Innovations In Powder Atomization For Tailored Superalloy Feedstocks

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy Powder Atomization Background and Objectives

Powder atomization has evolved significantly since its inception in the 1960s as a method for producing metal powders. Initially developed for conventional alloys, this technology has undergone substantial refinement to meet the increasingly stringent requirements of superalloy production. The evolution from simple gas atomization to sophisticated vacuum induction melting gas atomization (VIM-GA) and plasma rotating electrode processes (PREP) represents a technological trajectory driven by the aerospace, energy, and defense sectors' demand for higher performance materials.

The current technological landscape is characterized by a push toward greater precision in particle size distribution, morphology control, and chemical homogeneity. These advancements are critical as superalloys continue to be deployed in more extreme operating environments, where material performance directly impacts system reliability and efficiency. Recent innovations have focused on tailoring powder characteristics to specific application requirements, recognizing that the powder feedstock properties significantly influence the final component performance.

Market trends indicate a growing demand for superalloy powders with application-specific properties, particularly for additive manufacturing processes. This shift has accelerated research into atomization technologies that can produce powders with controlled oxygen content, minimal satellite formation, and optimized flowability. The integration of computational modeling with experimental approaches has emerged as a key enabler for predicting and controlling atomization outcomes.

The primary objective of current research in superalloy powder atomization is to develop processes that yield consistent, high-quality feedstocks with tailored characteristics. This includes achieving narrower particle size distributions, enhanced sphericity, and controlled internal microstructures. Additionally, there is significant interest in reducing process variability and increasing yield rates to improve economic viability.

Another critical goal is the development of atomization technologies capable of processing novel superalloy compositions, including those with reactive elements or complex phase structures. These advanced materials promise superior performance but present considerable processing challenges that conventional atomization methods struggle to address.

Environmental and sustainability considerations are also shaping the technological trajectory, with efforts directed toward reducing energy consumption, minimizing material waste, and developing closed-loop recycling systems for powder production. These objectives align with broader industry trends toward more sustainable manufacturing practices.

The convergence of these technological developments and market demands creates a dynamic landscape for innovation in superalloy powder atomization, with significant opportunities for breakthrough technologies that can deliver tailored feedstocks for next-generation applications.

The current technological landscape is characterized by a push toward greater precision in particle size distribution, morphology control, and chemical homogeneity. These advancements are critical as superalloys continue to be deployed in more extreme operating environments, where material performance directly impacts system reliability and efficiency. Recent innovations have focused on tailoring powder characteristics to specific application requirements, recognizing that the powder feedstock properties significantly influence the final component performance.

Market trends indicate a growing demand for superalloy powders with application-specific properties, particularly for additive manufacturing processes. This shift has accelerated research into atomization technologies that can produce powders with controlled oxygen content, minimal satellite formation, and optimized flowability. The integration of computational modeling with experimental approaches has emerged as a key enabler for predicting and controlling atomization outcomes.

The primary objective of current research in superalloy powder atomization is to develop processes that yield consistent, high-quality feedstocks with tailored characteristics. This includes achieving narrower particle size distributions, enhanced sphericity, and controlled internal microstructures. Additionally, there is significant interest in reducing process variability and increasing yield rates to improve economic viability.

Another critical goal is the development of atomization technologies capable of processing novel superalloy compositions, including those with reactive elements or complex phase structures. These advanced materials promise superior performance but present considerable processing challenges that conventional atomization methods struggle to address.

Environmental and sustainability considerations are also shaping the technological trajectory, with efforts directed toward reducing energy consumption, minimizing material waste, and developing closed-loop recycling systems for powder production. These objectives align with broader industry trends toward more sustainable manufacturing practices.

The convergence of these technological developments and market demands creates a dynamic landscape for innovation in superalloy powder atomization, with significant opportunities for breakthrough technologies that can deliver tailored feedstocks for next-generation applications.

Market Analysis for Advanced Superalloy Powder Applications

The global market for advanced superalloy powders continues to experience robust growth, driven primarily by increasing demand from aerospace, power generation, and additive manufacturing sectors. Current market valuations place the superalloy powder market at approximately 1.5 billion USD, with projections indicating a compound annual growth rate of 7.2% through 2028. This growth trajectory is supported by expanding applications in critical components for gas turbines, jet engines, and high-temperature industrial equipment.

