Comparative Study Of Extrinsic Versus Intrinsic Self Healing Approaches

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Materials Background and Objectives

Self-healing materials represent a revolutionary class of smart materials capable of repairing damage autonomously, extending their service life and reducing maintenance costs. The concept emerged in the early 2000s, inspired by biological systems that naturally repair wounds and fractures. Since then, the field has evolved significantly, with research expanding from simple crack-healing polymers to sophisticated multi-functional materials applicable across diverse industries including aerospace, automotive, construction, and biomedical engineering.

The evolution of self-healing materials has followed two distinct technological pathways: extrinsic and intrinsic approaches. Extrinsic self-healing relies on healing agents embedded within the material matrix that are released upon damage, while intrinsic self-healing leverages the inherent molecular or supramolecular interactions of the material itself to restore functionality. This technological dichotomy has shaped research directions and applications over the past two decades.

Recent technological trends indicate a growing interest in hybrid systems that combine both approaches to maximize healing efficiency and broaden application scope. Additionally, there is increasing focus on environmentally sustainable self-healing materials, responsive to external stimuli such as temperature, pH, or light, and integration with other smart material functionalities like shape memory or self-sensing capabilities.

The global market for self-healing materials is projected to grow at a CAGR of approximately 27% between 2021 and 2026, reflecting the technology's transition from laboratory curiosity to commercial viability. This growth is driven by increasing demand for durable materials with reduced maintenance requirements across multiple sectors.

The primary objectives of this comparative study are to systematically evaluate the fundamental mechanisms, performance metrics, and application domains of both extrinsic and intrinsic self-healing approaches. The study aims to identify the strengths, limitations, and complementarities of each approach, establish standardized assessment protocols for healing efficiency, and explore potential synergies through hybrid systems.

Furthermore, this research seeks to map the technology readiness levels of various self-healing strategies across different material classes, identify critical barriers to widespread commercial adoption, and forecast emerging research directions that could lead to breakthrough applications. By comprehensively analyzing these parallel technological pathways, this study will provide strategic insights for researchers, material scientists, and industry stakeholders to guide future development efforts in this rapidly evolving field.

The evolution of self-healing materials has followed two distinct technological pathways: extrinsic and intrinsic approaches. Extrinsic self-healing relies on healing agents embedded within the material matrix that are released upon damage, while intrinsic self-healing leverages the inherent molecular or supramolecular interactions of the material itself to restore functionality. This technological dichotomy has shaped research directions and applications over the past two decades.

Recent technological trends indicate a growing interest in hybrid systems that combine both approaches to maximize healing efficiency and broaden application scope. Additionally, there is increasing focus on environmentally sustainable self-healing materials, responsive to external stimuli such as temperature, pH, or light, and integration with other smart material functionalities like shape memory or self-sensing capabilities.

The global market for self-healing materials is projected to grow at a CAGR of approximately 27% between 2021 and 2026, reflecting the technology's transition from laboratory curiosity to commercial viability. This growth is driven by increasing demand for durable materials with reduced maintenance requirements across multiple sectors.

The primary objectives of this comparative study are to systematically evaluate the fundamental mechanisms, performance metrics, and application domains of both extrinsic and intrinsic self-healing approaches. The study aims to identify the strengths, limitations, and complementarities of each approach, establish standardized assessment protocols for healing efficiency, and explore potential synergies through hybrid systems.

Furthermore, this research seeks to map the technology readiness levels of various self-healing strategies across different material classes, identify critical barriers to widespread commercial adoption, and forecast emerging research directions that could lead to breakthrough applications. By comprehensively analyzing these parallel technological pathways, this study will provide strategic insights for researchers, material scientists, and industry stakeholders to guide future development efforts in this rapidly evolving field.

Market Analysis for Self-Healing Technologies

The self-healing materials market is experiencing significant growth, projected to reach $4.1 billion by 2025 with a compound annual growth rate of 27%. This expansion is driven by increasing demand across multiple sectors including construction, automotive, aerospace, and consumer electronics. Each industry seeks materials that can autonomously repair damage, extending product lifespans and reducing maintenance costs.

In the construction sector, self-healing concrete represents the largest market segment, addressing the critical issue of infrastructure deterioration. The automotive industry follows closely, implementing self-healing coatings and polymers to combat surface scratches and structural damage, thereby maintaining aesthetic appeal and functional integrity of vehicles.

