Powder Quality And Feedstock Preparation For Superalloy PBF-LB

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superalloy PBF-LB Powder Technology Background and Objectives

Powder Bed Fusion-Laser Beam (PBF-LB) technology has evolved significantly since its inception in the late 1980s, transforming from a rapid prototyping method to a viable manufacturing process for high-performance components. The application of this technology to superalloys represents a critical advancement in additive manufacturing, particularly for aerospace, energy, and defense sectors where extreme operating conditions demand exceptional material properties.

Superalloys, characterized by their superior mechanical strength, resistance to thermal creep deformation, surface stability, and corrosion resistance at high temperatures, have traditionally been processed through casting and forging. The transition to additive manufacturing processes presents both opportunities and challenges, with powder quality and feedstock preparation emerging as decisive factors in achieving consistent part quality.

The historical development of superalloy powder metallurgy has seen significant milestones, from the introduction of vacuum induction melting in the 1950s to the development of gas atomization processes in the 1970s, and more recently, the adaptation of these powders for additive manufacturing applications. This evolution has been driven by increasing demands for higher performance materials in critical applications.

Current technological trends indicate a growing focus on tailored powder characteristics specifically optimized for PBF-LB processes. This includes advancements in powder production methods to achieve spherical morphology, controlled particle size distribution, minimal satellite formation, and reduced oxygen content – all critical parameters for successful superalloy printing.

The primary technical objective in this field is to establish robust correlations between powder characteristics and final part properties, enabling predictive capabilities for process optimization. This includes developing standardized methodologies for powder characterization, handling, and recycling that address the unique challenges posed by superalloys in PBF-LB processes.

Additional objectives include enhancing powder flowability and spreadability while maintaining chemical homogeneity, minimizing contamination risks during powder handling and recycling, and developing in-situ monitoring techniques for real-time quality assessment. These advancements aim to overcome current limitations in build consistency, material property variability, and process reliability.

The convergence of superalloy metallurgy with additive manufacturing represents a frontier technology with transformative potential for industries requiring high-performance components. As research progresses, the development of specialized superalloy powders designed specifically for PBF-LB processes is expected to enable new design possibilities and performance capabilities previously unattainable through conventional manufacturing methods.

Superalloys, characterized by their superior mechanical strength, resistance to thermal creep deformation, surface stability, and corrosion resistance at high temperatures, have traditionally been processed through casting and forging. The transition to additive manufacturing processes presents both opportunities and challenges, with powder quality and feedstock preparation emerging as decisive factors in achieving consistent part quality.

The historical development of superalloy powder metallurgy has seen significant milestones, from the introduction of vacuum induction melting in the 1950s to the development of gas atomization processes in the 1970s, and more recently, the adaptation of these powders for additive manufacturing applications. This evolution has been driven by increasing demands for higher performance materials in critical applications.

Current technological trends indicate a growing focus on tailored powder characteristics specifically optimized for PBF-LB processes. This includes advancements in powder production methods to achieve spherical morphology, controlled particle size distribution, minimal satellite formation, and reduced oxygen content – all critical parameters for successful superalloy printing.

The primary technical objective in this field is to establish robust correlations between powder characteristics and final part properties, enabling predictive capabilities for process optimization. This includes developing standardized methodologies for powder characterization, handling, and recycling that address the unique challenges posed by superalloys in PBF-LB processes.

Additional objectives include enhancing powder flowability and spreadability while maintaining chemical homogeneity, minimizing contamination risks during powder handling and recycling, and developing in-situ monitoring techniques for real-time quality assessment. These advancements aim to overcome current limitations in build consistency, material property variability, and process reliability.

The convergence of superalloy metallurgy with additive manufacturing represents a frontier technology with transformative potential for industries requiring high-performance components. As research progresses, the development of specialized superalloy powders designed specifically for PBF-LB processes is expected to enable new design possibilities and performance capabilities previously unattainable through conventional manufacturing methods.

Market Analysis for Superalloy Additive Manufacturing

The global market for superalloy additive manufacturing has experienced significant growth in recent years, driven by increasing demand from aerospace, power generation, and medical industries. The market value for superalloy additive manufacturing reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 14.5% through 2028, potentially reaching $4.7 billion by the end of the forecast period.

