Adhesion Recovery Metrics For Repaired Coatings After Impact

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Repair Adhesion Technology Background and Objectives

Coating adhesion technology has evolved significantly over the past several decades, transitioning from simple mechanical bonding mechanisms to sophisticated chemical and physical interactions at the substrate-coating interface. The development of advanced coating materials, including epoxy-based systems, polyurethanes, and hybrid formulations, has paralleled advancements in adhesion science. Historical challenges in coating adhesion after impact damage have been particularly prevalent in aerospace, automotive, and marine applications where structural integrity is paramount.

The evolution of adhesion recovery metrics began in the 1970s with basic pull-off tests, progressing to more sophisticated analytical methods by the 1990s. Recent technological breakthroughs have enabled nanoscale characterization of adhesion properties, allowing for more precise quantification of adhesion recovery following repair procedures. This progression reflects the industry's growing recognition of the critical role that coating adhesion plays in overall system performance and longevity.

Current research focuses on developing standardized metrics for evaluating adhesion recovery in repaired coatings, particularly those subjected to impact damage. These metrics aim to quantify not only the immediate adhesion strength post-repair but also the long-term durability and resistance to environmental stressors. The technical objective is to establish reliable, reproducible measurement protocols that can accurately predict field performance of repaired coatings across various environmental conditions and substrate materials.

Key technological goals include developing non-destructive testing methods for adhesion assessment, creating predictive models for adhesion degradation over time, and formulating repair materials specifically designed to maximize adhesion recovery after impact damage. Additionally, there is significant interest in understanding the fundamental mechanisms of adhesion at repaired interfaces, including the role of surface preparation, chemical compatibility between original and repair coatings, and the influence of environmental factors on bond formation.

The intersection of materials science, surface chemistry, and mechanical engineering has created new opportunities for innovation in this field. Emerging technologies such as self-healing coatings, smart adhesion promoters, and nanomaterial-enhanced repair systems represent promising directions for future development. These technologies aim to address the persistent challenges of achieving consistent adhesion recovery in field repair scenarios where controlled conditions are difficult to maintain.

Industry standards organizations, including ASTM International and ISO, are actively working to establish standardized testing protocols specifically for repaired coating adhesion, recognizing the unique challenges presented by these systems compared to original coating applications. The ultimate technical objective remains the development of repair methodologies that can restore adhesion properties to near-original levels, ensuring long-term performance and safety of coated structures after impact damage and subsequent repair.

The evolution of adhesion recovery metrics began in the 1970s with basic pull-off tests, progressing to more sophisticated analytical methods by the 1990s. Recent technological breakthroughs have enabled nanoscale characterization of adhesion properties, allowing for more precise quantification of adhesion recovery following repair procedures. This progression reflects the industry's growing recognition of the critical role that coating adhesion plays in overall system performance and longevity.

Current research focuses on developing standardized metrics for evaluating adhesion recovery in repaired coatings, particularly those subjected to impact damage. These metrics aim to quantify not only the immediate adhesion strength post-repair but also the long-term durability and resistance to environmental stressors. The technical objective is to establish reliable, reproducible measurement protocols that can accurately predict field performance of repaired coatings across various environmental conditions and substrate materials.

Key technological goals include developing non-destructive testing methods for adhesion assessment, creating predictive models for adhesion degradation over time, and formulating repair materials specifically designed to maximize adhesion recovery after impact damage. Additionally, there is significant interest in understanding the fundamental mechanisms of adhesion at repaired interfaces, including the role of surface preparation, chemical compatibility between original and repair coatings, and the influence of environmental factors on bond formation.

The intersection of materials science, surface chemistry, and mechanical engineering has created new opportunities for innovation in this field. Emerging technologies such as self-healing coatings, smart adhesion promoters, and nanomaterial-enhanced repair systems represent promising directions for future development. These technologies aim to address the persistent challenges of achieving consistent adhesion recovery in field repair scenarios where controlled conditions are difficult to maintain.