Market analysis reveals distinct preferences between extrinsic and intrinsic healing approaches across different applications. Extrinsic systems, utilizing encapsulated healing agents, dominate in structural applications where specific healing chemistries are required. These systems currently hold approximately 60% of the commercial self-healing materials market due to their versatility and established manufacturing processes.

Intrinsic self-healing materials, which repair through inherent molecular mechanisms, are gaining traction in electronics and flexible devices, where seamless integration and repeated healing capabilities are essential. This segment is growing at 32% annually, outpacing the overall market as manufacturing techniques improve and costs decrease.

Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 35% annually, driven by rapid industrialization and infrastructure development in China and India.

Consumer willingness to pay premium prices for self-healing technologies varies significantly by sector. In high-value applications like aerospace, where maintenance costs are substantial, customers accept price premiums of 40-50%. In consumer electronics, the acceptable premium ranges from 15-25%, while construction applications typically tolerate 10-20% increases.

Market barriers include high initial development costs, scaling challenges, and regulatory uncertainties. The average R&D investment for commercializing a new self-healing technology exceeds $15 million, creating significant entry barriers for smaller companies. Consequently, strategic partnerships between material developers and end-product manufacturers have increased by 65% over the past three years.

Future market growth depends on addressing key technical challenges, particularly in developing systems that combine rapid healing response with mechanical robustness. As these challenges are overcome, the self-healing materials market is expected to expand into new applications including medical devices, renewable energy infrastructure, and smart textiles.

In the construction sector, self-healing concrete represents the largest market segment, addressing the critical issue of infrastructure deterioration. The automotive industry follows closely, implementing self-healing coatings and polymers to combat surface scratches and structural damage, thereby maintaining aesthetic appeal and functional integrity of vehicles.

Market analysis reveals distinct preferences between extrinsic and intrinsic healing approaches across different applications. Extrinsic systems, utilizing encapsulated healing agents, dominate in structural applications where specific healing chemistries are required. These systems currently hold approximately 60% of the commercial self-healing materials market due to their versatility and established manufacturing processes.

Intrinsic self-healing materials, which repair through inherent molecular mechanisms, are gaining traction in electronics and flexible devices, where seamless integration and repeated healing capabilities are essential. This segment is growing at 32% annually, outpacing the overall market as manufacturing techniques improve and costs decrease.

Regional analysis shows North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 35% annually, driven by rapid industrialization and infrastructure development in China and India.

Consumer willingness to pay premium prices for self-healing technologies varies significantly by sector. In high-value applications like aerospace, where maintenance costs are substantial, customers accept price premiums of 40-50%. In consumer electronics, the acceptable premium ranges from 15-25%, while construction applications typically tolerate 10-20% increases.

Market barriers include high initial development costs, scaling challenges, and regulatory uncertainties. The average R&D investment for commercializing a new self-healing technology exceeds $15 million, creating significant entry barriers for smaller companies. Consequently, strategic partnerships between material developers and end-product manufacturers have increased by 65% over the past three years.

Future market growth depends on addressing key technical challenges, particularly in developing systems that combine rapid healing response with mechanical robustness. As these challenges are overcome, the self-healing materials market is expected to expand into new applications including medical devices, renewable energy infrastructure, and smart textiles.

Current State and Challenges in Self-Healing Approaches

Self-healing materials represent a significant advancement in materials science, with research efforts divided between extrinsic and intrinsic approaches. Currently, extrinsic self-healing systems dominate commercial applications due to their established methodologies and scalable manufacturing processes. These systems typically employ microcapsules, vascular networks, or other container-based mechanisms to store and release healing agents when damage occurs. Major industrial players like Dow Chemical, 3M, and Henkel have successfully implemented extrinsic healing in coatings and adhesives, demonstrating the commercial viability of this approach.

Intrinsic self-healing materials, while less commercially prevalent, have shown remarkable progress in laboratory settings. These materials leverage reversible chemical bonds, supramolecular interactions, or dynamic covalent chemistry to achieve healing without external agents. Recent breakthroughs in vitrimers, Diels-Alder based polymers, and metal-ligand coordinated systems have significantly improved healing efficiencies and mechanical properties, narrowing the performance gap with traditional materials.

