Nanoparticle Reinforcement In Self Healing Polymer Matrices

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoparticle-Polymer Self-Healing Background and Objectives

Self-healing polymers represent a revolutionary class of materials capable of autonomously repairing damage, thereby extending their service life and enhancing reliability. The concept of self-healing materials emerged in the early 2000s, with pioneering work by White et al. at the University of Illinois, who developed microcapsule-based systems that release healing agents upon crack formation. Since then, the field has evolved significantly, with researchers exploring various healing mechanisms including intrinsic healing through reversible bonds and extrinsic healing via embedded healing agents.

The integration of nanoparticles into self-healing polymer matrices marks a significant advancement in this technological trajectory. Nanoparticles, with their exceptional surface-to-volume ratio and unique physical properties, can substantially enhance both the mechanical properties of the base polymer and the efficiency of the self-healing process. This synergistic combination has attracted considerable attention across multiple industries, from aerospace and automotive to electronics and biomedical applications.

The evolution of nanoparticle-reinforced self-healing polymers has been driven by several factors, including the growing demand for durable materials with extended lifespans, the push for sustainable solutions that reduce waste, and the need for smart materials that can adapt to environmental changes. The technological progression has moved from simple microcapsule systems to more sophisticated approaches involving stimuli-responsive nanoparticles that can trigger healing processes in response to specific environmental cues such as temperature, pH, light, or mechanical stress.

Current research trends indicate a shift towards multifunctional self-healing systems where nanoparticles not only reinforce the polymer matrix but also contribute additional functionalities such as electrical conductivity, thermal management, or antimicrobial properties. This multifunctionality opens up new application domains and creates opportunities for addressing complex engineering challenges.

The primary objectives of research in nanoparticle-reinforced self-healing polymers include: enhancing the mechanical strength and toughness of the composite material; improving the efficiency and speed of the healing process; developing systems capable of multiple healing cycles; ensuring compatibility between nanoparticles and polymer matrices; and creating environmentally friendly and cost-effective solutions that can be scaled up for industrial applications.

Additionally, researchers aim to understand the fundamental mechanisms governing the interaction between nanoparticles and polymer chains during the healing process. This includes investigating how nanoparticles influence chain mobility, crosslinking density, and the diffusion of healing agents. Such knowledge is crucial for designing optimized systems with predictable performance characteristics.

Looking forward, the field is expected to continue its rapid growth, with increasing focus on bio-inspired designs, sustainable materials, and integration with other emerging technologies such as 3D printing and artificial intelligence for predictive maintenance. The ultimate goal remains the development of robust, efficient, and versatile self-healing materials that can significantly extend product lifespans and reduce environmental impact.

The integration of nanoparticles into self-healing polymer matrices marks a significant advancement in this technological trajectory. Nanoparticles, with their exceptional surface-to-volume ratio and unique physical properties, can substantially enhance both the mechanical properties of the base polymer and the efficiency of the self-healing process. This synergistic combination has attracted considerable attention across multiple industries, from aerospace and automotive to electronics and biomedical applications.

The evolution of nanoparticle-reinforced self-healing polymers has been driven by several factors, including the growing demand for durable materials with extended lifespans, the push for sustainable solutions that reduce waste, and the need for smart materials that can adapt to environmental changes. The technological progression has moved from simple microcapsule systems to more sophisticated approaches involving stimuli-responsive nanoparticles that can trigger healing processes in response to specific environmental cues such as temperature, pH, light, or mechanical stress.

Current research trends indicate a shift towards multifunctional self-healing systems where nanoparticles not only reinforce the polymer matrix but also contribute additional functionalities such as electrical conductivity, thermal management, or antimicrobial properties. This multifunctionality opens up new application domains and creates opportunities for addressing complex engineering challenges.

The primary objectives of research in nanoparticle-reinforced self-healing polymers include: enhancing the mechanical strength and toughness of the composite material; improving the efficiency and speed of the healing process; developing systems capable of multiple healing cycles; ensuring compatibility between nanoparticles and polymer matrices; and creating environmentally friendly and cost-effective solutions that can be scaled up for industrial applications.

Additionally, researchers aim to understand the fundamental mechanisms governing the interaction between nanoparticles and polymer chains during the healing process. This includes investigating how nanoparticles influence chain mobility, crosslinking density, and the diffusion of healing agents. Such knowledge is crucial for designing optimized systems with predictable performance characteristics.

