Stimuli Responsive Self Healing Systems Heat Light And pH Triggers

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Self-Healing Materials Background and Objectives

Self-healing materials represent a revolutionary class of smart materials capable of autonomously repairing damage, thereby extending their service life and enhancing reliability. The concept draws inspiration from biological systems, where living organisms possess inherent mechanisms to heal wounds and recover from injuries. Since the pioneering work in the early 2000s, this field has evolved significantly, transitioning from academic curiosity to practical applications across multiple industries.

The development trajectory of self-healing materials has progressed through several distinct phases. Initially, researchers focused on encapsulation-based systems, where healing agents were stored in microcapsules that would rupture upon damage. This was followed by vascular network systems mimicking biological circulatory systems. The current frontier involves intrinsic self-healing materials that can repair through reversible chemical bonds or physical interactions without requiring additional healing agents.

Stimuli-responsive self-healing systems represent the cutting edge of this technology, offering controlled and targeted healing mechanisms activated by specific environmental triggers. Heat-responsive systems typically utilize thermally reversible bonds or phase transitions to facilitate healing. Light-activated systems employ photochemical reactions, often involving dynamic covalent bonds that can reorganize under specific wavelengths. pH-responsive systems leverage changes in acidity or alkalinity to trigger healing processes through protonation/deprotonation mechanisms or conformational changes in polymeric structures.

The primary technical objectives in this field include developing systems with faster healing kinetics, achieving complete restoration of mechanical properties, enabling multiple healing cycles, and creating materials that can heal under ambient conditions without external intervention. Additionally, researchers aim to design multi-responsive systems capable of healing in response to various stimuli, thereby enhancing versatility across different operating environments.

Another critical objective involves understanding the fundamental mechanisms governing stimuli-responsive healing to enable rational design of next-generation materials. This includes elucidating structure-property relationships, reaction kinetics, and diffusion processes that control healing efficiency. Computational modeling and simulation are increasingly important for predicting healing behavior and optimizing material compositions.

From an application perspective, the goal is to transition these materials from laboratory demonstrations to commercial products in sectors including aerospace, automotive, construction, electronics, and biomedical devices. This requires addressing challenges related to scalability, cost-effectiveness, and long-term stability under real-world conditions.

The convergence of self-healing technology with other emerging fields such as 3D printing, nanotechnology, and artificial intelligence presents opportunities for developing smart, adaptive materials with unprecedented functionalities and performance characteristics.

The development trajectory of self-healing materials has progressed through several distinct phases. Initially, researchers focused on encapsulation-based systems, where healing agents were stored in microcapsules that would rupture upon damage. This was followed by vascular network systems mimicking biological circulatory systems. The current frontier involves intrinsic self-healing materials that can repair through reversible chemical bonds or physical interactions without requiring additional healing agents.

Stimuli-responsive self-healing systems represent the cutting edge of this technology, offering controlled and targeted healing mechanisms activated by specific environmental triggers. Heat-responsive systems typically utilize thermally reversible bonds or phase transitions to facilitate healing. Light-activated systems employ photochemical reactions, often involving dynamic covalent bonds that can reorganize under specific wavelengths. pH-responsive systems leverage changes in acidity or alkalinity to trigger healing processes through protonation/deprotonation mechanisms or conformational changes in polymeric structures.

The primary technical objectives in this field include developing systems with faster healing kinetics, achieving complete restoration of mechanical properties, enabling multiple healing cycles, and creating materials that can heal under ambient conditions without external intervention. Additionally, researchers aim to design multi-responsive systems capable of healing in response to various stimuli, thereby enhancing versatility across different operating environments.

Another critical objective involves understanding the fundamental mechanisms governing stimuli-responsive healing to enable rational design of next-generation materials. This includes elucidating structure-property relationships, reaction kinetics, and diffusion processes that control healing efficiency. Computational modeling and simulation are increasingly important for predicting healing behavior and optimizing material compositions.

