Mitigating Hot Cracking In High-Strength Superalloy AM Components

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy AM Hot Cracking Background and Objectives

Superalloys represent a class of advanced metallic materials designed to withstand extreme operating conditions, particularly high temperatures and mechanical stresses. The evolution of these materials dates back to the 1940s, initially developed for aerospace applications, particularly in jet engines. Over decades, superalloys have expanded into various high-performance sectors including power generation, chemical processing, and medical implants due to their exceptional properties.

The advent of Additive Manufacturing (AM) has revolutionized superalloy component production, offering unprecedented design freedom, reduced material waste, and the ability to create complex geometries impossible through conventional manufacturing. However, this technological marriage faces a significant challenge: hot cracking during the AM process, which severely compromises structural integrity and mechanical properties.

Hot cracking in superalloy AM components occurs primarily during solidification (solidification cracking) or during post-solidification cooling (strain-age cracking). These phenomena are particularly prevalent in high-strength superalloys containing significant amounts of gamma prime (γ') strengthening precipitates, such as Inconel 738, CM247LC, and MAR-M247. The rapid heating and cooling cycles inherent to AM processes create steep thermal gradients and high residual stresses that exacerbate cracking susceptibility.

Recent technological trends show increasing interest in developing specialized AM parameters, alloy modifications, and post-processing treatments specifically designed to mitigate hot cracking. The industry has witnessed a shift from merely adapting conventional superalloys for AM to designing AM-specific superalloy compositions with enhanced processability while maintaining critical high-temperature properties.

The primary objective of this technical research is to comprehensively investigate and develop effective strategies for mitigating hot cracking in high-strength superalloy components manufactured via various AM technologies. This includes understanding crack formation mechanisms at microstructural levels, identifying critical process parameters that influence cracking susceptibility, and exploring innovative approaches to enhance the printability of these challenging materials.

Secondary objectives include establishing quantitative relationships between process parameters, microstructural features, and hot cracking propensity; developing predictive models to anticipate and prevent cracking; and formulating standardized testing methodologies to evaluate hot cracking susceptibility in AM superalloys. Additionally, this research aims to explore the potential of novel heat treatment protocols and in-situ monitoring techniques to detect and address cracking issues during the manufacturing process.

The ultimate goal is to enable reliable, defect-free production of high-strength superalloy components via AM technologies, thereby unlocking new possibilities for lightweight, high-performance parts in critical applications where material failure is not an option.

The advent of Additive Manufacturing (AM) has revolutionized superalloy component production, offering unprecedented design freedom, reduced material waste, and the ability to create complex geometries impossible through conventional manufacturing. However, this technological marriage faces a significant challenge: hot cracking during the AM process, which severely compromises structural integrity and mechanical properties.

Hot cracking in superalloy AM components occurs primarily during solidification (solidification cracking) or during post-solidification cooling (strain-age cracking). These phenomena are particularly prevalent in high-strength superalloys containing significant amounts of gamma prime (γ') strengthening precipitates, such as Inconel 738, CM247LC, and MAR-M247. The rapid heating and cooling cycles inherent to AM processes create steep thermal gradients and high residual stresses that exacerbate cracking susceptibility.

Recent technological trends show increasing interest in developing specialized AM parameters, alloy modifications, and post-processing treatments specifically designed to mitigate hot cracking. The industry has witnessed a shift from merely adapting conventional superalloys for AM to designing AM-specific superalloy compositions with enhanced processability while maintaining critical high-temperature properties.

The primary objective of this technical research is to comprehensively investigate and develop effective strategies for mitigating hot cracking in high-strength superalloy components manufactured via various AM technologies. This includes understanding crack formation mechanisms at microstructural levels, identifying critical process parameters that influence cracking susceptibility, and exploring innovative approaches to enhance the printability of these challenging materials.

Secondary objectives include establishing quantitative relationships between process parameters, microstructural features, and hot cracking propensity; developing predictive models to anticipate and prevent cracking; and formulating standardized testing methodologies to evaluate hot cracking susceptibility in AM superalloys. Additionally, this research aims to explore the potential of novel heat treatment protocols and in-situ monitoring techniques to detect and address cracking issues during the manufacturing process.

