Post-Print Heat Treatment Routes To Restore γ′ Microstructure

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy Heat Treatment Background and Objectives

Superalloys represent a class of advanced metallic materials designed to withstand extreme operating conditions, particularly at elevated temperatures. The development of these materials dates back to the 1940s, with significant advancements occurring during the jet engine revolution. Their exceptional high-temperature strength, creep resistance, and corrosion resistance make them indispensable in critical applications such as aerospace engines, gas turbines, and nuclear reactors.

The γ′ (gamma prime) precipitate phase, typically Ni3(Al,Ti), serves as the primary strengthening mechanism in nickel-based superalloys. This ordered intermetallic phase provides remarkable mechanical stability at high temperatures through coherent precipitation within the γ matrix. The size, morphology, distribution, and volume fraction of these precipitates critically determine the alloy's performance characteristics.

Additive manufacturing (AM) technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), have revolutionized the production of superalloy components by enabling complex geometries unachievable through conventional manufacturing. However, the rapid solidification rates inherent to these processes significantly alter the microstructure, often resulting in non-optimal γ′ precipitate distributions and compromised mechanical properties.

The thermal history during AM processing—characterized by extremely high cooling rates (103-106 K/s), directional heat flow, and repeated thermal cycling—creates unique challenges for γ′ precipitation. The as-printed microstructure typically exhibits fine dendritic structures, segregation of alloying elements, and either complete absence or non-ideal distribution of γ′ precipitates. This microstructural deviation from conventionally processed superalloys necessitates specialized post-print heat treatments.

Current research trends focus on developing tailored post-print heat treatment protocols specifically designed to restore optimal γ′ microstructure in additively manufactured superalloys. These treatments aim to dissolve undesirable phases, homogenize the chemical composition, relieve residual stresses, and precisely control the nucleation and growth of γ′ precipitates to achieve the desired size distribution and morphology.

The primary objective of this technical research is to comprehensively evaluate existing post-print heat treatment routes for restoring γ′ microstructure in additively manufactured superalloys, identify their limitations, and explore innovative approaches to optimize these treatments. The ultimate goal is to establish standardized yet adaptable heat treatment protocols that can consistently deliver conventionally-equivalent or superior mechanical properties in additively manufactured superalloy components across various industrial applications.

The γ′ (gamma prime) precipitate phase, typically Ni3(Al,Ti), serves as the primary strengthening mechanism in nickel-based superalloys. This ordered intermetallic phase provides remarkable mechanical stability at high temperatures through coherent precipitation within the γ matrix. The size, morphology, distribution, and volume fraction of these precipitates critically determine the alloy's performance characteristics.

Additive manufacturing (AM) technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), have revolutionized the production of superalloy components by enabling complex geometries unachievable through conventional manufacturing. However, the rapid solidification rates inherent to these processes significantly alter the microstructure, often resulting in non-optimal γ′ precipitate distributions and compromised mechanical properties.

The thermal history during AM processing—characterized by extremely high cooling rates (103-106 K/s), directional heat flow, and repeated thermal cycling—creates unique challenges for γ′ precipitation. The as-printed microstructure typically exhibits fine dendritic structures, segregation of alloying elements, and either complete absence or non-ideal distribution of γ′ precipitates. This microstructural deviation from conventionally processed superalloys necessitates specialized post-print heat treatments.

Current research trends focus on developing tailored post-print heat treatment protocols specifically designed to restore optimal γ′ microstructure in additively manufactured superalloys. These treatments aim to dissolve undesirable phases, homogenize the chemical composition, relieve residual stresses, and precisely control the nucleation and growth of γ′ precipitates to achieve the desired size distribution and morphology.

The primary objective of this technical research is to comprehensively evaluate existing post-print heat treatment routes for restoring γ′ microstructure in additively manufactured superalloys, identify their limitations, and explore innovative approaches to optimize these treatments. The ultimate goal is to establish standardized yet adaptable heat treatment protocols that can consistently deliver conventionally-equivalent or superior mechanical properties in additively manufactured superalloy components across various industrial applications.

Market Demand for Advanced Post-Print Heat Treatment Solutions

The additive manufacturing (AM) market for high-performance metal components has experienced significant growth, with the global market value reaching $12 billion in 2022 and projected to exceed $33 billion by 2028. Within this expanding sector, there is a rapidly increasing demand for advanced post-print heat treatment solutions specifically designed to restore and optimize γ′ microstructure in nickel-based superalloys and other precipitation-hardened alloys.