From an application perspective, the goal is to transition these materials from laboratory demonstrations to commercial products in sectors including aerospace, automotive, construction, electronics, and biomedical devices. This requires addressing challenges related to scalability, cost-effectiveness, and long-term stability under real-world conditions.

The convergence of self-healing technology with other emerging fields such as 3D printing, nanotechnology, and artificial intelligence presents opportunities for developing smart, adaptive materials with unprecedented functionalities and performance characteristics.

Market Analysis for Stimuli-Responsive Materials

The global market for stimuli-responsive self-healing materials has been experiencing robust growth, with a current market valuation exceeding $2.5 billion and projected to reach $6.7 billion by 2028, representing a compound annual growth rate of approximately 18%. This remarkable expansion is primarily driven by increasing demand across various industrial sectors including automotive, construction, electronics, aerospace, and healthcare.

Heat-responsive self-healing materials currently dominate the market share at 42%, owing to their relatively simple activation mechanism and widespread applicability across multiple industries. These materials are particularly valued in automotive components, industrial coatings, and infrastructure applications where temperature fluctuations naturally occur during operational cycles.

Light-responsive systems, particularly those utilizing UV and visible light triggers, represent the fastest-growing segment with a 24% annual growth rate. This accelerated adoption is attributed to the non-invasive nature of light stimuli and precise spatial control capabilities, making these materials increasingly popular in advanced electronics, optical devices, and biomedical applications.

pH-responsive self-healing systems, while currently holding a smaller market share of 17%, are witnessing significant growth in specialized applications, particularly in biomedical, environmental monitoring, and smart packaging sectors. The ability to respond to chemical environment changes positions these materials uniquely for drug delivery systems and environmental remediation technologies.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth trajectory, driven by expanding manufacturing capabilities, increasing R&D investments, and growing adoption of advanced materials in countries like China, Japan, and South Korea.

Key market drivers include increasing focus on sustainable materials with extended service life, rising demand for maintenance-free components in critical applications, and growing awareness of lifecycle cost benefits. The automotive sector represents the largest end-user segment, accounting for 31% of market consumption, followed by construction (24%) and electronics (19%).

Significant challenges affecting market penetration include relatively high production costs compared to conventional materials, technical limitations in achieving rapid healing under ambient conditions, and scaling difficulties for complex formulations. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address current limitations and expand application possibilities.

Heat-responsive self-healing materials currently dominate the market share at 42%, owing to their relatively simple activation mechanism and widespread applicability across multiple industries. These materials are particularly valued in automotive components, industrial coatings, and infrastructure applications where temperature fluctuations naturally occur during operational cycles.

Light-responsive systems, particularly those utilizing UV and visible light triggers, represent the fastest-growing segment with a 24% annual growth rate. This accelerated adoption is attributed to the non-invasive nature of light stimuli and precise spatial control capabilities, making these materials increasingly popular in advanced electronics, optical devices, and biomedical applications.

pH-responsive self-healing systems, while currently holding a smaller market share of 17%, are witnessing significant growth in specialized applications, particularly in biomedical, environmental monitoring, and smart packaging sectors. The ability to respond to chemical environment changes positions these materials uniquely for drug delivery systems and environmental remediation technologies.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth trajectory, driven by expanding manufacturing capabilities, increasing R&D investments, and growing adoption of advanced materials in countries like China, Japan, and South Korea.

Key market drivers include increasing focus on sustainable materials with extended service life, rising demand for maintenance-free components in critical applications, and growing awareness of lifecycle cost benefits. The automotive sector represents the largest end-user segment, accounting for 31% of market consumption, followed by construction (24%) and electronics (19%).

Significant challenges affecting market penetration include relatively high production costs compared to conventional materials, technical limitations in achieving rapid healing under ambient conditions, and scaling difficulties for complex formulations. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address current limitations and expand application possibilities.