Aerospace remains the dominant application sector, accounting for nearly 60% of the superalloy additive manufacturing market. This dominance stems from the critical need for high-performance components capable of withstanding extreme temperatures and stress conditions in aircraft engines and gas turbines. The power generation sector follows as the second-largest market segment at 25%, with medical applications representing about 10% of the market share.

Regionally, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). The remaining 5% is distributed across other regions. The United States, Germany, and China are the primary countries driving innovation and adoption in this space, with significant investments in research and development infrastructure.

Key market drivers include the growing demand for fuel-efficient aircraft engines, the need for complex geometries in high-performance components, and increasing focus on reducing material waste in manufacturing processes. The ability of PBF-LB technology to produce near-net-shape components with minimal post-processing requirements presents a compelling value proposition for manufacturers seeking to optimize their production processes.

Market restraints include the high cost of superalloy powders, technical challenges in powder quality control, and the need for specialized expertise in powder handling and processing. The average cost of nickel-based superalloy powders ranges from $200-500 per kilogram, significantly higher than conventional manufacturing materials.

Customer segments in this market include OEMs in aerospace and defense, power generation equipment manufacturers, medical device companies, and specialized service bureaus offering additive manufacturing capabilities. These customers increasingly demand consistent powder quality, reliable supply chains, and comprehensive technical support for their additive manufacturing operations.

The market shows a clear trend toward vertical integration, with major superalloy producers expanding into powder production specifically optimized for additive manufacturing processes. This integration strategy aims to ensure quality control throughout the supply chain and develop proprietary powder formulations that deliver superior performance in PBF-LB applications.

Aerospace remains the dominant application sector, accounting for nearly 60% of the superalloy additive manufacturing market. This dominance stems from the critical need for high-performance components capable of withstanding extreme temperatures and stress conditions in aircraft engines and gas turbines. The power generation sector follows as the second-largest market segment at 25%, with medical applications representing about 10% of the market share.

Regionally, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). The remaining 5% is distributed across other regions. The United States, Germany, and China are the primary countries driving innovation and adoption in this space, with significant investments in research and development infrastructure.

Key market drivers include the growing demand for fuel-efficient aircraft engines, the need for complex geometries in high-performance components, and increasing focus on reducing material waste in manufacturing processes. The ability of PBF-LB technology to produce near-net-shape components with minimal post-processing requirements presents a compelling value proposition for manufacturers seeking to optimize their production processes.

Market restraints include the high cost of superalloy powders, technical challenges in powder quality control, and the need for specialized expertise in powder handling and processing. The average cost of nickel-based superalloy powders ranges from $200-500 per kilogram, significantly higher than conventional manufacturing materials.

Customer segments in this market include OEMs in aerospace and defense, power generation equipment manufacturers, medical device companies, and specialized service bureaus offering additive manufacturing capabilities. These customers increasingly demand consistent powder quality, reliable supply chains, and comprehensive technical support for their additive manufacturing operations.

The market shows a clear trend toward vertical integration, with major superalloy producers expanding into powder production specifically optimized for additive manufacturing processes. This integration strategy aims to ensure quality control throughout the supply chain and develop proprietary powder formulations that deliver superior performance in PBF-LB applications.

Current Challenges in Superalloy Powder Production

Despite significant advancements in powder metallurgy, the production of high-quality superalloy powders for Powder Bed Fusion-Laser Beam (PBF-LB) processes faces several critical challenges. The primary obstacle remains achieving consistent powder characteristics across production batches. Variations in particle size distribution, morphology, and chemical composition can significantly impact the final mechanical properties of printed components, leading to unpredictable performance in high-stress applications such as aerospace turbine blades or medical implants.

Gas atomization, the predominant method for superalloy powder production, struggles with controlling oxygen content during the atomization process. Even minimal oxygen contamination can lead to oxide inclusions in the final parts, compromising fatigue resistance and high-temperature performance. This issue is particularly pronounced with reactive elements commonly found in superalloys such as aluminum, titanium, and hafnium, which readily form stable oxides even at trace oxygen levels.

