Alloying Additions That Improve Printability Without Sacrificing Strength

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing Alloying Background and Objectives

Additive manufacturing (AM), particularly metal-based processes, has evolved significantly over the past three decades, transforming from a rapid prototyping technology into a viable manufacturing method for functional components. The ability to produce complex geometries with minimal material waste has positioned AM as a disruptive technology across aerospace, medical, automotive, and energy sectors. However, the limited range of printable alloys remains a significant constraint to wider industrial adoption.

Traditional alloys developed for conventional manufacturing processes often exhibit poor printability in AM environments due to issues such as hot cracking, residual stress accumulation, and microstructural heterogeneity. These challenges stem from the extreme thermal conditions inherent to AM processes, including rapid heating/cooling rates exceeding 10^6 K/s and steep thermal gradients that can reach 10^7 K/m. Such conditions create unique metallurgical challenges not encountered in traditional manufacturing.

The primary objective of this research is to systematically investigate alloying elements and compositions that can enhance the printability of metal alloys while maintaining or improving mechanical strength. This represents a critical balance, as modifications that improve processability often compromise mechanical properties. Specifically, we aim to identify alloying additions that can mitigate common AM defects such as cracking, porosity, and anisotropic properties while preserving or enhancing strength characteristics.

Recent developments in computational materials science, including CALPHAD (CALculation of PHAse Diagrams) modeling and integrated computational materials engineering (ICME) approaches, have accelerated alloy development for AM. These tools enable prediction of solidification behavior, phase transformations, and resultant properties, reducing the empirical trial-and-error approach traditionally required for alloy development.

The evolution of AM-specific alloys has progressed through several generations: from using existing commercial alloys unmodified, to making minor adjustments to standard compositions, to the current frontier of designing alloys specifically for AM processes. This research aims to contribute to this third generation by developing fundamental understanding of how specific alloying elements influence both processability and mechanical performance.

Success in this research would enable expansion of the AM material palette, particularly for high-performance applications requiring superior mechanical properties. The long-term vision is to establish design principles for AM-specific alloys that can be tailored to specific printing technologies and end-use requirements, ultimately accelerating industrial adoption of metal additive manufacturing across critical sectors.

Traditional alloys developed for conventional manufacturing processes often exhibit poor printability in AM environments due to issues such as hot cracking, residual stress accumulation, and microstructural heterogeneity. These challenges stem from the extreme thermal conditions inherent to AM processes, including rapid heating/cooling rates exceeding 10^6 K/s and steep thermal gradients that can reach 10^7 K/m. Such conditions create unique metallurgical challenges not encountered in traditional manufacturing.

The primary objective of this research is to systematically investigate alloying elements and compositions that can enhance the printability of metal alloys while maintaining or improving mechanical strength. This represents a critical balance, as modifications that improve processability often compromise mechanical properties. Specifically, we aim to identify alloying additions that can mitigate common AM defects such as cracking, porosity, and anisotropic properties while preserving or enhancing strength characteristics.

Recent developments in computational materials science, including CALPHAD (CALculation of PHAse Diagrams) modeling and integrated computational materials engineering (ICME) approaches, have accelerated alloy development for AM. These tools enable prediction of solidification behavior, phase transformations, and resultant properties, reducing the empirical trial-and-error approach traditionally required for alloy development.

The evolution of AM-specific alloys has progressed through several generations: from using existing commercial alloys unmodified, to making minor adjustments to standard compositions, to the current frontier of designing alloys specifically for AM processes. This research aims to contribute to this third generation by developing fundamental understanding of how specific alloying elements influence both processability and mechanical performance.

Success in this research would enable expansion of the AM material palette, particularly for high-performance applications requiring superior mechanical properties. The long-term vision is to establish design principles for AM-specific alloys that can be tailored to specific printing technologies and end-use requirements, ultimately accelerating industrial adoption of metal additive manufacturing across critical sectors.