Looking forward, the field is expected to continue its rapid growth, with increasing focus on bio-inspired designs, sustainable materials, and integration with other emerging technologies such as 3D printing and artificial intelligence for predictive maintenance. The ultimate goal remains the development of robust, efficient, and versatile self-healing materials that can significantly extend product lifespans and reduce environmental impact.

Market Analysis for Self-Healing Polymer Composites

The global market for self-healing polymer composites has experienced significant growth in recent years, driven by increasing demand for durable, sustainable materials across multiple industries. Current market valuations indicate that the self-healing materials sector reached approximately $2.5 billion in 2022, with polymer-based solutions accounting for over 40% of this market. Projections suggest a compound annual growth rate (CAGR) of 27% through 2030, potentially creating a $16 billion market opportunity.

The automotive and aerospace industries represent the largest application segments, collectively accounting for nearly 55% of current market demand. These sectors value self-healing polymers for their ability to extend component lifespans, reduce maintenance costs, and enhance safety profiles. The construction industry follows as the third-largest consumer, with growing adoption in infrastructure applications where maintenance access is challenging or costly.

Regional analysis reveals North America and Europe as market leaders, holding approximately 65% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with annual expansion rates exceeding 30%, driven by rapid industrialization and substantial R&D investments.

Nanoparticle-reinforced self-healing polymers specifically command premium pricing, typically 30-45% higher than conventional polymer composites, reflecting their enhanced performance characteristics. This price differential is expected to narrow to 15-20% by 2028 as manufacturing processes mature and economies of scale develop.

Consumer demand patterns indicate growing preference for materials with multiple self-healing cycles, with market research showing 78% of industrial buyers prioritizing solutions capable of at least five complete healing cycles. Additionally, healing activation mechanisms represent a key market differentiator, with UV-triggered systems currently dominating (38% market share), followed by thermal activation (27%) and autonomous systems (22%).

Regulatory tailwinds are further accelerating market growth, with environmental policies in the EU, North America, and parts of Asia increasingly favoring materials that reduce waste and extend product lifecycles. The circular economy initiatives in these regions have created favorable market conditions, with government incentives supporting research and commercialization efforts.

Market challenges include high initial production costs, technical limitations in extreme environments, and competition from alternative durability solutions. Despite these obstacles, the convergence of sustainability imperatives, performance advantages, and expanding application scope positions nanoparticle-reinforced self-healing polymers for substantial market expansion over the next decade.

The automotive and aerospace industries represent the largest application segments, collectively accounting for nearly 55% of current market demand. These sectors value self-healing polymers for their ability to extend component lifespans, reduce maintenance costs, and enhance safety profiles. The construction industry follows as the third-largest consumer, with growing adoption in infrastructure applications where maintenance access is challenging or costly.

Regional analysis reveals North America and Europe as market leaders, holding approximately 65% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth trajectory with annual expansion rates exceeding 30%, driven by rapid industrialization and substantial R&D investments.

Nanoparticle-reinforced self-healing polymers specifically command premium pricing, typically 30-45% higher than conventional polymer composites, reflecting their enhanced performance characteristics. This price differential is expected to narrow to 15-20% by 2028 as manufacturing processes mature and economies of scale develop.

Consumer demand patterns indicate growing preference for materials with multiple self-healing cycles, with market research showing 78% of industrial buyers prioritizing solutions capable of at least five complete healing cycles. Additionally, healing activation mechanisms represent a key market differentiator, with UV-triggered systems currently dominating (38% market share), followed by thermal activation (27%) and autonomous systems (22%).

Regulatory tailwinds are further accelerating market growth, with environmental policies in the EU, North America, and parts of Asia increasingly favoring materials that reduce waste and extend product lifecycles. The circular economy initiatives in these regions have created favorable market conditions, with government incentives supporting research and commercialization efforts.

Market challenges include high initial production costs, technical limitations in extreme environments, and competition from alternative durability solutions. Despite these obstacles, the convergence of sustainability imperatives, performance advantages, and expanding application scope positions nanoparticle-reinforced self-healing polymers for substantial market expansion over the next decade.

