries seeking to implement the most appropriate AM solution for specific manufacturing challenges.

Another key objective is to evaluate the potential for hybrid manufacturing approaches that combine the strengths of both technologies. By integrating PBF-LB's precision with DED's flexibility, manufacturers could potentially overcome the limitations inherent to each individual process. This evaluation includes assessing the technical feasibility, process integration challenges, and economic implications of such hybrid approaches.

Furthermore, this technological comparison seeks to establish a roadmap for future research and development efforts. By identifying current technological gaps and limitations, stakeholders can prioritize innovation initiatives to enhance the capabilities of both PBF-LB and DED for repair applications and near-net shape production, ultimately advancing the state of additive manufacturing technology.

Market Demand Analysis for Metal AM Repair Solutions

The metal additive manufacturing (AM) repair market is experiencing significant growth, driven by increasing demand across aerospace, automotive, energy, and heavy machinery sectors. This growth is primarily fueled by the economic advantages of repairing high-value components rather than replacing them, which can reduce costs by 30-70% depending on the component complexity and material.

Aerospace remains the dominant market segment for metal AM repair solutions, with an estimated market share exceeding 40%. The industry's stringent requirements for lightweight, high-performance components with complex geometries make it an ideal candidate for AM repair technologies. Commercial aviation maintenance, repair, and overhaul (MRO) operations are increasingly adopting these technologies to extend the service life of critical engine components and structural parts.

The energy sector, particularly oil and gas and power generation, represents the second-largest market segment. Repair of turbine blades, impellers, and other high-value components in harsh operating environments has created substantial demand for advanced repair solutions. The ability to restore components with enhanced properties is particularly valuable in this sector.

Defense applications are showing the fastest growth rate in the metal AM repair market, with military organizations worldwide investing in field-deployable repair capabilities. This trend is driven by the need to maintain operational readiness and reduce logistics burdens in remote locations.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, primarily due to rapid industrialization in China and India.

Customer requirements are evolving toward integrated repair solutions that combine both PBF-LB and DED technologies. End-users increasingly demand repair solutions that can address a wider range of damage scenarios, from surface wear to significant material loss. This has created a market opportunity for hybrid systems that can leverage the precision of PBF-LB and the higher deposition rates of DED.

Material compatibility remains a critical market driver, with demand highest for repair solutions capable of processing nickel-based superalloys, titanium alloys, and tool steels. The ability to repair components while maintaining or enhancing material properties is a key differentiator in the competitive landscape.

Market forecasts suggest the global metal AM repair market will continue its strong growth trajectory, with particular emphasis on solutions that offer improved process monitoring, quality assurance, and certification pathways. As regulatory frameworks mature, technologies that can provide documented repair quality and consistency will capture premium market positions.

Aerospace remains the dominant market segment for metal AM repair solutions, with an estimated market share exceeding 40%. The industry's stringent requirements for lightweight, high-performance components with complex geometries make it an ideal candidate for AM repair technologies. Commercial aviation maintenance, repair, and overhaul (MRO) operations are increasingly adopting these technologies to extend the service life of critical engine components and structural parts.

The energy sector, particularly oil and gas and power generation, represents the second-largest market segment. Repair of turbine blades, impellers, and other high-value components in harsh operating environments has created substantial demand for advanced repair solutions. The ability to restore components with enhanced properties is particularly valuable in this sector.

Defense applications are showing the fastest growth rate in the metal AM repair market, with military organizations worldwide investing in field-deployable repair capabilities. This trend is driven by the need to maintain operational readiness and reduce logistics burdens in remote locations.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, primarily due to rapid industrialization in China and India.

Customer requirements are evolving toward integrated repair solutions that combine both PBF-LB and DED technologies. End-users increasingly demand repair solutions that can address a wider range of damage scenarios, from surface wear to significant material loss. This has created a market opportunity for hybrid systems that can leverage the precision of PBF-LB and the higher deposition rates of DED.

Material compatibility remains a critical market driver, with demand highest for repair solutions capable of processing nickel-based superalloys, titanium alloys, and tool steels. The ability to repair components while maintaining or enhancing material properties is a key differentiator in the competitive landscape.

Market forecasts suggest the global metal AM repair market will continue its strong growth trajectory, with particular emphasis on solutions that offer improved process monitoring, quality assurance, and certification pathways. As regulatory frameworks mature, technologies that can provide documented repair quality and consistency will capture premium market positions.