The geographical distribution of self-healing technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. Academic-industrial collaborations have accelerated in the past five years, particularly in automotive and aerospace sectors where durability requirements are stringent.

Despite impressive advances, several critical challenges persist across both approaches. For extrinsic systems, the primary limitations include finite healing capacity due to the depletion of healing agents, potential mechanical property degradation from container inclusions, and challenges in achieving uniform distribution of healing components throughout the material matrix. Additionally, shelf-life stability of reactive healing agents remains problematic for long-term applications.

Intrinsic systems face different obstacles, notably the trade-off between mechanical strength and healing efficiency. Materials with highly dynamic bonds that facilitate excellent healing often exhibit compromised mechanical properties under load. Furthermore, many intrinsic healing mechanisms require external stimuli such as heat or pressure, limiting their autonomous healing capabilities in ambient conditions. The healing kinetics of intrinsic systems also tend to be slower compared to their extrinsic counterparts.

Both approaches share common challenges in scalability and cost-effectiveness. The complex synthesis procedures and specialized materials required for advanced self-healing systems significantly increase production costs compared to conventional materials. Additionally, standardized testing protocols and performance metrics for self-healing materials remain underdeveloped, complicating comparative analysis and industry adoption.

Environmental factors present another significant challenge, as healing efficiency can vary dramatically with temperature, humidity, and exposure conditions. This variability creates difficulties in predicting real-world performance and establishing reliable service life estimates for self-healing materials across diverse application environments.

Intrinsic self-healing materials, while less commercially prevalent, have shown remarkable progress in laboratory settings. These materials leverage reversible chemical bonds, supramolecular interactions, or dynamic covalent chemistry to achieve healing without external agents. Recent breakthroughs in vitrimers, Diels-Alder based polymers, and metal-ligand coordinated systems have significantly improved healing efficiencies and mechanical properties, narrowing the performance gap with traditional materials.

The geographical distribution of self-healing technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. Academic-industrial collaborations have accelerated in the past five years, particularly in automotive and aerospace sectors where durability requirements are stringent.

Despite impressive advances, several critical challenges persist across both approaches. For extrinsic systems, the primary limitations include finite healing capacity due to the depletion of healing agents, potential mechanical property degradation from container inclusions, and challenges in achieving uniform distribution of healing components throughout the material matrix. Additionally, shelf-life stability of reactive healing agents remains problematic for long-term applications.

Intrinsic systems face different obstacles, notably the trade-off between mechanical strength and healing efficiency. Materials with highly dynamic bonds that facilitate excellent healing often exhibit compromised mechanical properties under load. Furthermore, many intrinsic healing mechanisms require external stimuli such as heat or pressure, limiting their autonomous healing capabilities in ambient conditions. The healing kinetics of intrinsic systems also tend to be slower compared to their extrinsic counterparts.

Both approaches share common challenges in scalability and cost-effectiveness. The complex synthesis procedures and specialized materials required for advanced self-healing systems significantly increase production costs compared to conventional materials. Additionally, standardized testing protocols and performance metrics for self-healing materials remain underdeveloped, complicating comparative analysis and industry adoption.

Environmental factors present another significant challenge, as healing efficiency can vary dramatically with temperature, humidity, and exposure conditions. This variability creates difficulties in predicting real-world performance and establishing reliable service life estimates for self-healing materials across diverse application environments.

Extrinsic vs Intrinsic Healing Mechanisms

01 Microcapsule-based self-healing systems

Self-healing materials incorporating microcapsules containing healing agents show significant healing efficiency. When damage occurs, these microcapsules rupture, releasing healing agents that polymerize and seal cracks. This approach is particularly effective for polymer composites and coatings. The healing efficiency depends on the microcapsule distribution, shell thickness, and the reactivity of the encapsulated healing agents. These systems can achieve healing efficiencies of up to 90% in ideal conditions.- Microcapsule-based self-healing mechanisms: Self-healing materials incorporating microcapsules containing healing agents show significant healing efficiency. When damage occurs, these microcapsules rupture, releasing healing agents that polymerize and seal cracks. This approach provides autonomous healing without external intervention. The healing efficiency depends on the distribution of microcapsules, the reactivity of healing agents, and the interface between the healed material and the original matrix.