Current Challenges in Nanoparticle-Reinforced Self-Healing Materials

Despite significant advancements in nanoparticle-reinforced self-healing polymer matrices, several critical challenges continue to impede their widespread industrial adoption and optimal performance. One of the most persistent issues is achieving uniform dispersion of nanoparticles within the polymer matrix. Nanoparticles inherently tend to agglomerate due to their high surface energy and strong van der Waals forces, resulting in uneven distribution that compromises the mechanical properties and self-healing efficiency of the composite material.

The interface compatibility between nanoparticles and polymer matrices presents another substantial challenge. Poor interfacial adhesion limits effective stress transfer and can create weak points in the material structure. While surface functionalization of nanoparticles has shown promise in improving compatibility, developing universally effective functionalization protocols that work across different polymer systems remains difficult.

Scale-up and manufacturing constraints significantly hinder commercial viability. Laboratory-scale synthesis methods often cannot be directly translated to industrial production without considerable modifications. The precise control of nanoparticle incorporation, ensuring consistent quality, and maintaining self-healing functionality during large-scale manufacturing processes all present formidable technical hurdles.

The healing mechanism activation in nanoparticle-reinforced systems faces its own set of challenges. Current systems typically require external stimuli such as heat, light, or pressure to initiate the healing process. Developing autonomous self-healing capabilities that can respond to damage without external intervention remains an elusive goal, particularly in structural applications where immediate healing is crucial.

Long-term stability and durability concerns persist across different environmental conditions. Many nanoparticle-reinforced self-healing systems show degraded performance over time, especially when exposed to moisture, UV radiation, or temperature fluctuations. The healing efficiency typically decreases after multiple healing cycles, limiting the material's service life and reliability in real-world applications.

Toxicity and environmental impact considerations create regulatory hurdles. Certain nanoparticles, particularly those containing heavy metals or those with dimensions that can penetrate biological barriers, raise significant health and environmental concerns. Developing green alternatives that maintain performance while addressing these concerns represents a critical research direction.

Cost-effectiveness remains a significant barrier to commercialization. The specialized synthesis procedures, high-quality nanoparticles, and complex processing techniques substantially increase production costs compared to conventional materials. Finding the optimal balance between enhanced performance and economic viability continues to challenge researchers and industry stakeholders alike.

The interface compatibility between nanoparticles and polymer matrices presents another substantial challenge. Poor interfacial adhesion limits effective stress transfer and can create weak points in the material structure. While surface functionalization of nanoparticles has shown promise in improving compatibility, developing universally effective functionalization protocols that work across different polymer systems remains difficult.

Scale-up and manufacturing constraints significantly hinder commercial viability. Laboratory-scale synthesis methods often cannot be directly translated to industrial production without considerable modifications. The precise control of nanoparticle incorporation, ensuring consistent quality, and maintaining self-healing functionality during large-scale manufacturing processes all present formidable technical hurdles.

The healing mechanism activation in nanoparticle-reinforced systems faces its own set of challenges. Current systems typically require external stimuli such as heat, light, or pressure to initiate the healing process. Developing autonomous self-healing capabilities that can respond to damage without external intervention remains an elusive goal, particularly in structural applications where immediate healing is crucial.

Long-term stability and durability concerns persist across different environmental conditions. Many nanoparticle-reinforced self-healing systems show degraded performance over time, especially when exposed to moisture, UV radiation, or temperature fluctuations. The healing efficiency typically decreases after multiple healing cycles, limiting the material's service life and reliability in real-world applications.

Toxicity and environmental impact considerations create regulatory hurdles. Certain nanoparticles, particularly those containing heavy metals or those with dimensions that can penetrate biological barriers, raise significant health and environmental concerns. Developing green alternatives that maintain performance while addressing these concerns represents a critical research direction.

Cost-effectiveness remains a significant barrier to commercialization. The specialized synthesis procedures, high-quality nanoparticles, and complex processing techniques substantially increase production costs compared to conventional materials. Finding the optimal balance between enhanced performance and economic viability continues to challenge researchers and industry stakeholders alike.