Aerospace remains the dominant application segment, accounting for nearly 45% of the total market share. The commercial aviation sector's recovery post-pandemic and increased defense spending globally have created sustained demand for high-performance superalloy powders. Engine manufacturers are particularly focused on materials that enable higher operating temperatures and improved fuel efficiency to meet stringent environmental regulations.

The power generation sector represents the second-largest market segment, with approximately 30% market share. As countries transition toward cleaner energy solutions, advanced gas turbines requiring superalloy components are seeing increased deployment. This trend is particularly evident in regions investing in combined cycle power plants and distributed energy systems.

Additive manufacturing applications, though currently representing only about 15% of the market, demonstrate the highest growth rate at nearly 12% annually. The ability to produce complex geometries with tailored microstructures is revolutionizing component design across multiple industries. This segment's expansion is further accelerated by decreasing equipment costs and growing technical expertise in metal 3D printing.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 65%. However, the Asia-Pacific region is experiencing the fastest growth, particularly in China, Japan, and India, where aerospace and energy infrastructure investments are substantial. These emerging markets are expected to account for over 30% of global demand by 2028.

Customer requirements are increasingly focused on powder consistency, sphericity, and tailored particle size distributions. End-users are willing to pay premium prices for powders that demonstrate superior flowability, packing density, and minimal contamination. This trend has driven atomization technology innovations, with gas atomization methods gaining preference over water atomization due to superior powder morphology and purity characteristics.

Aerospace remains the dominant application segment, accounting for nearly 45% of the total market share. The commercial aviation sector's recovery post-pandemic and increased defense spending globally have created sustained demand for high-performance superalloy powders. Engine manufacturers are particularly focused on materials that enable higher operating temperatures and improved fuel efficiency to meet stringent environmental regulations.

The power generation sector represents the second-largest market segment, with approximately 30% market share. As countries transition toward cleaner energy solutions, advanced gas turbines requiring superalloy components are seeing increased deployment. This trend is particularly evident in regions investing in combined cycle power plants and distributed energy systems.

Additive manufacturing applications, though currently representing only about 15% of the market, demonstrate the highest growth rate at nearly 12% annually. The ability to produce complex geometries with tailored microstructures is revolutionizing component design across multiple industries. This segment's expansion is further accelerated by decreasing equipment costs and growing technical expertise in metal 3D printing.

Regionally, North America and Europe currently dominate the market with a combined share of approximately 65%. However, the Asia-Pacific region is experiencing the fastest growth, particularly in China, Japan, and India, where aerospace and energy infrastructure investments are substantial. These emerging markets are expected to account for over 30% of global demand by 2028.

Customer requirements are increasingly focused on powder consistency, sphericity, and tailored particle size distributions. End-users are willing to pay premium prices for powders that demonstrate superior flowability, packing density, and minimal contamination. This trend has driven atomization technology innovations, with gas atomization methods gaining preference over water atomization due to superior powder morphology and purity characteristics.

Global Powder Atomization Technology Landscape and Barriers

The global powder atomization technology landscape has evolved significantly over the past decades, with major technological hubs emerging in North America, Europe, and East Asia. The United States maintains leadership in advanced atomization technologies, particularly for aerospace and defense applications, while European countries like Germany, Sweden, and the UK excel in precision atomization systems for high-performance alloys. China has rapidly expanded its capabilities, focusing on large-scale production facilities and cost-effective solutions.

Current atomization technologies for superalloy powder production include gas atomization (GA), vacuum induction gas atomization (VIGA), plasma atomization (PA), and rotating electrode process (REP). Each presents distinct advantages and limitations. GA remains the most widely adopted due to its scalability and cost-effectiveness, though it struggles with achieving ultrafine powder distributions. VIGA offers superior control of oxygen content but at significantly higher operational costs. PA produces highly spherical powders with excellent flowability but faces throughput limitations and high energy consumption.

The primary technical barriers in superalloy powder atomization include achieving consistent particle morphology, controlling interstitial element contamination, and managing the trade-off between production rate and powder quality. Particularly challenging is the atomization of reactive elements in superalloys, which often requires specialized melting and atomization environments to prevent oxidation and nitridation.

Economic barriers are equally significant, with high capital equipment costs ranging from $5-20 million for advanced atomization systems. Operating costs are further elevated by the need for high-purity inert gases and specialized handling procedures. These economic factors have created a concentrated market where few players can afford entry, limiting innovation diffusion.