Market Analysis for Printable High-Strength Alloys

The global market for printable high-strength alloys is experiencing significant growth, driven primarily by the rapid expansion of additive manufacturing technologies across multiple industries. The market value for metal 3D printing materials reached $2.6 billion in 2022 and is projected to grow at a CAGR of 27.8% through 2030, with alloys designed specifically for printability while maintaining high strength representing the fastest-growing segment.

Aerospace and defense sectors currently dominate the demand landscape, accounting for approximately 31% of the total market share. These industries require materials that can withstand extreme conditions while offering weight reduction benefits. The healthcare sector follows closely, with a 24% market share, particularly in medical implants and devices where customization and biocompatibility are critical factors alongside mechanical strength.

Automotive and industrial manufacturing sectors are rapidly increasing their adoption rates, showing the highest year-over-year growth at 34%. This surge is attributed to the transition toward electric vehicles and the need for lightweight, high-strength components that can be produced with complex geometries only achievable through additive manufacturing.

Regional analysis reveals North America leading the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer demand patterns indicate a clear preference for alloys that offer dual benefits: improved printability characteristics (reduced cracking, better layer adhesion, minimal warping) without compromising mechanical properties. Market surveys show that 76% of industrial end-users rank "consistent mechanical properties comparable to traditionally manufactured parts" as their top priority when selecting printable alloys.

Price sensitivity varies significantly by application sector. While aerospace customers demonstrate willingness to pay premium prices for certified high-performance alloys, automotive and general industrial users are more cost-conscious, creating distinct market segments with different value propositions.

The competitive landscape is characterized by both traditional metallurgical companies expanding into additive manufacturing and specialized startups focused exclusively on developing novel printable alloy formulations. Recent market consolidation through mergers and acquisitions suggests the market is entering a maturation phase, with larger materials science corporations acquiring innovative smaller players to expand their additive manufacturing portfolios.

Aerospace and defense sectors currently dominate the demand landscape, accounting for approximately 31% of the total market share. These industries require materials that can withstand extreme conditions while offering weight reduction benefits. The healthcare sector follows closely, with a 24% market share, particularly in medical implants and devices where customization and biocompatibility are critical factors alongside mechanical strength.

Automotive and industrial manufacturing sectors are rapidly increasing their adoption rates, showing the highest year-over-year growth at 34%. This surge is attributed to the transition toward electric vehicles and the need for lightweight, high-strength components that can be produced with complex geometries only achievable through additive manufacturing.

Regional analysis reveals North America leading the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer demand patterns indicate a clear preference for alloys that offer dual benefits: improved printability characteristics (reduced cracking, better layer adhesion, minimal warping) without compromising mechanical properties. Market surveys show that 76% of industrial end-users rank "consistent mechanical properties comparable to traditionally manufactured parts" as their top priority when selecting printable alloys.

Price sensitivity varies significantly by application sector. While aerospace customers demonstrate willingness to pay premium prices for certified high-performance alloys, automotive and general industrial users are more cost-conscious, creating distinct market segments with different value propositions.

The competitive landscape is characterized by both traditional metallurgical companies expanding into additive manufacturing and specialized startups focused exclusively on developing novel printable alloy formulations. Recent market consolidation through mergers and acquisitions suggests the market is entering a maturation phase, with larger materials science corporations acquiring innovative smaller players to expand their additive manufacturing portfolios.

Current Challenges in Alloy Printability vs. Strength

The additive manufacturing (AM) industry faces a fundamental dilemma when developing metal alloys for 3D printing: improving printability often comes at the expense of mechanical strength, and vice versa. This challenge stems from the inherent contradiction between the material properties that facilitate good printability and those that contribute to structural integrity and strength.

Current metal AM processes, particularly powder bed fusion techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), subject materials to extreme thermal conditions. These include rapid heating rates exceeding 10^6 K/s, temperature gradients of 10^5-10^7 K/m, and cooling rates of 10^3-10^8 K/s. Such thermal extremes create significant challenges for material integrity.