This demand is primarily driven by aerospace, power generation, and automotive industries, where components must maintain exceptional mechanical properties under extreme operating conditions. The aerospace sector alone accounts for approximately 30% of the metal AM market, with a particular focus on turbine components where γ′ precipitate control is critical for performance and longevity.

Original equipment manufacturers (OEMs) are increasingly specifying precise microstructural requirements for additively manufactured parts, creating a specialized market for advanced heat treatment processes. This trend is evidenced by recent procurement patterns from major aerospace manufacturers who now routinely include detailed γ′ microstructure specifications in their component requirements.

The market is further stimulated by regulatory pressures, particularly in safety-critical applications where certification demands verifiable microstructural integrity. This has created a premium segment for heat treatment solutions that can deliver consistent, predictable, and documentable γ′ restoration results.

Research indicates that manufacturers are willing to invest substantially in advanced heat treatment technologies that can reduce variability in final part properties. A recent industry survey revealed that 78% of high-value component manufacturers consider microstructural optimization as "extremely important" in their production processes, with 65% specifically highlighting γ′ precipitation control as a critical factor.

The geographical distribution of this demand shows concentration in regions with established aerospace and energy sector manufacturing hubs, particularly in North America, Western Europe, and increasingly in East Asia. China's investment in advanced manufacturing capabilities has created a rapidly growing market for sophisticated post-processing technologies, with annual growth rates exceeding 25% in this segment.

Service providers offering specialized post-print heat treatment capabilities are experiencing significant business growth, with some reporting annual revenue increases of 15-20% specifically from γ′ microstructure optimization services. This indicates a strong willingness among end-users to outsource this critical process step to specialists rather than developing in-house capabilities.

Market analysis suggests that solutions offering integrated process monitoring and microstructure verification capabilities command premium pricing, reflecting the high value placed on quality assurance in critical applications where γ′ microstructure directly impacts component performance and safety.

This demand is primarily driven by aerospace, power generation, and automotive industries, where components must maintain exceptional mechanical properties under extreme operating conditions. The aerospace sector alone accounts for approximately 30% of the metal AM market, with a particular focus on turbine components where γ′ precipitate control is critical for performance and longevity.

Original equipment manufacturers (OEMs) are increasingly specifying precise microstructural requirements for additively manufactured parts, creating a specialized market for advanced heat treatment processes. This trend is evidenced by recent procurement patterns from major aerospace manufacturers who now routinely include detailed γ′ microstructure specifications in their component requirements.

The market is further stimulated by regulatory pressures, particularly in safety-critical applications where certification demands verifiable microstructural integrity. This has created a premium segment for heat treatment solutions that can deliver consistent, predictable, and documentable γ′ restoration results.

Research indicates that manufacturers are willing to invest substantially in advanced heat treatment technologies that can reduce variability in final part properties. A recent industry survey revealed that 78% of high-value component manufacturers consider microstructural optimization as "extremely important" in their production processes, with 65% specifically highlighting γ′ precipitation control as a critical factor.

The geographical distribution of this demand shows concentration in regions with established aerospace and energy sector manufacturing hubs, particularly in North America, Western Europe, and increasingly in East Asia. China's investment in advanced manufacturing capabilities has created a rapidly growing market for sophisticated post-processing technologies, with annual growth rates exceeding 25% in this segment.

Service providers offering specialized post-print heat treatment capabilities are experiencing significant business growth, with some reporting annual revenue increases of 15-20% specifically from γ′ microstructure optimization services. This indicates a strong willingness among end-users to outsource this critical process step to specialists rather than developing in-house capabilities.

Market analysis suggests that solutions offering integrated process monitoring and microstructure verification capabilities command premium pricing, reflecting the high value placed on quality assurance in critical applications where γ′ microstructure directly impacts component performance and safety.

Current γ′ Restoration Challenges in Additive Manufacturing

The restoration of γ′ precipitates in additively manufactured nickel-based superalloys presents significant challenges due to the unique thermal history and microstructural characteristics inherent to the additive manufacturing (AM) process. Unlike conventional casting or forging methods, AM introduces rapid solidification rates and thermal cycling that substantially alter the precipitation behavior of strengthening phases, particularly the γ′ phase which is crucial for high-temperature mechanical properties.