Regulatory and standardization challenges persist across different regions, with inconsistent quality certification requirements complicating global trade in atomized superalloy powders. The aerospace industry's stringent qualification processes can take 2-5 years, creating substantial barriers to new technology adoption.

Environmental considerations are increasingly important, with traditional atomization processes facing scrutiny for their high energy consumption and gas usage. Newer technologies are emerging that focus on recycling process gases and improving energy efficiency, though these often come with additional capital requirements.

The geographical distribution of atomization technology development shows interesting patterns, with fundamental research concentrated in academic centers across North America and Europe, while production scaling innovations are increasingly emerging from East Asian research institutions and companies.

Current atomization technologies for superalloy powder production include gas atomization (GA), vacuum induction gas atomization (VIGA), plasma atomization (PA), and rotating electrode process (REP). Each presents distinct advantages and limitations. GA remains the most widely adopted due to its scalability and cost-effectiveness, though it struggles with achieving ultrafine powder distributions. VIGA offers superior control of oxygen content but at significantly higher operational costs. PA produces highly spherical powders with excellent flowability but faces throughput limitations and high energy consumption.

The primary technical barriers in superalloy powder atomization include achieving consistent particle morphology, controlling interstitial element contamination, and managing the trade-off between production rate and powder quality. Particularly challenging is the atomization of reactive elements in superalloys, which often requires specialized melting and atomization environments to prevent oxidation and nitridation.

Economic barriers are equally significant, with high capital equipment costs ranging from $5-20 million for advanced atomization systems. Operating costs are further elevated by the need for high-purity inert gases and specialized handling procedures. These economic factors have created a concentrated market where few players can afford entry, limiting innovation diffusion.

Regulatory and standardization challenges persist across different regions, with inconsistent quality certification requirements complicating global trade in atomized superalloy powders. The aerospace industry's stringent qualification processes can take 2-5 years, creating substantial barriers to new technology adoption.

Environmental considerations are increasingly important, with traditional atomization processes facing scrutiny for their high energy consumption and gas usage. Newer technologies are emerging that focus on recycling process gases and improving energy efficiency, though these often come with additional capital requirements.

The geographical distribution of atomization technology development shows interesting patterns, with fundamental research concentrated in academic centers across North America and Europe, while production scaling innovations are increasingly emerging from East Asian research institutions and companies.

Current Atomization Methods for Tailored Superalloy Production

01 Gas atomization techniques for superalloy powder production

Gas atomization is a primary method for producing superalloy powders with tailored properties. This process involves melting the superalloy and then disintegrating the molten metal into fine droplets using high-pressure gas jets. The rapid solidification during atomization results in powders with fine microstructures and homogeneous composition. By controlling parameters such as gas pressure, melt temperature, and nozzle design, manufacturers can tailor the particle size distribution, morphology, and internal structure of the powders to meet specific requirements for subsequent processing.- Gas atomization techniques for superalloy powder production: Gas atomization is a primary method for producing superalloy powders with tailored properties. This process involves melting the superalloy and then disintegrating the molten metal into fine droplets using high-pressure gas jets. The rapid solidification during atomization results in powders with fine microstructures and homogeneous composition. By controlling parameters such as gas pressure, melt temperature, and nozzle design, manufacturers can tailor the particle size distribution, morphology, and internal structure of the powders to meet specific requirements for subsequent processing.

- Alloy composition control for tailored powder properties: The chemical composition of superalloy feedstocks significantly influences the properties of the atomized powders. By carefully adjusting the proportions of elements such as nickel, cobalt, chromium, aluminum, titanium, and refractory metals, manufacturers can develop powders with enhanced high-temperature strength, oxidation resistance, and thermal stability. Advanced alloying strategies may include precise additions of trace elements or reactive elements to improve specific properties. The composition control begins with the master alloy preparation and continues through the atomization process, where rapid solidification can preserve the intended composition without excessive segregation.

- Process parameters optimization for particle size and morphology control: Achieving specific particle characteristics requires careful optimization of atomization process parameters. Factors such as melt superheat, gas-to-metal ratio, gas pressure, nozzle geometry, and cooling rate significantly affect the resulting powder properties. Higher gas pressures typically produce finer powders, while adjustments to the atomization nozzle design can influence particle sphericity. Advanced process control systems enable real-time adjustments to maintain consistent powder quality. These optimized parameters allow manufacturers to produce powders with precise size distributions and morphologies tailored for specific applications such as additive manufacturing, hot isostatic pressing, or thermal spray coatings.

