Durability Testing For Self Healing Coatings Under Cyclic Loads

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Coatings Background and Testing Objectives

Self-healing coatings represent a revolutionary advancement in materials science, designed to autonomously repair damage and extend service life without human intervention. These smart materials have evolved significantly since their conceptualization in the early 2000s, with major breakthroughs occurring around 2010 when microcapsule-based systems gained commercial viability. The technology has progressed from simple scratch-healing capabilities to sophisticated systems that can respond to multiple damage mechanisms.

The evolution trajectory shows a clear shift from passive healing mechanisms requiring external stimuli (such as heat) toward fully autonomous systems capable of detecting and repairing damage in real-time. This progression aligns with broader trends in smart materials development, where functionality increasingly mimics biological self-repair processes found in nature.

Current technical objectives in self-healing coating durability testing focus on quantifying performance under cyclic loading conditions—a critical yet underexplored aspect of these materials. While static testing protocols are well-established, standardized methodologies for evaluating healing efficiency under dynamic stress conditions remain underdeveloped. This represents a significant gap in the technology's maturation pathway.

The primary testing objectives include establishing reproducible protocols for simulating real-world cyclic loading scenarios, determining healing efficiency metrics under variable stress conditions, and correlating laboratory test results with field performance data. Additionally, there is a pressing need to understand the fundamental mechanisms of healing agent depletion over multiple damage-repair cycles.

Industry stakeholders seek to establish minimum performance thresholds for different application environments, particularly in high-stress sectors such as aerospace, automotive, and marine applications where cyclic loading is prevalent. The development of accelerated testing methods that can reliably predict long-term performance represents another critical objective.

Recent technological advancements have enabled more sophisticated in-situ monitoring of healing processes, allowing researchers to observe real-time molecular reorganization during repair events. This has opened new avenues for understanding the kinetics of self-healing under dynamic stress conditions and optimizing formulations accordingly.

The ultimate goal of durability testing advancement is to develop predictive models that can accurately forecast coating performance throughout its service life, accounting for environmental factors, mechanical stress patterns, and healing agent depletion rates. Such models would significantly reduce development cycles and enable more targeted innovation in self-healing coating technologies.

The evolution trajectory shows a clear shift from passive healing mechanisms requiring external stimuli (such as heat) toward fully autonomous systems capable of detecting and repairing damage in real-time. This progression aligns with broader trends in smart materials development, where functionality increasingly mimics biological self-repair processes found in nature.

Current technical objectives in self-healing coating durability testing focus on quantifying performance under cyclic loading conditions—a critical yet underexplored aspect of these materials. While static testing protocols are well-established, standardized methodologies for evaluating healing efficiency under dynamic stress conditions remain underdeveloped. This represents a significant gap in the technology's maturation pathway.

The primary testing objectives include establishing reproducible protocols for simulating real-world cyclic loading scenarios, determining healing efficiency metrics under variable stress conditions, and correlating laboratory test results with field performance data. Additionally, there is a pressing need to understand the fundamental mechanisms of healing agent depletion over multiple damage-repair cycles.

Industry stakeholders seek to establish minimum performance thresholds for different application environments, particularly in high-stress sectors such as aerospace, automotive, and marine applications where cyclic loading is prevalent. The development of accelerated testing methods that can reliably predict long-term performance represents another critical objective.

Recent technological advancements have enabled more sophisticated in-situ monitoring of healing processes, allowing researchers to observe real-time molecular reorganization during repair events. This has opened new avenues for understanding the kinetics of self-healing under dynamic stress conditions and optimizing formulations accordingly.

The ultimate goal of durability testing advancement is to develop predictive models that can accurately forecast coating performance throughout its service life, accounting for environmental factors, mechanical stress patterns, and healing agent depletion rates. Such models would significantly reduce development cycles and enable more targeted innovation in self-healing coating technologies.