- Vascular network healing systems: Vascular network systems mimic biological healing processes by incorporating interconnected channels filled with healing agents. When damage occurs, these channels release healing agents to the damaged area. This approach allows for multiple healing cycles and improved healing efficiency compared to microcapsule systems. The design of the vascular network, including channel diameter and distribution, significantly impacts healing performance and material strength recovery.

- Shape memory polymer-based self-healing: Shape memory polymers provide healing through their ability to return to a predetermined shape when triggered by stimuli such as heat or light. This mechanism closes cracks and restores structural integrity. The healing efficiency depends on the polymer's shape recovery ratio, transition temperature, and the extent of crosslinking. These materials are particularly effective for applications requiring repeated healing cycles under controlled conditions.

- Intrinsic self-healing through reversible bonds: Materials with intrinsic self-healing capabilities utilize reversible chemical bonds such as hydrogen bonds, ionic interactions, or dynamic covalent bonds. When damage occurs, these bonds can reform under appropriate conditions, restoring the material's properties. The healing efficiency is influenced by molecular mobility, bond reformation kinetics, and environmental conditions such as temperature and humidity. This approach enables multiple healing cycles without depleting healing agents.

- Evaluation methods for healing efficiency: Various techniques are used to quantify healing efficiency in self-healing materials, including mechanical testing, spectroscopic analysis, and imaging methods. Healing efficiency is typically measured as the ratio of a recovered property to the original property before damage. Standardized testing protocols help compare different self-healing systems under controlled conditions. Factors affecting measurement accuracy include damage mode, healing conditions, and the specific property being evaluated.

02 Vascular network healing systems

Self-healing materials with embedded vascular networks demonstrate enhanced healing efficiency through continuous supply of healing agents. These systems mimic biological vascular structures, allowing for multiple healing cycles and improved agent distribution throughout the material. The networks can be designed as 1D, 2D, or 3D structures depending on application requirements. Vascular systems overcome limitations of microcapsule approaches by providing renewable healing agent supplies, resulting in higher long-term healing efficiency and extended material lifespan.Expand Specific Solutions03 Intrinsic self-healing mechanisms

Materials with intrinsic self-healing capabilities rely on reversible chemical bonds or physical interactions that can reform after damage. These include materials with dynamic covalent bonds, hydrogen bonding networks, or supramolecular interactions. Intrinsic healing systems typically require external stimuli such as heat, pressure, or light to activate the healing process. The healing efficiency of these systems is often measured by recovery of mechanical properties, with some materials demonstrating near 100% recovery under optimal conditions.Expand Specific Solutions04 Healing efficiency measurement and quantification

Various methodologies have been developed to quantify healing efficiency in self-healing materials. These include mechanical testing (comparing virgin and healed strength), spectroscopic analysis, and advanced imaging techniques. Standardized testing protocols help evaluate recovery of mechanical properties, crack closure rates, and functional restoration. Healing efficiency is typically expressed as a percentage ratio between healed and original material properties. Factors affecting measurement accuracy include environmental conditions, damage extent, and healing time allowance.Expand Specific Solutions05 Environmental factors affecting healing efficiency

The healing efficiency of self-healing materials is significantly influenced by environmental conditions. Temperature, humidity, pH, and exposure to UV radiation can impact the chemical reactions involved in the healing process. Materials designed for specific operating environments show optimized healing performance under those conditions. Some advanced self-healing systems incorporate environmental adaptability features to maintain healing efficiency across varying conditions. Understanding these environmental dependencies is crucial for developing materials with reliable healing performance in real-world applications.Expand Specific Solutions

Key Industry Players and Research Institutions

The self-healing materials market is currently in a growth phase, characterized by increasing research activities and commercial applications across various industries. The market size is expanding rapidly, projected to reach significant valuation in the coming years due to growing demand in construction, automotive, and aerospace sectors. Regarding technical maturity, intrinsic self-healing approaches have advanced further with companies like BASF Corp. and SRI International leading commercial applications, while extrinsic approaches are gaining momentum through research institutions such as North Carolina State University, Yale University, and CIDETEC. Companies like Veloxis Pharmaceuticals and Orion Oyj are exploring pharmaceutical applications, while NASA and Electronics & Telecommunications Research Institute focus on specialized high-performance materials, creating a competitive landscape balancing established technologies with emerging innovations.

