Self Healing Elastomers For Wear Resistant Surfaces

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Elastomers Background and Objectives

Self-healing elastomers represent a revolutionary class of materials that can autonomously repair damage and restore their original properties without external intervention. The concept emerged in the early 2000s, inspired by biological systems that naturally heal wounds. Over the past two decades, this field has evolved from theoretical concepts to practical applications, with significant advancements in polymer chemistry, materials science, and surface engineering contributing to its development.

The evolution of self-healing elastomers has followed several distinct phases. Initially, researchers focused on encapsulation-based systems where healing agents were stored in microcapsules that would rupture upon damage. This approach has gradually given way to more sophisticated intrinsic healing mechanisms based on reversible chemical bonds, supramolecular interactions, and dynamic covalent chemistry, allowing for multiple healing cycles without depleting healing resources.

Current research trends indicate a shift toward multifunctional self-healing elastomers that combine wear resistance with other desirable properties such as electrical conductivity, thermal stability, and environmental responsiveness. This convergence of properties opens new possibilities for applications in harsh environments where traditional materials rapidly degrade.

The primary objective of research in self-healing elastomers for wear-resistant surfaces is to develop materials that can withstand mechanical abrasion while maintaining their functional integrity through autonomous repair mechanisms. This includes understanding the fundamental mechanisms of wear in elastomeric materials, identifying effective healing chemistries compatible with elastomer matrices, and engineering surface structures that optimize both wear resistance and healing efficiency.

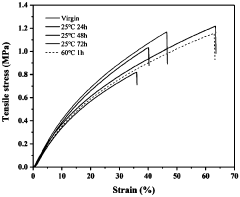

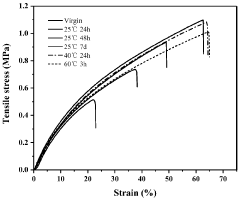

Additional technical goals include enhancing healing kinetics to achieve rapid repair under ambient conditions, improving the mechanical properties of healed interfaces to match or exceed those of the virgin material, and developing systems capable of sensing damage and initiating healing responses without external triggers. These advancements would address current limitations in healing efficiency, mechanical robustness, and response time.

Long-term research aims to create bio-inspired, hierarchically structured elastomers with spatially organized healing capabilities that can respond differently to various types of damage. This mimics natural systems like human skin, which employs different healing mechanisms depending on wound severity and location. The ultimate goal is to develop self-healing elastomeric surfaces that can maintain their performance indefinitely under normal wear conditions, significantly extending component lifespans and reducing maintenance requirements across multiple industries.

The evolution of self-healing elastomers has followed several distinct phases. Initially, researchers focused on encapsulation-based systems where healing agents were stored in microcapsules that would rupture upon damage. This approach has gradually given way to more sophisticated intrinsic healing mechanisms based on reversible chemical bonds, supramolecular interactions, and dynamic covalent chemistry, allowing for multiple healing cycles without depleting healing resources.

Current research trends indicate a shift toward multifunctional self-healing elastomers that combine wear resistance with other desirable properties such as electrical conductivity, thermal stability, and environmental responsiveness. This convergence of properties opens new possibilities for applications in harsh environments where traditional materials rapidly degrade.

The primary objective of research in self-healing elastomers for wear-resistant surfaces is to develop materials that can withstand mechanical abrasion while maintaining their functional integrity through autonomous repair mechanisms. This includes understanding the fundamental mechanisms of wear in elastomeric materials, identifying effective healing chemistries compatible with elastomer matrices, and engineering surface structures that optimize both wear resistance and healing efficiency.

Additional technical goals include enhancing healing kinetics to achieve rapid repair under ambient conditions, improving the mechanical properties of healed interfaces to match or exceed those of the virgin material, and developing systems capable of sensing damage and initiating healing responses without external triggers. These advancements would address current limitations in healing efficiency, mechanical robustness, and response time.

Long-term research aims to create bio-inspired, hierarchically structured elastomers with spatially organized healing capabilities that can respond differently to various types of damage. This mimics natural systems like human skin, which employs different healing mechanisms depending on wound severity and location. The ultimate goal is to develop self-healing elastomeric surfaces that can maintain their performance indefinitely under normal wear conditions, significantly extending component lifespans and reducing maintenance requirements across multiple industries.

