Advanced AI Models For Process Parameter Optimization In PBF-LB

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-Driven PBF-LB Process Optimization Background

Powder Bed Fusion-Laser Beam (PBF-LB) technology has emerged as a cornerstone of modern additive manufacturing, enabling the production of complex metal components with unprecedented design freedom. This advanced manufacturing process involves selectively melting metal powder layers using high-powered lasers to build three-dimensional objects. Despite its transformative potential, PBF-LB processes remain challenging to optimize due to the complex interplay of numerous process parameters including laser power, scanning speed, hatch spacing, layer thickness, and powder characteristics.

Traditional approaches to process parameter optimization have relied heavily on empirical methods and design of experiments (DOE), which are time-consuming, resource-intensive, and often yield suboptimal results. These conventional methods struggle to capture the non-linear relationships and interdependencies among process parameters, leading to inconsistent part quality, mechanical properties, and surface finish.

The integration of artificial intelligence into PBF-LB process optimization represents a paradigm shift in additive manufacturing. AI models offer the capability to analyze vast amounts of process data, identify complex patterns, and predict optimal parameter combinations that would be difficult or impossible to determine through traditional methods. Machine learning algorithms, particularly deep learning networks, have demonstrated remarkable success in modeling the intricate relationships between process parameters and part quality metrics.

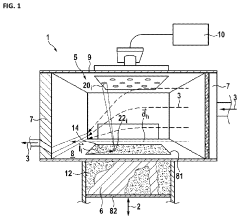

Recent advancements in computational power and data acquisition systems have accelerated the adoption of AI-driven approaches in PBF-LB manufacturing. In-situ monitoring technologies, including high-speed cameras, thermal sensors, and acoustic detectors, now generate rich datasets that capture the dynamic nature of the melting process. These data streams provide the foundation for developing sophisticated AI models that can predict and control process outcomes with unprecedented accuracy.

The evolution of AI applications in PBF-LB has progressed from simple regression models to complex neural networks capable of real-time process control. Early implementations focused primarily on post-process quality prediction, while current research emphasizes closed-loop control systems that can make dynamic adjustments during fabrication. This transition from reactive to proactive process optimization represents a critical advancement in achieving consistent, high-quality metal additive manufacturing.

The convergence of AI and PBF-LB technologies addresses several persistent challenges in metal additive manufacturing, including porosity formation, residual stress development, and microstructural heterogeneity. By leveraging advanced AI models, manufacturers can significantly reduce the trial-and-error approach traditionally associated with process parameter optimization, thereby accelerating product development cycles and reducing material waste.

Traditional approaches to process parameter optimization have relied heavily on empirical methods and design of experiments (DOE), which are time-consuming, resource-intensive, and often yield suboptimal results. These conventional methods struggle to capture the non-linear relationships and interdependencies among process parameters, leading to inconsistent part quality, mechanical properties, and surface finish.

The integration of artificial intelligence into PBF-LB process optimization represents a paradigm shift in additive manufacturing. AI models offer the capability to analyze vast amounts of process data, identify complex patterns, and predict optimal parameter combinations that would be difficult or impossible to determine through traditional methods. Machine learning algorithms, particularly deep learning networks, have demonstrated remarkable success in modeling the intricate relationships between process parameters and part quality metrics.

Recent advancements in computational power and data acquisition systems have accelerated the adoption of AI-driven approaches in PBF-LB manufacturing. In-situ monitoring technologies, including high-speed cameras, thermal sensors, and acoustic detectors, now generate rich datasets that capture the dynamic nature of the melting process. These data streams provide the foundation for developing sophisticated AI models that can predict and control process outcomes with unprecedented accuracy.

The evolution of AI applications in PBF-LB has progressed from simple regression models to complex neural networks capable of real-time process control. Early implementations focused primarily on post-process quality prediction, while current research emphasizes closed-loop control systems that can make dynamic adjustments during fabrication. This transition from reactive to proactive process optimization represents a critical advancement in achieving consistent, high-quality metal additive manufacturing.

The convergence of AI and PBF-LB technologies addresses several persistent challenges in metal additive manufacturing, including porosity formation, residual stress development, and microstructural heterogeneity. By leveraging advanced AI models, manufacturers can significantly reduce the trial-and-error approach traditionally associated with process parameter optimization, thereby accelerating product development cycles and reducing material waste.