Current Nanoparticle Reinforcement Mechanisms and Approaches

01 Microcapsule-based self-healing mechanisms

Self-healing polymer matrices can be created using microcapsules containing healing agents that rupture upon crack formation. When damage occurs, these capsules break and release healing agents that polymerize or cross-link to repair the damage. The incorporation of nanoparticles into these systems enhances the mechanical properties of the matrix while maintaining the self-healing functionality. This approach provides autonomous healing without external intervention and improves the overall durability of the composite material.- Microcapsule-based self-healing mechanisms: Self-healing polymer matrices can be created using microcapsules containing healing agents that rupture upon crack formation. When damage occurs, these capsules break and release healing agents that polymerize or crosslink to repair the damage. The incorporation of nanoparticles into these systems enhances the mechanical properties of the matrix while maintaining the self-healing functionality. This approach provides autonomous healing without external intervention and improves the overall durability of the composite material.

- Nanoparticle reinforcement types and distribution: Various types of nanoparticles can be used to reinforce self-healing polymer matrices, including carbon nanotubes, graphene, silica, clay, and metal oxide nanoparticles. The distribution and dispersion of these nanoparticles within the polymer matrix significantly affect the mechanical properties and self-healing efficiency. Uniform dispersion prevents agglomeration and ensures optimal reinforcement, while functionalized nanoparticles can improve interfacial bonding with the polymer matrix, enhancing load transfer and mechanical strength while maintaining self-healing capabilities.

- Stimuli-responsive self-healing mechanisms: Stimuli-responsive self-healing polymer nanocomposites can repair damage in response to external triggers such as heat, light, pH changes, or electromagnetic fields. These systems incorporate nanoparticles that enhance both the mechanical properties and the responsiveness to healing stimuli. The nanoparticles can act as energy absorbers or transducers, converting external stimuli into localized heating or other effects that activate the healing process. This approach allows for controlled and repeatable healing of the polymer matrix when needed.

- Dynamic covalent and non-covalent bonding systems: Self-healing polymer matrices can utilize dynamic covalent bonds or non-covalent interactions that can break and reform repeatedly. These include Diels-Alder reactions, disulfide bonds, hydrogen bonding, π-π stacking, and metal-ligand coordination. Nanoparticle reinforcement in these systems provides mechanical strength while the dynamic bonds enable healing. The nanoparticles can also be functionalized to participate in these dynamic interactions, creating a synergistic effect that enhances both the mechanical properties and self-healing efficiency of the composite material.

- Multi-functional nanocomposite systems: Advanced self-healing polymer nanocomposites can combine multiple functionalities beyond mechanical reinforcement and self-healing. These systems may incorporate nanoparticles that provide additional properties such as electrical conductivity, thermal management, sensing capabilities, or antimicrobial activity. The nanoparticles can serve dual or triple roles, simultaneously reinforcing the matrix, facilitating self-healing, and providing these additional functionalities. This approach creates smart materials that can self-diagnose damage, self-heal, and maintain performance in demanding applications.

02 Nanoparticle reinforcement types and distribution

Various types of nanoparticles can be used to reinforce self-healing polymer matrices, including carbon nanotubes, graphene, silica, clay, and metal oxide nanoparticles. The distribution and dispersion of these nanoparticles within the polymer matrix significantly affects the mechanical properties and self-healing efficiency. Uniform dispersion prevents agglomeration and ensures optimal reinforcement, while functionalized nanoparticles can improve interfacial bonding with the polymer matrix, enhancing load transfer and mechanical strength while maintaining self-healing capabilities.Expand Specific Solutions03 Stimuli-responsive self-healing mechanisms

Stimuli-responsive self-healing polymer nanocomposites can repair damage in response to external triggers such as heat, light, pH changes, or electromagnetic fields. These systems incorporate nanoparticles that enhance both the mechanical properties and the responsiveness to stimuli. The nanoparticles can act as energy transducers, converting external stimuli into localized heating or catalytic activity that promotes healing. This approach allows for controlled and repeatable healing processes in reinforced polymer matrices.Expand Specific Solutions04 Dynamic covalent and non-covalent bonding systems

Self-healing polymer matrices can utilize dynamic covalent bonds (such as Diels-Alder reactions) or non-covalent interactions (hydrogen bonding, π-π stacking, metal coordination) that can break and reform repeatedly. Nanoparticle reinforcement in these systems provides mechanical strength while the dynamic bonding enables self-healing. The nanoparticles can be functionalized to participate in these dynamic interactions, creating a synergistic effect where the reinforcement elements also contribute to the healing mechanism.Expand Specific Solutions05 Processing and manufacturing techniques