Industry standards organizations, including ASTM International and ISO, are actively working to establish standardized testing protocols specifically for repaired coating adhesion, recognizing the unique challenges presented by these systems compared to original coating applications. The ultimate technical objective remains the development of repair methodologies that can restore adhesion properties to near-original levels, ensuring long-term performance and safety of coated structures after impact damage and subsequent repair.

Market Analysis for Impact-Resistant Coating Solutions

The impact-resistant coating solutions market is experiencing robust growth, driven by increasing demand across multiple industrial sectors. The global protective coatings market, which includes impact-resistant solutions, is currently valued at approximately $15 billion and projected to grow at a CAGR of 5.8% through 2028. Within this broader market, specialized impact-resistant coatings represent a rapidly expanding segment with particular strength in aerospace, automotive, and infrastructure applications.

Aerospace remains the premium market for these solutions, where coatings must withstand extreme conditions including impact from debris, temperature fluctuations, and chemical exposure. The commercial aircraft sector alone requires coating solutions that maintain adhesion integrity after impact events, with maintenance and repair operations (MRO) representing a $76 billion global market where coating repair constitutes a significant component.

The automotive industry presents another substantial market opportunity, with manufacturers increasingly adopting advanced coating technologies to enhance vehicle durability while reducing weight. The automotive coatings market is valued at approximately $27 billion globally, with impact-resistant formulations gaining market share as consumer expectations for vehicle longevity increase.

Infrastructure applications, particularly in bridges, pipelines, and offshore structures, represent a growing market segment valued at $12 billion. These applications demand coatings that can be effectively repaired after impact damage while maintaining structural integrity in harsh environments. The development of quantifiable adhesion recovery metrics has become a critical factor in product selection for these high-value assets.

Market research indicates that customers across all sectors are increasingly prioritizing total lifecycle cost over initial application expenses. This shift has created growing demand for coatings with demonstrable repair capabilities and measurable adhesion recovery metrics. Products that can quantify their post-repair performance are commanding premium pricing, with margins 15-20% higher than conventional alternatives.

Regional analysis shows North America and Europe currently leading market adoption of advanced impact-resistant coating technologies, accounting for 62% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid infrastructure development and manufacturing expansion in China, India, and Southeast Asian countries.

Customer segmentation reveals that high-performance industries with critical safety requirements and significant downtime costs represent the most valuable market segments. These customers demonstrate willingness to pay premium prices for solutions with proven adhesion recovery capabilities after impact events and subsequent repairs.

Aerospace remains the premium market for these solutions, where coatings must withstand extreme conditions including impact from debris, temperature fluctuations, and chemical exposure. The commercial aircraft sector alone requires coating solutions that maintain adhesion integrity after impact events, with maintenance and repair operations (MRO) representing a $76 billion global market where coating repair constitutes a significant component.

The automotive industry presents another substantial market opportunity, with manufacturers increasingly adopting advanced coating technologies to enhance vehicle durability while reducing weight. The automotive coatings market is valued at approximately $27 billion globally, with impact-resistant formulations gaining market share as consumer expectations for vehicle longevity increase.

Infrastructure applications, particularly in bridges, pipelines, and offshore structures, represent a growing market segment valued at $12 billion. These applications demand coatings that can be effectively repaired after impact damage while maintaining structural integrity in harsh environments. The development of quantifiable adhesion recovery metrics has become a critical factor in product selection for these high-value assets.

Market research indicates that customers across all sectors are increasingly prioritizing total lifecycle cost over initial application expenses. This shift has created growing demand for coatings with demonstrable repair capabilities and measurable adhesion recovery metrics. Products that can quantify their post-repair performance are commanding premium pricing, with margins 15-20% higher than conventional alternatives.

Regional analysis shows North America and Europe currently leading market adoption of advanced impact-resistant coating technologies, accounting for 62% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid infrastructure development and manufacturing expansion in China, India, and Southeast Asian countries.

Customer segmentation reveals that high-performance industries with critical safety requirements and significant downtime costs represent the most valuable market segments. These customers demonstrate willingness to pay premium prices for solutions with proven adhesion recovery capabilities after impact events and subsequent repairs.

