Powder Handling And Safety Considerations For Nickel Superalloy AM

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nickel Superalloy AM Powder Technology Background

Nickel superalloys have emerged as critical materials in high-performance applications due to their exceptional mechanical properties, corrosion resistance, and thermal stability at elevated temperatures. These specialized alloys, primarily composed of nickel with additions of chromium, cobalt, aluminum, titanium, and other elements, were initially developed for aerospace and gas turbine applications in the mid-20th century. The evolution of nickel superalloys has been closely tied to advancements in manufacturing processes, with traditional methods including casting, forging, and powder metallurgy techniques.

The introduction of additive manufacturing (AM) technologies has revolutionized the production capabilities for nickel superalloys, offering unprecedented design freedom, reduced material waste, and the ability to create complex geometries that were previously impossible through conventional manufacturing methods. The powder-based AM processes for nickel superalloys began gaining significant traction in the early 2000s, with technologies such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) leading the advancement.

Powder characteristics play a fundamental role in determining the quality and properties of additively manufactured nickel superalloy components. The powder production methods, including gas atomization, plasma atomization, and rotary atomization, significantly influence particle morphology, size distribution, flowability, and chemical composition. These attributes directly impact the powder bed formation, laser-material interaction, melt pool dynamics, and ultimately the microstructure and mechanical properties of the final parts.

The handling of nickel superalloy powders presents unique challenges due to their reactive nature, potential health hazards, and sensitivity to environmental conditions. Nickel and its compounds are classified as carcinogenic, with exposure risks through inhalation, ingestion, and skin contact. Additionally, fine metal powders pose explosion and fire hazards when dispersed in air at certain concentrations. These safety considerations have driven the development of specialized powder handling systems, personal protective equipment, and facility designs for AM operations.

Recent technological advancements have focused on improving powder recyclability, reducing contamination risks, and enhancing process monitoring capabilities. The development of closed-loop powder handling systems, real-time quality monitoring tools, and standardized safety protocols has been instrumental in expanding the industrial adoption of nickel superalloy AM processes. Furthermore, research efforts are increasingly directed toward understanding the relationship between powder characteristics, processing parameters, and final part properties to optimize the entire manufacturing workflow.

The global market for nickel superalloy powders for AM applications has experienced substantial growth, driven by demands from aerospace, energy, medical, and automotive sectors seeking lightweight, high-performance components with complex geometries. This market expansion has catalyzed innovations in powder production technologies, quality control methodologies, and safety management systems to address the evolving needs of industrial AM implementations.

The introduction of additive manufacturing (AM) technologies has revolutionized the production capabilities for nickel superalloys, offering unprecedented design freedom, reduced material waste, and the ability to create complex geometries that were previously impossible through conventional manufacturing methods. The powder-based AM processes for nickel superalloys began gaining significant traction in the early 2000s, with technologies such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) leading the advancement.

Powder characteristics play a fundamental role in determining the quality and properties of additively manufactured nickel superalloy components. The powder production methods, including gas atomization, plasma atomization, and rotary atomization, significantly influence particle morphology, size distribution, flowability, and chemical composition. These attributes directly impact the powder bed formation, laser-material interaction, melt pool dynamics, and ultimately the microstructure and mechanical properties of the final parts.

The handling of nickel superalloy powders presents unique challenges due to their reactive nature, potential health hazards, and sensitivity to environmental conditions. Nickel and its compounds are classified as carcinogenic, with exposure risks through inhalation, ingestion, and skin contact. Additionally, fine metal powders pose explosion and fire hazards when dispersed in air at certain concentrations. These safety considerations have driven the development of specialized powder handling systems, personal protective equipment, and facility designs for AM operations.

Recent technological advancements have focused on improving powder recyclability, reducing contamination risks, and enhancing process monitoring capabilities. The development of closed-loop powder handling systems, real-time quality monitoring tools, and standardized safety protocols has been instrumental in expanding the industrial adoption of nickel superalloy AM processes. Furthermore, research efforts are increasingly directed toward understanding the relationship between powder characteristics, processing parameters, and final part properties to optimize the entire manufacturing workflow.

The global market for nickel superalloy powders for AM applications has experienced substantial growth, driven by demands from aerospace, energy, medical, and automotive sectors seeking lightweight, high-performance components with complex geometries. This market expansion has catalyzed innovations in powder production technologies, quality control methodologies, and safety management systems to address the evolving needs of industrial AM implementations.

Market Analysis for Nickel Superalloy AM Applications

The global market for nickel superalloy additive manufacturing is experiencing robust growth, driven primarily by aerospace, power generation, and medical sectors. The aerospace industry remains the dominant consumer, accounting for approximately 60% of nickel superalloy AM applications, with particular demand in turbine components, combustion chambers, and structural parts requiring exceptional high-temperature performance.

The power generation sector represents the second-largest market segment, with gas turbine manufacturers increasingly adopting nickel superalloy AM for complex components that benefit from design optimization and reduced assembly requirements. Medical applications, particularly in orthopedic implants, are showing the fastest growth rate due to the biocompatibility and mechanical properties of certain nickel superalloys.