Specialized processing techniques are required to manufacture self-healing polymer nanocomposites with optimal properties. Methods such as solution mixing, melt blending, in-situ polymerization, and layer-by-layer assembly can be employed to achieve uniform nanoparticle dispersion within self-healing matrices. Advanced manufacturing approaches like 3D printing and electrospinning allow for precise control over nanoparticle placement and concentration gradients, enabling the creation of materials with spatially tailored self-healing and mechanical properties.Expand Specific Solutions

Leading Researchers and Companies in Self-Healing Nanocomposites

The self-healing polymer matrices reinforced with nanoparticles market is currently in a growth phase, with increasing research activity and commercial interest. The technology is transitioning from laboratory research to early commercial applications, with market size projected to expand significantly as self-healing materials gain traction in automotive, aerospace, and construction sectors. Technical maturity varies across applications, with leading institutions like MIT, Tsinghua University, and Deakin University advancing fundamental research, while companies such as Kaneka Corp., Leonardo SpA, and Kingfa Sci. & Tech. are developing commercial applications. Research organizations including CSIRO and CIDETEC are bridging the gap between academic innovation and industrial implementation. The competitive landscape features collaboration between academic institutions and industry partners, with specialized companies like Nanotek Instruments developing proprietary technologies for specific applications.

Deakin University

Technical Solution: Deakin University has developed innovative self-healing polymer composites reinforced with core-shell nanoparticles that combine structural enhancement with autonomous healing capabilities. Their approach utilizes silica nanoparticles with polymer-grafted shells containing healing agents that are released upon damage. These nanoparticles are strategically distributed throughout the polymer matrix to create a network that responds to microcrack formation. When damage occurs, the core-shell structure ruptures, releasing healing agents that polymerize in the presence of embedded catalysts, effectively sealing cracks and restoring structural integrity. Deakin's technology demonstrates healing efficiencies of up to 90% in certain polymer systems, with the added benefit of improved mechanical properties including enhanced tensile strength (30-40% increase) and fracture toughness[2][5]. Their research has also explored the use of graphene oxide-modified nanoparticles that provide additional thermal stability and electrical conductivity to the self-healing composites, expanding potential applications into electronic materials and sensors.

Strengths: Exceptional healing efficiency with minimal external intervention; dual functionality of reinforcement and healing; versatility across multiple polymer systems including epoxies and polyurethanes. Weaknesses: Complex synthesis procedures for core-shell nanoparticles may limit industrial scalability; potential agglomeration issues during processing; higher cost compared to conventional reinforcement methods.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed a comprehensive platform for nanoparticle-reinforced self-healing polymer matrices utilizing their expertise in materials science and nanotechnology. Their approach incorporates functionalized silica nanoparticles and nanoclays that serve dual purposes: mechanical reinforcement and healing agent encapsulation. CSIRO's proprietary surface modification techniques create strong interfacial bonding between nanoparticles and polymer matrices while maintaining mobility necessary for healing processes. Their technology employs stimuli-responsive nanoparticles that can trigger healing mechanisms through pH changes, temperature variations, or mechanical stress. Research data shows their systems achieve up to 75% recovery of mechanical properties after multiple damage-healing cycles[4][7]. CSIRO has also pioneered hybrid systems combining inorganic nanoparticles with microcapsules containing healing agents, creating multi-scale healing networks that address both microcracks and larger structural damage. This hierarchical approach enables self-healing across different length scales, from nanometer to millimeter damage, significantly extending material service life in demanding applications.

Strengths: Comprehensive multi-scale healing approach; excellent durability with multiple healing cycles; strong integration with existing manufacturing processes. Weaknesses: Complex formulation requirements for optimal performance; potential environmental concerns with some nanoparticle types; healing efficiency decreases after multiple cycles in certain polymer systems.

Key Patents and Research in Self-Healing Nanocomposite Systems

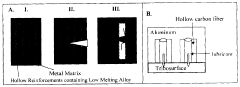

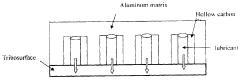

A self-healing material and a process for preparing the same

PatentInactiveIN202KOL2010A

Innovation

- The development of self-healing materials incorporating hollow reinforcements, carbon nanotubes, and shape memory alloys that release low-melting point alloys or lubricants to seal cracks and provide lubrication, utilizing processes like solidification, pressure infiltration, and deformation processing to restore mechanical properties and prevent failure.