Powder recyclability presents another significant challenge. The high cost of superalloy raw materials necessitates efficient powder recycling strategies, yet repeated exposure to the build environment causes progressive degradation through oxidation, moisture absorption, and contamination. Current methods for assessing powder degradation lack standardization, making quality control decisions subjective and inconsistent across the industry.

The sphericity and flowability of superalloy powders remain problematic for PBF-LB applications. Irregular particle shapes or satellite formations impede powder spreading during the build process, creating layer inconsistencies that manifest as porosity or lack-of-fusion defects in the final components. While plasma atomization produces highly spherical particles, its limited production capacity and higher cost restrict widespread adoption for superalloy powder production.

Chemical homogeneity within individual powder particles represents a sophisticated challenge, particularly for complex superalloy compositions containing numerous alloying elements. Rapid solidification during atomization can lead to elemental segregation and the formation of undesirable phases, which persist through the printing process and compromise the microstructural integrity of the final parts.

Storage and handling protocols for superalloy powders lack standardization across the industry. These materials are highly susceptible to environmental degradation through moisture absorption and oxidation, yet consensus on optimal storage conditions, shelf-life limitations, and handling procedures remains elusive. This uncertainty introduces additional variability into the manufacturing process, further complicating quality control efforts.

Gas atomization, the predominant method for superalloy powder production, struggles with controlling oxygen content during the atomization process. Even minimal oxygen contamination can lead to oxide inclusions in the final parts, compromising fatigue resistance and high-temperature performance. This issue is particularly pronounced with reactive elements commonly found in superalloys such as aluminum, titanium, and hafnium, which readily form stable oxides even at trace oxygen levels.

Powder recyclability presents another significant challenge. The high cost of superalloy raw materials necessitates efficient powder recycling strategies, yet repeated exposure to the build environment causes progressive degradation through oxidation, moisture absorption, and contamination. Current methods for assessing powder degradation lack standardization, making quality control decisions subjective and inconsistent across the industry.

The sphericity and flowability of superalloy powders remain problematic for PBF-LB applications. Irregular particle shapes or satellite formations impede powder spreading during the build process, creating layer inconsistencies that manifest as porosity or lack-of-fusion defects in the final components. While plasma atomization produces highly spherical particles, its limited production capacity and higher cost restrict widespread adoption for superalloy powder production.

Chemical homogeneity within individual powder particles represents a sophisticated challenge, particularly for complex superalloy compositions containing numerous alloying elements. Rapid solidification during atomization can lead to elemental segregation and the formation of undesirable phases, which persist through the printing process and compromise the microstructural integrity of the final parts.

Storage and handling protocols for superalloy powders lack standardization across the industry. These materials are highly susceptible to environmental degradation through moisture absorption and oxidation, yet consensus on optimal storage conditions, shelf-life limitations, and handling procedures remains elusive. This uncertainty introduces additional variability into the manufacturing process, further complicating quality control efforts.

Established Feedstock Preparation Methodologies

01 Particle size control and distribution

Controlling the particle size and distribution of superalloy powders is critical for ensuring consistent quality. Specific techniques involve sieving, classification, and advanced particle sizing methods to achieve uniform size distributions. Optimal particle size ranges are typically determined based on the intended application, with finer powders often used for applications requiring enhanced mechanical properties and surface finish.- Particle size control and distribution in superalloy powders: Controlling the particle size and distribution is crucial for superalloy powder quality. Specific size ranges are targeted to ensure optimal flow properties, packing density, and final mechanical properties. Advanced classification techniques are employed to achieve narrow particle size distributions, which contribute to uniform melting behavior during processing and consistent properties in the final components.

- Chemical composition and purity requirements: The chemical composition and purity of superalloy powders significantly impact their performance. Strict control of alloying elements within specified ranges ensures the desired mechanical and thermal properties. Minimizing impurities such as oxygen, nitrogen, and carbon is essential to prevent defects in the final components. Advanced purification methods are employed to reduce inclusions and contaminants that could compromise the integrity of manufactured parts.