Geographically, North America leads the market with substantial investments from aerospace giants and defense contractors. Europe follows closely, with strong adoption in Germany, France, and the UK driven by their aerospace and automotive industries. The Asia-Pacific region, particularly China and Japan, is experiencing the highest growth rate as these countries rapidly expand their advanced manufacturing capabilities.

Market analysts project the global nickel superalloy AM market to reach $2.3 billion by 2027, representing a compound annual growth rate of 22.4% from 2022. This growth trajectory is supported by increasing demand for lightweight, high-performance components in critical applications where traditional manufacturing methods face limitations.

The powder handling and safety considerations represent a significant factor influencing market dynamics. Companies with advanced powder management systems and comprehensive safety protocols are gaining competitive advantages, as these capabilities directly impact production efficiency, part quality, and operational costs. The market is witnessing increased demand for automated powder handling systems that minimize human exposure and reduce contamination risks.

End-users are increasingly prioritizing suppliers who can demonstrate robust safety protocols and quality assurance measures for powder handling. This trend is creating market differentiation opportunities for powder producers and AM service providers who invest in advanced containment systems, monitoring technologies, and operator training programs.

The regulatory landscape is also shaping market development, with stricter occupational safety standards being implemented globally regarding metal powder exposure. Companies that proactively address these requirements are better positioned to expand their market share across regions with varying regulatory frameworks.

The power generation sector represents the second-largest market segment, with gas turbine manufacturers increasingly adopting nickel superalloy AM for complex components that benefit from design optimization and reduced assembly requirements. Medical applications, particularly in orthopedic implants, are showing the fastest growth rate due to the biocompatibility and mechanical properties of certain nickel superalloys.

Geographically, North America leads the market with substantial investments from aerospace giants and defense contractors. Europe follows closely, with strong adoption in Germany, France, and the UK driven by their aerospace and automotive industries. The Asia-Pacific region, particularly China and Japan, is experiencing the highest growth rate as these countries rapidly expand their advanced manufacturing capabilities.

Market analysts project the global nickel superalloy AM market to reach $2.3 billion by 2027, representing a compound annual growth rate of 22.4% from 2022. This growth trajectory is supported by increasing demand for lightweight, high-performance components in critical applications where traditional manufacturing methods face limitations.

The powder handling and safety considerations represent a significant factor influencing market dynamics. Companies with advanced powder management systems and comprehensive safety protocols are gaining competitive advantages, as these capabilities directly impact production efficiency, part quality, and operational costs. The market is witnessing increased demand for automated powder handling systems that minimize human exposure and reduce contamination risks.

End-users are increasingly prioritizing suppliers who can demonstrate robust safety protocols and quality assurance measures for powder handling. This trend is creating market differentiation opportunities for powder producers and AM service providers who invest in advanced containment systems, monitoring technologies, and operator training programs.

The regulatory landscape is also shaping market development, with stricter occupational safety standards being implemented globally regarding metal powder exposure. Companies that proactively address these requirements are better positioned to expand their market share across regions with varying regulatory frameworks.

Current Challenges in Powder Handling Safety

The handling of metal powders in nickel superalloy additive manufacturing presents significant challenges that impact both process efficiency and workplace safety. Current powder handling systems often struggle with maintaining consistent powder flow properties, which directly affects part quality and reproducibility. Nickel superalloy powders are particularly susceptible to oxidation when exposed to air, leading to degradation of mechanical properties in the final components. This oxidation risk necessitates specialized handling equipment and procedures that many manufacturing facilities find difficult to implement effectively.

Powder contamination remains a persistent issue in the industry, with cross-contamination between different powder batches potentially introducing defects and compromising the integrity of manufactured parts. The fine particle size distribution of nickel superalloy powders (typically 15-45 μm) creates significant dust hazards during handling operations, with particles easily becoming airborne and creating both respiratory and explosion risks. Current filtration and containment systems often fail to adequately address these hazards, particularly in high-volume production environments.

Health risks associated with nickel powder exposure represent another major challenge. Nickel compounds are classified as carcinogenic, and prolonged exposure can lead to sensitization, dermatitis, and respiratory conditions. Despite regulatory guidelines, many facilities struggle to implement comprehensive exposure monitoring programs that can effectively track worker exposure levels over time.

The reactive nature of fine nickel powders presents significant fire and explosion hazards. These powders have high surface area-to-volume ratios that increase their reactivity, with potential for dust explosions when suspended in air at certain concentrations. Current safety systems often lack adequate explosion prevention and mitigation measures, particularly in facilities transitioning from traditional manufacturing to additive processes.

Powder recycling and waste management present additional challenges. The industry lacks standardized protocols for safely recovering, testing, and reusing powders across multiple build cycles. This results in significant material waste and increased operational costs. Furthermore, the disposal of contaminated or oxidized powders must comply with hazardous waste regulations, requiring specialized handling procedures that many facilities find difficult to implement.

Static electricity management during powder handling operations remains problematic, with current grounding and bonding practices often insufficient to prevent electrostatic discharge events that could ignite combustible dust clouds. This risk is compounded by the increasing automation of powder handling systems, which can generate static charges through mechanical movement and friction.