PBF-LB and DED: Current Capabilities and Limitations

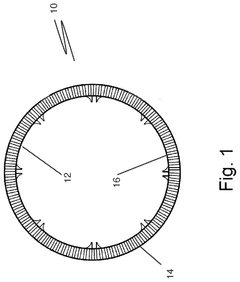

PBF-LB technology demonstrates exceptional precision capabilities, achieving dimensional accuracies of ±0.05mm and surface roughness values as low as Ra 5μm in optimal conditions. This precision stems from its fine powder bed environment and precise laser control systems. However, PBF-LB exhibits significant limitations in build volume, typically restricted to 250×250×300mm for standard systems, with only specialized equipment reaching 800×400×500mm dimensions. This constraint severely limits the technology's application for large-scale repair operations or substantial near-net shape production.

Material compatibility represents another critical consideration for PBF-LB systems. While they excel with specific metal alloys including titanium, aluminum, and nickel-based superalloys, they struggle with materials possessing high reflectivity or thermal conductivity. The closed powder bed environment also restricts material changes during builds, limiting multi-material applications essential for certain repair scenarios.

In contrast, DED technology offers substantially larger build volumes, with standard systems capable of producing parts up to 2000×1500×1000mm. This expanded capacity makes DED particularly suitable for large component repairs and near-net shape manufacturing of substantial parts. DED systems also demonstrate superior deposition rates, typically 0.5-2kg/h compared to PBF-LB's 0.1-0.2kg/h, significantly reducing production time for larger components.

DED technology exhibits remarkable versatility in material handling, supporting on-the-fly material changes during builds and enabling gradient material structures. This capability proves invaluable for repair applications where matching substrate materials or creating transition zones between different alloys becomes necessary. Additionally, DED can process a wider range of materials, including those challenging for PBF-LB systems.

However, DED technology presents notable limitations in dimensional accuracy (typically ±0.25mm) and surface finish (Ra 25μm or higher), requiring additional post-processing operations. The open-air processing environment also necessitates more robust shielding gas systems to prevent oxidation, particularly when working with reactive materials like titanium alloys.

Energy efficiency represents another significant difference between these technologies. PBF-LB systems typically utilize 30-40% of input energy for actual part creation, while DED systems achieve higher efficiency rates of 50-70% due to their direct deposition approach. This efficiency differential impacts both operational costs and environmental considerations for large-scale production scenarios.

Material compatibility represents another critical consideration for PBF-LB systems. While they excel with specific metal alloys including titanium, aluminum, and nickel-based superalloys, they struggle with materials possessing high reflectivity or thermal conductivity. The closed powder bed environment also restricts material changes during builds, limiting multi-material applications essential for certain repair scenarios.

In contrast, DED technology offers substantially larger build volumes, with standard systems capable of producing parts up to 2000×1500×1000mm. This expanded capacity makes DED particularly suitable for large component repairs and near-net shape manufacturing of substantial parts. DED systems also demonstrate superior deposition rates, typically 0.5-2kg/h compared to PBF-LB's 0.1-0.2kg/h, significantly reducing production time for larger components.

DED technology exhibits remarkable versatility in material handling, supporting on-the-fly material changes during builds and enabling gradient material structures. This capability proves invaluable for repair applications where matching substrate materials or creating transition zones between different alloys becomes necessary. Additionally, DED can process a wider range of materials, including those challenging for PBF-LB systems.

However, DED technology presents notable limitations in dimensional accuracy (typically ±0.25mm) and surface finish (Ra 25μm or higher), requiring additional post-processing operations. The open-air processing environment also necessitates more robust shielding gas systems to prevent oxidation, particularly when working with reactive materials like titanium alloys.

Energy efficiency represents another significant difference between these technologies. PBF-LB systems typically utilize 30-40% of input energy for actual part creation, while DED systems achieve higher efficiency rates of 50-70% due to their direct deposition approach. This efficiency differential impacts both operational costs and environmental considerations for large-scale production scenarios.

Comparative Analysis of PBF-LB vs DED Solutions

01 PBF-LB technology for repair and near-net shape production

Powder Bed Fusion-Laser Beam (PBF-LB) technology enables precise repair of damaged components and production of near-net shape parts. This additive manufacturing method uses a laser to selectively melt metal powder in a layer-by-layer approach, allowing for complex geometries with minimal post-processing. The technology is particularly effective for repairing high-value components in aerospace and automotive industries, offering significant material savings and reduced lead times compared to traditional manufacturing methods.- PBF-LB technology for repair and near-net shape production: Powder Bed Fusion-Laser Beam (PBF-LB) technology enables precise repair of damaged components and production of near-net shape parts. This additive manufacturing method uses a laser to selectively melt metal powder in a bed, allowing for complex geometries with minimal post-processing. The technology is particularly effective for repairing high-value components in aerospace and automotive industries, offering advantages in material efficiency and reduced lead times compared to traditional manufacturing methods.