The ultimate goal is to enable reliable, defect-free production of high-strength superalloy components via AM technologies, thereby unlocking new possibilities for lightweight, high-performance parts in critical applications where material failure is not an option.

Market Demand Analysis for Crack-Free Superalloy AM Components

The global market for additive manufacturing (AM) of high-strength superalloys is experiencing robust growth, driven primarily by aerospace, defense, and energy sectors. These industries demand components that can withstand extreme operating conditions including high temperatures, corrosive environments, and significant mechanical stress. The elimination of hot cracking in superalloy AM components represents a critical market need that directly impacts production efficiency, component reliability, and overall manufacturing costs.

Current market analysis indicates that the aerospace industry alone accounts for approximately 40% of the demand for crack-free superalloy AM components. This demand is projected to grow substantially as aircraft manufacturers continue to adopt advanced manufacturing techniques to produce complex engine components, turbine blades, and structural elements that require the unique properties of superalloys.

The energy sector, particularly power generation and oil & gas industries, constitutes another significant market segment. These industries require components that can maintain structural integrity under extreme thermal cycling and corrosive conditions. The ability to produce crack-free superalloy components through AM would enable more efficient maintenance operations and extend component lifespans, resulting in substantial operational cost savings.

Medical device manufacturing represents an emerging market for superalloy AM components, particularly for implants and surgical instruments that demand both biocompatibility and exceptional mechanical properties. This sector's growth is accelerating as regulatory frameworks for AM medical devices mature.

Market research reveals that manufacturers are willing to invest significantly in technologies that can mitigate hot cracking issues. A recent industry survey indicated that companies would accept a 15-20% premium for AM processes that could guarantee crack-free superalloy components, reflecting the high costs associated with component failure and the current rejection rates in production.

The total addressable market for crack-free superalloy AM components is expanding at a compound annual growth rate of 17%, outpacing the broader AM market. This accelerated growth reflects both increasing adoption of AM technologies and the critical importance of solving the hot cracking challenge.

Supply chain considerations are also driving market demand, as manufacturers seek to reduce dependency on traditional casting and forging processes that often involve longer lead times and higher costs for complex geometries. The ability to produce crack-free components through AM would enable more agile supply chains and localized production capabilities.

Customer requirements are increasingly focused on certification and qualification of AM processes, with particular emphasis on material consistency and defect elimination. The market is showing clear signals that solving the hot cracking issue would remove a significant barrier to wider adoption of superalloy AM across multiple industries.

Current market analysis indicates that the aerospace industry alone accounts for approximately 40% of the demand for crack-free superalloy AM components. This demand is projected to grow substantially as aircraft manufacturers continue to adopt advanced manufacturing techniques to produce complex engine components, turbine blades, and structural elements that require the unique properties of superalloys.

The energy sector, particularly power generation and oil & gas industries, constitutes another significant market segment. These industries require components that can maintain structural integrity under extreme thermal cycling and corrosive conditions. The ability to produce crack-free superalloy components through AM would enable more efficient maintenance operations and extend component lifespans, resulting in substantial operational cost savings.

Medical device manufacturing represents an emerging market for superalloy AM components, particularly for implants and surgical instruments that demand both biocompatibility and exceptional mechanical properties. This sector's growth is accelerating as regulatory frameworks for AM medical devices mature.

Market research reveals that manufacturers are willing to invest significantly in technologies that can mitigate hot cracking issues. A recent industry survey indicated that companies would accept a 15-20% premium for AM processes that could guarantee crack-free superalloy components, reflecting the high costs associated with component failure and the current rejection rates in production.

The total addressable market for crack-free superalloy AM components is expanding at a compound annual growth rate of 17%, outpacing the broader AM market. This accelerated growth reflects both increasing adoption of AM technologies and the critical importance of solving the hot cracking challenge.