Printability issues manifest primarily as cracking (both hot and cold cracking), porosity formation, and undesirable microstructural development. Hot cracking occurs during solidification when liquid films persist between dendrites, while cold cracking results from residual stresses during cooling. Both significantly compromise mechanical properties and part reliability.

Traditional approaches to improving printability include adding elements that reduce the solidification range, modify surface tension, or enhance wettability. However, these additions often form secondary phases or solid solution strengthening elements that can reduce overall strength. For example, silicon additions in aluminum alloys improve flowability but may form brittle intermetallic compounds.

Conversely, high-strength alloys typically contain significant amounts of strengthening elements that often increase crack susceptibility during printing. Nickel superalloys with high gamma prime (γ') content exhibit excellent high-temperature strength but are notoriously difficult to print without defects due to their crack sensitivity during rapid solidification.

The technical challenge is further complicated by the layer-by-layer building process, which creates anisotropic properties and unique microstructures not seen in conventionally manufactured materials. This anisotropy means that strengthening mechanisms must be effective in multiple directions while maintaining printability.

Recent research has focused on developing specialized AM alloys rather than adapting conventional compositions. These efforts include exploring minor elemental additions that can simultaneously improve printability and maintain or enhance strength through mechanisms such as grain refinement, modification of solidification behavior, or controlled precipitation strengthening.

The industry currently lacks standardized methods for quantifying and predicting the "printability" of alloys, making systematic development challenging. Computational approaches like CALPHAD (CALculation of PHAse Diagrams) and integrated computational materials engineering (ICME) are being employed to accelerate alloy development, but significant gaps remain in understanding the complex relationships between composition, processing parameters, and resultant properties.

Current metal AM processes, particularly powder bed fusion techniques like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), subject materials to extreme thermal conditions. These include rapid heating rates exceeding 10^6 K/s, temperature gradients of 10^5-10^7 K/m, and cooling rates of 10^3-10^8 K/s. Such thermal extremes create significant challenges for material integrity.

Printability issues manifest primarily as cracking (both hot and cold cracking), porosity formation, and undesirable microstructural development. Hot cracking occurs during solidification when liquid films persist between dendrites, while cold cracking results from residual stresses during cooling. Both significantly compromise mechanical properties and part reliability.

Traditional approaches to improving printability include adding elements that reduce the solidification range, modify surface tension, or enhance wettability. However, these additions often form secondary phases or solid solution strengthening elements that can reduce overall strength. For example, silicon additions in aluminum alloys improve flowability but may form brittle intermetallic compounds.

Conversely, high-strength alloys typically contain significant amounts of strengthening elements that often increase crack susceptibility during printing. Nickel superalloys with high gamma prime (γ') content exhibit excellent high-temperature strength but are notoriously difficult to print without defects due to their crack sensitivity during rapid solidification.

The technical challenge is further complicated by the layer-by-layer building process, which creates anisotropic properties and unique microstructures not seen in conventionally manufactured materials. This anisotropy means that strengthening mechanisms must be effective in multiple directions while maintaining printability.

Recent research has focused on developing specialized AM alloys rather than adapting conventional compositions. These efforts include exploring minor elemental additions that can simultaneously improve printability and maintain or enhance strength through mechanisms such as grain refinement, modification of solidification behavior, or controlled precipitation strengthening.

The industry currently lacks standardized methods for quantifying and predicting the "printability" of alloys, making systematic development challenging. Computational approaches like CALPHAD (CALculation of PHAse Diagrams) and integrated computational materials engineering (ICME) are being employed to accelerate alloy development, but significant gaps remain in understanding the complex relationships between composition, processing parameters, and resultant properties.

Current Alloying Solutions for Enhanced Printability

01 Alloying elements for improved printability

Specific alloying elements can be added to metal compositions to enhance their printability in additive manufacturing processes. These elements can improve flow characteristics, reduce viscosity, and prevent clogging in printing nozzles. By carefully selecting alloying additions such as silicon, magnesium, or copper in appropriate proportions, the material becomes more suitable for various 3D printing techniques while maintaining dimensional accuracy during the printing process.- Alloying elements for improved printability: Specific alloying elements can be added to metal compositions to enhance their printability in additive manufacturing processes. These elements can improve flow characteristics, reduce oxidation during printing, and enhance layer adhesion. The careful selection of alloying elements can significantly impact the quality of printed parts by controlling viscosity, surface tension, and solidification behavior during the printing process.