- Powder morphology and surface characteristics: The morphology and surface characteristics of superalloy powder particles affect their processability and final product quality. Spherical particles with smooth surfaces are preferred for better flowability and higher packing density. Surface oxidation must be minimized to prevent oxygen contamination during subsequent processing. Specialized atomization techniques are developed to achieve optimal particle shapes that enhance powder handling and processing efficiency.

- Production methods and atomization techniques: Various production methods and atomization techniques influence superalloy powder quality. Gas atomization, plasma rotating electrode process (PREP), and vacuum induction melting gas atomization (VIM-GA) are common methods used to produce high-quality superalloy powders. Each technique offers specific advantages in terms of particle morphology, size distribution, and purity levels. Process parameters during atomization must be carefully controlled to achieve consistent powder characteristics.

- Testing and quality assurance methods: Comprehensive testing and quality assurance methods are essential for evaluating superalloy powder quality. Techniques include particle size analysis, chemical composition verification, flowability testing, and microstructural examination. Advanced analytical methods such as scanning electron microscopy, X-ray diffraction, and gas analysis are employed to detect defects and ensure compliance with specifications. Standardized testing protocols help maintain consistency across production batches and ensure reliability in critical applications.

02 Chemical composition and purity

The chemical composition and purity of superalloy powders significantly impact their performance. Strict control of elemental composition, including precise amounts of nickel, cobalt, chromium, and other alloying elements, is essential. Minimizing impurities such as oxygen, nitrogen, and carbon is crucial for maintaining powder quality. Advanced analytical techniques are employed to verify composition and detect contaminants that could compromise the final product properties.Expand Specific Solutions03 Powder production methods

Various production methods influence superalloy powder quality, including gas atomization, plasma rotating electrode process (PREP), and mechanical alloying. Each method offers distinct advantages in terms of particle morphology, internal structure, and purity levels. Gas atomization typically produces spherical particles with good flowability, while PREP yields highly spherical powders with minimal satellite formation and excellent cleanliness.Expand Specific Solutions04 Powder morphology and flowability

The morphology of superalloy powder particles, particularly their sphericity and surface characteristics, directly affects flowability and packing density. Spherical particles with smooth surfaces typically exhibit superior flow properties, which are essential for consistent powder bed formation in additive manufacturing processes. Various techniques are employed to measure and enhance flowability, including Hall flowmeter testing and surface treatment methods.Expand Specific Solutions05 Heat treatment and processing of powders

Post-production processing techniques, including heat treatment, can significantly improve superalloy powder quality. These processes help homogenize the microstructure, relieve internal stresses, and optimize the powder for specific applications. Controlled atmosphere processing prevents oxidation and contamination during heat treatment. Some advanced techniques involve surface modification or coating of powder particles to enhance specific properties or compatibility with subsequent manufacturing processes.Expand Specific Solutions

Leading Manufacturers in Superalloy Powder Industry

The Powder Quality and Feedstock Preparation for Superalloy PBF-LB market is currently in a growth phase, with increasing adoption across aerospace, energy, and automotive sectors. The global market size is estimated at $350-450 million, expanding at 15-20% annually as additive manufacturing gains industrial acceptance. Technologically, the field is in mid-maturity, with established processes but ongoing innovation. Key players demonstrate varying levels of expertise: GE, Rolls-Royce, and Siemens Energy lead with advanced proprietary technologies; research institutions like Central South University and Northwestern Polytechnical University contribute fundamental research; while specialized powder manufacturers such as Xiamen Tungsten and Oerlikon Metco provide critical material solutions. The ecosystem shows a collaborative dynamic between OEMs, academic institutions, and specialized material suppliers driving continuous improvement.

Central Iron & Steel Research Institute

Technical Solution: Central Iron & Steel Research Institute has developed a comprehensive superalloy powder preparation system for PBF-LB applications focusing on cost-effective production methods. Their technology employs modified gas atomization processes with controlled atomization pressure and temperature profiles to achieve optimal particle size distribution and morphology. The institute has pioneered specialized heat treatment protocols for powder stress relief and surface oxide reduction prior to PBF-LB processing. Their approach includes advanced classification techniques using cyclonic separation combined with precision sieving to achieve tight particle size control. CISRI has implemented a systematic powder characterization methodology examining flowability under varying environmental conditions, apparent density variations, and chemical homogeneity across particle size fractions. Their system incorporates specialized powder handling equipment with inert gas protection throughout the preparation process to prevent contamination and oxidation of reactive elements in superalloy compositions.