- Post-atomization treatments for enhanced powder characteristics: After atomization, superalloy powders often undergo various post-processing treatments to further enhance their properties. These treatments may include heat treatment to relieve internal stresses, hot isostatic pressing to eliminate porosity, surface modification to improve flowability, or classification to achieve narrow particle size distributions. Some advanced processes involve controlled oxidation to create protective surface layers or chemical treatments to remove impurities. These post-atomization steps are crucial for optimizing powder behavior in subsequent manufacturing processes and ensuring consistent final part properties.

- Advanced atomization technologies for specialized superalloy powders: Emerging atomization technologies are being developed to produce superalloy powders with unique characteristics. These include plasma rotating electrode process (PREP), vacuum induction melting gas atomization (VIGA), electrode induction gas atomization (EIGA), and ultrasonic atomization. Each technology offers specific advantages for controlling powder purity, satellite formation, oxygen content, and microstructural features. For example, vacuum-based processes minimize oxidation and gas entrapment, while ultrasonic atomization can produce extremely fine powders with narrow size distributions. These specialized techniques enable the production of high-performance superalloy powders for critical applications in aerospace, energy, and medical industries.

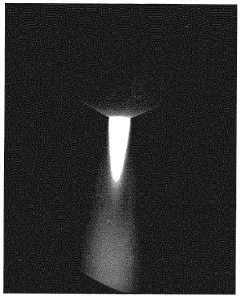

02 Plasma atomization for spherical superalloy powders

Plasma atomization is an advanced technique used to produce highly spherical superalloy powders with excellent flowability and packing density. In this process, a plasma torch is used to melt the feedstock material, which is then atomized into fine droplets that solidify into spherical particles. The high temperature of the plasma ensures complete melting of even refractory elements in superalloys, resulting in homogeneous composition. This technique is particularly valuable for producing powders for additive manufacturing applications where particle sphericity and consistent size distribution are critical for achieving high-quality printed components.Expand Specific Solutions03 Control of cooling rates for microstructure optimization

The cooling rate during atomization significantly influences the microstructure and properties of superalloy powders. By precisely controlling the cooling parameters, manufacturers can tailor the grain size, phase distribution, and precipitate formation in the powder particles. Rapid cooling typically results in finer microstructures with enhanced mechanical properties, while controlled slower cooling can promote specific phase formations. Advanced atomization systems incorporate features to manipulate cooling rates through gas temperature control, chamber design, and flight path optimization, enabling the production of powders with customized microstructural characteristics for specific applications.Expand Specific Solutions04 Alloying element distribution and homogeneity

Achieving uniform distribution of alloying elements throughout superalloy powder particles is crucial for consistent performance in final components. Atomization parameters can be optimized to minimize segregation and ensure homogeneous element distribution. Pre-alloying techniques, melt superheating, and controlled solidification during atomization help maintain compositional uniformity. Advanced characterization methods are employed to verify elemental homogeneity across powder batches. This control over alloying element distribution enables the production of superalloy powders with predictable and reliable properties for critical aerospace and energy applications.Expand Specific Solutions05 Post-atomization treatments for enhanced powder properties

Various post-atomization treatments can be applied to further enhance the properties of superalloy powders. These include heat treatments to relieve internal stresses or promote specific phase transformations, surface modifications to improve flowability or compatibility with binder systems, and classification processes to achieve precise particle size distributions. Spheroidization treatments can improve particle morphology, while hot isostatic pressing of powders can eliminate internal porosity. These post-processing steps allow manufacturers to fine-tune powder characteristics beyond what is achievable through atomization alone, resulting in feedstock materials optimized for specific manufacturing processes and end-use applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Powder Metallurgy

The powder atomization market for superalloy feedstocks is currently in a growth phase, driven by increasing demand in aerospace, energy, and additive manufacturing sectors. The global market size is expanding rapidly, with projections indicating substantial growth over the next decade. Technologically, the field is advancing from established gas atomization methods toward more sophisticated techniques. Leading academic institutions like Central South University and University of Science & Technology Beijing are conducting fundamental research, while commercial players demonstrate varying levels of technological maturity. Companies such as 6K Inc., PyroGenesis, and Forge Nano represent the innovation frontier with novel plasma and microwave atomization processes, while established manufacturers like Höganäs AB and Oerlikon Metco provide industrial-scale production capabilities with proven technologies.