Powder contamination remains a persistent issue in the industry, with cross-contamination between different powder batches potentially introducing defects and compromising the integrity of manufactured parts. The fine particle size distribution of nickel superalloy powders (typically 15-45 μm) creates significant dust hazards during handling operations, with particles easily becoming airborne and creating both respiratory and explosion risks. Current filtration and containment systems often fail to adequately address these hazards, particularly in high-volume production environments.

Health risks associated with nickel powder exposure represent another major challenge. Nickel compounds are classified as carcinogenic, and prolonged exposure can lead to sensitization, dermatitis, and respiratory conditions. Despite regulatory guidelines, many facilities struggle to implement comprehensive exposure monitoring programs that can effectively track worker exposure levels over time.

The reactive nature of fine nickel powders presents significant fire and explosion hazards. These powders have high surface area-to-volume ratios that increase their reactivity, with potential for dust explosions when suspended in air at certain concentrations. Current safety systems often lack adequate explosion prevention and mitigation measures, particularly in facilities transitioning from traditional manufacturing to additive processes.

Powder recycling and waste management present additional challenges. The industry lacks standardized protocols for safely recovering, testing, and reusing powders across multiple build cycles. This results in significant material waste and increased operational costs. Furthermore, the disposal of contaminated or oxidized powders must comply with hazardous waste regulations, requiring specialized handling procedures that many facilities find difficult to implement.

Static electricity management during powder handling operations remains problematic, with current grounding and bonding practices often insufficient to prevent electrostatic discharge events that could ignite combustible dust clouds. This risk is compounded by the increasing automation of powder handling systems, which can generate static charges through mechanical movement and friction.

Existing Powder Handling Safety Protocols

01 Handling and storage safety measures for nickel superalloy powders

Proper handling and storage procedures are essential for nickel superalloy powders due to their potential health hazards. Safety measures include using sealed containers to prevent powder dispersion, implementing controlled environments with proper ventilation systems, and utilizing specialized storage facilities that minimize exposure risks. Personal protective equipment such as respirators, gloves, and protective clothing should be worn when handling these materials to prevent inhalation and skin contact with potentially harmful particles.- Health hazards and exposure risks: Nickel superalloy powders pose significant health risks when inhaled or in contact with skin. These fine particles can cause respiratory issues, allergic reactions, and potential carcinogenic effects with prolonged exposure. Safety protocols must address the risks of nickel sensitization, dermatitis, and respiratory conditions. Proper ventilation systems, personal protective equipment, and exposure monitoring are essential to minimize these health hazards in manufacturing and handling environments.

- Safe handling and storage procedures: Proper handling and storage of nickel superalloy powders require specific protocols to prevent accidents and exposure. These include using sealed containers in cool, dry environments away from incompatible materials, implementing dust control measures, and establishing clear handling procedures. Storage areas should be properly ventilated with appropriate fire suppression systems. Regular inspection of containers for integrity and proper labeling with hazard information ensures safe management of these potentially reactive materials.

- Fire and explosion prevention: Nickel superalloy powders present significant fire and explosion hazards due to their fine particle size and potential reactivity. Prevention measures include controlling dust accumulation, using explosion-proof electrical equipment, implementing proper grounding procedures to prevent static discharge, and maintaining inert atmospheres during processing when necessary. Fire suppression systems specifically designed for metal fires should be readily available, and personnel should be trained in emergency response procedures for metal powder incidents.

- Environmental protection and waste management: Environmental considerations for nickel superalloy powders include preventing release into air, water, and soil systems. Proper filtration systems must be implemented to capture airborne particles, and wastewater treatment processes should remove metal contaminants before discharge. Waste management protocols should address the proper disposal or recycling of powder residues, contaminated packaging, and processing byproducts. Environmental monitoring programs help ensure compliance with regulations and minimize ecological impact from manufacturing operations.

- Safety equipment and protective measures: Comprehensive safety measures for working with nickel superalloy powders include specialized personal protective equipment such as respirators with appropriate filters, chemical-resistant gloves, protective clothing, and eye protection. Engineering controls like local exhaust ventilation, enclosed processing systems, and dust collection equipment minimize exposure. Regular safety training, emergency response procedures, decontamination facilities, and medical surveillance programs for workers handling these materials are essential components of a complete safety management system.

02 Health hazards and exposure prevention

Nickel superalloy powders present specific health risks including respiratory issues, skin sensitization, and potential carcinogenic effects with prolonged exposure. Prevention strategies focus on minimizing dust generation through wet processing methods, implementing engineering controls such as local exhaust ventilation, and establishing exposure monitoring programs. Medical surveillance for workers regularly exposed to these materials is recommended, along with training on proper handling techniques and emergency response procedures for accidental exposure.Expand Specific Solutions03 Fire and explosion prevention for metal powders

Nickel superalloy powders can present fire and explosion hazards due to their fine particle size and potential reactivity. Safety protocols include using inert gas environments during processing, implementing grounding procedures to prevent static electricity buildup, and installing specialized fire suppression systems designed for metal powder fires. Segregation from incompatible materials and moisture control are also critical aspects of preventing unwanted reactions that could lead to combustion or explosion events.Expand Specific Solutions04 Environmental protection and waste management