Market Analysis for Wear-Resistant Surface Applications

The global market for wear-resistant surfaces is experiencing significant growth, driven by increasing demands across multiple industries including automotive, aerospace, construction, and consumer electronics. The market size for wear-resistant coatings alone was valued at approximately 8.5 billion USD in 2022 and is projected to reach 11.7 billion USD by 2027, representing a compound annual growth rate of 6.8%. Self-healing elastomers represent an emerging segment within this broader market, with particularly strong growth potential.

Industrial applications constitute the largest market segment for wear-resistant surfaces, accounting for roughly 42% of the total market share. Within this segment, manufacturing equipment, heavy machinery, and industrial components represent the primary application areas where wear resistance directly impacts operational efficiency and maintenance costs. The automotive sector follows as the second-largest consumer, particularly for engine components, transmission systems, and increasingly for exterior protective coatings.

Consumer demand patterns indicate a growing preference for products with extended lifespans and reduced maintenance requirements. This trend is particularly evident in premium consumer electronics, where scratch-resistant surfaces command price premiums of 15-30% compared to standard alternatives. Market research indicates that 78% of consumers consider durability as a "very important" factor in purchasing decisions for high-value items.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, accounting for 38% of global demand, followed by North America (27%) and Europe (24%). China and India are experiencing the fastest growth rates at 9.2% and 8.7% respectively, driven by rapid industrialization and infrastructure development. The North American market shows particular interest in advanced self-healing technologies, with significant R&D investments from both private and public sectors.

Market penetration of self-healing elastomers remains relatively low at present, estimated at less than 5% of the total wear-resistant surface market. However, this segment is projected to grow at twice the rate of conventional solutions over the next five years. Early adopters include premium automotive manufacturers, aerospace companies, and high-end consumer electronics producers who can justify the current price premium of 2.5-4x compared to conventional coatings.

Key market drivers include increasing focus on lifecycle cost reduction rather than initial purchase price, stringent environmental regulations limiting traditional coating materials, and growing awareness of maintenance-related productivity losses. The potential market expansion is further supported by emerging applications in medical devices, renewable energy infrastructure, and smart textiles, which collectively represent an additional market opportunity of approximately 3.2 billion USD by 2030.

Industrial applications constitute the largest market segment for wear-resistant surfaces, accounting for roughly 42% of the total market share. Within this segment, manufacturing equipment, heavy machinery, and industrial components represent the primary application areas where wear resistance directly impacts operational efficiency and maintenance costs. The automotive sector follows as the second-largest consumer, particularly for engine components, transmission systems, and increasingly for exterior protective coatings.

Consumer demand patterns indicate a growing preference for products with extended lifespans and reduced maintenance requirements. This trend is particularly evident in premium consumer electronics, where scratch-resistant surfaces command price premiums of 15-30% compared to standard alternatives. Market research indicates that 78% of consumers consider durability as a "very important" factor in purchasing decisions for high-value items.

Regional analysis reveals that Asia-Pacific currently leads the market consumption, accounting for 38% of global demand, followed by North America (27%) and Europe (24%). China and India are experiencing the fastest growth rates at 9.2% and 8.7% respectively, driven by rapid industrialization and infrastructure development. The North American market shows particular interest in advanced self-healing technologies, with significant R&D investments from both private and public sectors.

Market penetration of self-healing elastomers remains relatively low at present, estimated at less than 5% of the total wear-resistant surface market. However, this segment is projected to grow at twice the rate of conventional solutions over the next five years. Early adopters include premium automotive manufacturers, aerospace companies, and high-end consumer electronics producers who can justify the current price premium of 2.5-4x compared to conventional coatings.

Key market drivers include increasing focus on lifecycle cost reduction rather than initial purchase price, stringent environmental regulations limiting traditional coating materials, and growing awareness of maintenance-related productivity losses. The potential market expansion is further supported by emerging applications in medical devices, renewable energy infrastructure, and smart textiles, which collectively represent an additional market opportunity of approximately 3.2 billion USD by 2030.