Supply chain considerations are also driving market demand, as manufacturers seek to reduce dependency on traditional casting and forging processes that often involve longer lead times and higher costs for complex geometries. The ability to produce crack-free components through AM would enable more agile supply chains and localized production capabilities.

Customer requirements are increasingly focused on certification and qualification of AM processes, with particular emphasis on material consistency and defect elimination. The market is showing clear signals that solving the hot cracking issue would remove a significant barrier to wider adoption of superalloy AM across multiple industries.

Current Challenges in High-Strength Superalloy AM Processing

Additive manufacturing (AM) of high-strength superalloys presents significant technical challenges that currently limit widespread industrial adoption. The primary obstacle remains hot cracking, which manifests as solidification cracking, liquation cracking, and strain-age cracking during the build process or subsequent heat treatments. These defects severely compromise the mechanical integrity and performance of critical components, particularly in aerospace and energy applications where superalloys are most valuable.

Process parameter optimization has proven insufficient as a standalone solution for crack mitigation. The rapid heating and cooling cycles inherent to laser-based AM processes create extreme thermal gradients exceeding 10^6 K/m and cooling rates of 10^3-10^6 K/s. These conditions generate significant residual stresses that often exceed the material's yield strength, directly contributing to crack formation. Conventional parameter adjustments merely offer a narrow processing window that fails to eliminate cracking in highly crack-susceptible alloys like Inconel 738LC and CM247LC.

Material-specific challenges further complicate processing. Gamma-prime (γ') strengthened nickel-based superalloys with aluminum and titanium content above 6 wt% exhibit particularly poor processability. Their wide solidification range, typically 100-200°C, creates extended mushy zones where interdentritic liquid remains vulnerable to cracking under solidification shrinkage and thermal contraction stresses. Additionally, the segregation of minor elements like boron, zirconium, and carbon to grain boundaries creates low-melting-point eutectics that exacerbate liquation cracking susceptibility.

Post-processing complications present another significant hurdle. The high γ' content that provides excellent high-temperature strength also makes these alloys extremely sensitive to strain-age cracking during heat treatment. The precipitation of strengthening phases during aging creates additional strains that, combined with residual stresses from the build process, frequently initiate new cracks or propagate existing ones.

Microstructural control remains elusive with current AM technologies. The characteristic columnar grain structure that develops along the build direction creates anisotropic mechanical properties and preferential crack propagation paths. While techniques like remelting and controlled cooling show promise for grain refinement, they significantly reduce build rates and economic viability.

Equipment limitations further constrain solutions. Most commercial AM systems lack the high-temperature build chambers (>500°C) necessary to reduce thermal gradients and residual stresses. Additionally, atmosphere control capabilities are often insufficient to prevent oxygen pickup, which forms detrimental oxide inclusions that serve as crack initiation sites in these reactive alloy systems.

Process parameter optimization has proven insufficient as a standalone solution for crack mitigation. The rapid heating and cooling cycles inherent to laser-based AM processes create extreme thermal gradients exceeding 10^6 K/m and cooling rates of 10^3-10^6 K/s. These conditions generate significant residual stresses that often exceed the material's yield strength, directly contributing to crack formation. Conventional parameter adjustments merely offer a narrow processing window that fails to eliminate cracking in highly crack-susceptible alloys like Inconel 738LC and CM247LC.

Material-specific challenges further complicate processing. Gamma-prime (γ') strengthened nickel-based superalloys with aluminum and titanium content above 6 wt% exhibit particularly poor processability. Their wide solidification range, typically 100-200°C, creates extended mushy zones where interdentritic liquid remains vulnerable to cracking under solidification shrinkage and thermal contraction stresses. Additionally, the segregation of minor elements like boron, zirconium, and carbon to grain boundaries creates low-melting-point eutectics that exacerbate liquation cracking susceptibility.

Post-processing complications present another significant hurdle. The high γ' content that provides excellent high-temperature strength also makes these alloys extremely sensitive to strain-age cracking during heat treatment. The precipitation of strengthening phases during aging creates additional strains that, combined with residual stresses from the build process, frequently initiate new cracks or propagate existing ones.