Market Analysis for AI in Additive Manufacturing

The global market for AI in additive manufacturing is experiencing robust growth, with a current valuation estimated at $400 million and projected to reach $2.1 billion by 2028, representing a CAGR of approximately 39%. This remarkable expansion is primarily driven by the increasing adoption of Powder Bed Fusion-Laser Beam (PBF-LB) technologies across various industrial sectors, particularly aerospace, automotive, healthcare, and industrial manufacturing.

The demand for AI-driven process parameter optimization in PBF-LB is particularly strong in regions with advanced manufacturing capabilities. North America currently holds the largest market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%. Within these regions, countries like the United States, Germany, and China are making substantial investments in research and development initiatives focused on integrating AI with additive manufacturing technologies.

Key market drivers include the growing need for quality assurance in critical components manufacturing, increasing pressure to reduce material waste and energy consumption, and the push for faster time-to-market in product development cycles. The implementation of AI models for process parameter optimization in PBF-LB has demonstrated potential cost savings of 15-20% through reduced material waste and 25-30% through improved production efficiency.

Market segmentation reveals distinct customer groups with varying needs. Large aerospace and defense manufacturers primarily seek AI solutions that ensure consistent part quality and material properties. Automotive manufacturers focus on solutions that optimize production speed while maintaining acceptable quality thresholds. Medical device manufacturers prioritize AI systems that can ensure biocompatibility and precise dimensional accuracy.

The competitive landscape is characterized by three main categories of players: established industrial automation companies expanding into AI-enhanced additive manufacturing (Siemens, GE Additive), specialized additive manufacturing firms developing proprietary AI capabilities (EOS, SLM Solutions), and AI technology startups focusing specifically on manufacturing optimization (Oqton, Additive Monitoring Systems).

Market challenges include the high initial investment required for implementing advanced AI systems, concerns regarding data security and intellectual property protection when utilizing cloud-based AI solutions, and the current shortage of skilled professionals who understand both additive manufacturing processes and machine learning techniques.

The demand for AI-driven process parameter optimization in PBF-LB is particularly strong in regions with advanced manufacturing capabilities. North America currently holds the largest market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%. Within these regions, countries like the United States, Germany, and China are making substantial investments in research and development initiatives focused on integrating AI with additive manufacturing technologies.

Key market drivers include the growing need for quality assurance in critical components manufacturing, increasing pressure to reduce material waste and energy consumption, and the push for faster time-to-market in product development cycles. The implementation of AI models for process parameter optimization in PBF-LB has demonstrated potential cost savings of 15-20% through reduced material waste and 25-30% through improved production efficiency.

Market segmentation reveals distinct customer groups with varying needs. Large aerospace and defense manufacturers primarily seek AI solutions that ensure consistent part quality and material properties. Automotive manufacturers focus on solutions that optimize production speed while maintaining acceptable quality thresholds. Medical device manufacturers prioritize AI systems that can ensure biocompatibility and precise dimensional accuracy.

The competitive landscape is characterized by three main categories of players: established industrial automation companies expanding into AI-enhanced additive manufacturing (Siemens, GE Additive), specialized additive manufacturing firms developing proprietary AI capabilities (EOS, SLM Solutions), and AI technology startups focusing specifically on manufacturing optimization (Oqton, Additive Monitoring Systems).

Market challenges include the high initial investment required for implementing advanced AI systems, concerns regarding data security and intellectual property protection when utilizing cloud-based AI solutions, and the current shortage of skilled professionals who understand both additive manufacturing processes and machine learning techniques.

Current AI Models in PBF-LB Parameter Optimization

The current landscape of AI models in Powder Bed Fusion-Laser Beam (PBF-LB) parameter optimization reveals a diverse ecosystem of computational approaches addressing the complex relationships between process parameters and part quality. Machine learning techniques have emerged as dominant tools, with supervised learning algorithms such as Support Vector Machines (SVM), Random Forests, and Artificial Neural Networks (ANNs) being widely implemented for predictive modeling of mechanical properties and defect formation.

Deep learning architectures have gained significant traction, particularly Convolutional Neural Networks (CNNs) which excel at extracting spatial features from in-situ monitoring data such as melt pool images and layer-wise photographs. These models have demonstrated remarkable accuracy in correlating visual patterns with subsurface defects and mechanical property variations, enabling real-time quality assessment during builds.