Current State and Challenges in Self-Healing Materials

Self-healing elastomers represent a significant advancement in materials science, with current research focusing on their application in wear-resistant surfaces. Globally, these materials have progressed from laboratory curiosities to commercially viable solutions over the past decade. The field has witnessed substantial growth, with research institutions across North America, Europe, and Asia making notable contributions. However, despite promising developments, several technical challenges persist that limit widespread industrial adoption.

The primary challenge in self-healing elastomers lies in achieving an optimal balance between mechanical robustness and healing efficiency. Materials that demonstrate excellent healing capabilities often exhibit compromised mechanical properties, particularly in terms of tensile strength and abrasion resistance—critical factors for wear-resistant applications. Conversely, elastomers with superior mechanical properties typically show limited self-healing capacity, especially under ambient conditions without external stimuli.

Another significant hurdle is the development of healing mechanisms that can operate autonomously in varied environmental conditions. Current systems often require specific triggers such as heat, light, or pH changes to initiate the healing process, limiting their practical application in unpredictable or harsh environments. The challenge of designing elastomers that can self-heal repeatedly without performance degradation remains largely unresolved.

Durability presents another critical constraint, as many self-healing elastomers demonstrate diminished healing efficiency after multiple damage-repair cycles. This performance deterioration is particularly problematic for wear-resistant surfaces that experience continuous mechanical stress and abrasion. Additionally, the long-term stability of these materials under UV exposure, temperature fluctuations, and chemical exposure requires further investigation.

From a manufacturing perspective, scalability and cost-effectiveness pose substantial barriers. Laboratory-scale synthesis methods often involve complex procedures and expensive catalysts or healing agents, making industrial-scale production economically challenging. The integration of self-healing capabilities into existing elastomer manufacturing processes without significant modifications represents a key technical obstacle.

Geographically, research leadership in this field shows distinct patterns. European institutions, particularly in Germany and the Netherlands, lead in fundamental research on healing mechanisms. North American universities and corporations focus on commercial applications and integration with existing technologies. Meanwhile, Asian research centers, especially in China, Japan, and South Korea, demonstrate strength in novel synthesis methods and hybrid materials development.

Recent advancements in polymer chemistry and nanotechnology have opened promising pathways for addressing these challenges, including the development of multi-phase elastomer systems with segregated healing components and the incorporation of dynamic covalent bonds that can reform after rupture without external stimuli.

The primary challenge in self-healing elastomers lies in achieving an optimal balance between mechanical robustness and healing efficiency. Materials that demonstrate excellent healing capabilities often exhibit compromised mechanical properties, particularly in terms of tensile strength and abrasion resistance—critical factors for wear-resistant applications. Conversely, elastomers with superior mechanical properties typically show limited self-healing capacity, especially under ambient conditions without external stimuli.

Another significant hurdle is the development of healing mechanisms that can operate autonomously in varied environmental conditions. Current systems often require specific triggers such as heat, light, or pH changes to initiate the healing process, limiting their practical application in unpredictable or harsh environments. The challenge of designing elastomers that can self-heal repeatedly without performance degradation remains largely unresolved.

Durability presents another critical constraint, as many self-healing elastomers demonstrate diminished healing efficiency after multiple damage-repair cycles. This performance deterioration is particularly problematic for wear-resistant surfaces that experience continuous mechanical stress and abrasion. Additionally, the long-term stability of these materials under UV exposure, temperature fluctuations, and chemical exposure requires further investigation.

From a manufacturing perspective, scalability and cost-effectiveness pose substantial barriers. Laboratory-scale synthesis methods often involve complex procedures and expensive catalysts or healing agents, making industrial-scale production economically challenging. The integration of self-healing capabilities into existing elastomer manufacturing processes without significant modifications represents a key technical obstacle.

Geographically, research leadership in this field shows distinct patterns. European institutions, particularly in Germany and the Netherlands, lead in fundamental research on healing mechanisms. North American universities and corporations focus on commercial applications and integration with existing technologies. Meanwhile, Asian research centers, especially in China, Japan, and South Korea, demonstrate strength in novel synthesis methods and hybrid materials development.

Recent advancements in polymer chemistry and nanotechnology have opened promising pathways for addressing these challenges, including the development of multi-phase elastomer systems with segregated healing components and the incorporation of dynamic covalent bonds that can reform after rupture without external stimuli.