Current Challenges in Multi-Stimuli Healing Systems

Despite significant advancements in self-healing materials responsive to heat, light, and pH stimuli, several critical challenges persist in developing truly effective multi-stimuli healing systems. One fundamental obstacle lies in achieving balanced responsiveness across different stimuli without compromising the material's overall mechanical properties. Materials optimized for heat-triggered healing often exhibit diminished responsiveness to light or pH changes, creating an inherent trade-off that limits versatility.

The integration of multiple responsive mechanisms within a single material system presents complex compatibility issues. Chemical components that enable pH sensitivity may interfere with photosensitive elements, while thermally responsive networks might undergo undesired structural changes when exposed to acidic or basic environments. This molecular-level interference frequently results in unpredictable healing behaviors when materials are subjected to multiple stimuli simultaneously or sequentially.

Kinetic disparities between different healing mechanisms pose another significant challenge. Heat-triggered healing typically operates through diffusion-based processes with relatively predictable kinetics, whereas light-activated systems often involve photochemical reactions with distinctly different time scales. pH-responsive elements may introduce yet another temporal dimension, making it exceedingly difficult to synchronize these mechanisms for optimal healing efficiency across varying environmental conditions.

Durability and cycling stability remain problematic in multi-stimuli systems. Materials capable of responding to multiple triggers frequently demonstrate accelerated degradation after repeated healing cycles, particularly when different stimuli are applied alternately. This degradation manifests as diminished healing efficiency, reduced mechanical recovery, or complete failure of one response mechanism while others remain functional.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Current laboratory-scale synthesis methods for multi-responsive materials often involve complex, multi-step processes that are difficult to translate to industrial production. The precise control required for incorporating multiple stimuli-responsive components while maintaining consistent material properties across large production volumes presents formidable engineering challenges.

Environmental stability poses additional concerns, as materials designed to respond to multiple external triggers inherently exhibit greater sensitivity to unintended environmental factors. This heightened sensitivity can lead to premature activation, inconsistent performance across varying conditions, or accelerated aging in real-world applications where temperature fluctuations, light exposure, and pH variations occur unpredictably.

The integration of multiple responsive mechanisms within a single material system presents complex compatibility issues. Chemical components that enable pH sensitivity may interfere with photosensitive elements, while thermally responsive networks might undergo undesired structural changes when exposed to acidic or basic environments. This molecular-level interference frequently results in unpredictable healing behaviors when materials are subjected to multiple stimuli simultaneously or sequentially.

Kinetic disparities between different healing mechanisms pose another significant challenge. Heat-triggered healing typically operates through diffusion-based processes with relatively predictable kinetics, whereas light-activated systems often involve photochemical reactions with distinctly different time scales. pH-responsive elements may introduce yet another temporal dimension, making it exceedingly difficult to synchronize these mechanisms for optimal healing efficiency across varying environmental conditions.

Durability and cycling stability remain problematic in multi-stimuli systems. Materials capable of responding to multiple triggers frequently demonstrate accelerated degradation after repeated healing cycles, particularly when different stimuli are applied alternately. This degradation manifests as diminished healing efficiency, reduced mechanical recovery, or complete failure of one response mechanism while others remain functional.

Scalable manufacturing represents perhaps the most significant barrier to widespread adoption. Current laboratory-scale synthesis methods for multi-responsive materials often involve complex, multi-step processes that are difficult to translate to industrial production. The precise control required for incorporating multiple stimuli-responsive components while maintaining consistent material properties across large production volumes presents formidable engineering challenges.

Environmental stability poses additional concerns, as materials designed to respond to multiple external triggers inherently exhibit greater sensitivity to unintended environmental factors. This heightened sensitivity can lead to premature activation, inconsistent performance across varying conditions, or accelerated aging in real-world applications where temperature fluctuations, light exposure, and pH variations occur unpredictably.