Strengths: Cost-effective production methods make advanced superalloy powders more accessible; strong fundamental research approach to powder metallurgy principles. Weaknesses: Less automated than some Western competitors; limited experience with certain specialized superalloy compositions used in aerospace applications.

General Electric Company

Technical Solution: General Electric has developed a comprehensive approach to superalloy powder quality control for PBF-LB (Powder Bed Fusion-Laser Beam) processes. Their technology involves advanced powder characterization techniques including laser diffraction, scanning electron microscopy, and X-ray computed tomography to ensure precise particle size distribution, morphology, and internal porosity detection. GE's proprietary feedstock preparation includes vacuum induction gas atomization (VIGA) processes that produce highly spherical powders with minimal satellite formation and controlled oxygen content below 100 ppm for nickel-based superalloys. Their system incorporates real-time monitoring during atomization to adjust parameters for optimal powder characteristics. Additionally, GE has implemented automated sieving and classification systems with inert atmosphere handling to prevent contamination, alongside comprehensive powder recycling protocols that maintain consistent powder properties through multiple build cycles.

Strengths: Vertical integration from powder production to final part manufacturing provides complete quality control; proprietary atomization technology yields superior powder morphology and chemistry consistency. Weaknesses: Higher cost structure compared to competitors; system requires significant capital investment and specialized expertise to operate effectively.

Critical Patents in Superalloy Powder Processing

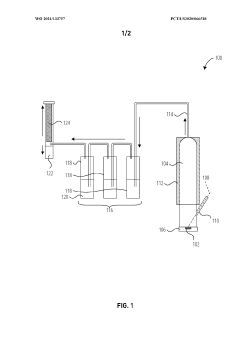

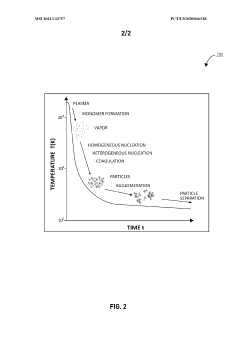

Laser ablation methods and systems for producing feedstock powder suitable for laser-based additive manufacturing

PatentWO2021133757A1

Innovation

- The use of controlled-cooling laser ablation techniques to vaporize source materials in a temperature-controlled vaporization chamber, creating microparticles with uniform composition, shape, and phase, suitable for laser-based additive manufacturing, utilizing relatively inexpensive bulk solid or coarse powder source materials.

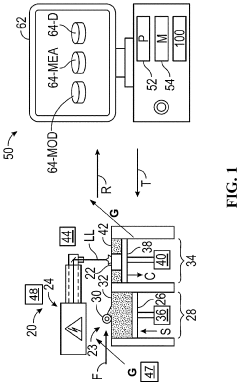

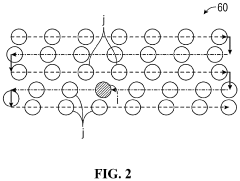

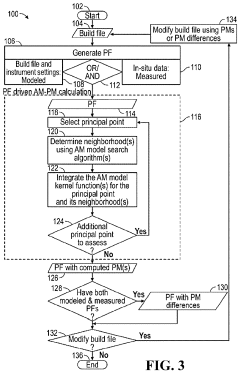

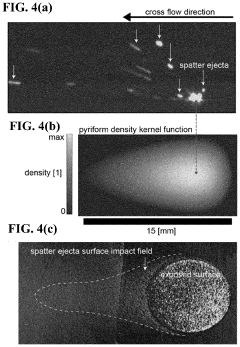

Method and pyriform process metric to predict and mitigate spatter- induced defects in powder bed fusion-laser beam metals additive manufacturing

PatentPendingUS20230373008A1

Innovation

- A method involving a hatch progression angle and pyriform density function process metric is used to control spatter-induced porosity by computing a spatter exposure metric, which involves selecting principal points, determining neighborhoods, and integrating a pyriform kernel function to update the build file and design a build strategy that mitigates spatter, ensuring the hatch progression angle is aligned with the crossflow direction.