Current challenges in γ′ restoration begin with the heterogeneous microstructure produced during AM. The layer-by-layer building process creates distinct thermal gradients resulting in non-uniform γ′ size, morphology, and distribution throughout the component. This heterogeneity makes it difficult to design universal heat treatment protocols that can effectively restore optimal γ′ microstructure across the entire part.

Another significant challenge lies in the chemical segregation that occurs during rapid solidification. Elements such as aluminum and titanium, which are primary γ′ formers, tend to segregate at cellular boundaries, creating composition gradients that affect subsequent precipitation behavior. This segregation can lead to localized variations in γ′ volume fraction and stability, complicating the restoration process.

The presence of residual stresses in as-built AM components further complicates γ′ restoration efforts. These stresses can influence diffusion kinetics and precipitation behavior during post-print heat treatments, potentially leading to unexpected microstructural evolution. Additionally, the high dislocation density in as-built structures can serve as heterogeneous nucleation sites for γ′, affecting the size distribution and morphology of precipitates during heat treatment.

Porosity and lack-of-fusion defects common in AM parts create additional complications for γ′ restoration. These defects can act as sinks for alloying elements or create local stress concentrations that affect precipitation kinetics in surrounding regions. Furthermore, the fine-grained structure typical of AM materials provides numerous grain boundaries that can compete with γ′ precipitation for solute atoms.

The optimization of heat treatment parameters presents another challenge. Traditional solution and aging treatments developed for cast or wrought superalloys often prove inadequate for AM materials due to their distinct starting microstructure. Determining the optimal temperature, time, and cooling rates for homogenization, solution treatment, and aging steps requires extensive experimentation and characterization.

Advanced characterization techniques are essential for understanding γ′ restoration processes, yet present their own challenges. Techniques such as high-resolution electron microscopy and atom probe tomography are needed to accurately quantify γ′ size, distribution, and chemistry at nanoscale levels, but these methods are time-consuming and not readily available for routine industrial quality control.

Current challenges in γ′ restoration begin with the heterogeneous microstructure produced during AM. The layer-by-layer building process creates distinct thermal gradients resulting in non-uniform γ′ size, morphology, and distribution throughout the component. This heterogeneity makes it difficult to design universal heat treatment protocols that can effectively restore optimal γ′ microstructure across the entire part.

Another significant challenge lies in the chemical segregation that occurs during rapid solidification. Elements such as aluminum and titanium, which are primary γ′ formers, tend to segregate at cellular boundaries, creating composition gradients that affect subsequent precipitation behavior. This segregation can lead to localized variations in γ′ volume fraction and stability, complicating the restoration process.

The presence of residual stresses in as-built AM components further complicates γ′ restoration efforts. These stresses can influence diffusion kinetics and precipitation behavior during post-print heat treatments, potentially leading to unexpected microstructural evolution. Additionally, the high dislocation density in as-built structures can serve as heterogeneous nucleation sites for γ′, affecting the size distribution and morphology of precipitates during heat treatment.

Porosity and lack-of-fusion defects common in AM parts create additional complications for γ′ restoration. These defects can act as sinks for alloying elements or create local stress concentrations that affect precipitation kinetics in surrounding regions. Furthermore, the fine-grained structure typical of AM materials provides numerous grain boundaries that can compete with γ′ precipitation for solute atoms.

The optimization of heat treatment parameters presents another challenge. Traditional solution and aging treatments developed for cast or wrought superalloys often prove inadequate for AM materials due to their distinct starting microstructure. Determining the optimal temperature, time, and cooling rates for homogenization, solution treatment, and aging steps requires extensive experimentation and characterization.

Advanced characterization techniques are essential for understanding γ′ restoration processes, yet present their own challenges. Techniques such as high-resolution electron microscopy and atom probe tomography are needed to accurately quantify γ′ size, distribution, and chemistry at nanoscale levels, but these methods are time-consuming and not readily available for routine industrial quality control.