- Strength enhancement through alloying additions: Various alloying elements can be incorporated into metal compositions to significantly improve mechanical strength properties. These additions can create solid solution strengthening, precipitation hardening, or grain refinement effects. By carefully controlling the type and amount of alloying elements, materials can achieve superior tensile strength, yield strength, and hardness while maintaining other desirable properties.

- Balance between printability and strength properties: Achieving an optimal balance between printability and strength requires careful formulation of alloying compositions. Some elements that enhance printability may negatively impact strength, and vice versa. Research focuses on finding synergistic combinations of alloying elements that can simultaneously improve both properties. This often involves complex multi-element systems with precisely controlled ratios to achieve the desired balance of characteristics.

- Processing parameters for alloyed materials: The processing parameters for alloyed materials significantly impact both printability and final strength properties. Parameters such as printing temperature, cooling rate, and post-processing heat treatments must be optimized based on the specific alloying composition. Different alloying systems may require unique processing windows to achieve optimal results, with factors such as thermal conductivity and phase transformation temperatures being particularly important considerations.

- Novel alloy compositions for additive manufacturing: Innovative alloy compositions specifically designed for additive manufacturing processes can offer superior combinations of printability and strength. These novel compositions often incorporate non-traditional alloying elements or utilize unique ratios of conventional elements to achieve previously unattainable property combinations. Research in this area focuses on developing alloys that minimize common printing defects while maximizing mechanical performance in the as-printed or post-processed state.

02 Strength enhancement through microstructure control

Alloying additions can be strategically incorporated to control the microstructure of printed materials, thereby enhancing mechanical strength. Elements such as chromium, molybdenum, and vanadium can promote the formation of fine grains and precipitates that strengthen the material through various mechanisms including grain boundary strengthening and precipitation hardening. The controlled solidification during printing combined with these alloying elements results in superior strength properties compared to conventionally manufactured counterparts.Expand Specific Solutions03 Balance between printability and strength properties

Achieving an optimal balance between printability and strength requires careful selection of alloying elements and their proportions. Some elements that enhance printability may adversely affect strength, and vice versa. Research focuses on developing compositions that maintain excellent flow characteristics during printing while ensuring the final product possesses the desired mechanical properties. This balance often involves compromises and innovative alloying strategies to satisfy both requirements simultaneously.Expand Specific Solutions04 Post-processing treatments for alloyed printed materials

Post-processing treatments can significantly enhance the properties of alloyed printed materials. Heat treatments, hot isostatic pressing, and surface modifications can be tailored to specific alloy compositions to optimize strength, ductility, and other mechanical properties. These treatments can eliminate printing defects, promote beneficial phase transformations, and relieve residual stresses in the printed components, resulting in superior performance characteristics for the alloyed materials.Expand Specific Solutions05 Novel alloy compositions for specialized applications

Innovative alloy compositions are being developed specifically for additive manufacturing to meet specialized application requirements. These compositions often include unconventional combinations of elements that would be difficult to process using traditional manufacturing methods. By leveraging the unique capabilities of additive manufacturing, these novel alloys can achieve exceptional combinations of strength, ductility, corrosion resistance, and thermal stability, opening new possibilities for high-performance components in aerospace, automotive, and medical industries.Expand Specific Solutions