Reinforcement Learning (RL) frameworks represent a more recent development, where algorithms learn optimal parameter settings through iterative interaction with simulation environments or physical machines. Q-learning and Deep Q-Networks have shown promise in navigating the vast parameter space of laser power, scan speed, hatch spacing, and layer thickness to maximize density while minimizing defects.

Bayesian Optimization approaches have proven particularly valuable for PBF-LB parameter tuning, as they efficiently handle the expensive nature of experimental validation. These models construct probabilistic surrogate functions of the parameter-property relationship, strategically suggesting new parameter combinations that balance exploration of unknown regions with exploitation of promising areas.

Physics-informed neural networks (PINNs) represent a hybrid approach gaining momentum, incorporating fundamental physical equations of heat transfer and material phase transformations into neural network architectures. This integration of domain knowledge with data-driven learning has improved model generalizability across different materials and machine configurations.

Transfer learning techniques address the data scarcity challenge in PBF-LB by leveraging knowledge from related materials or processes to accelerate model training for new applications. Models pre-trained on extensive datasets for common materials like Ti-6Al-4V can be fine-tuned with limited data for novel alloys, significantly reducing the experimental burden.

Ensemble methods combining multiple AI models have demonstrated superior robustness in parameter optimization, mitigating the risk of overfitting to limited training data. These approaches typically integrate predictions from diverse algorithm families to provide more reliable parameter recommendations and uncertainty quantification.

Despite these advances, current AI models still face challenges in capturing the full complexity of PBF-LB processes, particularly the multi-scale phenomena spanning from powder particle interactions to macroscopic part properties. Most models operate as "black boxes" with limited interpretability, complicating their adoption in highly regulated industries like aerospace and medical device manufacturing.

Deep learning architectures have gained significant traction, particularly Convolutional Neural Networks (CNNs) which excel at extracting spatial features from in-situ monitoring data such as melt pool images and layer-wise photographs. These models have demonstrated remarkable accuracy in correlating visual patterns with subsurface defects and mechanical property variations, enabling real-time quality assessment during builds.

Reinforcement Learning (RL) frameworks represent a more recent development, where algorithms learn optimal parameter settings through iterative interaction with simulation environments or physical machines. Q-learning and Deep Q-Networks have shown promise in navigating the vast parameter space of laser power, scan speed, hatch spacing, and layer thickness to maximize density while minimizing defects.

Bayesian Optimization approaches have proven particularly valuable for PBF-LB parameter tuning, as they efficiently handle the expensive nature of experimental validation. These models construct probabilistic surrogate functions of the parameter-property relationship, strategically suggesting new parameter combinations that balance exploration of unknown regions with exploitation of promising areas.

Physics-informed neural networks (PINNs) represent a hybrid approach gaining momentum, incorporating fundamental physical equations of heat transfer and material phase transformations into neural network architectures. This integration of domain knowledge with data-driven learning has improved model generalizability across different materials and machine configurations.

Transfer learning techniques address the data scarcity challenge in PBF-LB by leveraging knowledge from related materials or processes to accelerate model training for new applications. Models pre-trained on extensive datasets for common materials like Ti-6Al-4V can be fine-tuned with limited data for novel alloys, significantly reducing the experimental burden.

Ensemble methods combining multiple AI models have demonstrated superior robustness in parameter optimization, mitigating the risk of overfitting to limited training data. These approaches typically integrate predictions from diverse algorithm families to provide more reliable parameter recommendations and uncertainty quantification.

Despite these advances, current AI models still face challenges in capturing the full complexity of PBF-LB processes, particularly the multi-scale phenomena spanning from powder particle interactions to macroscopic part properties. Most models operate as "black boxes" with limited interpretability, complicating their adoption in highly regulated industries like aerospace and medical device manufacturing.

Existing AI Solutions for PBF-LB Process Control

01 AI-based optimization of manufacturing process parameters

Artificial intelligence models can be used to optimize manufacturing process parameters by analyzing historical data and predicting optimal settings. These systems can continuously learn from production data to improve process efficiency, reduce defects, and enhance product quality. The AI models can adjust parameters in real-time based on changing conditions and provide recommendations for optimal operating conditions.- AI-driven parameter optimization for manufacturing processes: Artificial intelligence models can be used to optimize process parameters in manufacturing environments. These systems analyze historical data and real-time inputs to determine optimal settings for various industrial processes, resulting in improved product quality, reduced waste, and increased efficiency. The AI models can continuously learn and adapt to changing conditions, providing dynamic parameter adjustments that outperform traditional static optimization methods.