Market Demand Analysis for Durable Self-Healing Coatings

The global market for self-healing coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries seeking enhanced durability and reduced maintenance costs. The market value reached approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 18.2% through 2030, potentially reaching $5.7 billion by the end of the decade.

Automotive and aerospace sectors represent the largest market segments, collectively accounting for over 40% of the current demand. These industries require coatings that can withstand extreme environmental conditions while maintaining aesthetic and functional properties over extended periods. The ability of self-healing coatings to repair minor damages autonomously addresses a critical pain point in these high-value applications.

Construction and infrastructure sectors are emerging as rapidly growing markets, with increasing adoption rates of 23% annually. Building facades, bridges, and public infrastructure face continuous exposure to environmental stressors and mechanical loads, creating substantial demand for coatings that can extend maintenance cycles and reduce lifetime costs.

Consumer electronics manufacturers have begun incorporating self-healing coatings in premium devices, with market penetration increasing from 5% in 2020 to 12% in 2023. This trend is expected to accelerate as consumers increasingly value durability and longevity in electronic products.

Market research indicates that 78% of industrial customers prioritize long-term performance over initial cost when selecting coating solutions. This preference has created a premium segment within the market where durability under cyclic loading conditions serves as a key differentiator. Products demonstrating superior performance in standardized durability tests command price premiums of 30-45% compared to conventional alternatives.

Regional analysis shows North America and Europe currently leading market consumption at 35% and 30% respectively, though Asia-Pacific represents the fastest-growing region with 24% annual growth. This geographic shift reflects the expanding manufacturing base and increasing quality standards in developing economies.

Customer surveys reveal that 82% of industrial buyers consider durability under cyclic loading conditions as "very important" or "critical" when evaluating self-healing coating products. However, only 23% report being "very satisfied" with current offerings, indicating a significant gap between market needs and available solutions.

The market demonstrates increasing demand for specialized testing protocols that can accurately predict real-world performance under cyclic loading conditions. Companies that can validate their products' durability claims through standardized testing methodologies gain significant competitive advantages in tender processes and specification decisions.

Automotive and aerospace sectors represent the largest market segments, collectively accounting for over 40% of the current demand. These industries require coatings that can withstand extreme environmental conditions while maintaining aesthetic and functional properties over extended periods. The ability of self-healing coatings to repair minor damages autonomously addresses a critical pain point in these high-value applications.

Construction and infrastructure sectors are emerging as rapidly growing markets, with increasing adoption rates of 23% annually. Building facades, bridges, and public infrastructure face continuous exposure to environmental stressors and mechanical loads, creating substantial demand for coatings that can extend maintenance cycles and reduce lifetime costs.

Consumer electronics manufacturers have begun incorporating self-healing coatings in premium devices, with market penetration increasing from 5% in 2020 to 12% in 2023. This trend is expected to accelerate as consumers increasingly value durability and longevity in electronic products.

Market research indicates that 78% of industrial customers prioritize long-term performance over initial cost when selecting coating solutions. This preference has created a premium segment within the market where durability under cyclic loading conditions serves as a key differentiator. Products demonstrating superior performance in standardized durability tests command price premiums of 30-45% compared to conventional alternatives.

Regional analysis shows North America and Europe currently leading market consumption at 35% and 30% respectively, though Asia-Pacific represents the fastest-growing region with 24% annual growth. This geographic shift reflects the expanding manufacturing base and increasing quality standards in developing economies.

Customer surveys reveal that 82% of industrial buyers consider durability under cyclic loading conditions as "very important" or "critical" when evaluating self-healing coating products. However, only 23% report being "very satisfied" with current offerings, indicating a significant gap between market needs and available solutions.

The market demonstrates increasing demand for specialized testing protocols that can accurately predict real-world performance under cyclic loading conditions. Companies that can validate their products' durability claims through standardized testing methodologies gain significant competitive advantages in tender processes and specification decisions.