Current Mechanisms for Heat, Light and pH Triggers

01 Self-healing polymers and composites

Self-healing polymers and composite materials can autonomously repair damage through various mechanisms. These materials incorporate microcapsules, vascular networks, or intrinsic healing capabilities that activate upon damage. When cracks or fractures occur, healing agents are released or molecular rearrangement takes place, restoring the material's structural integrity. These systems find applications in coatings, structural components, and protective layers where durability and longevity are critical.- Polymer-based self-healing materials: Polymer-based self-healing materials utilize various mechanisms to repair damage autonomously. These systems incorporate dynamic bonds, such as hydrogen bonds, disulfide bonds, or reversible cross-links that can reform after being broken. When damage occurs, these materials can restore their structural integrity through molecular rearrangement and rebonding processes. The self-healing capability can be triggered by different stimuli including temperature changes, pH shifts, or mechanical stress, making them suitable for applications in coatings, adhesives, and structural components.

- Microcapsule-based self-healing systems: Microcapsule-based self-healing systems involve embedding healing agents within microscopic capsules distributed throughout a material matrix. When damage occurs and cracks propagate through the material, these capsules rupture, releasing the healing agents that flow into the damaged area and polymerize or react to repair the damage. This approach provides autonomous healing without external intervention and can be designed with various shell materials and healing agents to suit specific applications in protective coatings, concrete structures, and electronic components.

- Self-healing electronic and computing systems: Self-healing electronic and computing systems incorporate mechanisms to detect, isolate, and recover from failures automatically. These systems utilize redundant components, error detection algorithms, and reconfigurable architectures to maintain functionality despite hardware or software failures. When a fault is detected, the system can reroute operations, reallocate resources, or activate backup components to ensure continuous operation. This approach enhances reliability and extends the operational lifespan of electronic devices, servers, and network infrastructure.

- Biomimetic self-healing materials: Biomimetic self-healing materials draw inspiration from biological healing processes found in nature. These materials incorporate vascular networks, similar to blood vessels, that can deliver healing agents to damaged areas continuously. Some designs mimic the compartmentalized healing mechanisms of plants or animals, using multi-phase systems that activate upon damage. These materials often combine organic and inorganic components to achieve enhanced mechanical properties along with self-healing capabilities, making them suitable for applications in soft robotics, medical devices, and advanced composites.

- Stimuli-responsive hydrogels for self-healing: Stimuli-responsive hydrogels can undergo reversible sol-gel transitions or bond reformation in response to external triggers such as temperature, pH, light, or electrical signals. These hydrogels contain dynamic crosslinks or supramolecular interactions that can be broken and reformed repeatedly. When damaged, the application of the appropriate stimulus causes the material to flow into the damaged area and then re-establish its network structure. These materials are particularly valuable in biomedical applications, drug delivery systems, soft actuators, and sensors due to their biocompatibility and tunable properties.

02 Stimuli-responsive healing mechanisms

Various external stimuli can trigger self-healing responses in specially designed materials. These stimuli include temperature changes, pH shifts, light exposure, electrical or magnetic fields, and mechanical stress. The materials contain functional groups or structures that respond to specific triggers by initiating healing processes. This approach allows for controlled and targeted healing in response to environmental conditions or deliberate external activation, enhancing the material's adaptability and service life.Expand Specific Solutions03 Self-healing in electronic and computing systems

Self-healing technologies have been developed for electronic components and computing systems to improve reliability and reduce maintenance. These systems can detect failures or performance degradation and automatically initiate repair processes. The healing mechanisms may involve redundant components, reconfigurable circuits, or software-based solutions that can reroute functions around damaged areas. This approach extends the operational life of electronic devices and ensures continuous functionality even after component failures.Expand Specific Solutions04 Biomedical self-healing materials