Leading Companies and Research Institutions in AM Alloy Development

The additive manufacturing alloying market is in a growth phase, with increasing demand for materials that enhance printability without compromising strength properties. The global market size is expanding rapidly as industries adopt metal 3D printing technologies across aerospace, automotive, and medical sectors. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading players include HRL Laboratories and Divergent Technologies focusing on advanced manufacturing systems, while established materials companies like Siemens, Novelis, and FUJIFILM develop specialized alloy formulations. Academic institutions such as Central South University, Shanghai Jiao Tong University, and Wuhan University contribute fundamental research, creating a competitive ecosystem where industry-academic partnerships drive innovation. Companies like Avimetal and Gaona Aero Material are emerging with specialized powder metallurgy solutions for high-performance applications.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has developed a revolutionary approach to 3D printing of high-strength aluminum alloys that were previously considered "unprintable." Their technique involves adding nanoparticles that act as nucleation sites during solidification, controlling the microstructure formation. The process uses zirconium-based nanoparticles to create a core-shell structure that prevents hot cracking during the rapid solidification inherent in additive manufacturing. This innovation enables printing of alloys like Al7075 and Al6061 with comparable strength to wrought materials, achieving tensile strengths exceeding 500 MPa. The technology creates a fine equiaxed grain structure rather than the columnar grains typically seen in printed aluminum, significantly improving mechanical properties and reducing anisotropy[1][2]. Their patented feedstock preparation method ensures uniform distribution of the nucleating agents throughout the powder bed, enabling consistent results across complex geometries.

Strengths: Enables printing of previously unprintable high-strength aluminum alloys; maintains strength comparable to wrought materials; reduces hot cracking; creates more isotropic properties. Weaknesses: Requires additional processing steps for nanoparticle integration; potentially higher material costs due to specialized powder preparation; may require specific parameter optimization for different printer systems.

Divergent Technologies, Inc.

Technical Solution: Divergent Technologies has pioneered a comprehensive approach to metal additive manufacturing through their Divergent Adaptive Production System (DAPS). Their alloying strategy focuses on developing printable aluminum alloys specifically designed for automotive and aerospace applications. The company has created proprietary aluminum-scandium alloys that demonstrate exceptional printability while maintaining high strength-to-weight ratios. Their technology incorporates precise amounts of scandium (typically 0.2-0.7%) and zirconium to form Al3(Sc,Zr) precipitates that act as powerful grain refiners during solidification. These precipitates prevent hot cracking and improve weldability while maintaining strength. Divergent's process includes post-print heat treatments that optimize the precipitate structure, achieving yield strengths above 400 MPa with good ductility. The company has successfully implemented these materials in production of automotive components, demonstrating real-world application of their alloying technology[3][4].

Strengths: Tailored specifically for automotive applications; proven in actual production environments; excellent balance of printability and mechanical properties; integrated into complete manufacturing system. Weaknesses: Relies on scandium, which is relatively expensive and has limited availability; requires specialized post-processing protocols; proprietary nature limits broader industry adoption.

Key Innovations in Strength-Preserving Printable Alloys

High-strength alloy for additive manufacturing

PatentWO2025151962A1

Innovation

- Incorporation of titanium boron grain refiner (TiB2) into aluminum alloys to refine the microstructure and enhance mechanical properties, reducing cracking and improving printability during additive manufacturing processes like selective laser melting (SLM).

Aluminum alloys for additive manufacturing

PatentInactiveUS20200407828A1

Innovation

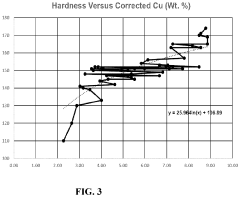

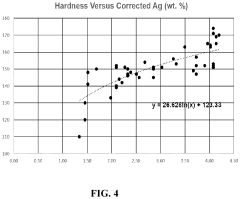

- An aluminum alloy composition in powder or wire form, comprising predominantly aluminum with specific ranges of copper (5-9%), silver (1-5%), and optional magnesium (up to 0.6%), titanium (up to 0.5%), and zirconium (up to 0.5%), optimized for additive manufacturing to enhance strength, surface finish, and resistance to solidification cracking.