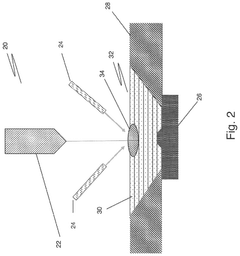

- DED technology for component repair and restoration: Directed Energy Deposition (DED) technology excels in repair applications, particularly for worn or damaged metal components. By precisely depositing material only where needed, DED can restore components to their original specifications with minimal heat-affected zones. This approach is especially valuable for high-value parts in aerospace, defense, and heavy machinery sectors, offering significant cost savings compared to component replacement. The process allows for multi-material deposition and can be used to enhance surface properties of existing parts.

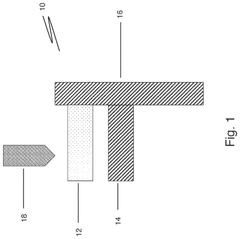

- Hybrid manufacturing combining additive and subtractive processes: Hybrid manufacturing systems integrate additive manufacturing technologies like PBF-LB and DED with subtractive processes such as CNC machining. This combination allows for the production of complex near-net shape components that require high dimensional accuracy and surface finish. The additive process builds the basic geometry while the subtractive process refines critical features. This approach optimizes material usage, reduces production time, and enables the manufacture of components that would be difficult or impossible to produce using traditional methods alone.

- Material development for PBF-LB and DED processes: Specialized materials have been developed specifically for PBF-LB and DED additive manufacturing processes to enhance repair capabilities and near-net shape production. These materials include customized metal powders with optimized particle size distribution, flowability, and thermal properties. Advanced alloys designed for these processes offer improved weldability, reduced cracking susceptibility, and enhanced mechanical properties in the as-built condition. The development of these materials has expanded the range of applications for additive repair and production techniques across various industries.

- Process monitoring and quality control in additive repair: Advanced monitoring and quality control systems have been developed for PBF-LB and DED processes to ensure reliable repair and near-net shape production. These systems incorporate real-time monitoring of process parameters such as melt pool dynamics, thermal gradients, and deposition rates. Machine learning algorithms analyze this data to detect anomalies and predict potential defects. Closed-loop control systems can automatically adjust process parameters to maintain quality throughout the build. These technologies are crucial for ensuring the structural integrity and performance of additively manufactured repair features and components.

02 DED technology for component repair and restoration

Directed Energy Deposition (DED) technology excels in repair applications, particularly for large components and high-value parts. This process deposits material directly where needed, making it ideal for restoring worn or damaged surfaces. DED can utilize various energy sources including lasers, electron beams, or plasma arcs to melt the feedstock material. The technology allows for gradient materials and functionally graded structures, enabling repairs that match or exceed the original component's properties while minimizing heat-affected zones.Expand Specific Solutions03 Hybrid manufacturing combining additive and subtractive processes

Hybrid manufacturing systems integrate additive technologies like PBF-LB or DED with subtractive processes such as CNC machining. This combination allows for the deposition of material through additive manufacturing followed by precision machining to achieve final dimensional accuracy. The hybrid approach is particularly valuable for repair applications where both material addition and surface finishing are required. This integration enhances the capability to produce complex near-net shape components with superior surface quality and dimensional accuracy.Expand Specific Solutions04 Material considerations for PBF-LB and DED processes

Material selection and preparation are critical factors in both PBF-LB and DED additive manufacturing technologies. For PBF-LB, powder characteristics such as particle size distribution, flowability, and packing density significantly impact the quality of the final part. DED processes can utilize both powder and wire feedstock, with each offering distinct advantages for different repair scenarios. Advanced materials including superalloys, titanium alloys, and specialized steels can be processed using these technologies, enabling repairs and near-net shape production for high-performance applications.Expand Specific Solutions05 Process monitoring and quality control in additive repair