Proper disposal and environmental protection measures for nickel superalloy powders involve specialized waste handling procedures to prevent environmental contamination. This includes containment systems for powder collection, recycling processes for unused materials, and treatment methods to neutralize potential environmental hazards. Wastewater from processing operations requires treatment to remove metal particulates before discharge, and air filtration systems should be employed to capture airborne particles during manufacturing processes.Expand Specific Solutions05 Safe manufacturing and processing techniques

Manufacturing and processing nickel superalloy powders safely requires specialized equipment and techniques. These include enclosed production systems that minimize worker exposure, automated handling systems to reduce direct contact, and process controls that monitor and maintain safe operating conditions. Additive manufacturing and powder metallurgy operations involving these materials require particular attention to particle size control, oxygen content management, and contamination prevention to ensure both product quality and operational safety.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The additive manufacturing of nickel superalloys for powder handling is currently in a growth phase, with the market expanding rapidly due to increasing aerospace and energy sector demands. The global market size is estimated to reach significant value as industries adopt these advanced manufacturing techniques for high-performance components. From a technical maturity perspective, the field shows varying levels of development among key players. Leading companies like Rolls-Royce, GE, Safran, and Siemens Energy have established robust capabilities in powder metallurgy and safety protocols, while research institutions such as Central South University and the Institute of Metal Research Chinese Academy of Sciences are advancing fundamental knowledge. Specialized manufacturers including EOS GmbH, Renishaw, and Aubert & Duval have developed proprietary powder handling systems addressing safety concerns specific to nickel superalloys, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated powder management system specifically for nickel-based superalloys used in aerospace and defense applications. Their approach centers on a closed-loop powder handling architecture that minimizes environmental exposure through automated dispensing, sieving, and recycling operations. Honeywell employs specialized anti-static containers with inert gas purging capabilities to prevent oxidation and moisture absorption during storage and transfer. Their powder qualification process includes comprehensive particle size distribution analysis, flowability testing, and chemical composition verification using ICP-MS techniques to detect trace contaminants that could affect final part properties. For worker safety, Honeywell has implemented a hierarchical control strategy including engineering controls (ventilated workstations with HEPA filtration), administrative controls (specialized training programs), and personal protective equipment optimized for handling nano-scale nickel particles. Their facilities incorporate specialized fire suppression systems designed specifically for metal powder fires, using agents that won't react with nickel alloys or create hazardous byproducts.

Strengths: Exceptional integration between powder handling systems and quality control processes ensures consistent material properties. Their specialized safety protocols address both chronic and acute health hazards associated with nickel powder exposure. Weaknesses: The system requires significant technical expertise to operate effectively, creating potential workforce challenges. The specialized equipment and facilities represent substantial capital investment requirements.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered a multi-tiered approach to nickel superalloy powder handling for additive manufacturing of critical aerospace components. Their system incorporates specialized powder storage facilities with controlled humidity (<0.5%) and oxygen levels to prevent degradation of reactive nickel superalloy powders. The company employs a proprietary powder validation protocol that includes rheological testing, particle morphology analysis, and chemical composition verification before any powder enters their production workflow. For handling operations, Rolls-Royce utilizes vacuum-assisted transfer systems that minimize powder dispersion and worker exposure, complemented by real-time monitoring of airborne particulate concentrations. Their facilities feature dedicated powder processing rooms with specialized anti-static flooring, grounding systems, and explosion-proof electrical installations. Rolls-Royce has also developed a comprehensive powder lifecycle management system that tracks each powder batch from receipt through multiple build cycles, with defined criteria for powder retirement based on cumulative exposure time, oxygen pickup, and morphological changes.

Strengths: Exceptional traceability systems ensure complete powder history documentation for regulatory compliance in aerospace applications. Their comprehensive testing protocols maintain extremely high powder quality standards. Weaknesses: The extensive testing and validation procedures add significant time and cost to the manufacturing process. The system is optimized for high-value, low-volume aerospace components rather than higher throughput industrial applications.

Critical Safety Innovations for Nickel Powder Management

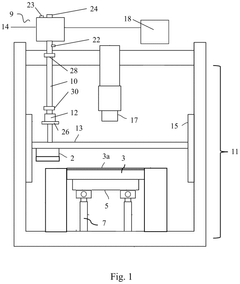

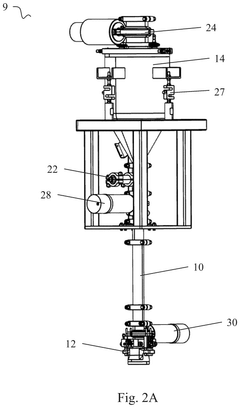

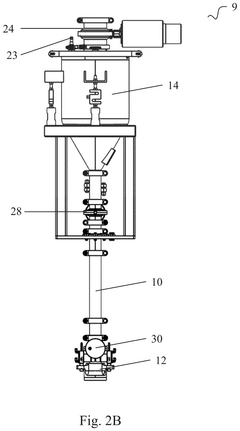

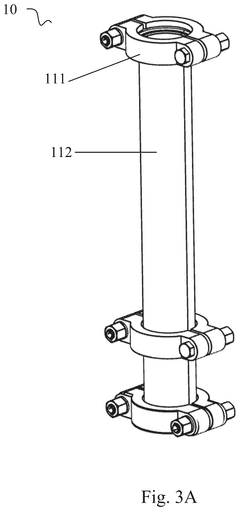

Method and apparatus for powder material handling in additive manufacturing

PatentPendingUS20240424570A1

Innovation

- Preload container system designed to hold predetermined amounts of powder material and rapidly transfer it from powder supply to recoater in less than 10 seconds, enabling efficient multi-layer build processes.