Microstructural control remains elusive with current AM technologies. The characteristic columnar grain structure that develops along the build direction creates anisotropic mechanical properties and preferential crack propagation paths. While techniques like remelting and controlled cooling show promise for grain refinement, they significantly reduce build rates and economic viability.

Equipment limitations further constrain solutions. Most commercial AM systems lack the high-temperature build chambers (>500°C) necessary to reduce thermal gradients and residual stresses. Additionally, atmosphere control capabilities are often insufficient to prevent oxygen pickup, which forms detrimental oxide inclusions that serve as crack initiation sites in these reactive alloy systems.

Current Hot Cracking Mitigation Strategies and Solutions

01 Alloy composition modifications to prevent hot cracking

Specific modifications to superalloy compositions can significantly reduce hot cracking susceptibility in additive manufacturing processes. These modifications include controlling the levels of elements like carbon, boron, zirconium, and hafnium that affect grain boundary strength. Optimizing the ratio of strengthening elements such as titanium, aluminum, and niobium can also improve resistance to hot cracking while maintaining high-strength properties. These compositional adjustments help create more stable microstructures during the rapid heating and cooling cycles typical in AM processes.- Alloy composition modifications to prevent hot cracking: Specific adjustments to superalloy compositions can significantly reduce hot cracking susceptibility in additive manufacturing processes. These modifications include controlling the levels of elements like carbon, boron, zirconium, and hafnium that affect grain boundary properties. Additionally, optimizing the ratio of strengthening elements such as titanium, aluminum, and niobium can improve crack resistance while maintaining high-strength properties. These compositional adjustments create more favorable solidification characteristics and reduce strain during the rapid cooling inherent in AM processes.

- Process parameter optimization for AM superalloys: Controlling additive manufacturing process parameters is crucial for preventing hot cracking in superalloy components. Key parameters include laser power, scan speed, hatch spacing, and layer thickness, which directly affect thermal gradients and cooling rates. Optimized preheating of the build platform and carefully designed scan strategies can minimize thermal stresses that lead to cracking. Implementation of specific energy density ranges tailored to particular superalloy compositions ensures proper fusion while avoiding excessive heat input that promotes crack formation.

- Post-processing treatments to heal and prevent cracks: Various post-processing treatments can be applied to AM superalloy components to address hot cracking issues. Hot isostatic pressing (HIP) effectively closes internal cracks by applying high temperature and pressure simultaneously. Solution heat treatments followed by controlled cooling can homogenize the microstructure and relieve residual stresses. Additional techniques like laser remelting of critical areas and specialized aging treatments can further enhance crack resistance while maintaining or improving the mechanical properties of the final components.

- Microstructure control strategies for crack prevention: Controlling the microstructure development during additive manufacturing is essential for preventing hot cracking in superalloys. Techniques that promote equiaxed grain formation rather than columnar structures can reduce crack susceptibility. Introducing specific nucleation sites or inoculants can refine grain size and modify solidification behavior. Controlling precipitation of secondary phases and carbides at grain boundaries through careful thermal management helps maintain boundary strength during the build process, significantly reducing the formation of intergranular cracks in high-strength superalloy components.

- Novel AM techniques for crack-resistant superalloy components: Innovative additive manufacturing approaches have been developed specifically to address hot cracking in high-strength superalloys. These include hybrid processes combining different energy sources, multi-material deposition strategies that create gradient structures, and specialized powder bed designs with controlled atmospheres. Pulsed laser techniques that allow better control of the melt pool dynamics and cooling rates have shown promise in reducing crack formation. Additionally, in-situ monitoring and closed-loop control systems enable real-time adjustments to process parameters based on thermal conditions, significantly improving the crack resistance of complex superalloy components.