6K Inc.

Technical Solution: 6K Inc. has developed a revolutionary UniMelt microwave plasma technology for powder atomization of superalloys. Their process uses a microwave plasma system that can reach temperatures exceeding 6000K, enabling the production of highly spherical, high-purity metal powders with controlled particle size distribution. The UniMelt platform converts scrap alloys directly into premium powders in a single step, significantly reducing energy consumption compared to traditional gas or plasma atomization methods. 6K's technology allows for precise tailoring of powder characteristics including morphology, flowability, and chemistry to meet specific application requirements for aerospace, defense, and medical implant industries. The company has demonstrated the ability to produce nickel-based superalloy powders (including Inconel and Hastelloy variants) with oxygen levels below 100 ppm and exceptional batch-to-batch consistency, critical for additive manufacturing applications.

Strengths: Significantly lower energy consumption (up to 90% less than conventional methods); ability to upcycle scrap material; precise control over particle characteristics; high production rates. Weaknesses: Relatively new technology with limited long-term performance data; may require specialized handling equipment; potentially higher initial capital investment compared to conventional atomization systems.

PyroGenesis, Inc.

Technical Solution: PyroGenesis has pioneered advanced plasma atomization technology specifically optimized for superalloy powder production. Their proprietary Plasma Atomization Process (PAP) utilizes three converging plasma torches that generate temperatures exceeding 10,000°C to melt and atomize metal wire feedstock into highly spherical powders. For superalloy applications, PyroGenesis has developed specialized plasma parameters and reactor designs that minimize oxygen contamination (typically <100 ppm) while maintaining tight control over particle size distribution. Their NexGen™ plasma atomization system incorporates in-situ monitoring capabilities that allow real-time adjustments to process parameters, ensuring consistent powder quality even with complex superalloy compositions containing reactive elements like aluminum and titanium. The company has successfully produced powders from nickel-based superalloys including Inconel 718, Waspaloy, and René 41 with exceptional flowability and packing density characteristics ideal for additive manufacturing applications in aerospace and energy sectors.

Strengths: Production of highly spherical particles with excellent flowability; tight control over particle size distribution; scalable production capacity; ability to process reactive alloys. Weaknesses: Higher production costs compared to gas atomization; energy-intensive process; challenging to produce very fine powders (<10μm) in high volumes; requires specialized expertise to operate.

Critical Patents and Breakthroughs in Powder Atomization

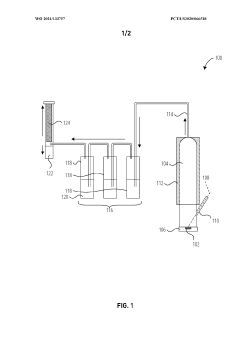

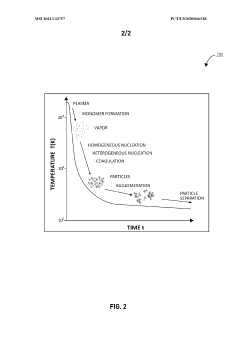

Laser ablation methods and systems for producing feedstock powder suitable for laser-based additive manufacturing

PatentWO2021133757A1

Innovation

- The use of controlled-cooling laser ablation techniques to vaporize source materials in a temperature-controlled vaporization chamber, creating microparticles with uniform composition, shape, and phase, suitable for laser-based additive manufacturing, utilizing relatively inexpensive bulk solid or coarse powder source materials.

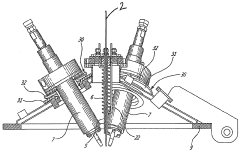

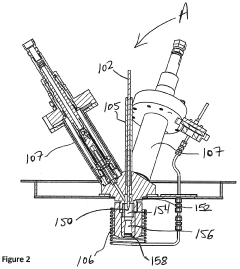

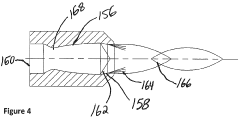

Method for cost-effective production of ultrafine spherical powders at large scale using thruster-assisted plasma atomization

PatentPendingAU2024202767A1

Innovation

- The integration of a thruster at the apex zone of the plasma atomization apparatus, which accelerates liquid particles and a mixture of hot gas and plasma to supersonic speeds, shearing them into finer particles within a confinement chamber, and using a diffuser to maintain high temperatures and prevent stalactite formation.