- Isolated environment maintenance during powder transfer operations, protecting sensitive materials from environmental exposure and contamination.

- Specialized movable seal interface between powder supply and recoater hopper to maintain isolation while enabling efficient material transfer.

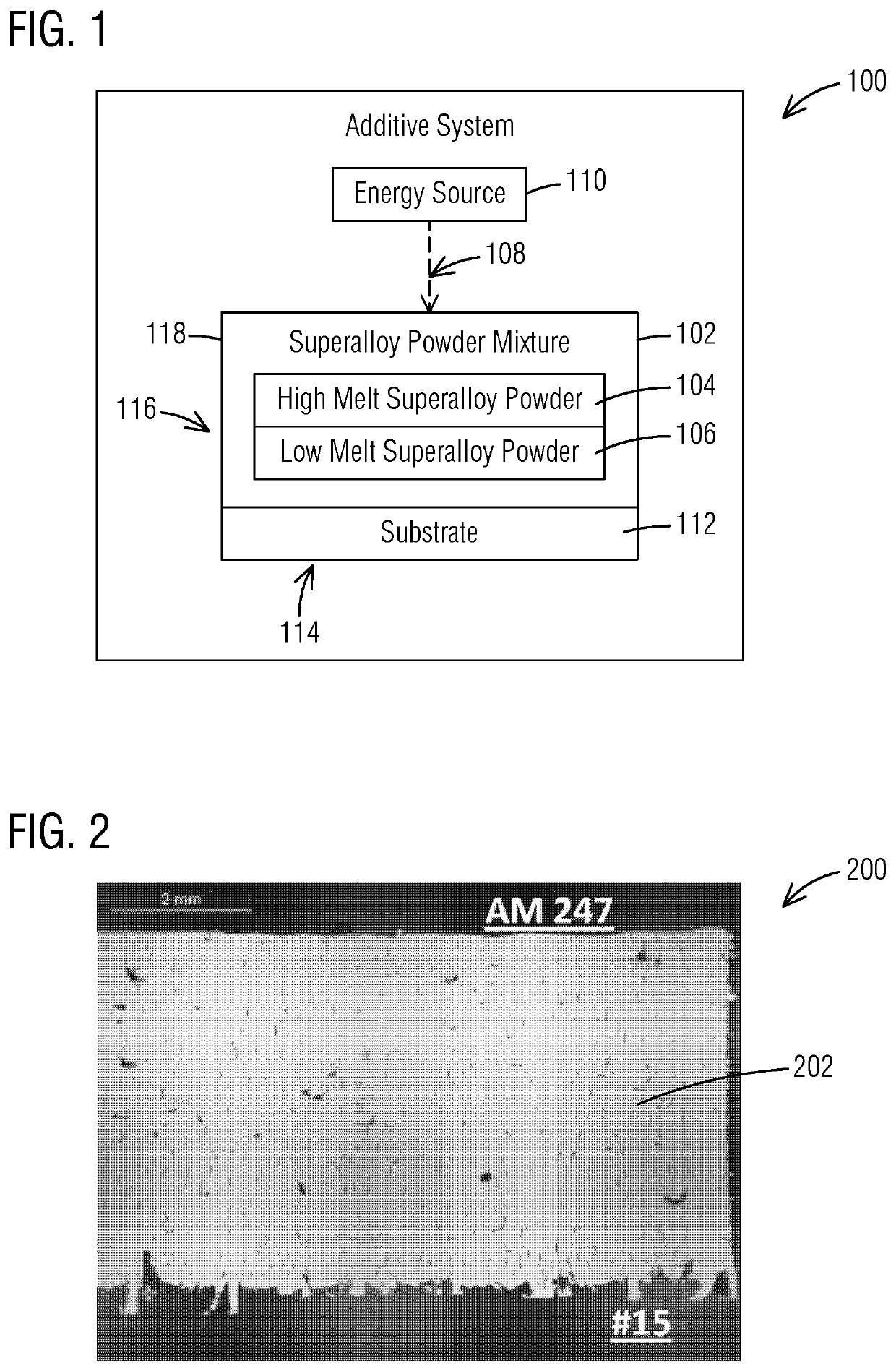

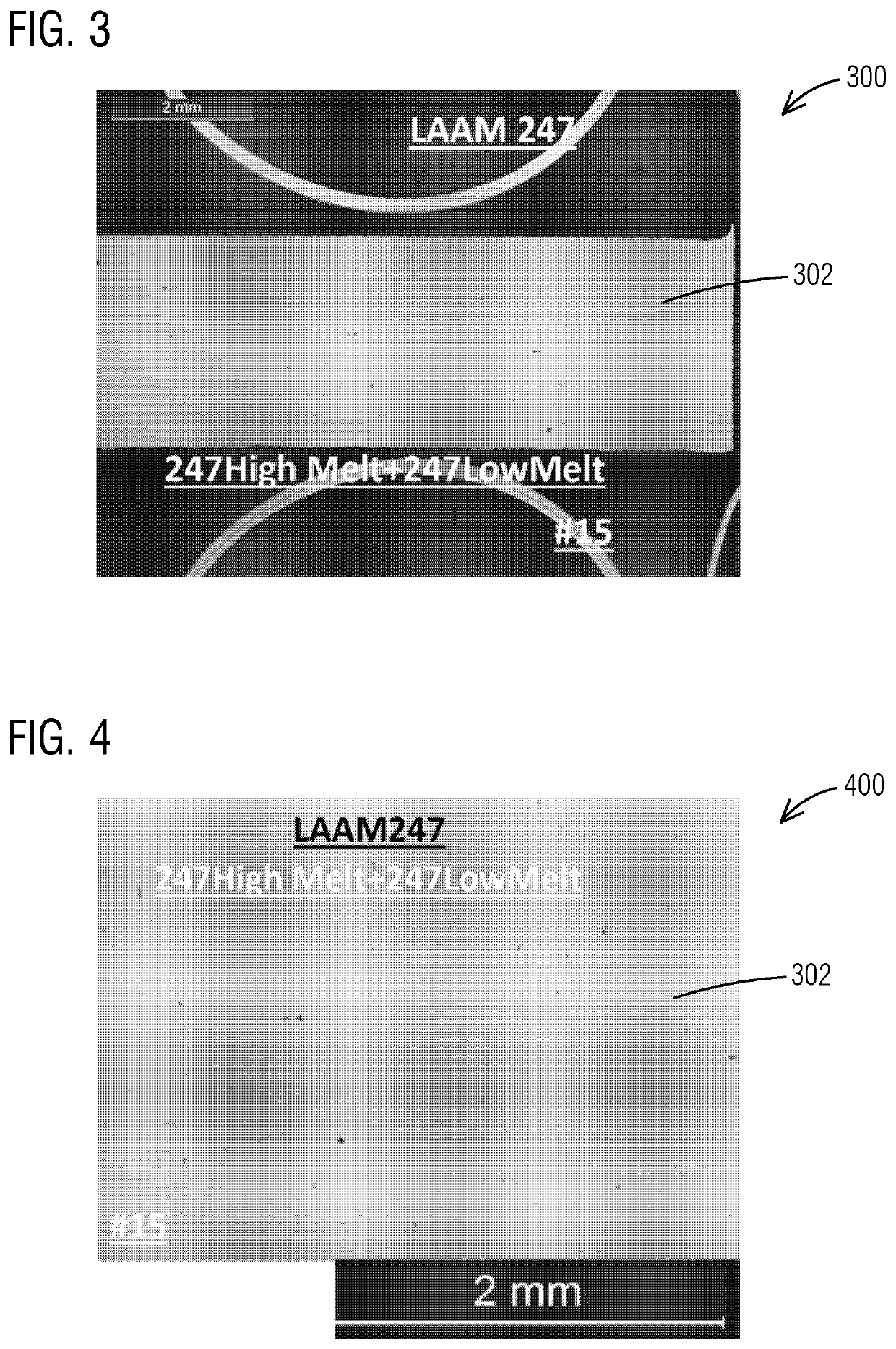

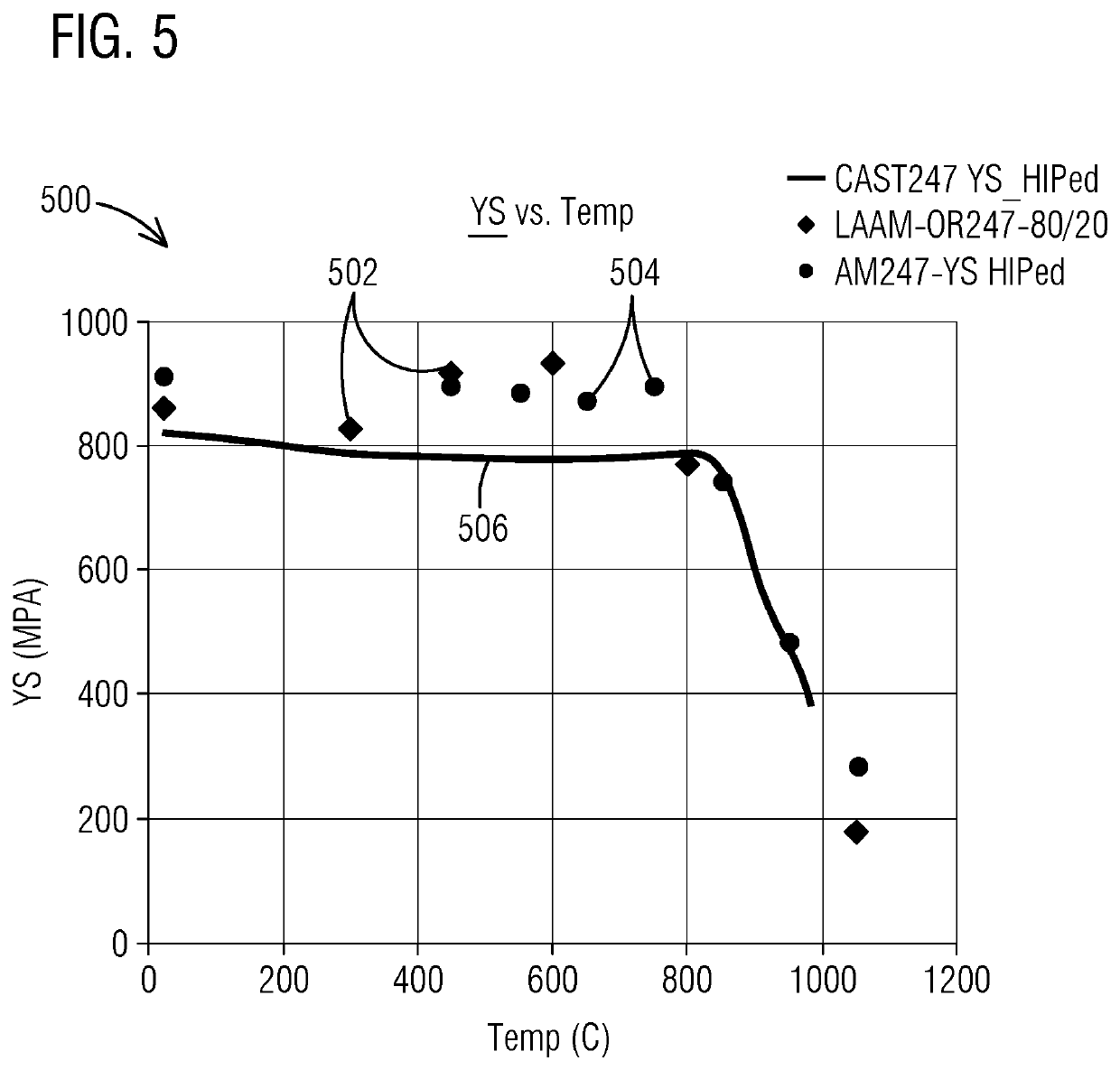

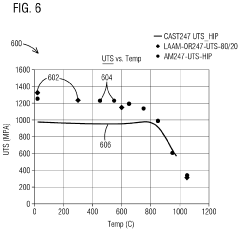

Superalloy powder mixture for liquid assisted additive manufacturing of a superalloy component

PatentPendingUS20220226893A1

Innovation

- A superalloy powder mixture comprising a high melt superalloy powder and a low melt superalloy powder, with specific weight ratios and chemical compositions, is used for additive manufacturing and welding, where the low melt superalloy powder has a lower solidus temperature than the high melt superalloy powder, reducing microcracking and eliminating the need for hot isostatic pressing.

Regulatory Compliance for Metal AM Powders

Regulatory compliance for metal additive manufacturing (AM) powders, particularly nickel superalloys, involves navigating a complex landscape of international, national, and industry-specific standards. Organizations such as ASTM International, ISO, and OSHA have established frameworks that manufacturers must adhere to when handling these potentially hazardous materials. ASTM F3049 specifically addresses standard practices for characterizing properties of metal powders used in AM processes, while ISO/ASTM 52907 provides guidelines for powder feedstock specifications.