Current γ′ Microstructure Restoration Methodologies

01 Heat treatment parameters for γ' microstructure restoration

Specific heat treatment parameters including temperature, time, and cooling rates are critical for restoring the γ' microstructure in additively manufactured superalloys. These parameters must be carefully controlled to achieve the desired precipitation of γ' phase with optimal size, distribution, and morphology. The heat treatment typically involves solution treatment followed by aging steps to nucleate and grow the strengthening γ' precipitates that were disrupted during the printing process.- Heat treatment parameters for γ' microstructure restoration: Specific heat treatment parameters including temperature ranges, holding times, and cooling rates are critical for the restoration of γ' microstructure in post-print components. These parameters are carefully controlled to achieve optimal precipitation of γ' phase, which is essential for the mechanical properties of superalloys. The heat treatment typically involves solution treatment followed by aging steps to control the size, distribution, and morphology of γ' precipitates.

- Controlled cooling processes for precipitate formation: Controlled cooling processes after additive manufacturing are essential for the formation of desired γ' precipitates. These processes involve specific cooling rates that allow for nucleation and growth of precipitates with optimal size and distribution. The cooling rate affects the morphology, size distribution, and volume fraction of γ' precipitates, which directly impact the mechanical properties of the final component.

- Multi-stage heat treatment for microstructure optimization: Multi-stage heat treatment protocols are employed to optimize the γ' microstructure in additively manufactured components. These protocols typically involve an initial solution treatment to dissolve existing precipitates, followed by one or more aging treatments at different temperatures to control the precipitation sequence. This approach allows for tailored microstructures with specific γ' size distributions and morphologies to achieve desired mechanical properties.

- Homogenization treatments to eliminate print-induced heterogeneity: Homogenization treatments are applied to eliminate microstructural heterogeneity resulting from the layer-by-layer building process in additive manufacturing. These treatments involve holding the component at elevated temperatures for extended periods to allow for diffusion of alloying elements and elimination of segregation. This process is crucial for achieving uniform γ' distribution throughout the component, which ensures consistent mechanical properties.

- Atmosphere control during post-print heat treatment: The atmosphere during post-print heat treatment significantly impacts the restoration of γ' microstructure. Vacuum or inert gas environments are often used to prevent oxidation and decarburization of the component surface. In some cases, controlled reactive atmospheres may be employed to achieve specific surface characteristics while maintaining the desired bulk γ' microstructure. Proper atmosphere control ensures the integrity of the microstructure throughout the component.

02 Multi-stage heat treatment processes

Multi-stage heat treatment processes are employed to restore the γ' microstructure in 3D printed nickel-based superalloys. These processes typically involve an initial solution treatment at high temperature to homogenize the microstructure, followed by one or more aging treatments at lower temperatures. The multi-stage approach allows for controlled nucleation and growth of γ' precipitates, resulting in optimized mechanical properties and microstructural stability.Expand Specific Solutions03 Atmosphere control during post-print heat treatment

The atmosphere during post-print heat treatment significantly impacts the restoration of γ' microstructure. Controlled atmospheres such as vacuum, inert gas, or reducing atmospheres prevent oxidation and other undesirable reactions during high-temperature processing. Proper atmosphere control ensures the intended precipitation of γ' phase without contamination or degradation, particularly important for components with complex geometries or thin sections produced through additive manufacturing.Expand Specific Solutions04 Microstructure characterization techniques for γ' phase

Advanced characterization techniques are essential for evaluating the effectiveness of post-print heat treatments in restoring γ' microstructure. These include electron microscopy (SEM, TEM), X-ray diffraction (XRD), and thermal analysis methods that allow for quantitative assessment of γ' precipitate size, distribution, volume fraction, and morphology. These techniques provide critical feedback for optimizing heat treatment parameters and validating the restoration of desired microstructural features.Expand Specific Solutions05 Alloy-specific heat treatment protocols

Different nickel-based superalloys require tailored heat treatment protocols to effectively restore γ' microstructure after additive manufacturing. The chemical composition of the alloy, particularly the content of γ' forming elements like aluminum and titanium, dictates the specific heat treatment parameters needed. Custom heat treatment schedules are developed for each alloy system to achieve the optimal balance of γ' precipitation, grain structure, and mechanical properties.Expand Specific Solutions

Key Industry Players in Superalloy Heat Treatment

The post-print heat treatment market for γ′ microstructure restoration is currently in a growth phase, with increasing demand driven by advanced manufacturing sectors, particularly aerospace and energy. The market size is expanding as additive manufacturing technologies become more mainstream, creating greater need for specialized heat treatment processes. Technologically, the field shows varying maturity levels across players. Leading companies like Safran and DuPont demonstrate advanced capabilities in high-temperature alloy treatments, while research institutions such as Xi'an Jiaotong University and CNRS are pushing boundaries in fundamental metallurgical science. Companies including Toshiba, ROHM, and Jabil are developing proprietary heat treatment technologies, though standardization remains a challenge. The competitive landscape features both specialized materials science firms and diversified industrial conglomerates seeking to optimize post-print microstructural properties.