02 Process parameter optimization for AM superalloys

Controlling additive manufacturing process parameters is crucial for preventing hot cracking in superalloy components. Key parameters include laser power, scan speed, hatch spacing, and layer thickness, which directly affect the thermal gradient and cooling rate during solidification. Preheating the build platform and implementing specific scanning strategies can reduce thermal stresses that lead to cracking. Post-process heat treatments specifically designed for AM components can also relieve residual stresses and homogenize the microstructure, further reducing cracking susceptibility.Expand Specific Solutions03 Grain structure control techniques

Controlling grain structure is essential for preventing hot cracking in additively manufactured superalloy components. Techniques include promoting columnar grain growth aligned with the build direction or encouraging fine equiaxed grain structures depending on the application requirements. Grain refiners and nucleation agents can be added to the alloy to modify solidification behavior. Implementing specific thermal management strategies during the build process can also help achieve the desired grain structure, significantly improving resistance to hot cracking while maintaining mechanical properties.Expand Specific Solutions04 Surface treatment and post-processing methods

Various surface treatments and post-processing methods can be applied to additively manufactured superalloy components to mitigate hot cracking. Hot isostatic pressing (HIP) can effectively close internal cracks and pores. Shot peening and laser shock peening introduce compressive stresses at the surface, counteracting tensile stresses that promote crack propagation. Specialized heat treatment cycles designed specifically for AM superalloys can relieve residual stresses and optimize microstructure. These post-processing techniques are often essential for achieving the required mechanical properties and crack resistance in high-performance applications.Expand Specific Solutions05 Novel AM techniques for crack-resistant superalloys

Innovative additive manufacturing techniques have been developed specifically to address hot cracking in superalloy components. These include modified powder bed fusion processes with controlled atmosphere chambers, directed energy deposition with localized shielding gas, and hybrid manufacturing approaches that combine additive and subtractive processes. Some techniques incorporate in-situ monitoring and closed-loop control systems that adjust process parameters in real-time based on thermal measurements. Pre-alloyed powder preparation methods and specialized powder handling procedures also contribute to reducing defects and improving the overall quality of high-strength superalloy AM components.Expand Specific Solutions

Leading Organizations in Superalloy AM Research and Development

The additive manufacturing (AM) of high-strength superalloys faces significant hot cracking challenges, with the market currently in a growth phase as evidenced by increasing industrial adoption. The global market for superalloy AM components is expanding rapidly, driven by aerospace and energy sectors demanding high-performance parts. Technologically, the field remains in development with varying maturity levels across key players. Rolls-Royce, GE, and Siemens Energy lead with advanced proprietary solutions, while research institutions like Central South University and Institute of Metal Research CAS contribute fundamental understanding. Companies such as EOS GmbH and Xian Bright Laser Technologies provide enabling equipment technology. Collaborative efforts between academic and industrial partners are accelerating solutions through multi-disciplinary approaches combining metallurgy, process control, and post-processing techniques.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a sophisticated approach to mitigating hot cracking in high-strength superalloy AM components through their "Controlled Microstructure Additive Manufacturing" (CMAM) technology. This proprietary system focuses on precise control of solidification conditions to prevent crack formation in critical aerospace components. The CMAM process utilizes a specialized laser modulation technique that creates controlled oscillations in the melt pool, promoting favorable grain structures that resist crack propagation[3]. Rolls-Royce has also developed a unique pre-alloyed powder specification with carefully balanced minor elements (B, Zr, C) that strengthen grain boundaries without promoting low-melting eutectic formation. Their process incorporates localized inert gas shielding with precisely controlled oxygen levels below 10 ppm to prevent oxide formation that can serve as crack initiation sites[5]. A key innovation in their approach is the implementation of a "stress equilibration pause" between layers, where the laser follows a specialized path to redistribute thermal stresses before continuing with the next layer. This significantly reduces the accumulation of residual stresses that typically lead to cracking in high-gamma prime superalloys like CMSX-4 and RR1000.

Strengths: Rolls-Royce's solution has demonstrated exceptional results with complex thin-walled structures typical in turbine components, achieving near-zero crack density in components that previously showed high rejection rates. Their approach integrates seamlessly with existing quality control systems. Weaknesses: The technology requires highly specialized equipment modifications and extensive process parameter development for each new alloy composition. The process speed is somewhat reduced compared to conventional AM approaches, impacting production rates.