Current Testing Methodologies and Technical Challenges

The durability testing of self-healing coatings under cyclic loads currently employs several established methodologies, each with specific advantages and limitations. Accelerated weathering tests, including UV exposure chambers and salt spray tests, are widely used to simulate environmental stressors that coatings encounter in real-world applications. These methods, however, often fail to accurately replicate the complex combination of mechanical stress and environmental factors that coatings experience simultaneously in practical settings.

Mechanical testing approaches such as scratch resistance tests, abrasion resistance evaluations, and impact tests provide valuable data on coating performance under specific stress conditions. The Taber abraser test, for instance, measures wear resistance by subjecting coatings to rotary abrasion, while nanoindentation techniques assess hardness and elastic modulus at the microscale. Nevertheless, these tests typically apply stresses in isolation rather than in the cyclic, variable patterns characteristic of real-world applications.

Cyclic loading tests represent a more advanced methodology, utilizing equipment such as fatigue testing machines that apply repeated stress-strain cycles to coating systems. These tests can be configured to simulate various loading conditions, including tension-compression cycles, bending, and torsion. Despite their relevance, standardization remains a significant challenge, with limited consensus on testing parameters specific to self-healing coatings.

A major technical challenge in current testing methodologies is the lack of real-time monitoring capabilities for self-healing processes during cyclic loading. Most existing approaches require test interruption for healing assessment, potentially disrupting the natural healing mechanisms. Additionally, accelerated testing protocols often fail to account for the time-dependent nature of self-healing processes, leading to potential underestimation of healing efficiency in real-world scenarios.

The correlation between laboratory test results and field performance represents another significant challenge. Laboratory conditions rarely capture the full complexity of environmental factors, mechanical stresses, and their interactions that coatings experience in practical applications. This discrepancy creates uncertainty in predicting long-term durability based on accelerated testing data.

Furthermore, the multifunctional nature of modern self-healing coatings complicates testing procedures. These coatings often incorporate multiple healing mechanisms and additional functionalities such as corrosion resistance or hydrophobicity, requiring comprehensive testing protocols that can evaluate multiple performance criteria simultaneously. Current methodologies typically focus on isolated properties, failing to capture these complex interactions.

Standardization issues persist across the industry, with limited consensus on testing parameters, sample preparation methods, and performance evaluation criteria specifically designed for self-healing coatings. This lack of standardization hampers meaningful comparison between different coating systems and creates challenges for quality control and product development.

Mechanical testing approaches such as scratch resistance tests, abrasion resistance evaluations, and impact tests provide valuable data on coating performance under specific stress conditions. The Taber abraser test, for instance, measures wear resistance by subjecting coatings to rotary abrasion, while nanoindentation techniques assess hardness and elastic modulus at the microscale. Nevertheless, these tests typically apply stresses in isolation rather than in the cyclic, variable patterns characteristic of real-world applications.

Cyclic loading tests represent a more advanced methodology, utilizing equipment such as fatigue testing machines that apply repeated stress-strain cycles to coating systems. These tests can be configured to simulate various loading conditions, including tension-compression cycles, bending, and torsion. Despite their relevance, standardization remains a significant challenge, with limited consensus on testing parameters specific to self-healing coatings.

A major technical challenge in current testing methodologies is the lack of real-time monitoring capabilities for self-healing processes during cyclic loading. Most existing approaches require test interruption for healing assessment, potentially disrupting the natural healing mechanisms. Additionally, accelerated testing protocols often fail to account for the time-dependent nature of self-healing processes, leading to potential underestimation of healing efficiency in real-world scenarios.

The correlation between laboratory test results and field performance represents another significant challenge. Laboratory conditions rarely capture the full complexity of environmental factors, mechanical stresses, and their interactions that coatings experience in practical applications. This discrepancy creates uncertainty in predicting long-term durability based on accelerated testing data.

Furthermore, the multifunctional nature of modern self-healing coatings complicates testing procedures. These coatings often incorporate multiple healing mechanisms and additional functionalities such as corrosion resistance or hydrophobicity, requiring comprehensive testing protocols that can evaluate multiple performance criteria simultaneously. Current methodologies typically focus on isolated properties, failing to capture these complex interactions.