Sustainability in Superalloy Powder Production

Sustainability in superalloy powder production has become increasingly critical as the aerospace, energy, and automotive industries expand their adoption of powder bed fusion laser beam (PBF-LB) additive manufacturing technologies. The environmental footprint of superalloy powder production presents significant challenges, with energy consumption during atomization processes reaching up to 10-15 kWh per kilogram of powder produced. This intensive energy requirement contributes substantially to the carbon footprint of the entire manufacturing chain.

Traditional gas and plasma atomization methods, while effective for producing high-quality spherical powders, utilize substantial amounts of inert gases such as argon and nitrogen. These processes not only consume considerable energy but also generate waste heat and unused powder fractions. Recent industry analyses indicate that up to 30% of atomized powder may fall outside the desired particle size distribution for PBF-LB applications, creating significant material inefficiency.

Water atomization offers a more energy-efficient alternative, consuming approximately 40% less energy than gas atomization. However, the irregular particle morphology produced often requires additional processing steps to achieve suitability for PBF-LB applications. This trade-off between energy efficiency and powder quality represents a central sustainability challenge in the industry.

Recycling and reuse strategies have emerged as essential components of sustainable superalloy powder production. Advanced sieving and classification systems now enable manufacturers to reclaim up to 95% of out-of-specification powder for reprocessing. Closed-loop recycling systems that capture and reuse inert gases during atomization have demonstrated potential to reduce gas consumption by 60-70% compared to conventional open systems.

Emerging technologies such as electrode induction gas atomization (EIGA) and plasma rotating electrode process (PREP) show promise for reducing energy consumption while maintaining high powder quality. These methods can decrease energy requirements by 20-25% compared to conventional gas atomization while producing powders with excellent flowability and minimal satellite formation.

Life cycle assessment (LCA) studies of superalloy powder production reveal that raw material extraction accounts for approximately 40-50% of the total environmental impact, with manufacturing processes contributing another 30-40%. This underscores the importance of developing sustainable sourcing strategies for critical elements such as nickel, cobalt, and chromium, particularly as global demand for these materials continues to rise with the expansion of additive manufacturing applications.

Traditional gas and plasma atomization methods, while effective for producing high-quality spherical powders, utilize substantial amounts of inert gases such as argon and nitrogen. These processes not only consume considerable energy but also generate waste heat and unused powder fractions. Recent industry analyses indicate that up to 30% of atomized powder may fall outside the desired particle size distribution for PBF-LB applications, creating significant material inefficiency.

Water atomization offers a more energy-efficient alternative, consuming approximately 40% less energy than gas atomization. However, the irregular particle morphology produced often requires additional processing steps to achieve suitability for PBF-LB applications. This trade-off between energy efficiency and powder quality represents a central sustainability challenge in the industry.

Recycling and reuse strategies have emerged as essential components of sustainable superalloy powder production. Advanced sieving and classification systems now enable manufacturers to reclaim up to 95% of out-of-specification powder for reprocessing. Closed-loop recycling systems that capture and reuse inert gases during atomization have demonstrated potential to reduce gas consumption by 60-70% compared to conventional open systems.

Emerging technologies such as electrode induction gas atomization (EIGA) and plasma rotating electrode process (PREP) show promise for reducing energy consumption while maintaining high powder quality. These methods can decrease energy requirements by 20-25% compared to conventional gas atomization while producing powders with excellent flowability and minimal satellite formation.

Life cycle assessment (LCA) studies of superalloy powder production reveal that raw material extraction accounts for approximately 40-50% of the total environmental impact, with manufacturing processes contributing another 30-40%. This underscores the importance of developing sustainable sourcing strategies for critical elements such as nickel, cobalt, and chromium, particularly as global demand for these materials continues to rise with the expansion of additive manufacturing applications.