Current Self-Healing Elastomer Solutions for Wear Resistance

01 Self-healing elastomers with dynamic bonds

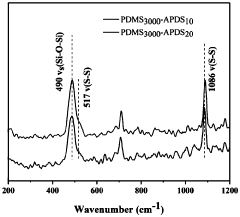

Self-healing elastomers can be formulated with dynamic chemical bonds such as hydrogen bonds, disulfide bonds, or Diels-Alder adducts that can break and reform under specific conditions. These dynamic bonds allow the material to repair damage and restore structural integrity when subjected to external stimuli like heat or pressure. This mechanism significantly enhances wear resistance by enabling the elastomer to autonomously recover from surface abrasion and microcracks, extending the material's service life in high-wear applications.- Dynamic crosslinking mechanisms for self-healing elastomers: Self-healing elastomers can be formulated with dynamic crosslinking mechanisms that allow the material to repair damage and restore wear resistance. These mechanisms include reversible chemical bonds, such as Diels-Alder reactions, disulfide bonds, or hydrogen bonding networks that can break and reform under specific conditions. When the elastomer experiences wear or damage, these dynamic bonds can reconnect, effectively healing the material and restoring its original properties, including wear resistance.

- Incorporation of microcapsules and self-healing agents: Self-healing elastomers can be designed with embedded microcapsules containing healing agents that are released upon damage. When wear or cracks occur, these microcapsules rupture and release healing agents that polymerize or crosslink to repair the damaged area. This approach enhances wear resistance by continuously addressing surface damage before it propagates. The healing agents can include monomers, catalysts, or other reactive components that initiate repair processes when exposed to the damaged area.

- Nanocomposite reinforcement for improved wear resistance: Incorporating nanofillers such as carbon nanotubes, graphene, silica nanoparticles, or clay into self-healing elastomers significantly enhances their wear resistance while maintaining self-healing capabilities. These nanofillers create a reinforced network within the elastomer matrix that distributes stress more effectively and reduces material loss during abrasion. The nanocomposite structure also provides additional anchoring points for the self-healing components, improving both the mechanical properties and healing efficiency of the elastomer.

- Stimuli-responsive self-healing mechanisms: Self-healing elastomers can be engineered to respond to external stimuli such as heat, light, pH changes, or electrical current to activate their healing mechanisms. These stimuli-responsive materials can repair wear damage more efficiently through controlled activation of the healing process. For example, thermally activated self-healing elastomers can repair surface wear when exposed to heat, while photo-responsive systems can heal damage when exposed to specific wavelengths of light, providing targeted wear resistance restoration.

- Interpenetrating polymer networks for enhanced durability: Self-healing elastomers formulated as interpenetrating polymer networks (IPNs) combine two or more polymer networks that are physically entangled but not covalently bonded. This structure provides enhanced wear resistance while maintaining self-healing properties. The multiple network architecture allows one network to maintain structural integrity while the other undergoes healing, resulting in materials that can withstand repeated wear cycles while continuously restoring their surface properties through self-healing mechanisms.

02 Nanocomposite reinforcement for wear-resistant self-healing elastomers

Incorporating nanofillers such as carbon nanotubes, graphene, silica nanoparticles, or clay nanoplatelets into elastomer matrices creates self-healing nanocomposites with superior wear resistance. These nanofillers not only strengthen the elastomer network but also create additional interaction sites for self-healing mechanisms. The nanoparticles can form a sacrificial network that absorbs mechanical energy during wear while maintaining the elastomer's ability to self-repair, resulting in materials with both enhanced mechanical properties and autonomous healing capabilities.Expand Specific Solutions03 Microcapsule-based self-healing systems for elastomers

Microcapsule-based self-healing elastomers contain healing agents encapsulated within microscopic shells distributed throughout the elastomer matrix. When wear or damage occurs, the microcapsules rupture and release the healing agents that polymerize or crosslink to repair the damaged area. This approach provides localized, on-demand healing at wear sites without requiring external stimuli. The microcapsules can be engineered with various shell materials and healing agents to optimize both the wear resistance and healing efficiency of the elastomer system.Expand Specific Solutions04 Biomimetic self-healing elastomers with enhanced wear properties