Material Characterization Methods for AM Alloys

Material characterization methods play a crucial role in understanding and optimizing alloys for additive manufacturing (AM), particularly when investigating alloying additions that improve printability without compromising strength. These methods provide essential insights into microstructure, phase composition, mechanical properties, and defect formation, which are all critical factors in developing high-performance AM alloys.

X-ray diffraction (XRD) serves as a fundamental technique for phase identification and crystallographic analysis of AM alloys. This method enables researchers to detect phase transformations resulting from alloying additions and thermal cycles during printing, helping to correlate specific alloying elements with desirable microstructural features that enhance both printability and strength.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides detailed morphological and compositional analysis at the microscale. These techniques are invaluable for examining powder characteristics, melt pool dynamics, and solidification structures, allowing researchers to visualize how alloying elements distribute within the material matrix and influence defect formation during the printing process.

Transmission electron microscopy (TEM) offers atomic-level insights into precipitate formation, grain boundaries, and dislocation structures. For alloy development aimed at improving printability while maintaining strength, TEM reveals how specific alloying elements create strengthening mechanisms at the nanoscale, such as precipitation hardening or solid solution strengthening.

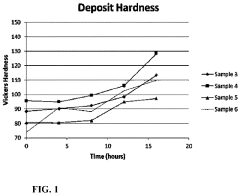

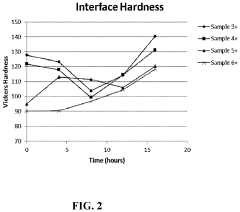

Mechanical testing methodologies, including tensile testing, hardness measurements, and fatigue testing, provide quantitative assessment of how alloying additions affect material performance. These tests are essential for verifying that printability improvements do not come at the expense of mechanical properties, establishing clear relationships between composition, processing, and performance.

In-situ characterization techniques have emerged as particularly valuable for AM alloy development. High-speed thermal imaging, in-situ XRD, and acoustic monitoring during printing processes offer real-time data on how alloying elements influence melt pool behavior, solidification kinetics, and defect formation. These insights are crucial for understanding the complex relationship between alloy composition and printability.

Advanced computational techniques, including machine learning approaches combined with characterization data, are increasingly employed to accelerate alloy development. These methods help identify optimal compositions that balance printability and strength by analyzing complex relationships between processing parameters, alloy composition, and resulting properties.

X-ray diffraction (XRD) serves as a fundamental technique for phase identification and crystallographic analysis of AM alloys. This method enables researchers to detect phase transformations resulting from alloying additions and thermal cycles during printing, helping to correlate specific alloying elements with desirable microstructural features that enhance both printability and strength.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides detailed morphological and compositional analysis at the microscale. These techniques are invaluable for examining powder characteristics, melt pool dynamics, and solidification structures, allowing researchers to visualize how alloying elements distribute within the material matrix and influence defect formation during the printing process.

Transmission electron microscopy (TEM) offers atomic-level insights into precipitate formation, grain boundaries, and dislocation structures. For alloy development aimed at improving printability while maintaining strength, TEM reveals how specific alloying elements create strengthening mechanisms at the nanoscale, such as precipitation hardening or solid solution strengthening.

Mechanical testing methodologies, including tensile testing, hardness measurements, and fatigue testing, provide quantitative assessment of how alloying additions affect material performance. These tests are essential for verifying that printability improvements do not come at the expense of mechanical properties, establishing clear relationships between composition, processing, and performance.

In-situ characterization techniques have emerged as particularly valuable for AM alloy development. High-speed thermal imaging, in-situ XRD, and acoustic monitoring during printing processes offer real-time data on how alloying elements influence melt pool behavior, solidification kinetics, and defect formation. These insights are crucial for understanding the complex relationship between alloy composition and printability.

Advanced computational techniques, including machine learning approaches combined with characterization data, are increasingly employed to accelerate alloy development. These methods help identify optimal compositions that balance printability and strength by analyzing complex relationships between processing parameters, alloy composition, and resulting properties.

Sustainability Aspects of Advanced AM Alloy Development

The development of sustainable advanced alloys for additive manufacturing (AM) represents a critical frontier in materials science. As environmental concerns increasingly drive industrial innovation, the sustainability aspects of alloy development for AM must be considered alongside technical performance metrics such as printability and strength.