Standardization issues persist across the industry, with limited consensus on testing parameters, sample preparation methods, and performance evaluation criteria specifically designed for self-healing coatings. This lack of standardization hampers meaningful comparison between different coating systems and creates challenges for quality control and product development.

Existing Cyclic Load Testing Protocols

01 Microcapsule-based self-healing mechanisms

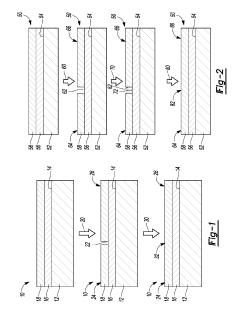

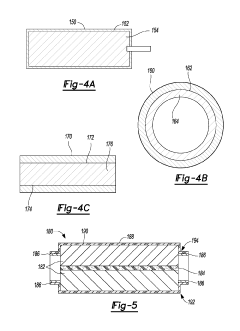

Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When a crack or scratch occurs, the microcapsules rupture and release the healing agent, which then polymerizes or reacts to repair the damage. This mechanism provides autonomous healing without external intervention, significantly improving the durability and service life of the coating. The healing efficiency depends on the distribution of microcapsules, the reactivity of the healing agent, and the compatibility with the coating matrix.- Microcapsule-based self-healing mechanisms: Self-healing coatings can be formulated with microcapsules containing healing agents that are released when the coating is damaged. When a crack or scratch occurs, the microcapsules rupture and release the healing agent, which then polymerizes or reacts to fill the damaged area. This mechanism provides autonomous healing without external intervention, significantly improving the durability and service life of the coating. The healing efficiency depends on the distribution of microcapsules, the reactivity of the healing agent, and the compatibility with the coating matrix.

- Intrinsic self-healing polymer networks: Intrinsic self-healing coatings utilize reversible chemical bonds or dynamic crosslinking within the polymer network to achieve healing properties. These systems can repair damage through mechanisms such as hydrogen bonding, disulfide exchange, Diels-Alder reactions, or metal-ligand coordination. When damaged, the polymer chains can reconnect through these reversible interactions when appropriate conditions (such as temperature or pH) are applied. This approach eliminates the need for healing agents and provides multiple healing cycles, enhancing the overall durability of the coating system.

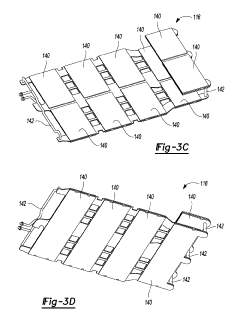

- Nanocomposite reinforcement for enhanced durability: Incorporating nanoparticles such as silica, clay, graphene, or carbon nanotubes into self-healing coating formulations can significantly improve mechanical properties and durability. These nanocomposites enhance scratch resistance, tensile strength, and barrier properties while maintaining or improving the self-healing capability. The nanoparticles can also serve as anchoring points for self-healing components or catalysts, creating a more efficient healing system. The improved mechanical properties result in coatings that are less prone to damage in the first place, while still maintaining the ability to repair when damage does occur.

- Environmental resistance enhancement techniques: Improving the durability of self-healing coatings against environmental factors such as UV radiation, moisture, temperature fluctuations, and chemical exposure is critical for long-term performance. Techniques include incorporating UV absorbers, antioxidants, and corrosion inhibitors into the coating formulation. Additionally, multi-layer coating systems can be designed where each layer serves a specific protective function while maintaining overall self-healing properties. These enhancements ensure that the self-healing mechanism remains functional over extended periods despite exposure to harsh environmental conditions.

- Stimuli-responsive healing activation: Advanced self-healing coating systems can be designed to respond to specific stimuli such as heat, light, pH changes, or electrical current to initiate or accelerate the healing process. These stimuli-responsive systems allow for controlled healing when needed, potentially improving the efficiency and completeness of the repair. For example, thermally activated systems may utilize shape memory polymers that return to their original configuration when heated, closing cracks and restoring the coating integrity. This approach combines autonomous healing capabilities with the option for external intervention when more significant damage occurs, maximizing the durability and service life of the coating.