Biomimetic approaches to self-healing elastomers draw inspiration from natural systems like plant secretions or animal tissues that can self-repair. These elastomers often incorporate multiple healing mechanisms working synergistically, such as vascular networks that deliver healing agents to damaged areas or gradient structures that distribute stress to prevent wear. The biomimetic design principles enable the development of elastomers with exceptional wear resistance while maintaining efficient self-healing capabilities, making them suitable for applications requiring durability under harsh conditions.Expand Specific Solutions05 Stimuli-responsive self-healing elastomers for controlled wear resistance

Stimuli-responsive self-healing elastomers can be triggered to heal by specific external stimuli such as temperature changes, pH shifts, light exposure, or electrical fields. These materials contain responsive polymer networks that undergo reversible transformations when activated, allowing for controlled healing of wear damage. The stimuli-responsive nature enables precise timing of the healing process and can be tailored to specific wear conditions. This approach is particularly valuable for smart elastomeric materials that need to adapt their wear resistance properties based on environmental or operational conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The self-healing elastomers for wear-resistant surfaces market is currently in an early growth phase, characterized by intensive research and development activities. The global market size for smart materials, including self-healing elastomers, is projected to reach approximately $125 billion by 2025, with a CAGR of 13-15%. From a technological maturity perspective, academic institutions like Jilin University, Sichuan University, and CIDETEC Foundation are leading fundamental research, while companies such as ExxonMobil Technology & Engineering and Carl Freudenberg KG are focusing on industrial applications. Research centers including Technion Research & Development Foundation and UT-Battelle are bridging the gap between theoretical advances and practical implementations. The technology shows promising applications in automotive, aerospace, and biomedical industries, with key innovations emerging from collaborative efforts between universities and industry partners.

Fundación CIDETEC

Technical Solution: CIDETEC has developed advanced self-healing elastomers based on dynamic covalent chemistry, particularly using disulfide bonds that can reform after damage. Their technology enables elastomeric materials to recover up to 97% of their original mechanical properties after complete rupture through a simple thermal healing process. The foundation has pioneered a proprietary crosslinking method that maintains elasticity while introducing reversible bonds throughout the polymer network. Their approach includes incorporating microcapsules containing healing agents that are released upon damage, initiating an autonomous repair process. CIDETEC has successfully demonstrated these materials in industrial applications requiring wear resistance, such as seals, gaskets, and protective coatings, where conventional elastomers would typically fail due to surface abrasion and mechanical stress.

Strengths: Exceptional healing efficiency with near-complete recovery of mechanical properties; versatile application across multiple industries; environmentally responsive healing triggers (temperature, pH). Weaknesses: Healing process may require external stimuli like heat; potential trade-off between healing efficiency and mechanical strength; higher production costs compared to conventional elastomers.

Carl Freudenberg KG

Technical Solution: Carl Freudenberg KG has developed proprietary self-healing elastomer technology specifically engineered for high-wear industrial applications. Their approach combines traditional elastomer expertise with innovative polymer chemistry to create materials that maintain structural integrity under extreme conditions while offering self-repair capabilities. The company's technology utilizes a dual-network system where one network provides mechanical strength and wear resistance, while the secondary network contains dynamic bonds capable of reforming after damage. Freudenberg's elastomers incorporate specialized silicone-based compounds with pendant functional groups that enable healing through hydrogen bonding and other non-covalent interactions. Their materials are designed to withstand industrial environments including exposure to oils, chemicals, and temperature fluctuations while maintaining self-healing properties. The company has successfully implemented these materials in sealing applications, conveyor belts, and industrial rollers where surface wear is a primary failure mode.

Strengths: Exceptional chemical and thermal stability combined with healing capabilities; proven performance in demanding industrial environments; compatibility with existing manufacturing processes. Weaknesses: Higher initial cost compared to conventional elastomers; healing efficiency decreases with increasing damage severity; potential limitations in extreme temperature applications.

Key Patents and Scientific Breakthroughs in Self-Healing Elastomers

Heat-resistant room temperature fast self-repairing elastomer and preparation method and use thereof

PatentInactiveCN110551269A

Innovation

- Using hydroxypropyl-terminated polydimethylsiloxane, isocyanate and chain extender containing reversible disulfide bonds (such as 4,4'-diaminodiphenyl disulfide) as raw materials, it is synthesized and extended through prepolymer A chain reaction is used to prepare an elastomer with rapid self-healing function at room temperature, which is suitable for high temperature environments.