Sustainability Considerations in Superalloy Powder Manufacturing

The environmental impact of superalloy powder manufacturing has become increasingly significant as industries strive for more sustainable practices. Traditional powder atomization processes consume substantial energy and resources, contributing to a considerable carbon footprint. Recent life cycle assessments indicate that the production of one ton of nickel-based superalloy powder can generate approximately 12-15 tons of CO2 equivalent emissions, primarily from high-temperature processing and inert gas consumption.

Water atomization methods, while more energy-efficient than gas atomization, present challenges related to water consumption and contamination. Advanced recycling systems have been developed to capture and purify process water, reducing fresh water requirements by up to 85% in modern facilities. Additionally, closed-loop water systems minimize discharge of potentially hazardous metal-contaminated effluents into local watersheds.

Inert gas recovery and reuse represents another critical sustainability advancement. New membrane separation technologies and cryogenic recovery systems can recapture up to 95% of argon and nitrogen used in gas atomization processes. This not only reduces the environmental impact associated with inert gas production but also offers significant operational cost savings, with payback periods typically ranging from 18-36 months depending on production volume.

Raw material sourcing ethics have gained prominence in sustainability considerations. Approximately 60% of cobalt, a common superalloy constituent, comes from regions with documented human rights concerns. Leading manufacturers have implemented blockchain-based traceability systems to ensure ethical sourcing, while others are developing superalloy compositions with reduced dependence on conflict minerals.

Energy efficiency improvements represent perhaps the most impactful sustainability initiative. Induction melting systems with advanced power controls have demonstrated energy savings of 20-30% compared to conventional systems. Furthermore, waste heat recovery systems can capture thermal energy from atomization processes for facility heating or preheating of raw materials, improving overall energy utilization by up to 25%.

Powder yield optimization also contributes significantly to sustainability. Advanced atomization nozzle designs and process controls have increased first-pass yield rates from typical industry standards of 60-70% to over 85% in state-of-the-art facilities. This reduction in off-specification material directly translates to lower resource consumption and waste generation per unit of usable product.

The industry is increasingly adopting circular economy principles, with closed-loop recycling of superalloy scrap becoming standard practice. Advanced sorting technologies using AI-powered optical recognition systems can now separate mixed superalloy scrap with 99.9% purity, enabling direct recycling into premium powder feedstocks without quality compromise.

Water atomization methods, while more energy-efficient than gas atomization, present challenges related to water consumption and contamination. Advanced recycling systems have been developed to capture and purify process water, reducing fresh water requirements by up to 85% in modern facilities. Additionally, closed-loop water systems minimize discharge of potentially hazardous metal-contaminated effluents into local watersheds.

Inert gas recovery and reuse represents another critical sustainability advancement. New membrane separation technologies and cryogenic recovery systems can recapture up to 95% of argon and nitrogen used in gas atomization processes. This not only reduces the environmental impact associated with inert gas production but also offers significant operational cost savings, with payback periods typically ranging from 18-36 months depending on production volume.

Raw material sourcing ethics have gained prominence in sustainability considerations. Approximately 60% of cobalt, a common superalloy constituent, comes from regions with documented human rights concerns. Leading manufacturers have implemented blockchain-based traceability systems to ensure ethical sourcing, while others are developing superalloy compositions with reduced dependence on conflict minerals.

Energy efficiency improvements represent perhaps the most impactful sustainability initiative. Induction melting systems with advanced power controls have demonstrated energy savings of 20-30% compared to conventional systems. Furthermore, waste heat recovery systems can capture thermal energy from atomization processes for facility heating or preheating of raw materials, improving overall energy utilization by up to 25%.

Powder yield optimization also contributes significantly to sustainability. Advanced atomization nozzle designs and process controls have increased first-pass yield rates from typical industry standards of 60-70% to over 85% in state-of-the-art facilities. This reduction in off-specification material directly translates to lower resource consumption and waste generation per unit of usable product.