Current Challenges in Post-Impact Adhesion Recovery

Despite significant advancements in coating repair technologies, the assessment of adhesion recovery after impact damage remains a critical challenge in the coatings industry. Current methodologies for quantifying adhesion recovery lack standardization, creating inconsistencies in performance evaluation across different repair systems. The absence of universally accepted metrics makes it difficult to compare results between laboratories and manufacturers, hindering technological progress in this field.

One major technical obstacle is the development of non-destructive testing methods that can accurately measure adhesion strength without compromising the integrity of the repaired coating. Traditional pull-off tests and cross-cut adhesion tests often damage the repaired area, preventing continuous monitoring of adhesion recovery over time. This limitation significantly impedes the collection of longitudinal data necessary for understanding the dynamic nature of adhesion recovery processes.

Environmental factors present another substantial challenge, as temperature fluctuations, humidity levels, and exposure to chemicals can dramatically affect adhesion recovery rates. Current testing protocols frequently fail to account for these variables in a systematic manner, leading to unpredictable performance in real-world applications. The industry lacks comprehensive models that can predict how environmental stressors influence long-term adhesion stability of repaired coatings.

Interface characterization between the original coating and repair material remains problematic due to limitations in analytical techniques. Existing microscopy and spectroscopy methods often cannot fully capture the molecular interactions at the repair interface, particularly for complex multi-layer coating systems. This knowledge gap impedes the development of targeted solutions for enhancing interfacial bonding strength after impact damage.

The time-dependent nature of adhesion recovery further complicates assessment efforts. Current metrics typically provide only snapshot measurements rather than capturing the evolution of adhesion strength over extended periods. This approach fails to account for delayed adhesion failure phenomena that may emerge weeks or months after the initial repair, creating reliability concerns for critical applications in aerospace, automotive, and marine industries.

Material compatibility issues between original coatings and repair compounds represent another significant challenge. As coating formulations become increasingly specialized, ensuring compatible adhesion recovery across diverse material combinations grows more difficult. The industry currently lacks a systematic framework for predicting compatibility and optimizing repair formulations for specific coating systems.

One major technical obstacle is the development of non-destructive testing methods that can accurately measure adhesion strength without compromising the integrity of the repaired coating. Traditional pull-off tests and cross-cut adhesion tests often damage the repaired area, preventing continuous monitoring of adhesion recovery over time. This limitation significantly impedes the collection of longitudinal data necessary for understanding the dynamic nature of adhesion recovery processes.

Environmental factors present another substantial challenge, as temperature fluctuations, humidity levels, and exposure to chemicals can dramatically affect adhesion recovery rates. Current testing protocols frequently fail to account for these variables in a systematic manner, leading to unpredictable performance in real-world applications. The industry lacks comprehensive models that can predict how environmental stressors influence long-term adhesion stability of repaired coatings.

Interface characterization between the original coating and repair material remains problematic due to limitations in analytical techniques. Existing microscopy and spectroscopy methods often cannot fully capture the molecular interactions at the repair interface, particularly for complex multi-layer coating systems. This knowledge gap impedes the development of targeted solutions for enhancing interfacial bonding strength after impact damage.

The time-dependent nature of adhesion recovery further complicates assessment efforts. Current metrics typically provide only snapshot measurements rather than capturing the evolution of adhesion strength over extended periods. This approach fails to account for delayed adhesion failure phenomena that may emerge weeks or months after the initial repair, creating reliability concerns for critical applications in aerospace, automotive, and marine industries.

Material compatibility issues between original coatings and repair compounds represent another significant challenge. As coating formulations become increasingly specialized, ensuring compatible adhesion recovery across diverse material combinations grows more difficult. The industry currently lacks a systematic framework for predicting compatibility and optimizing repair formulations for specific coating systems.