- Machine learning frameworks for predictive process control: Advanced machine learning frameworks enable predictive process control by analyzing patterns in process data to anticipate parameter drift and quality issues before they occur. These systems incorporate various algorithms including neural networks, random forests, and gradient boosting to model complex relationships between process parameters and output quality. The predictive capabilities allow for proactive adjustments to maintain optimal performance and prevent defects in production environments.

- Deep learning techniques for multi-variable parameter optimization: Deep learning architectures are particularly effective for optimizing processes with multiple interdependent variables. These systems can identify non-linear relationships and complex interactions between parameters that traditional optimization methods might miss. By simultaneously considering numerous variables and their combined effects on process outcomes, deep learning models can discover optimal parameter combinations that significantly improve process efficiency and product quality across various industrial applications.

- Reinforcement learning for adaptive process optimization: Reinforcement learning algorithms enable adaptive process optimization by treating parameter adjustment as a sequential decision-making problem. These systems learn optimal control policies through trial-and-error interactions with the process environment, continuously improving their parameter selection strategies based on feedback about process outcomes. This approach is particularly valuable for dynamic processes where conditions change frequently and traditional optimization methods struggle to maintain optimal performance.

- Hybrid AI systems for real-time parameter tuning: Hybrid artificial intelligence systems combine multiple AI techniques to enable real-time parameter tuning across industrial processes. These systems integrate machine learning models with expert systems, fuzzy logic controllers, and evolutionary algorithms to create robust optimization frameworks that can handle uncertainty, process variability, and changing production requirements. The hybrid approach leverages the strengths of different AI methodologies to achieve superior parameter optimization results compared to single-algorithm solutions.

02 Machine learning techniques for parameter prediction and control

Machine learning algorithms can be employed to predict and control process parameters across various industrial applications. These techniques include neural networks, decision trees, and reinforcement learning that analyze complex relationships between input variables and desired outcomes. The models can identify patterns in large datasets that would be impossible for humans to detect, enabling more precise parameter tuning and process control.Expand Specific Solutions03 Real-time adaptive optimization systems

Real-time adaptive systems utilize AI models to continuously monitor and adjust process parameters based on feedback loops. These systems can respond to changing conditions without human intervention, making immediate adjustments to maintain optimal performance. The adaptive nature allows for handling unexpected variations in raw materials, environmental conditions, or equipment performance while maintaining product quality and process efficiency.Expand Specific Solutions04 Integration of AI with simulation and digital twins

AI models can be integrated with simulation tools and digital twins to create comprehensive parameter optimization frameworks. These integrated systems allow for virtual testing of parameter adjustments before implementation in physical processes, reducing risk and development time. The combination of AI predictive capabilities with detailed process simulations enables more accurate optimization across multiple parameters simultaneously.Expand Specific Solutions05 Multi-objective optimization for complex industrial processes

AI-based multi-objective optimization techniques can balance competing goals in complex industrial processes. These approaches consider multiple performance indicators simultaneously, such as energy efficiency, product quality, throughput, and environmental impact. The AI models can identify Pareto-optimal solutions that represent the best possible trade-offs between different objectives, allowing process engineers to make informed decisions based on specific business priorities.Expand Specific Solutions

Leading Companies in AI-Powered Additive Manufacturing

The market for Advanced AI Models for Process Parameter Optimization in PBF-LB (Powder Bed Fusion-Laser Beam) is in a growth phase, with increasing adoption across manufacturing sectors. The global market size is expanding rapidly as industries seek to enhance efficiency and quality in additive manufacturing processes. From a technological maturity perspective, academic institutions like Huazhong University of Science & Technology, University of Waterloo, and Johns Hopkins University are driving fundamental research, while industrial players including Siemens, TRUMPF, Mitsubishi Electric, and GlobalFoundries are commercializing solutions. Companies like Robert Bosch and Bystronic Laser are integrating these AI optimization models into their manufacturing systems, creating a competitive landscape where collaboration between academic research and industrial application is essential for market leadership.