Advanced monitoring systems and quality control protocols are essential for successful repair and near-net shape production using PBF-LB and DED technologies. In-situ monitoring techniques including thermal imaging, optical tomography, and acoustic emission analysis enable real-time detection of defects and process anomalies. Closed-loop control systems can adjust process parameters dynamically to maintain consistent quality. Post-process inspection methods such as CT scanning and ultrasonic testing verify the integrity of repaired components, ensuring they meet or exceed the performance requirements of the original parts.Expand Specific Solutions

Leading Companies in PBF-LB and DED Technologies

The additive manufacturing landscape for PBF-LB and DED technologies is currently in a growth phase, with the market expanding rapidly as industries recognize their complementary capabilities for repair and near-net shape production. The global market is projected to reach significant scale, driven by aerospace, defense, and industrial applications. Technologically, PBF-LB has reached higher maturity levels with companies like RTX Corp., Divergent Technologies, and DMG MORI leading implementation in high-precision components. DED technology, championed by EWI, Prima Additive, and Siemens Energy, is gaining traction for repair applications and larger structures due to its flexibility. Research institutions including Tsinghua University, Nanyang Technological University, and A*STAR are accelerating innovation through collaborative industry partnerships, pushing both technologies toward mainstream industrial adoption.

Edison Welding Institute, Inc.

Technical Solution: Edison Welding Institute (EWI) has conducted extensive comparative research between PBF-LB and DED technologies for repair and near-net shape applications. Their analysis shows that PBF-LB achieves feature resolution down to 0.1mm with surface roughness values of Ra 5-15μm, while their optimized DED processes typically achieve 0.5mm resolution with Ra 25-50μm surface finish. EWI has developed specialized DED techniques for repair applications, including adaptive path planning that adjusts deposition parameters based on real-time thermal imaging, reducing heat-affected zone size by up to 40% compared to conventional approaches. For aerospace component repair, EWI's hybrid DED system incorporates in-situ metrology that enables closed-loop control of geometry, achieving dimensional accuracy within ±0.2mm on complex repair geometries. Their comparative material studies demonstrate that DED-repaired components can achieve 95-98% of base material properties when proper post-processing is applied, compared to 85-90% typically achieved with PBF-LB repairs. EWI has also pioneered multi-material DED processes that enable functional grading between dissimilar metals, creating repair interfaces with enhanced mechanical properties that outperform homogeneous repairs in thermal cycling tests by up to 30% longer fatigue life.

EWI's strength is their comprehensive testing and validation capabilities, allowing for direct comparison of both technologies across multiple parameters including microstructure, mechanical properties, and process economics. Their application-specific process development approach ensures optimized solutions for particular repair scenarios. The limitation is that their research findings often require significant adaptation when scaling to production environments, and their custom solutions typically require specialized equipment configurations not readily available in commercial systems.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed comprehensive comparative frameworks for PBF-LB and DED technologies, with particular focus on repair applications and near-net shape manufacturing for aerospace and defense sectors. Their research has established that PBF-LB achieves superior dimensional accuracy (±0.05mm) and surface finish (Ra 5-10μm) compared to DED (±0.25mm accuracy, Ra 25-40μm), making it preferable for components with fine features. However, CSIRO's modified DED processes demonstrate deposition rates of 0.5-2 kg/h, significantly outpacing PBF-LB rates of 0.05-0.2 kg/h for the same materials. For repair applications, CSIRO has pioneered hybrid sensor systems that combine thermal imaging with acoustic monitoring to detect and prevent defect formation during DED processing, reducing repair rejection rates by approximately 60%. Their material science research has shown that DED-repaired components can achieve equivalent or superior fatigue performance to virgin material when appropriate heat treatment protocols are applied, whereas PBF-LB repairs typically require hot isostatic pressing to eliminate porosity that can reduce fatigue life. CSIRO has also developed specialized software tools that optimize process parameters for both technologies based on component geometry and material properties, reducing development time for new repair applications by up to 70%.

CSIRO's strength lies in their holistic approach that considers not only technical performance but also economic and environmental impacts of each technology. Their extensive material characterization capabilities enable precise tailoring of processes to specific repair scenarios. The main limitation is the research-focused nature of their work, which sometimes prioritizes fundamental understanding over immediate industrial implementation, resulting in solutions that require further development before commercial deployment.