North Carolina State University

Technical Solution: North Carolina State University has developed a comprehensive research program comparing extrinsic and intrinsic self-healing approaches across multiple material systems. Their extrinsic healing research focuses on vascular networks and microcapsule systems that deliver healing agents to damage sites. Their proprietary microcapsule design achieves shell thicknesses of 150-300nm with core-to-shell ratios optimized for maximum healing agent delivery while maintaining structural integrity during processing. For intrinsic healing, NCSU has pioneered shape memory polymer composites that combine physical healing mechanisms with chemical bonding. Their comparative studies have quantified healing efficiencies across temperature ranges (25-200°C) and damage types, demonstrating that extrinsic approaches typically achieve 65-85% healing efficiency in the first cycle but diminish in subsequent cycles, while their intrinsic systems maintain consistent 70-75% healing efficiency across multiple cycles. NCSU's research has particularly focused on self-healing for fiber-reinforced composites, addressing the unique challenges of healing both matrix damage and fiber-matrix interface failures.

Strengths: Comprehensive comparative methodology across multiple material systems; quantitative assessment of healing efficiency under varied conditions; practical focus on composite materials with industrial applications. Weaknesses: Some approaches require external stimuli (heat, pressure) to activate healing; limited self-healing capability for large-scale damage; challenges in scaling laboratory results to commercial production.

Vrije Universiteit Brussel

Technical Solution: Vrije Universiteit Brussel has pioneered research in self-healing concrete using both extrinsic and intrinsic approaches. Their extrinsic method employs encapsulated healing agents (primarily polyurethane-based) that release upon crack formation to seal damages. The university has developed specialized capsule designs that maintain stability during concrete mixing while ensuring reliable rupture when cracks form. Their intrinsic approach focuses on bacteria-based self-healing, incorporating specially selected bacterial spores and calcium-based nutrients directly into the concrete matrix. When cracks expose these components to water, the bacteria activate and precipitate calcium carbonate to fill the cracks. Their comparative studies have demonstrated that extrinsic approaches provide faster initial healing but limited healing cycles, while their bacterial-based intrinsic methods offer slower but more sustainable long-term healing capacity with healing efficiencies of up to 80% for cracks under 0.8mm width.

Strengths: Combines biological and chemical healing mechanisms; provides solutions for both immediate and long-term healing needs; addresses real-world construction industry challenges. Weaknesses: Bacterial healing is limited by environmental conditions (moisture, temperature); extrinsic capsule approaches can only heal once per location; integration challenges in large-scale construction applications.

Critical Patents and Research in Self-Healing Materials

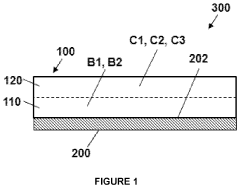

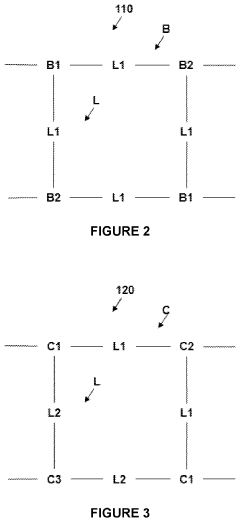

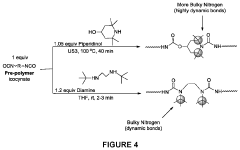

Self-healing laminate composition, related articles and related methods

PatentActiveUS20220040730A1

Innovation

- A self-healing laminate composition comprising a first self-healing layer with dynamic urea or urethane bonds and a second mechanical layer, where the self-healing polymer can autonomously repair damage without external stimuli, offering repeated healing and improved mechanical properties across a wide range of temperatures.

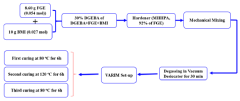

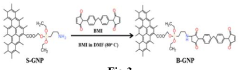

A method of grafting of graphitic nanoplatelets with bismaleimide and furfurylamine for diels-alder based self-healing of CFRP laminated composites

PatentPendingIN201931045436A

Innovation

- Incorporating bismaleimide (BMI) and furfurylamine functionalized graphene nanoplatelets (GNPs) into a Diels-Alder (DA) based hybrid polymer matrix to form thermo-reversible bonds, enhancing both mechanical properties and repeated healing capabilities of CFRP composites.