DMG MORI Digital GmbH

Technical Solution: DMG MORI Digital has developed a comprehensive AI-powered parameter optimization platform for PBF-LB processes that leverages both supervised and unsupervised learning techniques. Their system employs a hierarchical neural network architecture that first classifies material types and part geometries, then recommends initial parameter sets based on similarity to previously successful builds. The platform incorporates a Gaussian Process-based Bayesian optimization framework that efficiently explores the parameter space while minimizing the number of experimental builds required. DMG MORI's solution features an advanced computer vision system that analyzes layer-by-layer images to detect process anomalies and correlate them with specific parameter combinations. Their AI models incorporate material science principles through physics-informed constraints, ensuring that parameter recommendations remain within metallurgically sound boundaries. The system also includes a unique feature that accounts for machine-specific variations, allowing for parameter transfer between different PBF-LB systems with appropriate calibration factors applied automatically.

Strengths: Sophisticated Bayesian optimization approach that minimizes experimental iterations; strong integration with material science principles; effective handling of machine-to-machine variations. Weaknesses: Requires extensive initial data collection for new materials; complex implementation that may present challenges for smaller manufacturing operations.

TRUMPF Werkzeugmaschinen GmbH + Co. KG

Technical Solution: TRUMPF has pioneered an AI-driven parameter optimization system for PBF-LB that focuses on in-process quality assurance and real-time parameter adjustment. Their technology employs convolutional neural networks to analyze high-resolution melt pool imaging data, detecting anomalies and predicting potential defects before they manifest in the final part. TRUMPF's system incorporates a multi-sensor fusion approach that combines thermal imaging, optical emissions data, and acoustic monitoring to create comprehensive process signatures. These signatures are then analyzed by deep learning algorithms to establish correlations between process parameters and part quality. The company has developed a proprietary reinforcement learning framework that continuously optimizes laser parameters (power, speed, focus, scan strategy) based on feedback from both in-process monitoring and post-build quality assessment. Their solution includes a physics-based simulation module that works in tandem with the AI system to validate parameter recommendations before implementation, reducing the risk of failed builds while exploring new parameter spaces.

Strengths: Exceptional real-time monitoring capabilities with multi-sensor integration; strong focus on practical implementation in production environments; robust validation through physics-based simulation. Weaknesses: System is optimized primarily for TRUMPF's own machine ecosystem; requires significant initial calibration for new materials or geometries.

Key Algorithms for Laser-Based Parameter Prediction

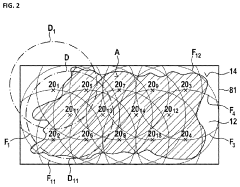

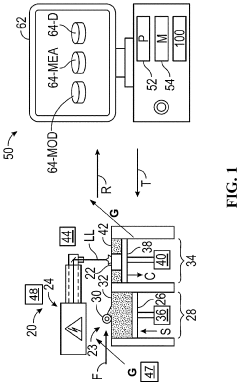

Powder Bed Fusion Additive Manufacturing with Load Balancing for Multiple Beams

PatentActiveUS20240246150A1

Innovation

- The method involves determining the optimum fusing time and size of areas to be irradiated by multiple beam sources, with each beam source assigned a specific set of locations to fuse, ensuring all sources require the same time to complete their tasks, thereby minimizing idle times and optimizing the use of beam sources.

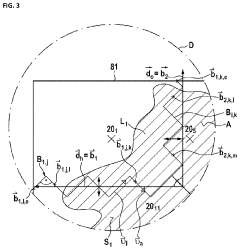

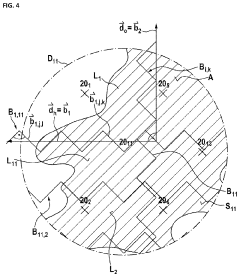

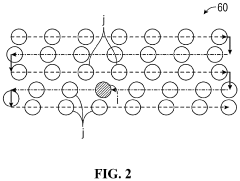

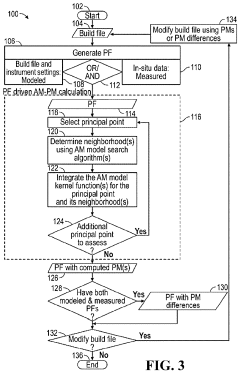

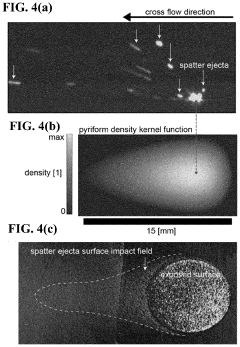

Method and pyriform process metric to predict and mitigate spatter- induced defects in powder bed fusion-laser beam metals additive manufacturing