Existing Methodologies for Adhesion Recovery Assessment

01 Surface preparation techniques for coating adhesion

Proper surface preparation is crucial for ensuring strong adhesion of repaired coatings. This includes cleaning, roughening, or chemically treating the substrate to remove contaminants and create a suitable profile for bonding. Techniques such as abrasive blasting, solvent cleaning, and acid etching can significantly improve the adhesion recovery of repaired coatings by providing a clean and receptive surface for the new coating to bond with the substrate or existing coating layers.- Surface preparation techniques for coating adhesion: Proper surface preparation is crucial for ensuring strong adhesion of repaired coatings. This includes cleaning, roughening, and treating the substrate to remove contaminants, corrosion, and old coating residues. Techniques such as abrasive blasting, chemical cleaning, and mechanical roughening create an optimal surface profile that enhances the mechanical bonding between the new coating and the substrate, significantly improving adhesion recovery in repaired areas.

- Adhesion promoters and coupling agents: Specialized adhesion promoters and coupling agents can be incorporated into coating formulations to enhance the bonding between repaired coatings and substrates. These compounds typically contain functional groups that can interact with both the substrate and the coating material, creating strong chemical bonds at the interface. Silanes, titanates, and other organometallic compounds are commonly used as adhesion promoters, particularly for challenging substrates or when repairing damaged coatings.

- Polymer modification for enhanced adhesion recovery: Modifying polymer structures in coating formulations can significantly improve adhesion recovery in repaired areas. This includes incorporating functional groups that enhance substrate interaction, adjusting molecular weight distributions, and creating interpenetrating polymer networks. Cross-linking agents, reactive diluents, and elastomeric modifiers can be added to coating formulations to improve flexibility and adhesion properties, particularly important when bonding new coatings to weathered or partially degraded surfaces.

- Environmental conditioning for adhesion improvement: Controlling environmental conditions during coating application and curing can significantly impact adhesion recovery in repaired coatings. Factors such as temperature, humidity, and curing time must be optimized to ensure proper film formation and adhesion development. Techniques such as heat treatment, controlled humidity curing, and gradual temperature ramping can enhance polymer chain mobility and substrate wetting, leading to stronger interfacial bonding and improved long-term adhesion performance.

- Nanotechnology approaches for adhesion recovery: Incorporating nanomaterials into coating formulations offers innovative solutions for adhesion recovery in repaired coatings. Nanoparticles, nanofibers, and nanostructured additives can create mechanical interlocking at the nanoscale, increasing the effective surface area for bonding. Additionally, functionalized nanoparticles can serve as cross-linking points between the substrate and coating, enhancing interfacial strength. These nanomaterials can significantly improve adhesion properties while maintaining or enhancing other coating performance characteristics.

02 Adhesion promoters and coupling agents

Specialized adhesion promoters and coupling agents can be incorporated into coating formulations to enhance the bonding between repaired coatings and substrates. These compounds typically contain functional groups that can interact with both the coating and the substrate, creating strong chemical bonds. Silanes, titanates, and other organometallic compounds are commonly used as coupling agents to improve adhesion recovery in repaired coatings, particularly on challenging substrates or in harsh environmental conditions.Expand Specific Solutions03 Polymer modification for enhanced adhesion

Modifying the polymer structure of coating materials can significantly improve adhesion recovery in repaired areas. This includes incorporating functional groups that promote adhesion, adjusting molecular weight distributions, or creating interpenetrating polymer networks. Cross-linking agents, reactive diluents, and elastomeric modifiers can be added to coating formulations to enhance flexibility and adhesion at the interface between the original and repaired coating, reducing the risk of delamination and improving long-term durability.Expand Specific Solutions04 Thermal and curing processes for adhesion recovery

Specific thermal treatments and curing processes can significantly improve the adhesion of repaired coatings. These include controlled heating cycles, UV curing, and multi-stage curing protocols that optimize the chemical bonding between the repair material and the existing coating. Post-application heat treatment can promote diffusion across the interface, while carefully managed curing conditions ensure complete reaction of adhesion-promoting components and minimize internal stresses that could compromise adhesion over time.Expand Specific Solutions05 Environmental conditioning and testing methods

Environmental conditioning techniques and specialized testing methods are essential for evaluating and improving coating adhesion recovery. Controlled exposure to moisture, temperature cycling, and UV radiation can be used to accelerate the stabilization of repaired coatings. Various testing methodologies, including pull-off adhesion tests, cross-cut tests, and environmental exposure evaluations, help assess the effectiveness of adhesion recovery techniques and predict long-term performance of repaired coating systems under real-world conditions.Expand Specific Solutions