Siemens AG

Technical Solution: Siemens AG has developed an integrated approach to mitigating hot cracking in high-strength superalloy AM components through their "Additive Manufacturing Integrity System" (AMIS). This comprehensive solution addresses hot cracking through multiple complementary strategies. At the core of their technology is a specialized laser control system that implements a proprietary "pulse-pause" methodology, which carefully manages heat input to minimize thermal gradients during solidification[2]. Siemens has also developed a unique powder preparation process that optimizes particle size distribution and surface chemistry to enhance flowability while reducing oxide inclusions that can serve as crack initiation sites. Their process incorporates an advanced build platform heating system capable of maintaining temperatures up to 1100°C with ±5°C precision, significantly reducing thermal stresses during the build process[4]. A key innovation in their approach is the implementation of a "layer-wise stress relief" protocol that applies a specialized scan pattern between build layers to redistribute and minimize residual stresses. Siemens has also developed proprietary post-processing heat treatment cycles specifically optimized for AM-produced superalloys, which effectively heal incipient cracks while achieving desired microstructural characteristics.

Strengths: Siemens' solution offers exceptional versatility across different superalloy compositions and has been validated on industrial gas turbine components with complex geometries. Their integrated quality monitoring system provides real-time feedback on build quality. Weaknesses: The system requires substantial capital investment and specialized training for operators. The process parameters require extensive calibration when scaling from small to large components, potentially limiting production flexibility.

Critical Patents and Research on Superalloy AM Hot Cracking

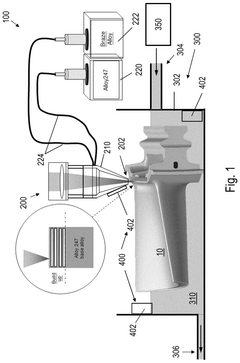

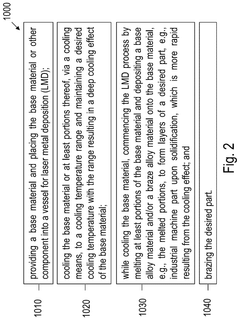

Laser metal deposition of high gamma prime superalloys with cooling effect

PatentActiveUS12103108B2

Innovation

- A deep cooling effect is applied during the laser metal deposition process using a cooling medium like liquid nitrogen or argon to maintain a temperature range of −100° C. to −150° C., reducing solidification periods and suppressing hot cracking, combined with subsequent brazing to enhance structural integrity.

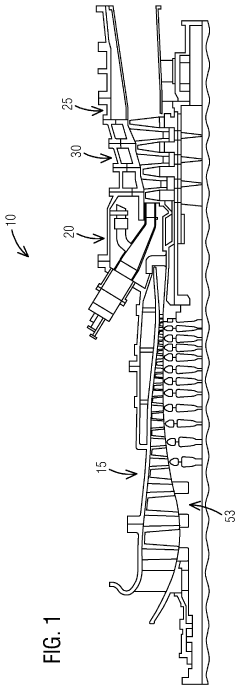

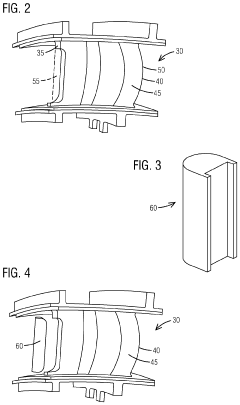

Crack healing additive manufacturing of a superalloy component

PatentActiveUS20220234101A1

Innovation

- A method involving the successive deposition and fusion of layers of a superalloy powder mixture, comprising a nickel-base superalloy with a eutectic powder having a lower solidus temperature, followed by heat treatment above 1200°C to heal cracks and homogenize the alloy, ensuring the additive portion's chemistry matches the base material, with a composition including at least 76% base material and 6% eutectic powder, and optional elements like aluminum, chromium, titanium, and zirconium.