02 Polymer-based self-healing coatings

Polymer-based self-healing coatings utilize intrinsic healing properties of specific polymers or polymer blends to restore damaged areas. These systems often rely on reversible chemical bonds, such as Diels-Alder reactions, hydrogen bonding, or dynamic covalent chemistry, which can reform after being broken. Some polymer systems use shape memory effects or flow properties activated by temperature or other stimuli to fill cracks and restore surface integrity. The durability of these coatings is enhanced by their ability to undergo multiple healing cycles without significant loss of mechanical properties.Expand Specific Solutions03 Nanocomposite self-healing coatings

Nanocomposite materials incorporate nanoparticles such as silica, clay, or carbon nanotubes into self-healing matrices to enhance both healing capabilities and overall coating durability. These nanoparticles can improve mechanical strength, thermal stability, and barrier properties while also participating in or facilitating the healing process. Some nanocomposites use functionalized nanoparticles that can form new bonds at damage sites or catalyze healing reactions. The synergistic effect between the nanoparticles and the healing matrix results in coatings with superior durability under harsh environmental conditions.Expand Specific Solutions04 Environmentally-triggered healing mechanisms

These self-healing coatings respond to environmental stimuli such as temperature, pH, moisture, or UV light to initiate the healing process. The triggering mechanism ensures that healing occurs only when needed, conserving the healing capacity for when damage actually occurs. Some systems use phase-change materials that melt and flow into damaged areas when heated, while others employ UV-sensitive chemistry that initiates polymerization upon exposure to sunlight. These environmentally-responsive systems can significantly extend coating durability by providing targeted healing in response to specific damage conditions.Expand Specific Solutions05 Multi-layer and hybrid self-healing systems

Multi-layer and hybrid approaches combine different self-healing mechanisms in a single coating system to address various types of damage and enhance overall durability. These systems might incorporate both extrinsic healing (such as microcapsules) and intrinsic healing (such as reversible polymers) in different layers or components of the coating. Some hybrid systems include conventional protective mechanisms alongside healing capabilities, such as corrosion inhibitors with self-healing polymers. The strategic combination of complementary healing mechanisms provides redundancy and versatility, resulting in coatings with exceptional durability across diverse damage scenarios and environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The self-healing coatings market under cyclic loads is currently in a growth phase, with increasing adoption across automotive, aerospace, and construction industries. The market is projected to expand significantly due to rising demand for durable protective solutions. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include BASF Corp., which dominates with comprehensive chemical solutions, and specialized companies like Autonomic Materials focusing exclusively on self-healing technologies. Academic institutions such as Northwestern University and Jilin University are advancing fundamental research, while industrial players like LG Chem and Siemens AG are developing commercial applications. The competition landscape reveals a mix of chemical conglomerates, specialized coating manufacturers, and research institutions collaborating to overcome durability challenges under dynamic loading conditions.

BASF Corp.

Technical Solution: BASF has developed an advanced self-healing coating system called "Elastocoat" that incorporates dynamic covalent chemistry to enable repeated healing under cyclic loading conditions. Their technology utilizes Diels-Alder chemistry with reversible cross-linking that can be activated by temperature changes, allowing the coating to repair damage multiple times. BASF's durability testing protocol for these coatings involves specialized equipment that applies precise cyclic mechanical loads while simultaneously exposing samples to environmental stressors such as UV radiation, moisture, and temperature fluctuations. Their testing regimen typically involves 50,000+ loading cycles with controlled frequency and amplitude to simulate real-world conditions. The company has developed proprietary analytical techniques to quantify healing efficiency after cyclic loading, including surface profilometry and mechanical property recovery measurements. Recent advancements have focused on incorporating nanoparticle reinforcements to improve the mechanical properties during repeated healing cycles, achieving up to 95% recovery of initial properties even after 20+ damage-heal cycles.