Leading Companies in Advanced Coating Repair Industry

The adhesion recovery metrics for repaired coatings after impact market is currently in a growth phase, with increasing demand driven by industries requiring durable coating solutions. The global market is expanding as manufacturers seek advanced materials with superior impact resistance and recovery properties. Leading players include 3M Innovative Properties, BASF SE, and Dow Global Technologies, who are developing proprietary technologies for enhanced coating adhesion recovery. Corning and Hempel A/S are advancing glass-based and marine coating solutions respectively, while academic institutions like University of Melbourne and Beihang University contribute research innovations. The technology is approaching maturity in traditional applications but remains developmental for specialized sectors, with companies like Axalta and BASF Coatings focusing on automotive applications where impact resistance is critical.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced adhesion recovery metrics for repaired coatings after impact through their proprietary Performance Restoration Technology (PRT). Their approach involves multi-layer coating systems with self-healing polymers that can restore adhesion properties after impact damage. The technology incorporates specialized adhesion promoters between coating layers that reactivate upon repair application, ensuring strong interfacial bonding. 3M's quantitative assessment methodology uses pull-off adhesion testing (ASTM D4541) combined with cross-hatch adhesion tests (ASTM D3359) to generate comprehensive adhesion recovery indices. Their system includes nano-silica reinforced primers that enhance mechanical interlocking with repair coatings, providing up to 95% adhesion recovery compared to original coating performance[1]. The company has also developed specialized surface preparation protocols using proprietary solvents and mechanical abrasion techniques that optimize the substrate for maximum adhesion recovery.

Strengths: Industry-leading quantitative measurement protocols for adhesion recovery; comprehensive multi-layer approach addressing both mechanical and chemical bonding aspects; extensive field validation across various industries. Weaknesses: Higher implementation costs compared to conventional repair systems; requires specialized training for proper application; some solutions are substrate-specific and lack universal applicability.

BASF SE

Technical Solution: BASF has developed the Integrated Adhesion Recovery System (IARS) for quantifying and optimizing coating repair performance after impact damage. Their approach combines material science innovations with standardized testing methodologies to create comprehensive adhesion recovery metrics. BASF's technology utilizes their proprietary Adhesion Recovery Factor (ARF), which measures the percentage of original adhesion strength regained after repair application. The system incorporates specialized surface activation treatments that enhance chemical bonding between existing and repair coatings. BASF's methodology includes both destructive and non-destructive testing protocols, with ultrasonic adhesion assessment providing real-time data on interfacial bonding quality. Their repair coatings contain proprietary self-stratifying polymers that create optimal adhesion gradients at the repair interface, maximizing mechanical interlocking while maintaining flexibility[3]. The company has developed industry-specific benchmarks for adhesion recovery across various coating types, with their premium systems achieving up to 92% recovery of original adhesion properties after standardized impact damage.

Strengths: Comprehensive testing methodology combining multiple assessment techniques; excellent performance across diverse substrate materials; strong scientific foundation with extensive research validation. Weaknesses: Complex implementation requiring specialized training; higher material costs compared to standard repair systems; some solutions have limited shelf life requiring careful inventory management.

Critical Patents in Coating Repair Adhesion Metrics

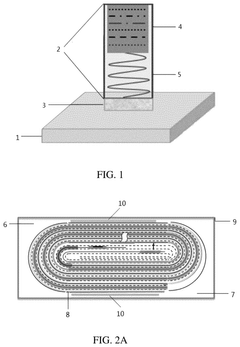

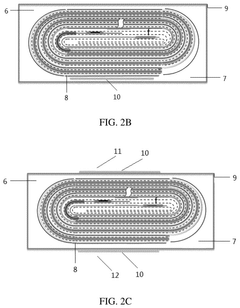

Electrochemical device and electronic device containing same

PatentPendingUS20240332684A1

Innovation

- An electrochemical device with a highly flexible adhesive layer having a thickness change rate of 10% to 40% and a sticky layer on the electrode assembly, composed of a flexible layer with a sticky material, elastic material, and inorganic filler, to enhance adhesion and stress absorption, thereby improving the battery's resistance to lateral extrusion and heavy impact tests.