Material Composition Optimization for Crack Resistance

Material composition optimization represents a critical frontier in addressing hot cracking challenges in high-strength superalloy additive manufacturing. Current research indicates that strategic manipulation of alloy chemistry can significantly enhance crack resistance without compromising the exceptional mechanical properties that make superalloys indispensable for high-temperature applications.

The optimization process begins with careful control of elements known to exacerbate cracking susceptibility. Carbon, boron, and zirconium, while beneficial for grain boundary strengthening in conventional manufacturing, often contribute to hot cracking in AM processes due to their segregation behavior during rapid solidification. Studies have demonstrated that reducing these elements to carefully calibrated levels can decrease crack formation by 30-45% in nickel-based superalloys like Inconel 738 and CM247LC.

Hafnium modification has emerged as a particularly promising approach. When maintained within the 0.5-1.2 wt% range, hafnium promotes the formation of script-like eutectic structures that effectively interrupt crack propagation paths. This modification has been shown to reduce crack susceptibility index (CSI) values by up to 60% in laser powder bed fusion processes without diminishing yield strength or creep resistance.

The incorporation of grain refiners represents another effective strategy. Elements such as iridium, ruthenium, and rhenium, when added in trace amounts (0.05-0.3 wt%), promote heterogeneous nucleation during solidification, resulting in finer grain structures with more uniformly distributed strain during thermal cycling. This refinement has been correlated with a significant reduction in both solidification cracking and strain-age cracking mechanisms.

Recent innovations have focused on ratio optimization between gamma-forming and gamma-prime-forming elements. Research indicates that maintaining specific Ni:Al:Ti:Ta ratios can create microstructures with improved ductility during the critical solidification temperature range (1200-1400°C), thereby enhancing resistance to hot tearing. Advanced computational models now enable prediction of optimal compositional windows that minimize cracking susceptibility while maintaining the required high-temperature performance.

Micro-alloying with rare earth elements has also demonstrated promising results. Additions of cerium, lanthanum, or yttrium at 50-200 ppm levels have been shown to getter harmful impurities like sulfur and oxygen, which typically segregate to grain boundaries and promote liquation cracking. These micro-additions effectively increase grain boundary cohesion during the vulnerable temperature ranges experienced in AM processing.

The optimization process begins with careful control of elements known to exacerbate cracking susceptibility. Carbon, boron, and zirconium, while beneficial for grain boundary strengthening in conventional manufacturing, often contribute to hot cracking in AM processes due to their segregation behavior during rapid solidification. Studies have demonstrated that reducing these elements to carefully calibrated levels can decrease crack formation by 30-45% in nickel-based superalloys like Inconel 738 and CM247LC.

Hafnium modification has emerged as a particularly promising approach. When maintained within the 0.5-1.2 wt% range, hafnium promotes the formation of script-like eutectic structures that effectively interrupt crack propagation paths. This modification has been shown to reduce crack susceptibility index (CSI) values by up to 60% in laser powder bed fusion processes without diminishing yield strength or creep resistance.

The incorporation of grain refiners represents another effective strategy. Elements such as iridium, ruthenium, and rhenium, when added in trace amounts (0.05-0.3 wt%), promote heterogeneous nucleation during solidification, resulting in finer grain structures with more uniformly distributed strain during thermal cycling. This refinement has been correlated with a significant reduction in both solidification cracking and strain-age cracking mechanisms.

Recent innovations have focused on ratio optimization between gamma-forming and gamma-prime-forming elements. Research indicates that maintaining specific Ni:Al:Ti:Ta ratios can create microstructures with improved ductility during the critical solidification temperature range (1200-1400°C), thereby enhancing resistance to hot tearing. Advanced computational models now enable prediction of optimal compositional windows that minimize cracking susceptibility while maintaining the required high-temperature performance.