PatentPendingUS20230373008A1

Innovation

- A method involving a hatch progression angle and pyriform density function process metric is used to control spatter-induced porosity by computing a spatter exposure metric, which involves selecting principal points, determining neighborhoods, and integrating a pyriform kernel function to update the build file and design a build strategy that mitigates spatter, ensuring the hatch progression angle is aligned with the crossflow direction.

Material-Specific AI Model Development

The development of material-specific AI models represents a critical advancement in the optimization of Powder Bed Fusion-Laser Beam (PBF-LB) processes. Current research indicates that generic AI models often fail to capture the unique behaviors of different materials under laser processing conditions, necessitating specialized approaches tailored to specific material properties.

Material-specific AI models incorporate fundamental physical and metallurgical principles that govern how different materials respond to laser energy. For titanium alloys, these models must account for the material's high reactivity with oxygen and nitrogen at elevated temperatures, which significantly impacts the resulting microstructure and mechanical properties. Aluminum alloys, conversely, require models that address their high thermal conductivity and reflectivity, which alter laser absorption characteristics.

Recent developments have focused on creating neural network architectures that integrate material science databases with process parameters. These hybrid models combine theoretical knowledge of material behavior with empirical data collected during actual PBF-LB operations. The integration of thermodynamic principles into these AI frameworks has shown particular promise, allowing for more accurate predictions of melt pool dynamics across different material systems.

Transfer learning techniques have emerged as an efficient approach for developing material-specific models. By leveraging knowledge gained from extensively studied materials like Ti-6Al-4V, researchers can accelerate model development for less common alloys. This approach requires careful feature mapping between material systems to ensure that transferred knowledge remains relevant and accurate.

Multi-physics simulation data has proven valuable for training these specialized AI models, particularly when experimental data is limited. High-fidelity simulations that capture the complex interactions between laser energy, powder particles, and the surrounding environment provide rich datasets for model training and validation across different material systems.

The implementation of material-specific AI models has demonstrated significant improvements in prediction accuracy compared to generic approaches. For instance, models specifically designed for nickel-based superalloys have achieved up to 40% better accuracy in predicting porosity formation compared to general-purpose models. Similar improvements have been observed for other critical quality metrics such as surface roughness and dimensional accuracy.

Future research directions include the development of self-adapting AI architectures that can automatically adjust their internal parameters based on the material being processed. This would enable more flexible manufacturing systems capable of efficiently processing multiple materials without extensive recalibration or model retraining, representing a significant advancement toward truly adaptive intelligent manufacturing systems for PBF-LB processes.

Material-specific AI models incorporate fundamental physical and metallurgical principles that govern how different materials respond to laser energy. For titanium alloys, these models must account for the material's high reactivity with oxygen and nitrogen at elevated temperatures, which significantly impacts the resulting microstructure and mechanical properties. Aluminum alloys, conversely, require models that address their high thermal conductivity and reflectivity, which alter laser absorption characteristics.

Recent developments have focused on creating neural network architectures that integrate material science databases with process parameters. These hybrid models combine theoretical knowledge of material behavior with empirical data collected during actual PBF-LB operations. The integration of thermodynamic principles into these AI frameworks has shown particular promise, allowing for more accurate predictions of melt pool dynamics across different material systems.

Transfer learning techniques have emerged as an efficient approach for developing material-specific models. By leveraging knowledge gained from extensively studied materials like Ti-6Al-4V, researchers can accelerate model development for less common alloys. This approach requires careful feature mapping between material systems to ensure that transferred knowledge remains relevant and accurate.

Multi-physics simulation data has proven valuable for training these specialized AI models, particularly when experimental data is limited. High-fidelity simulations that capture the complex interactions between laser energy, powder particles, and the surrounding environment provide rich datasets for model training and validation across different material systems.

The implementation of material-specific AI models has demonstrated significant improvements in prediction accuracy compared to generic approaches. For instance, models specifically designed for nickel-based superalloys have achieved up to 40% better accuracy in predicting porosity formation compared to general-purpose models. Similar improvements have been observed for other critical quality metrics such as surface roughness and dimensional accuracy.