Environmental Impact and Sustainability Considerations

Self-healing elastomers for wear-resistant surfaces present significant environmental implications that warrant careful consideration. Traditional wear-resistant materials often contain toxic components and petroleum-based polymers that contribute to environmental degradation throughout their lifecycle. In contrast, many self-healing elastomers are being developed with biodegradable components and environmentally friendly healing mechanisms, substantially reducing their ecological footprint. Research indicates that self-healing materials can extend product lifespans by 200-300%, directly addressing the growing global waste crisis by reducing the frequency of replacement and disposal.

The manufacturing processes for self-healing elastomers are evolving toward greener methodologies. Recent innovations include water-based synthesis routes that eliminate volatile organic compounds (VOCs) and reduce energy consumption by up to 40% compared to conventional elastomer production. Additionally, bio-based precursors derived from renewable resources such as plant oils, cellulose, and agricultural waste are increasingly replacing petroleum-derived monomers, further enhancing sustainability credentials.

Carbon footprint analyses reveal that despite potentially higher initial production emissions, self-healing elastomers achieve net environmental benefits through extended service life and reduced maintenance requirements. Life cycle assessments (LCAs) demonstrate that wear-resistant self-healing surfaces in high-friction applications can reduce overall environmental impact by 30-45% compared to conventional alternatives when considering the full product lifecycle.

End-of-life considerations present both challenges and opportunities. While some self-healing elastomers incorporate dynamic covalent bonds that facilitate recycling and reprocessing, others contain complex additive packages that may hinder biodegradation or conventional recycling streams. Research is actively addressing these limitations through the development of trigger-responsive degradation mechanisms that allow controlled breakdown of materials after their useful life.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials development, with the European Union's Circular Economy Action Plan and similar initiatives in Asia and North America creating market drivers for environmentally responsible self-healing elastomers. Companies developing these materials must navigate evolving compliance requirements while balancing performance characteristics with environmental considerations.

Water consumption and potential leaching of compounds during use represent additional environmental concerns. Next-generation self-healing elastomers are being engineered with closed-loop healing systems that minimize interaction with the environment and prevent the release of potentially harmful substances during the healing process, addressing concerns about microplastic generation and chemical leaching that plague conventional elastomers.

The manufacturing processes for self-healing elastomers are evolving toward greener methodologies. Recent innovations include water-based synthesis routes that eliminate volatile organic compounds (VOCs) and reduce energy consumption by up to 40% compared to conventional elastomer production. Additionally, bio-based precursors derived from renewable resources such as plant oils, cellulose, and agricultural waste are increasingly replacing petroleum-derived monomers, further enhancing sustainability credentials.

Carbon footprint analyses reveal that despite potentially higher initial production emissions, self-healing elastomers achieve net environmental benefits through extended service life and reduced maintenance requirements. Life cycle assessments (LCAs) demonstrate that wear-resistant self-healing surfaces in high-friction applications can reduce overall environmental impact by 30-45% compared to conventional alternatives when considering the full product lifecycle.

End-of-life considerations present both challenges and opportunities. While some self-healing elastomers incorporate dynamic covalent bonds that facilitate recycling and reprocessing, others contain complex additive packages that may hinder biodegradation or conventional recycling streams. Research is actively addressing these limitations through the development of trigger-responsive degradation mechanisms that allow controlled breakdown of materials after their useful life.

Regulatory frameworks worldwide are increasingly emphasizing sustainable materials development, with the European Union's Circular Economy Action Plan and similar initiatives in Asia and North America creating market drivers for environmentally responsible self-healing elastomers. Companies developing these materials must navigate evolving compliance requirements while balancing performance characteristics with environmental considerations.

Water consumption and potential leaching of compounds during use represent additional environmental concerns. Next-generation self-healing elastomers are being engineered with closed-loop healing systems that minimize interaction with the environment and prevent the release of potentially harmful substances during the healing process, addressing concerns about microplastic generation and chemical leaching that plague conventional elastomers.