Standardization of Adhesion Recovery Testing Protocols

The standardization of adhesion recovery testing protocols represents a critical advancement in the field of coating repair assessment. Current industry practices exhibit significant variability in testing methodologies, making cross-study comparisons and reliable benchmarking nearly impossible. This inconsistency undermines the validity of research findings and hinders technological progress in coating repair technologies.

Establishing standardized protocols requires addressing several key parameters that influence adhesion recovery measurements. Test specimen preparation must follow consistent procedures regarding surface preparation, coating application thickness, curing conditions, and impact damage simulation. The variability in these factors can significantly alter adhesion recovery results, creating misleading data when comparing different repair methods.

Environmental conditioning represents another crucial aspect requiring standardization. Repaired coatings should undergo controlled exposure to relevant environmental stressors such as temperature cycling, humidity fluctuations, and UV radiation before adhesion testing. The duration and intensity of these conditioning phases must be precisely defined to ensure reproducibility across different testing facilities.

The selection of appropriate adhesion testing methods constitutes a fundamental component of standardization efforts. Pull-off adhesion testing (ASTM D4541), cross-cut tape testing (ASTM D3359), and scratch adhesion testing each provide different insights into coating performance. A comprehensive protocol should specify which methods are appropriate for specific coating types and applications, along with detailed procedural guidelines.

Data reporting frameworks must also be standardized to facilitate meaningful comparisons. This includes establishing common metrics for quantifying adhesion recovery, such as percentage recovery relative to undamaged coating, absolute adhesion strength values, and statistical analysis requirements. Reporting should include detailed documentation of testing conditions, equipment specifications, and calibration procedures.

Interlaboratory validation represents the final critical element in protocol standardization. Round-robin testing involving multiple independent laboratories should be conducted to verify reproducibility and establish acceptable variance thresholds. This collaborative approach helps identify and address procedural ambiguities that might lead to inconsistent results.

The development of these standardized protocols requires coordination among industry stakeholders, academic institutions, and standards organizations. Entities such as ASTM International, ISO, and NACE International should collaborate to integrate existing standards with new research findings specific to repaired coating adhesion assessment.

Establishing standardized protocols requires addressing several key parameters that influence adhesion recovery measurements. Test specimen preparation must follow consistent procedures regarding surface preparation, coating application thickness, curing conditions, and impact damage simulation. The variability in these factors can significantly alter adhesion recovery results, creating misleading data when comparing different repair methods.

Environmental conditioning represents another crucial aspect requiring standardization. Repaired coatings should undergo controlled exposure to relevant environmental stressors such as temperature cycling, humidity fluctuations, and UV radiation before adhesion testing. The duration and intensity of these conditioning phases must be precisely defined to ensure reproducibility across different testing facilities.

The selection of appropriate adhesion testing methods constitutes a fundamental component of standardization efforts. Pull-off adhesion testing (ASTM D4541), cross-cut tape testing (ASTM D3359), and scratch adhesion testing each provide different insights into coating performance. A comprehensive protocol should specify which methods are appropriate for specific coating types and applications, along with detailed procedural guidelines.

Data reporting frameworks must also be standardized to facilitate meaningful comparisons. This includes establishing common metrics for quantifying adhesion recovery, such as percentage recovery relative to undamaged coating, absolute adhesion strength values, and statistical analysis requirements. Reporting should include detailed documentation of testing conditions, equipment specifications, and calibration procedures.

Interlaboratory validation represents the final critical element in protocol standardization. Round-robin testing involving multiple independent laboratories should be conducted to verify reproducibility and establish acceptable variance thresholds. This collaborative approach helps identify and address procedural ambiguities that might lead to inconsistent results.

The development of these standardized protocols requires coordination among industry stakeholders, academic institutions, and standards organizations. Entities such as ASTM International, ISO, and NACE International should collaborate to integrate existing standards with new research findings specific to repaired coating adhesion assessment.