Technical Innovations in Metal Repair Applications

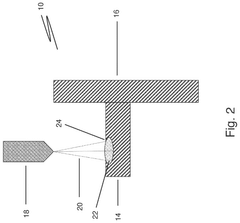

Hybrid additive manufacturing repair with powder bed fusion feature and directed energy deposition joining

PatentPendingUS20250242451A1

Innovation

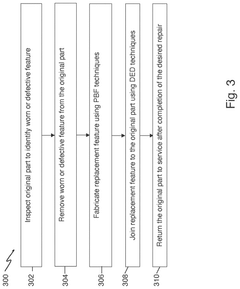

- A hybrid repair process combining powder bed fusion (PBF) and directed energy deposition (DED) techniques is used to fabricate and join replacement features to original parts, utilizing the same base material, thereby reducing or eliminating heat-affected zones and improving repair quality.

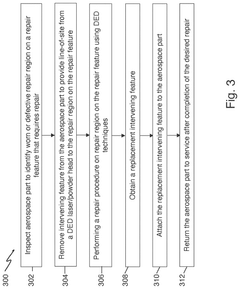

Additive manufacturing removal and replacement of feature to enable access during directed energy deposition repair process

PatentPendingUS20250242408A1

Innovation

- The method involves removing intervening features to create line-of-sight for DED laser/powder heads, repairing the exposed site using DED techniques, and reattaching a replacement feature using DED or additive manufacturing (AM) methods.

Material Compatibility and Process Parameters

Material compatibility is a critical factor when comparing PBF-LB and DED processes for repair and near-net shape applications. PBF-LB demonstrates excellent compatibility with a wide range of metal powders including titanium alloys, nickel-based superalloys, aluminum alloys, and stainless steels. The controlled environment of PBF-LB, typically utilizing an inert gas atmosphere, minimizes oxidation and contamination, making it particularly suitable for reactive materials like titanium. However, PBF-LB requires specific powder characteristics including spherical morphology, optimal size distribution (typically 15-45 μm), and excellent flowability to ensure uniform layer deposition.

DED technology offers broader material flexibility, accommodating both powder and wire feedstock forms. This versatility extends to processing materials with higher melting points and those prone to cracking during rapid solidification. DED can effectively handle larger particle sizes (50-150 μm) and demonstrates superior capability for multi-material deposition, enabling functionally graded components and dissimilar material joints. This attribute is particularly valuable in repair applications where the substrate material may differ from the repair material.

Process parameters significantly influence the quality and properties of components produced by both technologies. For PBF-LB, critical parameters include laser power (typically 200-1000W), scan speed (0.5-7 m/s), hatch spacing (60-150 μm), and layer thickness (20-100 μm). The energy density, calculated from these parameters, must be optimized for each specific material to achieve desired microstructure and mechanical properties while minimizing defects such as porosity and residual stress.

DED process parameters exhibit wider operational windows, with laser powers ranging from 500W to 4kW, travel speeds of 5-20 mm/s, and material feed rates of 2-10 g/min for powder-based systems. The larger melt pool characteristic of DED processes results in different cooling rates (10³-10⁴ K/s) compared to PBF-LB (10⁵-10⁶ K/s), yielding distinct microstructural features and mechanical properties.

Environmental control requirements also differ significantly between the two processes. PBF-LB typically requires oxygen levels below 0.1% to prevent oxidation and combustion risks, while DED can operate with localized shielding gas delivery, offering greater flexibility for large component processing and in-situ repairs. This distinction becomes particularly important when considering the integration of these technologies into existing manufacturing environments or field repair operations.

DED technology offers broader material flexibility, accommodating both powder and wire feedstock forms. This versatility extends to processing materials with higher melting points and those prone to cracking during rapid solidification. DED can effectively handle larger particle sizes (50-150 μm) and demonstrates superior capability for multi-material deposition, enabling functionally graded components and dissimilar material joints. This attribute is particularly valuable in repair applications where the substrate material may differ from the repair material.

Process parameters significantly influence the quality and properties of components produced by both technologies. For PBF-LB, critical parameters include laser power (typically 200-1000W), scan speed (0.5-7 m/s), hatch spacing (60-150 μm), and layer thickness (20-100 μm). The energy density, calculated from these parameters, must be optimized for each specific material to achieve desired microstructure and mechanical properties while minimizing defects such as porosity and residual stress.

DED process parameters exhibit wider operational windows, with laser powers ranging from 500W to 4kW, travel speeds of 5-20 mm/s, and material feed rates of 2-10 g/min for powder-based systems. The larger melt pool characteristic of DED processes results in different cooling rates (10³-10⁴ K/s) compared to PBF-LB (10⁵-10⁶ K/s), yielding distinct microstructural features and mechanical properties.