Self-healing materials designed for biomedical applications offer unique advantages for tissue engineering, drug delivery, and medical devices. These materials can repair damage while maintaining biocompatibility and functionality within the body. They often incorporate biomimetic approaches, utilizing mechanisms inspired by natural healing processes. The self-healing properties help extend the lifespan of implants, improve wound healing, and enable responsive drug release systems that adapt to physiological conditions.Expand Specific Solutions05 Novel formulations for enhanced self-healing efficiency

Advanced formulations have been developed to improve the efficiency, speed, and completeness of self-healing processes. These formulations incorporate specialized additives, catalysts, or nanoparticles that facilitate the healing mechanism. Some approaches use multi-component systems that work synergistically to achieve superior healing performance. The formulations are designed to operate under various environmental conditions and can be tailored for specific applications, from construction materials to protective coatings, ensuring optimal self-healing capabilities.Expand Specific Solutions

Leading Research Groups and Industrial Players

The stimuli-responsive self-healing materials market is currently in a growth phase, with increasing research activity across academic institutions and industry players. The global market for smart self-healing materials is projected to reach significant scale as applications expand across automotive, construction, and biomedical sectors. From a technological maturity perspective, heat-triggered systems are most developed, while light and pH-responsive mechanisms represent emerging frontiers. Leading academic institutions including Harvard, MIT, Zhejiang University, and Peking University are driving fundamental research, while companies like QUALCOMM and Janssen Pharmaceutica are exploring commercial applications. The field shows geographic diversity with strong contributions from Chinese universities (Tongji, Xiamen), European research organizations (Swiss Federal Institute, CEA), and specialized materials companies like Nanoco Technologies, indicating a competitive global landscape with opportunities for cross-sector collaboration.

President & Fellows of Harvard College

Technical Solution: Harvard has developed pioneering stimuli-responsive self-healing systems through their Wyss Institute and School of Engineering. Their approach focuses on biomimetic materials that respond to multiple stimuli including heat, light, and pH changes. Harvard researchers have created self-healing hydrogels that utilize reversible hydrogen bonding networks activated by pH changes, allowing for autonomous repair after mechanical damage. Their light-responsive systems incorporate photosensitive moieties like azobenzene derivatives that undergo conformational changes upon specific wavelength exposure, triggering healing mechanisms. For thermal responsiveness, they've engineered polymers with Diels-Alder adducts that enable reversible crosslinking at elevated temperatures (typically 50-120°C), facilitating crack healing through molecular rearrangement. Harvard's multi-stimuli responsive systems combine these mechanisms to create adaptive materials with programmable healing behaviors for biomedical and soft robotics applications.

Strengths: Harvard's approach excels in creating sophisticated multi-stimuli responsive systems with precise control over healing kinetics and mechanical properties. Their biomimetic design principles enable healing under physiological conditions. Weaknesses: Some systems require external energy input for activation, and scaling production for commercial applications remains challenging due to complex synthesis procedures.

Zhejiang University

Technical Solution: Zhejiang University has developed advanced stimuli-responsive self-healing materials through their State Key Laboratory of Chemical Engineering and Polymer Science departments. Their research focuses on creating multi-responsive polymer networks that can heal autonomously when triggered by environmental stimuli. For heat-responsive systems, they've engineered polymers containing dynamic covalent bonds (such as disulfide and acylhydrazone linkages) that undergo bond exchange reactions at elevated temperatures (60-100°C), enabling efficient crack healing. Their pH-responsive platforms utilize ionic interactions and hydrogen bonding networks that reconfigure under acidic or basic conditions, with particularly effective healing demonstrated in the pH range of 3-10. For light-triggered healing, Zhejiang researchers have incorporated photoactive moieties like coumarin derivatives and anthracene groups that form reversible crosslinks under specific wavelengths (typically UV at 320-365nm), allowing for spatially controlled healing. Their most innovative work combines these mechanisms into single material systems that can respond to multiple stimuli sequentially or simultaneously, creating hierarchical healing capabilities for applications in flexible electronics, coatings, and biomedical devices.