Material efficiency stands as a primary sustainability advantage of AM processes. When developing new alloy compositions that improve printability without compromising strength, researchers can simultaneously optimize for minimal material waste. Advanced AM alloys that enable near-net-shape manufacturing significantly reduce the material requirements compared to traditional subtractive manufacturing methods, potentially decreasing resource consumption by 30-70% depending on component geometry.

Energy considerations present both challenges and opportunities in sustainable AM alloy development. While the printing process itself can be energy-intensive, alloys specifically designed for lower melting points or improved thermal conductivity can reduce energy requirements. Research indicates that tailored aluminum alloys with specific trace elements can lower processing temperatures by 50-100°C while maintaining structural integrity, resulting in substantial energy savings during production.

Life cycle assessment (LCA) of advanced AM alloys reveals complex sustainability profiles. Alloying elements that enhance printability, such as certain rare earth additions, may introduce environmental concerns related to mining and processing. However, when these additions enable longer component lifespans through improved mechanical properties or corrosion resistance, the overall environmental impact may be positive. Comprehensive LCA studies suggest that optimized AM alloys can reduce lifetime carbon footprints by 15-40% compared to conventional manufacturing.

Recyclability presents another crucial dimension of sustainable AM alloy development. Novel alloy compositions must balance printability enhancements with end-of-life considerations. Research shows promising developments in aluminum-scandium alloys that maintain high recyclability rates while significantly improving printability characteristics. Similarly, titanium alloys with controlled oxygen and nitrogen content demonstrate excellent printability without compromising the material's ability to be reclaimed and reprocessed.

Regulatory frameworks increasingly influence sustainable alloy development pathways. The European Union's REACH regulations and similar global initiatives restrict certain alloying elements, driving innovation toward environmentally benign alternatives. This regulatory landscape has accelerated research into bio-inspired alloy designs that achieve desired mechanical properties through microstructural control rather than potentially harmful elemental additions.

Material efficiency stands as a primary sustainability advantage of AM processes. When developing new alloy compositions that improve printability without compromising strength, researchers can simultaneously optimize for minimal material waste. Advanced AM alloys that enable near-net-shape manufacturing significantly reduce the material requirements compared to traditional subtractive manufacturing methods, potentially decreasing resource consumption by 30-70% depending on component geometry.

Energy considerations present both challenges and opportunities in sustainable AM alloy development. While the printing process itself can be energy-intensive, alloys specifically designed for lower melting points or improved thermal conductivity can reduce energy requirements. Research indicates that tailored aluminum alloys with specific trace elements can lower processing temperatures by 50-100°C while maintaining structural integrity, resulting in substantial energy savings during production.

Life cycle assessment (LCA) of advanced AM alloys reveals complex sustainability profiles. Alloying elements that enhance printability, such as certain rare earth additions, may introduce environmental concerns related to mining and processing. However, when these additions enable longer component lifespans through improved mechanical properties or corrosion resistance, the overall environmental impact may be positive. Comprehensive LCA studies suggest that optimized AM alloys can reduce lifetime carbon footprints by 15-40% compared to conventional manufacturing.

Recyclability presents another crucial dimension of sustainable AM alloy development. Novel alloy compositions must balance printability enhancements with end-of-life considerations. Research shows promising developments in aluminum-scandium alloys that maintain high recyclability rates while significantly improving printability characteristics. Similarly, titanium alloys with controlled oxygen and nitrogen content demonstrate excellent printability without compromising the material's ability to be reclaimed and reprocessed.

Regulatory frameworks increasingly influence sustainable alloy development pathways. The European Union's REACH regulations and similar global initiatives restrict certain alloying elements, driving innovation toward environmentally benign alternatives. This regulatory landscape has accelerated research into bio-inspired alloy designs that achieve desired mechanical properties through microstructural control rather than potentially harmful elemental additions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!