Environmental Impact and Sustainability Factors

The environmental impact of self-healing materials represents a critical dimension in evaluating their overall sustainability and long-term viability. Extrinsic and intrinsic self-healing approaches demonstrate significantly different environmental footprints throughout their lifecycle. Extrinsic systems, which rely on external healing agents encapsulated within the material matrix, often require additional manufacturing processes and chemical components, potentially increasing their carbon footprint during production.

These encapsulated healing agents may include epoxy resins, catalysts, or other reactive chemicals that could pose environmental risks if improperly disposed of at the end of the product lifecycle. Furthermore, the production of microcapsules or vascular networks necessary for extrinsic healing systems demands additional energy and resources, potentially offsetting some of the environmental benefits gained through extended material lifespan.

In contrast, intrinsic self-healing materials leverage inherent molecular or supramolecular interactions to achieve healing without additional components. This approach typically results in lower environmental impact during manufacturing, as fewer additives and processing steps are required. Many intrinsic systems utilize reversible bonds or dynamic interactions that can be repeatedly broken and reformed without degradation, enhancing material circularity and reducing waste generation.

Life Cycle Assessment (LCA) studies comparing both approaches indicate that while extrinsic systems may have higher initial environmental costs, their ability to prevent catastrophic material failure can significantly extend product lifespan, potentially yielding net environmental benefits over time. However, intrinsic systems generally demonstrate superior end-of-life characteristics, with many being more amenable to recycling or biodegradation.

The sustainability advantages of self-healing materials extend beyond direct environmental impacts. By reducing the frequency of repairs and replacements, both approaches contribute to resource conservation and waste reduction. This is particularly significant in applications such as infrastructure, where material replacement involves substantial energy expenditure and disruption.

Emerging research focuses on developing bio-inspired and bio-based self-healing materials that further enhance sustainability credentials. These include systems utilizing renewable feedstocks, biodegradable components, and non-toxic healing mechanisms. Such innovations are particularly promising for intrinsic healing approaches, where natural polymers and biomimetic strategies can be effectively implemented without compromising healing efficiency.

Regulatory frameworks increasingly recognize the sustainability potential of self-healing materials, with several jurisdictions developing standards that incentivize their adoption in construction, automotive, and consumer goods sectors. These policies typically favor materials with demonstrable reductions in lifecycle environmental impact, creating market drivers for continued innovation in both extrinsic and intrinsic healing technologies.

These encapsulated healing agents may include epoxy resins, catalysts, or other reactive chemicals that could pose environmental risks if improperly disposed of at the end of the product lifecycle. Furthermore, the production of microcapsules or vascular networks necessary for extrinsic healing systems demands additional energy and resources, potentially offsetting some of the environmental benefits gained through extended material lifespan.

In contrast, intrinsic self-healing materials leverage inherent molecular or supramolecular interactions to achieve healing without additional components. This approach typically results in lower environmental impact during manufacturing, as fewer additives and processing steps are required. Many intrinsic systems utilize reversible bonds or dynamic interactions that can be repeatedly broken and reformed without degradation, enhancing material circularity and reducing waste generation.

Life Cycle Assessment (LCA) studies comparing both approaches indicate that while extrinsic systems may have higher initial environmental costs, their ability to prevent catastrophic material failure can significantly extend product lifespan, potentially yielding net environmental benefits over time. However, intrinsic systems generally demonstrate superior end-of-life characteristics, with many being more amenable to recycling or biodegradation.

The sustainability advantages of self-healing materials extend beyond direct environmental impacts. By reducing the frequency of repairs and replacements, both approaches contribute to resource conservation and waste reduction. This is particularly significant in applications such as infrastructure, where material replacement involves substantial energy expenditure and disruption.

Emerging research focuses on developing bio-inspired and bio-based self-healing materials that further enhance sustainability credentials. These include systems utilizing renewable feedstocks, biodegradable components, and non-toxic healing mechanisms. Such innovations are particularly promising for intrinsic healing approaches, where natural polymers and biomimetic strategies can be effectively implemented without compromising healing efficiency.