The industry is increasingly adopting circular economy principles, with closed-loop recycling of superalloy scrap becoming standard practice. Advanced sorting technologies using AI-powered optical recognition systems can now separate mixed superalloy scrap with 99.9% purity, enabling direct recycling into premium powder feedstocks without quality compromise.

Quality Control and Standardization for Superalloy Powders

Quality control and standardization are critical components in the production of superalloy powders for advanced manufacturing applications. The increasing demand for high-performance superalloy components in aerospace, energy, and medical sectors has necessitated rigorous quality management systems to ensure consistency and reliability of powder feedstocks. Current industry standards primarily focus on chemical composition, particle size distribution, flowability, and morphology as key quality parameters.

ASTM International and ISO have developed several standards specifically for metal powders, including ASTM F3049 for powder characterization and ASTM F3303 for powder sampling. However, these standards require continuous refinement to address the unique challenges posed by superalloy powders, particularly those with complex compositions designed for specific applications.

Advanced analytical techniques have become essential tools in quality control protocols. X-ray diffraction (XRD) enables crystallographic analysis, while scanning electron microscopy (SEM) provides detailed morphological information. Laser diffraction has emerged as the industry standard for particle size analysis, offering rapid and accurate measurements across a wide size range. Chemical composition verification increasingly relies on inductively coupled plasma mass spectrometry (ICP-MS) for trace element detection at parts-per-billion levels.

Contamination control represents a significant challenge in superalloy powder production. Even minute levels of oxygen, nitrogen, or carbon can dramatically alter mechanical properties of the final component. Leading manufacturers have implemented clean room environments and inert gas handling systems throughout the atomization and packaging processes to minimize contamination risks.

Traceability systems have evolved substantially, with digital solutions now enabling complete tracking from raw material to finished powder. These systems document processing parameters, quality test results, and handling conditions, creating a comprehensive digital fingerprint for each powder batch. This level of documentation is particularly valuable for aerospace and medical applications where regulatory compliance demands extensive material history.

Statistical process control (SPC) methodologies are increasingly applied to powder production, allowing manufacturers to identify process drift before quality issues emerge. Real-time monitoring systems can track critical parameters during atomization, enabling immediate adjustments to maintain consistent powder characteristics. These approaches have significantly reduced batch-to-batch variability, a historical challenge in powder metallurgy.

International harmonization of standards remains an ongoing effort, with organizations like the Metal Powder Industries Federation (MPIF) working to align requirements across different regions. This standardization is essential for global supply chains, ensuring that powders produced in different facilities meet identical specifications regardless of geographic location.

ASTM International and ISO have developed several standards specifically for metal powders, including ASTM F3049 for powder characterization and ASTM F3303 for powder sampling. However, these standards require continuous refinement to address the unique challenges posed by superalloy powders, particularly those with complex compositions designed for specific applications.

Advanced analytical techniques have become essential tools in quality control protocols. X-ray diffraction (XRD) enables crystallographic analysis, while scanning electron microscopy (SEM) provides detailed morphological information. Laser diffraction has emerged as the industry standard for particle size analysis, offering rapid and accurate measurements across a wide size range. Chemical composition verification increasingly relies on inductively coupled plasma mass spectrometry (ICP-MS) for trace element detection at parts-per-billion levels.

Contamination control represents a significant challenge in superalloy powder production. Even minute levels of oxygen, nitrogen, or carbon can dramatically alter mechanical properties of the final component. Leading manufacturers have implemented clean room environments and inert gas handling systems throughout the atomization and packaging processes to minimize contamination risks.

Traceability systems have evolved substantially, with digital solutions now enabling complete tracking from raw material to finished powder. These systems document processing parameters, quality test results, and handling conditions, creating a comprehensive digital fingerprint for each powder batch. This level of documentation is particularly valuable for aerospace and medical applications where regulatory compliance demands extensive material history.

Statistical process control (SPC) methodologies are increasingly applied to powder production, allowing manufacturers to identify process drift before quality issues emerge. Real-time monitoring systems can track critical parameters during atomization, enabling immediate adjustments to maintain consistent powder characteristics. These approaches have significantly reduced batch-to-batch variability, a historical challenge in powder metallurgy.

International harmonization of standards remains an ongoing effort, with organizations like the Metal Powder Industries Federation (MPIF) working to align requirements across different regions. This standardization is essential for global supply chains, ensuring that powders produced in different facilities meet identical specifications regardless of geographic location.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!