For nickel superalloy powders, compliance with occupational exposure limits is particularly critical due to their carcinogenic and sensitizing properties. The OSHA Permissible Exposure Limit (PEL) for nickel compounds is set at 1.0 mg/m³, with NIOSH recommending an even lower exposure limit of 0.015 mg/m³. Manufacturers must implement robust monitoring systems to ensure workplace exposures remain below these thresholds, requiring regular air sampling and personnel monitoring programs.

Transportation and storage of nickel superalloy powders fall under hazardous materials regulations, including the UN Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and regional implementations such as EU REACH and US DOT regulations. These frameworks mandate specific packaging requirements, labeling protocols, and safety data sheet documentation that must accompany powder materials throughout the supply chain.

Waste management compliance presents another regulatory challenge, as nickel-containing waste may be classified as hazardous under various environmental protection frameworks. The US EPA regulates nickel compounds under the Resource Conservation and Recovery Act (RCRA), requiring special disposal procedures and documentation. Similarly, the EU Waste Framework Directive imposes strict controls on metal powder waste handling and disposal.

Facility certification requirements add another layer of compliance complexity. Organizations pursuing medical or aerospace applications must often obtain certifications such as ISO 13485 or AS9100, which impose additional quality management and traceability requirements for powder handling processes. These standards necessitate comprehensive documentation of powder lifecycle management from receipt through processing and disposal.

Emerging regulations around nanomaterials may also impact nickel superalloy powder handling, as some AM powders contain particles in the nanoscale range. Regulatory bodies worldwide are developing frameworks to address potential unique hazards associated with nanomaterials, which may impose additional testing and control requirements on powder manufacturers and users in the near future.

For nickel superalloy powders, compliance with occupational exposure limits is particularly critical due to their carcinogenic and sensitizing properties. The OSHA Permissible Exposure Limit (PEL) for nickel compounds is set at 1.0 mg/m³, with NIOSH recommending an even lower exposure limit of 0.015 mg/m³. Manufacturers must implement robust monitoring systems to ensure workplace exposures remain below these thresholds, requiring regular air sampling and personnel monitoring programs.