Quality Standards and Certification Requirements

The quality standards and certification requirements for superalloy powders used in Powder Bed Fusion-Laser Beam (PBF-LB) processes are critical to ensuring consistent part performance and reliability. International standards organizations have established comprehensive frameworks that govern the production, testing, and certification of these specialized materials. Key standards include ASTM F3049, which provides guidelines for characterizing metal powders used in additive manufacturing processes, and ISO/ASTM 52907, which outlines technical specifications for metal powder feedstock.

For superalloy powders specifically, manufacturers must adhere to stringent chemical composition requirements as defined in standards such as AMS 7000 for nickel-based superalloys and AMS 4998 for cobalt-based superalloys. These standards specify acceptable ranges for critical elements that influence the mechanical properties and microstructural stability of the final components. Powder certification typically requires detailed documentation of chemical analysis performed using techniques such as inductively coupled plasma (ICP) spectroscopy or X-ray fluorescence (XRF).

Physical characteristics of superalloy powders are equally regulated, with standards focusing on particle size distribution (ASTM B822), flowability (ASTM B213), and apparent density (ASTM B212). For aerospace applications, additional requirements are imposed through standards like AMS 7002, which addresses process controls for metal powder production specifically for additive manufacturing. The aerospace industry often requires suppliers to maintain AS9100 certification, which extends ISO 9001 quality management systems with specific requirements for aviation, space, and defense organizations.

Traceability requirements represent another critical aspect of powder certification. Standards such as ASTM F3303 provide guidelines for documentation of powder lot history, including raw material sources, processing parameters, and testing results. This traceability chain must be maintained throughout the powder lifecycle, from production through storage, handling, and eventual use in the PBF-LB process.

Emerging certification requirements are increasingly focusing on powder recyclability and consistency across multiple reuse cycles. Standards like ASTM F3456 address the evaluation of powder degradation during processing, establishing protocols for assessing changes in oxygen content, flowability, and particle morphology after exposure to the build environment. These standards are particularly relevant for superalloys, which can be susceptible to oxidation and compositional shifts during repeated thermal cycling.

Industry-specific certification requirements add another layer of complexity, with medical device manufacturers following FDA guidance documents and aerospace companies adhering to proprietary specifications from entities like Pratt & Whitney, GE Aviation, and Rolls-Royce. These specifications often exceed the requirements of international standards, imposing additional testing protocols and tighter tolerance bands for critical powder characteristics.

For superalloy powders specifically, manufacturers must adhere to stringent chemical composition requirements as defined in standards such as AMS 7000 for nickel-based superalloys and AMS 4998 for cobalt-based superalloys. These standards specify acceptable ranges for critical elements that influence the mechanical properties and microstructural stability of the final components. Powder certification typically requires detailed documentation of chemical analysis performed using techniques such as inductively coupled plasma (ICP) spectroscopy or X-ray fluorescence (XRF).

Physical characteristics of superalloy powders are equally regulated, with standards focusing on particle size distribution (ASTM B822), flowability (ASTM B213), and apparent density (ASTM B212). For aerospace applications, additional requirements are imposed through standards like AMS 7002, which addresses process controls for metal powder production specifically for additive manufacturing. The aerospace industry often requires suppliers to maintain AS9100 certification, which extends ISO 9001 quality management systems with specific requirements for aviation, space, and defense organizations.

Traceability requirements represent another critical aspect of powder certification. Standards such as ASTM F3303 provide guidelines for documentation of powder lot history, including raw material sources, processing parameters, and testing results. This traceability chain must be maintained throughout the powder lifecycle, from production through storage, handling, and eventual use in the PBF-LB process.

Emerging certification requirements are increasingly focusing on powder recyclability and consistency across multiple reuse cycles. Standards like ASTM F3456 address the evaluation of powder degradation during processing, establishing protocols for assessing changes in oxygen content, flowability, and particle morphology after exposure to the build environment. These standards are particularly relevant for superalloys, which can be susceptible to oxidation and compositional shifts during repeated thermal cycling.

Industry-specific certification requirements add another layer of complexity, with medical device manufacturers following FDA guidance documents and aerospace companies adhering to proprietary specifications from entities like Pratt & Whitney, GE Aviation, and Rolls-Royce. These specifications often exceed the requirements of international standards, imposing additional testing protocols and tighter tolerance bands for critical powder characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!