Zhejiang University

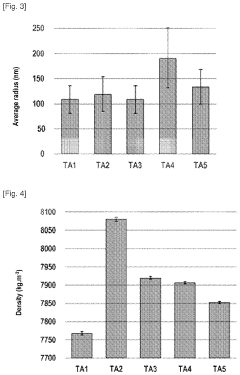

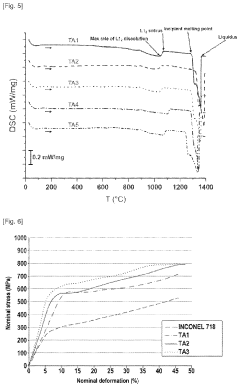

Technical Solution: Zhejiang University has developed an innovative post-print heat treatment methodology for nickel-based superalloys that combines conventional thermal processing with electromagnetic field assistance. Their approach begins with a solution treatment at 1150-1220°C under vacuum conditions to dissolve segregated phases and homogenize the microstructure, followed by controlled cooling at rates of 10-15°C/min. The distinctive aspect of their technology is the application of a pulsed electromagnetic field during the aging treatment (conducted at 760-820°C), which they have demonstrated accelerates γ' precipitation kinetics by approximately 30% compared to conventional thermal-only treatments. Their research shows that the electromagnetic field influences diffusion processes and nucleation rates, resulting in more uniform γ' size distributions with average precipitate diameters controlled to within 250-300nm. The university has also pioneered a cyclic heat treatment protocol that alternates between different aging temperatures (cycling between 760°C and 650°C) to develop optimized bimodal γ' distributions. Their published research demonstrates that components treated with this method exhibit improved creep resistance at elevated temperatures (850-950°C) with approximately 20% longer rupture lives compared to conventionally heat-treated additive parts.

Strengths: The electromagnetic field-assisted approach significantly reduces treatment time while improving microstructural homogeneity. Their cyclic heat treatment protocol creates tailored bimodal γ' distributions that enhance high-temperature mechanical properties. Weaknesses: The electromagnetic field equipment adds complexity and cost to the heat treatment process. The technology is still primarily at the research stage and requires further validation for industrial-scale implementation.

Ansaldo Energia IP UK Ltd.

Technical Solution: Ansaldo Energia has developed advanced post-print heat treatment protocols specifically designed for gas turbine components manufactured through additive manufacturing. Their approach focuses on a multi-stage heat treatment process that begins with solution annealing at temperatures between 1080-1200°C to homogenize the microstructure, followed by controlled cooling and aging treatments at 760-850°C to precisely control γ' precipitate size and distribution. The company employs vacuum heat treatment technology with precise temperature control (±5°C) to prevent oxidation while ensuring uniform thermal exposure across complex geometries. Their process incorporates Hot Isostatic Pressing (HIP) at pressures of 100-200 MPa prior to heat treatment to eliminate internal porosity, which significantly improves the fatigue resistance of printed components. Ansaldo has successfully implemented this technology for industrial gas turbine components, achieving γ' distributions comparable to conventionally manufactured parts.

Strengths: Their integrated HIP and heat treatment approach effectively addresses both microstructural restoration and porosity elimination in a coordinated process. The vacuum heat treatment technology prevents oxidation issues common in high-temperature treatments of superalloys. Weaknesses: The multi-stage process requires significant energy consumption and specialized equipment, increasing production costs. The treatment protocols are primarily optimized for large industrial components rather than smaller precision parts.

Critical Patents in Post-Print Heat Treatment Processes

Method for post-weld heat treatment of welded components made of gamma prime strengthened superalloys

PatentActiveUS20140366995A1

Innovation

- A post-weld heat treatment method involving rapid heating (20-40°C/min) followed by slow heating (5°C/min) and rapid cooling (≥20°C/min) to minimize gamma prime precipitations in the weld, with an optional precipitation hardening treatment to ensure similar precipitation rates in the weld and base material, preventing cracking.