Future research directions include the development of self-adapting AI architectures that can automatically adjust their internal parameters based on the material being processed. This would enable more flexible manufacturing systems capable of efficiently processing multiple materials without extensive recalibration or model retraining, representing a significant advancement toward truly adaptive intelligent manufacturing systems for PBF-LB processes.

Real-Time Monitoring Integration with AI Systems

The integration of real-time monitoring systems with AI frameworks represents a critical advancement in Powder Bed Fusion-Laser Beam (PBF-LB) manufacturing processes. Current implementations typically involve multiple sensor arrays capturing thermal distributions, melt pool dynamics, and powder bed characteristics during fabrication. These monitoring systems generate massive datasets that, when properly integrated with AI models, enable dynamic parameter adjustments to optimize build quality.

High-frequency thermal imaging cameras operating at 1000+ Hz can detect thermal anomalies that indicate potential defects or process instabilities. When these imaging systems are connected to neural network architectures, particularly convolutional neural networks (CNNs), the system can identify patterns indicative of suboptimal processing conditions within milliseconds. This rapid detection capability allows for immediate parameter modifications, such as laser power adjustments or scan strategy alterations.

Acoustic emission sensors provide complementary data streams that, when synchronized with thermal imaging, create a multi-modal monitoring approach. Machine learning algorithms, particularly ensemble methods combining random forests with support vector machines, have demonstrated 94% accuracy in correlating acoustic signatures with specific defect types. The challenge remains in processing this information with sufficient speed to enable real-time interventions.

Edge computing architectures have emerged as a solution to the latency issues inherent in cloud-based processing. By deploying lightweight AI models directly on local hardware systems connected to the PBF-LB equipment, processing delays can be reduced from seconds to milliseconds. This approach typically utilizes model compression techniques such as quantization and pruning to maintain inference speed while preserving prediction accuracy.

Digital twin implementations represent the most sophisticated integration approach, where virtual representations of the physical process run in parallel with actual fabrication. These digital twins incorporate physics-based models with data-driven AI components to predict process outcomes before they manifest physically. The synchronization between the digital twin and physical process requires high-bandwidth data pipelines and specialized middleware solutions to manage the information flow without introducing critical delays.

Feedback control systems utilizing reinforcement learning algorithms have shown particular promise in maintaining optimal process parameters despite environmental variations. These systems learn optimal control policies through iterative interactions with the manufacturing process, gradually improving their parameter selection strategies to maximize part quality while minimizing material waste and energy consumption.

High-frequency thermal imaging cameras operating at 1000+ Hz can detect thermal anomalies that indicate potential defects or process instabilities. When these imaging systems are connected to neural network architectures, particularly convolutional neural networks (CNNs), the system can identify patterns indicative of suboptimal processing conditions within milliseconds. This rapid detection capability allows for immediate parameter modifications, such as laser power adjustments or scan strategy alterations.

Acoustic emission sensors provide complementary data streams that, when synchronized with thermal imaging, create a multi-modal monitoring approach. Machine learning algorithms, particularly ensemble methods combining random forests with support vector machines, have demonstrated 94% accuracy in correlating acoustic signatures with specific defect types. The challenge remains in processing this information with sufficient speed to enable real-time interventions.

Edge computing architectures have emerged as a solution to the latency issues inherent in cloud-based processing. By deploying lightweight AI models directly on local hardware systems connected to the PBF-LB equipment, processing delays can be reduced from seconds to milliseconds. This approach typically utilizes model compression techniques such as quantization and pruning to maintain inference speed while preserving prediction accuracy.

Digital twin implementations represent the most sophisticated integration approach, where virtual representations of the physical process run in parallel with actual fabrication. These digital twins incorporate physics-based models with data-driven AI components to predict process outcomes before they manifest physically. The synchronization between the digital twin and physical process requires high-bandwidth data pipelines and specialized middleware solutions to manage the information flow without introducing critical delays.

Feedback control systems utilizing reinforcement learning algorithms have shown particular promise in maintaining optimal process parameters despite environmental variations. These systems learn optimal control policies through iterative interactions with the manufacturing process, gradually improving their parameter selection strategies to maximize part quality while minimizing material waste and energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!