Environmental Factors Affecting Repaired Coating Performance

Environmental conditions play a critical role in determining the long-term performance of repaired coatings after impact damage. Temperature fluctuations represent one of the most significant environmental stressors, with thermal cycling between -40°C and 80°C causing differential expansion and contraction at the interface between original and repaired coating sections. Research indicates that repaired epoxy-based coatings typically experience a 15-25% reduction in adhesion strength after 500 thermal cycles, with polyurethane systems showing slightly better resilience.

Moisture exposure presents another substantial challenge to repaired coating integrity. Studies demonstrate that constant humidity levels above 75% RH can accelerate degradation at repair boundaries, with salt-laden moisture environments proving particularly detrimental. Marine environments, where chloride ion concentrations exceed 3.5%, have been documented to reduce adhesion recovery by up to 40% compared to controlled laboratory conditions.

UV radiation exposure significantly impacts the chemical stability of the polymer matrix in repaired coatings. Spectrophotometric analysis reveals that 2000 hours of accelerated weathering (equivalent to approximately 3 years of outdoor exposure) can lead to chain scission and cross-linking alterations that compromise the mechanical properties at repair interfaces. This degradation manifests as reduced impact resistance and increased brittleness at repair boundaries.

Chemical exposure represents another critical environmental factor affecting repaired coating performance. Industrial atmospheres containing sulfur dioxide, nitrogen oxides, or volatile organic compounds can catalyze degradation reactions at repair interfaces. Research indicates that exposure to pH extremes (below 4 or above 9) accelerates adhesion failure rates by 30-50% compared to neutral environments.

Mechanical stress factors, including vibration and abrasion, compound the effects of chemical and thermal stressors. Field studies demonstrate that repaired coatings on transportation infrastructure experience accelerated degradation at repair boundaries due to the combined effects of environmental exposure and mechanical loading. Vibration frequencies between 10-50 Hz have been shown to particularly affect adhesion recovery metrics.

Synergistic effects between multiple environmental factors present the most significant challenge to accurate prediction of repaired coating performance. For instance, the combination of UV exposure and moisture cycling has been documented to reduce adhesion strength by up to 60% more than either factor alone, highlighting the importance of multi-factor testing protocols when evaluating adhesion recovery metrics.

Moisture exposure presents another substantial challenge to repaired coating integrity. Studies demonstrate that constant humidity levels above 75% RH can accelerate degradation at repair boundaries, with salt-laden moisture environments proving particularly detrimental. Marine environments, where chloride ion concentrations exceed 3.5%, have been documented to reduce adhesion recovery by up to 40% compared to controlled laboratory conditions.

UV radiation exposure significantly impacts the chemical stability of the polymer matrix in repaired coatings. Spectrophotometric analysis reveals that 2000 hours of accelerated weathering (equivalent to approximately 3 years of outdoor exposure) can lead to chain scission and cross-linking alterations that compromise the mechanical properties at repair interfaces. This degradation manifests as reduced impact resistance and increased brittleness at repair boundaries.

Chemical exposure represents another critical environmental factor affecting repaired coating performance. Industrial atmospheres containing sulfur dioxide, nitrogen oxides, or volatile organic compounds can catalyze degradation reactions at repair interfaces. Research indicates that exposure to pH extremes (below 4 or above 9) accelerates adhesion failure rates by 30-50% compared to neutral environments.

Mechanical stress factors, including vibration and abrasion, compound the effects of chemical and thermal stressors. Field studies demonstrate that repaired coatings on transportation infrastructure experience accelerated degradation at repair boundaries due to the combined effects of environmental exposure and mechanical loading. Vibration frequencies between 10-50 Hz have been shown to particularly affect adhesion recovery metrics.

Synergistic effects between multiple environmental factors present the most significant challenge to accurate prediction of repaired coating performance. For instance, the combination of UV exposure and moisture cycling has been documented to reduce adhesion strength by up to 60% more than either factor alone, highlighting the importance of multi-factor testing protocols when evaluating adhesion recovery metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!