Transportation and storage of nickel superalloy powders fall under hazardous materials regulations, including the UN Globally Harmonized System of Classification and Labelling of Chemicals (GHS) and regional implementations such as EU REACH and US DOT regulations. These frameworks mandate specific packaging requirements, labeling protocols, and safety data sheet documentation that must accompany powder materials throughout the supply chain.

Waste management compliance presents another regulatory challenge, as nickel-containing waste may be classified as hazardous under various environmental protection frameworks. The US EPA regulates nickel compounds under the Resource Conservation and Recovery Act (RCRA), requiring special disposal procedures and documentation. Similarly, the EU Waste Framework Directive imposes strict controls on metal powder waste handling and disposal.

Facility certification requirements add another layer of compliance complexity. Organizations pursuing medical or aerospace applications must often obtain certifications such as ISO 13485 or AS9100, which impose additional quality management and traceability requirements for powder handling processes. These standards necessitate comprehensive documentation of powder lifecycle management from receipt through processing and disposal.

Emerging regulations around nanomaterials may also impact nickel superalloy powder handling, as some AM powders contain particles in the nanoscale range. Regulatory bodies worldwide are developing frameworks to address potential unique hazards associated with nanomaterials, which may impose additional testing and control requirements on powder manufacturers and users in the near future.

Environmental Impact Assessment

The environmental impact of nickel superalloy powder handling in additive manufacturing processes extends beyond immediate workplace safety concerns to broader ecological considerations. Nickel-based superalloy powders, when improperly managed, can contaminate soil and water systems through accidental spills or inadequate disposal practices. These materials contain heavy metals that persist in the environment and can bioaccumulate in living organisms, potentially disrupting ecosystems and food chains.

Air quality represents another significant environmental concern. Fine metal powders can become airborne during handling operations, contributing to particulate matter pollution if ventilation systems are inadequate or if powder containment fails. These emissions may affect local air quality and potentially contribute to respiratory health issues in surrounding communities if manufacturing facilities are located near residential areas.

Energy consumption associated with powder production and handling systems also contributes to the environmental footprint. The atomization processes used to create nickel superalloy powders are energy-intensive, often relying on fossil fuel-derived electricity. Additionally, the specialized environmental control systems required for safe powder handling—including HEPA filtration, climate control, and inert gas environments—consume significant energy resources during continuous operation.

Water usage presents another environmental consideration, particularly in powder production and post-processing operations. Water used in atomization processes or for cleaning equipment may become contaminated with metal particles and require specialized treatment before discharge, adding complexity to wastewater management systems.

Regulatory frameworks increasingly address these environmental concerns. The EU's REACH regulations and similar programs worldwide now require comprehensive environmental risk assessments for materials containing nickel compounds. Manufacturers must document potential environmental exposure pathways and implement mitigation strategies accordingly.

Sustainable practices in powder handling are emerging as industry priorities. These include closed-loop recycling systems for unused powders, advanced filtration technologies to minimize airborne emissions, and energy-efficient handling equipment. Some manufacturers have implemented powder reclamation systems that can recover and recondition up to 95% of unused powder, significantly reducing waste generation and raw material consumption.

Life cycle assessment (LCA) methodologies are increasingly being applied to additive manufacturing powder processes, allowing companies to quantify environmental impacts across the entire production chain and identify opportunities for improvement. These assessments typically reveal that environmental optimization of powder handling processes can contribute significantly to reducing the overall ecological footprint of nickel superalloy additive manufacturing operations.

Air quality represents another significant environmental concern. Fine metal powders can become airborne during handling operations, contributing to particulate matter pollution if ventilation systems are inadequate or if powder containment fails. These emissions may affect local air quality and potentially contribute to respiratory health issues in surrounding communities if manufacturing facilities are located near residential areas.

Energy consumption associated with powder production and handling systems also contributes to the environmental footprint. The atomization processes used to create nickel superalloy powders are energy-intensive, often relying on fossil fuel-derived electricity. Additionally, the specialized environmental control systems required for safe powder handling—including HEPA filtration, climate control, and inert gas environments—consume significant energy resources during continuous operation.

Water usage presents another environmental consideration, particularly in powder production and post-processing operations. Water used in atomization processes or for cleaning equipment may become contaminated with metal particles and require specialized treatment before discharge, adding complexity to wastewater management systems.

Regulatory frameworks increasingly address these environmental concerns. The EU's REACH regulations and similar programs worldwide now require comprehensive environmental risk assessments for materials containing nickel compounds. Manufacturers must document potential environmental exposure pathways and implement mitigation strategies accordingly.

Sustainable practices in powder handling are emerging as industry priorities. These include closed-loop recycling systems for unused powders, advanced filtration technologies to minimize airborne emissions, and energy-efficient handling equipment. Some manufacturers have implemented powder reclamation systems that can recover and recondition up to 95% of unused powder, significantly reducing waste generation and raw material consumption.

Life cycle assessment (LCA) methodologies are increasingly being applied to additive manufacturing powder processes, allowing companies to quantify environmental impacts across the entire production chain and identify opportunities for improvement. These assessments typically reveal that environmental optimization of powder handling processes can contribute significantly to reducing the overall ecological footprint of nickel superalloy additive manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!