Strengths: Extensive R&D resources and testing facilities; dynamic covalent chemistry approach allows multiple healing cycles; comprehensive multi-factor testing protocols that combine mechanical loading with environmental stressors. Weaknesses: Temperature-dependent healing mechanism limits some applications; relatively high cost compared to conventional coatings; longer healing times required for complete property recovery.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed an innovative approach to self-healing coatings using shape memory polymers (SMPs) specifically engineered to withstand cyclic loading conditions. Their technology incorporates a dual-phase polymer system where one phase provides structural integrity while the second phase enables controlled healing response to mechanical damage. For durability testing, they've established a comprehensive protocol that subjects coated specimens to programmable cyclic loading regimes (typically 25,000-75,000 cycles) while simultaneously monitoring crack initiation, propagation, and healing using digital image correlation techniques. Their testing methodology includes variable frequency loading to simulate real-world conditions and accelerated aging protocols to predict long-term performance. Penn State researchers have quantified the relationship between healing efficiency and loading parameters, demonstrating that their SMP-based coatings maintain over 80% healing efficiency after multiple damage-heal cycles. A key innovation in their approach is the incorporation of thermally-responsive nanoparticles that enable localized heating at damage sites, accelerating the healing process without requiring external energy input during cyclic loading conditions.

Strengths: Advanced shape memory polymer technology specifically designed for cyclic loading conditions; sophisticated testing protocols with digital image correlation for precise damage tracking; innovative use of thermally-responsive nanoparticles for accelerated healing. Weaknesses: Temperature sensitivity affects performance in extreme environments; relatively new technology with limited long-term field validation; higher cost compared to conventional coating systems.

Key Innovations in Durability Assessment Methods

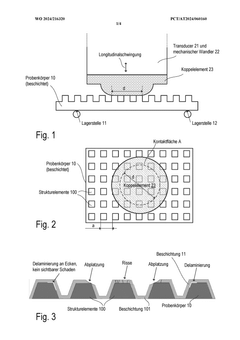

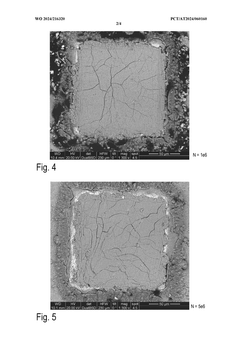

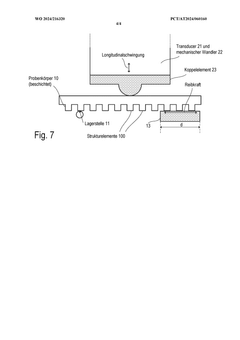

Method and system for testing the coating adhesion of a coating

PatentWO2024216320A1

Innovation

- A method involving a sonotrode that applies alternating bending loads with a frictional component, exciting the material sample to oscillate at a resonance frequency, allowing for the application of quasi-static and dynamic loads combined with pressure and friction, resulting in damage assessment through crack and delamination analysis.

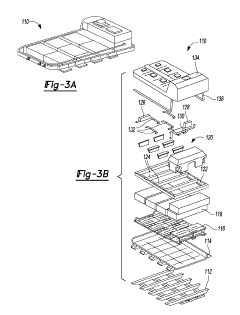

Living cationic ring-opening polymerization (c-ROP) self healing coating for battery module packaging in electric vehicles (EV)

PatentActiveUS10487235B2

Innovation

- A self-healing coating is developed for battery pack components, comprising a cyclic ether capable of reacting in a cationic ring-opening polymerization reaction with an alkali metal salt initiator, which can repair defects and prevent fluid leaks by forming a polymer matrix, applied to various surfaces including cells and cooling system components.