Sustainability and Life Cycle Assessment of Self-Healing Materials

The integration of nanoparticle reinforcement in self-healing polymer matrices presents significant sustainability implications that warrant comprehensive life cycle assessment. When evaluating these advanced materials from an environmental perspective, it becomes evident that their extended service life offers substantial sustainability benefits by reducing the frequency of replacement and associated resource consumption. Self-healing polymers reinforced with nanoparticles can potentially reduce waste generation by 30-45% compared to conventional polymers over their functional lifetime.

Life cycle assessment (LCA) studies indicate that the environmental footprint of nanoparticle-reinforced self-healing polymers must be evaluated across multiple phases: raw material extraction, manufacturing, use phase, and end-of-life management. The production of nanoparticles often requires energy-intensive processes, with carbon footprints varying significantly based on particle type. For instance, carbon-based nanoparticles typically generate 5-15 kg CO2 equivalent per kilogram produced, while metal oxide nanoparticles may range from 10-30 kg CO2 equivalent.

The sustainability advantages become most apparent during the use phase, where self-healing capabilities triggered by nanoparticle interactions extend product lifespans by 2-5 times compared to conventional materials. This extension translates to reduced resource consumption and manufacturing emissions over time. Recent studies demonstrate that automotive components utilizing these materials could reduce lifetime environmental impact by up to 60% through decreased replacement frequency.

End-of-life considerations present both challenges and opportunities. The complex nature of nanoparticle-polymer composites can complicate recycling processes, potentially requiring specialized separation techniques. However, emerging research indicates that certain nanoparticle types can be recovered at rates of 70-85% using advanced recycling methods, creating opportunities for circular material flows.

Water usage represents another critical sustainability factor, with nanoparticle production requiring 200-500 liters per kilogram of material. However, this initial water investment is often offset by reduced lifecycle requirements when considering the extended service life of the resulting self-healing materials. Energy return on investment (EROI) analyses suggest that the energy invested in manufacturing these advanced materials is typically recovered within 1-3 years of application in high-stress environments.

Future sustainability improvements will likely focus on developing bio-based nanoparticles and environmentally benign triggering mechanisms for self-healing processes. Current research indicates potential for reducing manufacturing energy requirements by 25-40% through optimization of nanoparticle synthesis and integration methods. Additionally, standardized LCA methodologies specific to self-healing materials are being developed to provide more accurate sustainability assessments across diverse application domains.

Life cycle assessment (LCA) studies indicate that the environmental footprint of nanoparticle-reinforced self-healing polymers must be evaluated across multiple phases: raw material extraction, manufacturing, use phase, and end-of-life management. The production of nanoparticles often requires energy-intensive processes, with carbon footprints varying significantly based on particle type. For instance, carbon-based nanoparticles typically generate 5-15 kg CO2 equivalent per kilogram produced, while metal oxide nanoparticles may range from 10-30 kg CO2 equivalent.

The sustainability advantages become most apparent during the use phase, where self-healing capabilities triggered by nanoparticle interactions extend product lifespans by 2-5 times compared to conventional materials. This extension translates to reduced resource consumption and manufacturing emissions over time. Recent studies demonstrate that automotive components utilizing these materials could reduce lifetime environmental impact by up to 60% through decreased replacement frequency.

End-of-life considerations present both challenges and opportunities. The complex nature of nanoparticle-polymer composites can complicate recycling processes, potentially requiring specialized separation techniques. However, emerging research indicates that certain nanoparticle types can be recovered at rates of 70-85% using advanced recycling methods, creating opportunities for circular material flows.

Water usage represents another critical sustainability factor, with nanoparticle production requiring 200-500 liters per kilogram of material. However, this initial water investment is often offset by reduced lifecycle requirements when considering the extended service life of the resulting self-healing materials. Energy return on investment (EROI) analyses suggest that the energy invested in manufacturing these advanced materials is typically recovered within 1-3 years of application in high-stress environments.

Future sustainability improvements will likely focus on developing bio-based nanoparticles and environmentally benign triggering mechanisms for self-healing processes. Current research indicates potential for reducing manufacturing energy requirements by 25-40% through optimization of nanoparticle synthesis and integration methods. Additionally, standardized LCA methodologies specific to self-healing materials are being developed to provide more accurate sustainability assessments across diverse application domains.