Superalloy with optimized properties and a limited density

PatentActiveUS11821060B2

Innovation

- Development of nickel-based and cobalt-based superalloys with specific compositions that minimize the formation of topologically close-packed phases, incorporating elements like chromium, cobalt, aluminum, and iron to maintain gamma-prime hardening phases and reduce density, while optimizing resistance to oxidation and corrosion at high temperatures.

Material Property Optimization Through Heat Treatment

Heat treatment processes are critical for optimizing material properties in additive manufacturing, particularly for nickel-based superalloys where the γ′ precipitate phase significantly influences mechanical performance. Post-print heat treatments serve as essential procedures to restore the ideal γ′ microstructure that may have been compromised during the rapid solidification inherent to additive manufacturing processes.

The optimization pathway typically begins with solution treatment at temperatures between 1080°C and 1200°C, which dissolves existing precipitates and homogenizes the microstructure. This critical first step eliminates segregation and prepares the material for controlled precipitation during subsequent aging treatments.

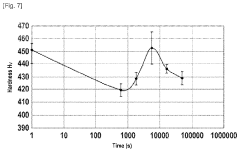

Primary aging treatments, conducted at temperatures ranging from 760°C to 980°C, facilitate the nucleation and growth of fine γ′ precipitates. The temperature selection directly influences precipitate size distribution, with lower temperatures favoring higher nucleation rates and finer precipitate sizes. Duration control is equally important, as extended aging periods can lead to precipitate coarsening and reduced mechanical properties.

Secondary aging treatments at lower temperatures (620°C to 760°C) further refine the microstructure by promoting additional precipitation of smaller γ′ particles. This dual-aging approach creates a bimodal distribution of precipitates that optimizes both strength and ductility, providing superior creep resistance and fatigue performance.

Cooling rates between treatment stages significantly impact the final microstructure. Rapid cooling from solution treatment temperatures can preserve supersaturation for subsequent aging, while controlled cooling rates can be employed to deliberately initiate precipitation of specific morphologies and distributions of γ′ phases.

Advanced heat treatment protocols may incorporate cyclic thermal exposures, which have demonstrated effectiveness in refining precipitate distributions and enhancing mechanical properties beyond what conventional isothermal treatments can achieve. These protocols exploit the dissolution and reprecipitation mechanisms to create more uniform and stable microstructures.

Atmosphere control during heat treatment is another critical parameter, as oxygen exposure can lead to surface oxidation and depletion of aluminum and titanium—key elements for γ′ formation. Vacuum or inert gas environments are therefore essential for preserving alloy composition throughout the thermal processing sequence.

The optimization process ultimately requires balancing multiple competing factors: precipitate size, morphology, volume fraction, and distribution must all be carefully controlled to achieve the desired combination of strength, ductility, creep resistance, and fatigue performance for specific application requirements.

The optimization pathway typically begins with solution treatment at temperatures between 1080°C and 1200°C, which dissolves existing precipitates and homogenizes the microstructure. This critical first step eliminates segregation and prepares the material for controlled precipitation during subsequent aging treatments.

Primary aging treatments, conducted at temperatures ranging from 760°C to 980°C, facilitate the nucleation and growth of fine γ′ precipitates. The temperature selection directly influences precipitate size distribution, with lower temperatures favoring higher nucleation rates and finer precipitate sizes. Duration control is equally important, as extended aging periods can lead to precipitate coarsening and reduced mechanical properties.

Secondary aging treatments at lower temperatures (620°C to 760°C) further refine the microstructure by promoting additional precipitation of smaller γ′ particles. This dual-aging approach creates a bimodal distribution of precipitates that optimizes both strength and ductility, providing superior creep resistance and fatigue performance.

Cooling rates between treatment stages significantly impact the final microstructure. Rapid cooling from solution treatment temperatures can preserve supersaturation for subsequent aging, while controlled cooling rates can be employed to deliberately initiate precipitation of specific morphologies and distributions of γ′ phases.

Advanced heat treatment protocols may incorporate cyclic thermal exposures, which have demonstrated effectiveness in refining precipitate distributions and enhancing mechanical properties beyond what conventional isothermal treatments can achieve. These protocols exploit the dissolution and reprecipitation mechanisms to create more uniform and stable microstructures.