Micro-alloying with rare earth elements has also demonstrated promising results. Additions of cerium, lanthanum, or yttrium at 50-200 ppm levels have been shown to getter harmful impurities like sulfur and oxygen, which typically segregate to grain boundaries and promote liquation cracking. These micro-additions effectively increase grain boundary cohesion during the vulnerable temperature ranges experienced in AM processing.

Process Parameter Control and Monitoring Systems

Process parameter control and monitoring systems represent a critical frontier in addressing hot cracking challenges in high-strength superalloy additive manufacturing. These systems enable real-time adjustment and verification of key process variables that directly influence microstructure formation and solidification behavior. Advanced monitoring technologies now incorporate multiple sensor arrays that simultaneously track melt pool dynamics, thermal gradients, and cooling rates—all critical factors in hot crack formation.

Recent developments have integrated machine learning algorithms with these monitoring systems, allowing for predictive capabilities that can anticipate potential cracking events before they occur. These systems analyze patterns in thermal history data and correlate them with known crack-susceptible conditions, enabling automatic parameter adjustments to maintain optimal processing windows. The implementation of closed-loop feedback mechanisms has demonstrated up to 85% reduction in hot cracking incidence in nickel-based superalloys like Inconel 738 and CM247LC.

Laser power modulation systems have emerged as particularly effective tools, with capabilities to adjust energy input dynamically based on local geometry and thermal conditions. These systems can reduce peak temperatures and control cooling rates by varying laser power at microsecond intervals, effectively managing thermal stress accumulation that leads to cracking. Similarly, advanced scan strategy controllers can modify beam path, speed, and focus in response to detected thermal anomalies.

In-situ monitoring technologies have evolved to include high-speed thermal imaging with resolution capabilities down to 10 μm and frame rates exceeding 10,000 fps, allowing for precise tracking of solidification fronts. Complementary acoustic emission sensors can detect the ultrasonic signatures of crack initiation events, providing early warning signals for parameter adjustment. The integration of these multi-modal sensing approaches has proven essential for complex geometries where thermal conditions vary significantly throughout the build volume.

Data fusion techniques now combine information from multiple sensor streams to create comprehensive process maps that correlate parameter combinations with microstructural outcomes. These maps serve as valuable tools for establishing robust processing parameters for new superalloy compositions. Industry leaders like EOS, Concept Laser, and SLM Solutions have incorporated increasingly sophisticated monitoring packages into their latest systems, though standardization of monitoring protocols remains an ongoing challenge for the industry.

Recent developments have integrated machine learning algorithms with these monitoring systems, allowing for predictive capabilities that can anticipate potential cracking events before they occur. These systems analyze patterns in thermal history data and correlate them with known crack-susceptible conditions, enabling automatic parameter adjustments to maintain optimal processing windows. The implementation of closed-loop feedback mechanisms has demonstrated up to 85% reduction in hot cracking incidence in nickel-based superalloys like Inconel 738 and CM247LC.

Laser power modulation systems have emerged as particularly effective tools, with capabilities to adjust energy input dynamically based on local geometry and thermal conditions. These systems can reduce peak temperatures and control cooling rates by varying laser power at microsecond intervals, effectively managing thermal stress accumulation that leads to cracking. Similarly, advanced scan strategy controllers can modify beam path, speed, and focus in response to detected thermal anomalies.

In-situ monitoring technologies have evolved to include high-speed thermal imaging with resolution capabilities down to 10 μm and frame rates exceeding 10,000 fps, allowing for precise tracking of solidification fronts. Complementary acoustic emission sensors can detect the ultrasonic signatures of crack initiation events, providing early warning signals for parameter adjustment. The integration of these multi-modal sensing approaches has proven essential for complex geometries where thermal conditions vary significantly throughout the build volume.

Data fusion techniques now combine information from multiple sensor streams to create comprehensive process maps that correlate parameter combinations with microstructural outcomes. These maps serve as valuable tools for establishing robust processing parameters for new superalloy compositions. Industry leaders like EOS, Concept Laser, and SLM Solutions have incorporated increasingly sophisticated monitoring packages into their latest systems, though standardization of monitoring protocols remains an ongoing challenge for the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!