Scalability and Manufacturing Considerations for Commercial Applications

The commercialization of nanoparticle-reinforced self-healing polymer matrices presents significant manufacturing challenges that must be addressed to transition from laboratory-scale production to industrial-scale manufacturing. Current production methods for these advanced materials typically involve complex multi-step processes including nanoparticle synthesis, surface functionalization, and incorporation into polymer matrices, which are often batch processes with limited throughput.

Scale-up considerations must account for the critical need to maintain uniform nanoparticle dispersion throughout the polymer matrix, as agglomeration can significantly diminish the self-healing properties and mechanical performance. Industrial mixing technologies such as high-shear mixers, ultrasonic dispersers, and twin-screw extruders show promise for achieving homogeneous distributions at larger scales, though process parameters require careful optimization for each specific nanoparticle-polymer system.

Cost factors represent another substantial barrier to commercialization. Raw material expenses for high-quality nanoparticles (carbon nanotubes, graphene, silica, or metal oxide nanoparticles) remain prohibitively high for many applications. Development of more economical synthesis routes and identification of alternative, less expensive nanoparticle types could significantly improve commercial viability.

Quality control and characterization present unique challenges at industrial scales. Techniques commonly used in research settings, such as transmission electron microscopy and atomic force microscopy, are impractical for continuous production monitoring. Development of rapid, in-line characterization methods capable of verifying nanoparticle dispersion, concentration, and matrix integration is essential for quality assurance in commercial manufacturing.

Regulatory considerations and safety protocols must also be established for large-scale handling of nanomaterials. Current occupational exposure limits and handling guidelines for many nanoparticles remain under development, creating uncertainty for manufacturers. Closed-system processing equipment and appropriate filtration systems will be necessary to ensure worker safety and environmental protection.

Recent advancements in continuous manufacturing technologies offer promising solutions to some of these challenges. Microfluidic systems and flow chemistry approaches enable more precise control over nanoparticle synthesis and functionalization, while reactive extrusion techniques allow for simultaneous polymerization and nanoparticle incorporation, potentially streamlining production processes.

Industry-academic partnerships have begun addressing these manufacturing challenges, with several pilot-scale production facilities demonstrating improved throughput and consistency. However, significant investment in process engineering and equipment design remains necessary before these materials can achieve price points competitive with conventional polymers for widespread commercial adoption.

Scale-up considerations must account for the critical need to maintain uniform nanoparticle dispersion throughout the polymer matrix, as agglomeration can significantly diminish the self-healing properties and mechanical performance. Industrial mixing technologies such as high-shear mixers, ultrasonic dispersers, and twin-screw extruders show promise for achieving homogeneous distributions at larger scales, though process parameters require careful optimization for each specific nanoparticle-polymer system.

Cost factors represent another substantial barrier to commercialization. Raw material expenses for high-quality nanoparticles (carbon nanotubes, graphene, silica, or metal oxide nanoparticles) remain prohibitively high for many applications. Development of more economical synthesis routes and identification of alternative, less expensive nanoparticle types could significantly improve commercial viability.

Quality control and characterization present unique challenges at industrial scales. Techniques commonly used in research settings, such as transmission electron microscopy and atomic force microscopy, are impractical for continuous production monitoring. Development of rapid, in-line characterization methods capable of verifying nanoparticle dispersion, concentration, and matrix integration is essential for quality assurance in commercial manufacturing.

Regulatory considerations and safety protocols must also be established for large-scale handling of nanomaterials. Current occupational exposure limits and handling guidelines for many nanoparticles remain under development, creating uncertainty for manufacturers. Closed-system processing equipment and appropriate filtration systems will be necessary to ensure worker safety and environmental protection.

Recent advancements in continuous manufacturing technologies offer promising solutions to some of these challenges. Microfluidic systems and flow chemistry approaches enable more precise control over nanoparticle synthesis and functionalization, while reactive extrusion techniques allow for simultaneous polymerization and nanoparticle incorporation, potentially streamlining production processes.

Industry-academic partnerships have begun addressing these manufacturing challenges, with several pilot-scale production facilities demonstrating improved throughput and consistency. However, significant investment in process engineering and equipment design remains necessary before these materials can achieve price points competitive with conventional polymers for widespread commercial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!