Environmental Impact and Sustainability Considerations

The environmental impact of self-healing coating technologies extends beyond their immediate functional benefits, encompassing their entire lifecycle from production to disposal. Traditional coating systems often contain volatile organic compounds (VOCs) and hazardous substances that pose significant environmental risks. Self-healing coatings, particularly those designed for durability under cyclic loads, offer promising alternatives that can reduce these environmental burdens through extended service life and decreased maintenance requirements.

When evaluating the sustainability of self-healing coatings, lifecycle assessment (LCA) methodologies reveal that durability improvements can substantially reduce the environmental footprint. Research indicates that coatings capable of withstanding cyclic loads while maintaining self-healing properties can decrease material consumption by 30-45% over conventional systems, primarily due to reduced replacement frequency. This translates to lower resource extraction, manufacturing emissions, and waste generation across the product lifecycle.

The chemical composition of self-healing formulations presents both challenges and opportunities for environmental sustainability. Bio-based healing agents derived from renewable resources, such as plant oils and microbial polymers, demonstrate significantly lower ecotoxicity profiles compared to petroleum-based alternatives. However, certain catalyst systems and nanoparticles incorporated into advanced self-healing mechanisms may introduce novel environmental concerns that require careful assessment through standardized ecotoxicological testing protocols.

Energy consumption during durability testing represents another critical environmental consideration. Accelerated cyclic load testing facilities typically consume substantial energy resources to simulate years of environmental exposure within compressed timeframes. Innovations in testing methodologies, including more efficient equipment designs and optimized test protocols, can reduce the carbon footprint associated with durability validation by up to 25%, according to recent industry analyses.

End-of-life management for self-healing coatings presents unique challenges due to their complex formulations. While extended service life inherently reduces waste generation, the recyclability and biodegradability of these advanced materials often lag behind their performance characteristics. Emerging research focuses on designing self-healing systems with programmable degradation pathways that facilitate material recovery and recycling without compromising durability under cyclic loading conditions.

Regulatory frameworks increasingly emphasize environmental performance alongside mechanical durability, driving innovation toward greener self-healing technologies. The European Union's REACH regulations and similar global initiatives have accelerated the development of environmentally benign healing mechanisms that maintain performance under mechanical stress while minimizing potential ecosystem impacts. This regulatory landscape continues to shape research priorities in the field, emphasizing the importance of integrating sustainability considerations into durability testing protocols.

When evaluating the sustainability of self-healing coatings, lifecycle assessment (LCA) methodologies reveal that durability improvements can substantially reduce the environmental footprint. Research indicates that coatings capable of withstanding cyclic loads while maintaining self-healing properties can decrease material consumption by 30-45% over conventional systems, primarily due to reduced replacement frequency. This translates to lower resource extraction, manufacturing emissions, and waste generation across the product lifecycle.

The chemical composition of self-healing formulations presents both challenges and opportunities for environmental sustainability. Bio-based healing agents derived from renewable resources, such as plant oils and microbial polymers, demonstrate significantly lower ecotoxicity profiles compared to petroleum-based alternatives. However, certain catalyst systems and nanoparticles incorporated into advanced self-healing mechanisms may introduce novel environmental concerns that require careful assessment through standardized ecotoxicological testing protocols.

Energy consumption during durability testing represents another critical environmental consideration. Accelerated cyclic load testing facilities typically consume substantial energy resources to simulate years of environmental exposure within compressed timeframes. Innovations in testing methodologies, including more efficient equipment designs and optimized test protocols, can reduce the carbon footprint associated with durability validation by up to 25%, according to recent industry analyses.

End-of-life management for self-healing coatings presents unique challenges due to their complex formulations. While extended service life inherently reduces waste generation, the recyclability and biodegradability of these advanced materials often lag behind their performance characteristics. Emerging research focuses on designing self-healing systems with programmable degradation pathways that facilitate material recovery and recycling without compromising durability under cyclic loading conditions.