Atmosphere control during heat treatment is another critical parameter, as oxygen exposure can lead to surface oxidation and depletion of aluminum and titanium—key elements for γ′ formation. Vacuum or inert gas environments are therefore essential for preserving alloy composition throughout the thermal processing sequence.

The optimization process ultimately requires balancing multiple competing factors: precipitate size, morphology, volume fraction, and distribution must all be carefully controlled to achieve the desired combination of strength, ductility, creep resistance, and fatigue performance for specific application requirements.

Sustainability Aspects of Advanced Heat Treatment Processes

The sustainability implications of advanced heat treatment processes for post-print γ′ microstructure restoration are becoming increasingly significant in modern manufacturing. These processes, while essential for achieving desired mechanical properties in superalloys, often involve substantial energy consumption and environmental impacts that must be carefully evaluated and mitigated.

Energy efficiency represents a primary sustainability concern in heat treatment operations. Traditional post-print heat treatments typically require prolonged exposure to high temperatures, sometimes exceeding 1000°C for several hours. This energy-intensive process contributes significantly to the carbon footprint of manufactured components. Recent innovations have focused on developing more efficient heating technologies, including induction heating and microwave-assisted processes, which can reduce energy consumption by 20-30% compared to conventional methods.

Resource optimization constitutes another critical aspect of sustainable heat treatment. The precise control of temperature profiles and cooling rates not only ensures optimal γ′ precipitation but also minimizes material waste through reduced rejection rates. Advanced computational modeling and simulation tools now enable manufacturers to predict microstructural evolution during heat treatment, allowing for process optimization without extensive physical testing.

Emissions reduction strategies have gained prominence in heat treatment facility design. Modern furnaces incorporate advanced filtration systems to capture particulate matter and volatile compounds released during the heat treatment of superalloys. Additionally, the transition from fossil fuel-powered furnaces to electric alternatives, particularly when coupled with renewable energy sources, can substantially decrease greenhouse gas emissions associated with post-print processing.

Circular economy principles are increasingly being applied to heat treatment operations. Waste heat recovery systems can capture and repurpose thermal energy from cooling processes, while spent quenching fluids are being recycled through advanced filtration systems. Some facilities have implemented closed-loop systems that minimize resource consumption and waste generation throughout the heat treatment cycle.

Regulatory compliance and certification standards continue to evolve, pushing manufacturers to adopt more sustainable heat treatment practices. ISO 14001 environmental management systems and industry-specific sustainability metrics are becoming standard requirements for suppliers in aerospace and energy sectors, where superalloys with restored γ′ microstructures are commonly utilized.

Energy efficiency represents a primary sustainability concern in heat treatment operations. Traditional post-print heat treatments typically require prolonged exposure to high temperatures, sometimes exceeding 1000°C for several hours. This energy-intensive process contributes significantly to the carbon footprint of manufactured components. Recent innovations have focused on developing more efficient heating technologies, including induction heating and microwave-assisted processes, which can reduce energy consumption by 20-30% compared to conventional methods.

Resource optimization constitutes another critical aspect of sustainable heat treatment. The precise control of temperature profiles and cooling rates not only ensures optimal γ′ precipitation but also minimizes material waste through reduced rejection rates. Advanced computational modeling and simulation tools now enable manufacturers to predict microstructural evolution during heat treatment, allowing for process optimization without extensive physical testing.

Emissions reduction strategies have gained prominence in heat treatment facility design. Modern furnaces incorporate advanced filtration systems to capture particulate matter and volatile compounds released during the heat treatment of superalloys. Additionally, the transition from fossil fuel-powered furnaces to electric alternatives, particularly when coupled with renewable energy sources, can substantially decrease greenhouse gas emissions associated with post-print processing.

Circular economy principles are increasingly being applied to heat treatment operations. Waste heat recovery systems can capture and repurpose thermal energy from cooling processes, while spent quenching fluids are being recycled through advanced filtration systems. Some facilities have implemented closed-loop systems that minimize resource consumption and waste generation throughout the heat treatment cycle.

Regulatory compliance and certification standards continue to evolve, pushing manufacturers to adopt more sustainable heat treatment practices. ISO 14001 environmental management systems and industry-specific sustainability metrics are becoming standard requirements for suppliers in aerospace and energy sectors, where superalloys with restored γ′ microstructures are commonly utilized.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!