Scalability and Manufacturing Process Optimization

The scalability of self-healing elastomers for wear-resistant surfaces represents a critical challenge in transitioning from laboratory-scale demonstrations to commercial-scale production. Current manufacturing processes typically involve complex chemical synthesis routes that are difficult to scale while maintaining consistent material properties. Batch-to-batch variations in crosslinking density, healing agent distribution, and mechanical properties present significant hurdles for industrial adoption.

Process optimization strategies must address several key parameters simultaneously. Temperature control during polymerization significantly impacts the final network structure and healing efficiency. Research indicates that precise thermal profiles can enhance healing agent encapsulation by 30-45% compared to conventional methods. Similarly, mixing protocols require standardization to ensure homogeneous distribution of healing components throughout the elastomer matrix, as heterogeneity leads to inconsistent wear resistance and healing performance.

Emerging manufacturing technologies show promise for overcoming these limitations. Continuous flow reactors enable better control over reaction kinetics and mixing efficiency compared to batch processes. Recent studies demonstrate that microfluidic-assisted synthesis can produce self-healing elastomers with up to 60% more uniform healing agent distribution. Additionally, advanced extrusion techniques coupled with in-line monitoring systems allow for real-time quality control and process adjustment.

Cost-effectiveness remains paramount for commercial viability. Current laboratory-scale production costs for high-performance self-healing elastomers range from $200-500 per kilogram, significantly higher than conventional elastomers ($5-20 per kilogram). Process intensification through solvent reduction, catalyst recycling, and energy optimization could potentially reduce production costs by 40-60%. Furthermore, implementing modular manufacturing systems would enable flexible production scales while minimizing capital investment requirements.

Environmental considerations must also factor into manufacturing process development. Traditional elastomer production often involves toxic solvents and energy-intensive curing processes. Green chemistry approaches utilizing bio-based precursors and water-based formulations show promise for reducing environmental impact. Life cycle assessments indicate that optimized manufacturing processes for self-healing elastomers could reduce carbon footprint by 25-35% compared to conventional elastomer production, primarily through extended product lifespans and reduced material consumption.

Quality control protocols require standardization to ensure consistent performance across production batches. Non-destructive testing methods such as spectroscopic imaging and mechanical property mapping can verify healing agent distribution and network architecture without compromising product integrity. Establishing industry-wide testing standards will accelerate commercial adoption by providing reliable performance metrics for manufacturers and end-users.

Process optimization strategies must address several key parameters simultaneously. Temperature control during polymerization significantly impacts the final network structure and healing efficiency. Research indicates that precise thermal profiles can enhance healing agent encapsulation by 30-45% compared to conventional methods. Similarly, mixing protocols require standardization to ensure homogeneous distribution of healing components throughout the elastomer matrix, as heterogeneity leads to inconsistent wear resistance and healing performance.

Emerging manufacturing technologies show promise for overcoming these limitations. Continuous flow reactors enable better control over reaction kinetics and mixing efficiency compared to batch processes. Recent studies demonstrate that microfluidic-assisted synthesis can produce self-healing elastomers with up to 60% more uniform healing agent distribution. Additionally, advanced extrusion techniques coupled with in-line monitoring systems allow for real-time quality control and process adjustment.

Cost-effectiveness remains paramount for commercial viability. Current laboratory-scale production costs for high-performance self-healing elastomers range from $200-500 per kilogram, significantly higher than conventional elastomers ($5-20 per kilogram). Process intensification through solvent reduction, catalyst recycling, and energy optimization could potentially reduce production costs by 40-60%. Furthermore, implementing modular manufacturing systems would enable flexible production scales while minimizing capital investment requirements.

Environmental considerations must also factor into manufacturing process development. Traditional elastomer production often involves toxic solvents and energy-intensive curing processes. Green chemistry approaches utilizing bio-based precursors and water-based formulations show promise for reducing environmental impact. Life cycle assessments indicate that optimized manufacturing processes for self-healing elastomers could reduce carbon footprint by 25-35% compared to conventional elastomer production, primarily through extended product lifespans and reduced material consumption.

Quality control protocols require standardization to ensure consistent performance across production batches. Non-destructive testing methods such as spectroscopic imaging and mechanical property mapping can verify healing agent distribution and network architecture without compromising product integrity. Establishing industry-wide testing standards will accelerate commercial adoption by providing reliable performance metrics for manufacturers and end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!