Regulatory frameworks increasingly emphasize environmental performance alongside mechanical durability, driving innovation toward greener self-healing technologies. The European Union's REACH regulations and similar global initiatives have accelerated the development of environmentally benign healing mechanisms that maintain performance under mechanical stress while minimizing potential ecosystem impacts. This regulatory landscape continues to shape research priorities in the field, emphasizing the importance of integrating sustainability considerations into durability testing protocols.

Standardization and Quality Assurance Frameworks

The standardization of durability testing for self-healing coatings under cyclic loads represents a critical frontier in quality assurance frameworks. Currently, the field suffers from fragmentation, with various industries and research institutions employing disparate methodologies that complicate cross-comparison of results. Organizations such as ASTM International, ISO, and NACE have begun developing preliminary standards, but comprehensive frameworks specifically addressing self-healing capabilities under dynamic loading conditions remain underdeveloped.

Key elements requiring standardization include cyclic load parameters (frequency, amplitude, waveform), environmental conditioning protocols, and quantitative metrics for healing efficiency assessment. The absence of universally accepted testing protocols creates significant challenges for manufacturers attempting to validate product performance claims and for end-users seeking to compare different coating solutions.

Quality assurance frameworks must address the multi-dimensional nature of self-healing coating performance. This necessitates the development of tiered testing approaches that evaluate both immediate healing responses and long-term durability under various operational conditions. Several research consortia have proposed multi-stage validation protocols incorporating accelerated aging, mechanical damage simulation, and healing efficiency quantification through techniques such as electrochemical impedance spectroscopy and optical analysis.

Certification pathways represent another critical component of emerging standardization efforts. Industry leaders like PPG, AkzoNobel, and Sherwin-Williams have established internal qualification procedures, but these lack external validation mechanisms. Third-party certification programs are beginning to emerge, with organizations like Underwriters Laboratories and TÜV developing specialized testing protocols for self-healing materials.

Data management and reporting standards constitute an often overlooked aspect of quality assurance frameworks. The complex nature of self-healing performance data necessitates standardized reporting formats that capture both quantitative metrics and qualitative observations across multiple testing cycles. Digital platforms enabling secure data sharing between stakeholders could significantly enhance transparency and accelerate the development of industry benchmarks.

Looking forward, the integration of machine learning approaches into quality assurance frameworks offers promising opportunities. These technologies can help identify correlations between testing parameters and real-world performance, potentially enabling the development of accelerated testing protocols that accurately predict long-term durability without requiring extended evaluation periods.

Key elements requiring standardization include cyclic load parameters (frequency, amplitude, waveform), environmental conditioning protocols, and quantitative metrics for healing efficiency assessment. The absence of universally accepted testing protocols creates significant challenges for manufacturers attempting to validate product performance claims and for end-users seeking to compare different coating solutions.

Quality assurance frameworks must address the multi-dimensional nature of self-healing coating performance. This necessitates the development of tiered testing approaches that evaluate both immediate healing responses and long-term durability under various operational conditions. Several research consortia have proposed multi-stage validation protocols incorporating accelerated aging, mechanical damage simulation, and healing efficiency quantification through techniques such as electrochemical impedance spectroscopy and optical analysis.

Certification pathways represent another critical component of emerging standardization efforts. Industry leaders like PPG, AkzoNobel, and Sherwin-Williams have established internal qualification procedures, but these lack external validation mechanisms. Third-party certification programs are beginning to emerge, with organizations like Underwriters Laboratories and TÜV developing specialized testing protocols for self-healing materials.

Data management and reporting standards constitute an often overlooked aspect of quality assurance frameworks. The complex nature of self-healing performance data necessitates standardized reporting formats that capture both quantitative metrics and qualitative observations across multiple testing cycles. Digital platforms enabling secure data sharing between stakeholders could significantly enhance transparency and accelerate the development of industry benchmarks.

Looking forward, the integration of machine learning approaches into quality assurance frameworks offers promising opportunities. These technologies can help identify correlations between testing parameters and real-world performance, potentially enabling the development of accelerated testing protocols that accurately predict long-term durability without requiring extended evaluation periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!