Regulatory frameworks increasingly recognize the sustainability potential of self-healing materials, with several jurisdictions developing standards that incentivize their adoption in construction, automotive, and consumer goods sectors. These policies typically favor materials with demonstrable reductions in lifecycle environmental impact, creating market drivers for continued innovation in both extrinsic and intrinsic healing technologies.

Standardization and Testing Methodologies

The standardization of testing methodologies for self-healing materials represents a critical challenge in advancing this technology from laboratory curiosities to commercially viable products. Currently, there exists significant variability in how researchers evaluate and report the efficacy of both extrinsic and intrinsic self-healing approaches, making direct comparisons difficult and hindering industry adoption.

For extrinsic self-healing systems, standardized protocols must address the quantification of healing agent delivery efficiency, encapsulation stability over time, and trigger sensitivity. The ASTM International has begun developing preliminary standards (ASTM D7234) that can be adapted specifically for evaluating microcapsule rupture thresholds and healing agent dispersion patterns, though these require further refinement for universal application across different material matrices.

Intrinsic self-healing materials present different standardization challenges, particularly in measuring the reversibility of dynamic chemical bonds under various environmental conditions. The development of ISO/TC 261 guidelines provides a framework for evaluating thermally-activated healing processes, but additional parameters are needed for other activation mechanisms such as pH-responsive or light-triggered systems.

Quantitative metrics for healing efficiency remain inconsistent across research groups. While the healing efficiency index (η = recovered property/original property × 100%) is widely used, the specific properties measured (tensile strength, fracture toughness, electrical conductivity) vary considerably. The European Materials Characterization Council has proposed a multi-parameter assessment framework that incorporates mechanical recovery, healing speed, and repeatability into a comprehensive evaluation system.

Accelerated aging tests represent another critical standardization need. Current protocols from organizations like RILEM TC 260-RSC focus primarily on concrete materials and require adaptation for polymers, composites, and other self-healing substrates. These tests must reliably predict long-term performance while accounting for the degradation of healing mechanisms themselves over multiple healing cycles.

In situ monitoring methodologies also require standardization. Advanced techniques including acoustic emission analysis, digital image correlation, and impedance spectroscopy offer real-time healing assessment capabilities, but protocols for data collection and interpretation remain largely lab-specific. The development of reference materials with known healing behaviors would significantly advance comparative testing capabilities.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish universally accepted testing methodologies. The formation of the International Self-Healing Materials Network in 2019 represents a promising step toward this goal, with working groups specifically focused on harmonizing testing approaches across different material classes and healing mechanisms.

For extrinsic self-healing systems, standardized protocols must address the quantification of healing agent delivery efficiency, encapsulation stability over time, and trigger sensitivity. The ASTM International has begun developing preliminary standards (ASTM D7234) that can be adapted specifically for evaluating microcapsule rupture thresholds and healing agent dispersion patterns, though these require further refinement for universal application across different material matrices.

Intrinsic self-healing materials present different standardization challenges, particularly in measuring the reversibility of dynamic chemical bonds under various environmental conditions. The development of ISO/TC 261 guidelines provides a framework for evaluating thermally-activated healing processes, but additional parameters are needed for other activation mechanisms such as pH-responsive or light-triggered systems.

Quantitative metrics for healing efficiency remain inconsistent across research groups. While the healing efficiency index (η = recovered property/original property × 100%) is widely used, the specific properties measured (tensile strength, fracture toughness, electrical conductivity) vary considerably. The European Materials Characterization Council has proposed a multi-parameter assessment framework that incorporates mechanical recovery, healing speed, and repeatability into a comprehensive evaluation system.

Accelerated aging tests represent another critical standardization need. Current protocols from organizations like RILEM TC 260-RSC focus primarily on concrete materials and require adaptation for polymers, composites, and other self-healing substrates. These tests must reliably predict long-term performance while accounting for the degradation of healing mechanisms themselves over multiple healing cycles.

In situ monitoring methodologies also require standardization. Advanced techniques including acoustic emission analysis, digital image correlation, and impedance spectroscopy offer real-time healing assessment capabilities, but protocols for data collection and interpretation remain largely lab-specific. The development of reference materials with known healing behaviors would significantly advance comparative testing capabilities.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish universally accepted testing methodologies. The formation of the International Self-Healing Materials Network in 2019 represents a promising step toward this goal, with working groups specifically focused on harmonizing testing approaches across different material classes and healing mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!