Environmental control requirements also differ significantly between the two processes. PBF-LB typically requires oxygen levels below 0.1% to prevent oxidation and combustion risks, while DED can operate with localized shielding gas delivery, offering greater flexibility for large component processing and in-situ repairs. This distinction becomes particularly important when considering the integration of these technologies into existing manufacturing environments or field repair operations.

Cost-Benefit Analysis of Repair vs New Production

When evaluating the economic viability of repair versus new production using advanced manufacturing technologies like PBF-LB and DED, several critical factors must be considered. The initial investment for PBF-LB systems typically ranges from $500,000 to $1.5 million, while DED systems generally cost between $400,000 and $1 million. However, the total cost equation extends far beyond equipment acquisition.

For repair applications, DED demonstrates significant advantages with operational costs approximately 30-40% lower than complete replacement manufacturing. This is primarily due to material efficiency, as DED processes utilize 90-95% of the feedstock material compared to PBF-LB's 60-70% utilization rate. When repairing high-value components such as turbine blades or industrial tooling, material savings alone can justify the investment in DED technology.

Time-to-market considerations further favor repair strategies. DED repair processes typically require 40-60% less production time than manufacturing new components, particularly for complex geometries or specialized alloys. This translates to reduced downtime for critical equipment and faster return to operational status, a crucial factor in industries like aerospace, energy, and heavy manufacturing where equipment availability directly impacts revenue.

The environmental impact analysis reveals that repair strategies using DED can reduce the carbon footprint by up to 70% compared to new production. This stems from decreased raw material consumption, reduced energy requirements, and minimized transportation needs. As environmental regulations tighten globally, these sustainability benefits increasingly translate to tangible financial advantages through carbon credits, regulatory compliance, and enhanced brand value.

Lifecycle cost analysis demonstrates that components repaired via DED typically maintain 85-95% of the original part's performance characteristics while extending service life by 60-80% of the original duration. This creates a compelling value proposition, particularly for components with high initial manufacturing costs or those made from expensive materials like nickel superalloys or titanium alloys.

Risk assessment must account for the technical limitations of each approach. PBF-LB excels in producing new components with complex internal features but presents challenges for repair scenarios due to limited build volumes and potential thermal stress issues. Conversely, DED offers superior flexibility for repair but may not achieve the same dimensional precision as PBF-LB for entirely new components, potentially necessitating additional post-processing.

The optimal economic strategy often involves a hybrid approach, utilizing DED for repair of high-value components where material and time savings justify the investment, while reserving new production via PBF-LB for cases where design optimization or internal feature complexity provides compelling performance advantages that outweigh the higher production costs.

For repair applications, DED demonstrates significant advantages with operational costs approximately 30-40% lower than complete replacement manufacturing. This is primarily due to material efficiency, as DED processes utilize 90-95% of the feedstock material compared to PBF-LB's 60-70% utilization rate. When repairing high-value components such as turbine blades or industrial tooling, material savings alone can justify the investment in DED technology.

Time-to-market considerations further favor repair strategies. DED repair processes typically require 40-60% less production time than manufacturing new components, particularly for complex geometries or specialized alloys. This translates to reduced downtime for critical equipment and faster return to operational status, a crucial factor in industries like aerospace, energy, and heavy manufacturing where equipment availability directly impacts revenue.

The environmental impact analysis reveals that repair strategies using DED can reduce the carbon footprint by up to 70% compared to new production. This stems from decreased raw material consumption, reduced energy requirements, and minimized transportation needs. As environmental regulations tighten globally, these sustainability benefits increasingly translate to tangible financial advantages through carbon credits, regulatory compliance, and enhanced brand value.

Lifecycle cost analysis demonstrates that components repaired via DED typically maintain 85-95% of the original part's performance characteristics while extending service life by 60-80% of the original duration. This creates a compelling value proposition, particularly for components with high initial manufacturing costs or those made from expensive materials like nickel superalloys or titanium alloys.

Risk assessment must account for the technical limitations of each approach. PBF-LB excels in producing new components with complex internal features but presents challenges for repair scenarios due to limited build volumes and potential thermal stress issues. Conversely, DED offers superior flexibility for repair but may not achieve the same dimensional precision as PBF-LB for entirely new components, potentially necessitating additional post-processing.

The optimal economic strategy often involves a hybrid approach, utilizing DED for repair of high-value components where material and time savings justify the investment, while reserving new production via PBF-LB for cases where design optimization or internal feature complexity provides compelling performance advantages that outweigh the higher production costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!