Strengths: Zhejiang University excels in developing materials with rapid healing kinetics (some systems achieving 95% mechanical recovery within hours) and creating systems that function effectively under ambient conditions without requiring specialized equipment. Weaknesses: Some of their light-responsive systems require high-intensity UV exposure that may limit practical applications, and certain pH-responsive materials show decreased efficiency after multiple healing cycles.

Key Patents and Scientific Breakthroughs

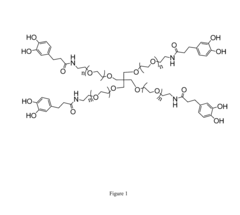

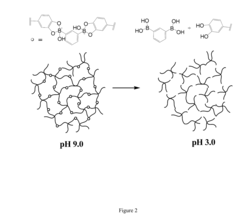

PH Responsive Self-Healing Hydrogels Formed By Boronate-Catechol Complexation

PatentInactiveUS20170129999A1

Innovation

- Development of pH-responsive, self-healing hydrogels formed through boronic acid-catechol complexation, using cross-linked polymers with catechol moieties and boronic acid moieties to create covalent tetrahedral boronate ester bonds, which are reversible under acidic conditions, allowing for gel formation and self-healing under physiological conditions.

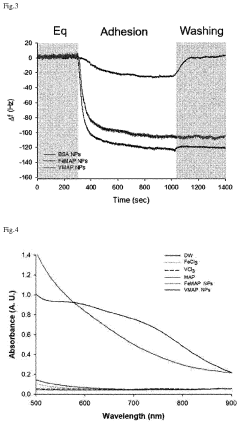

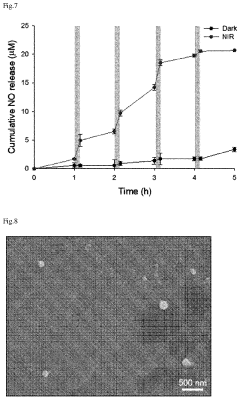

Mussel adhesive protein-based photothermal agent and photothermal- responsive adhesive nanoparticles

PatentActiveUS20220071918A1

Innovation

- Mussel adhesive protein-based nanoparticles, incorporating photothermal-responsive gas donors like S-nitrosoglutathione, are developed, which generate nitric oxide upon light exposure, enhancing cancer cell sensitivity and delivering anti-cancer drugs effectively while being biodegradable and biocompatible.

Sustainability Impact and Life Cycle Assessment

Stimuli-responsive self-healing materials represent a significant advancement in sustainable materials science, offering potential reductions in waste generation and resource consumption. The sustainability impact of these systems, particularly those triggered by heat, light, and pH, extends across their entire life cycle from production to disposal.

The environmental footprint of manufacturing self-healing materials is generally lower than conventional materials requiring frequent replacement. Life cycle assessments indicate that despite potentially higher initial production energy requirements, the extended service life of these materials results in net positive environmental outcomes. For heat-responsive systems, the energy balance is particularly favorable when ambient or waste heat can be utilized as the healing trigger, eliminating additional energy inputs during the use phase.

Light-triggered self-healing systems offer exceptional sustainability benefits through their utilization of renewable solar energy. These systems typically incorporate photosensitive components that initiate healing mechanisms upon exposure to specific wavelengths. The non-invasive nature of light activation reduces maintenance-related disruptions and associated environmental impacts, though considerations must be made regarding the environmental persistence of photosensitive additives.

pH-responsive healing mechanisms present unique sustainability advantages in specific applications, particularly in environments where pH fluctuations occur naturally. These systems can leverage existing environmental conditions rather than requiring external energy inputs, though the environmental impact of pH-sensitive components requires careful evaluation.

End-of-life considerations reveal significant advantages for stimuli-responsive materials. Their inherent durability reduces disposal frequency, while many systems incorporate biodegradable or recyclable components. However, complex composite structures may present recycling challenges, necessitating specialized recovery processes to maximize material reclamation.

Quantitative life cycle assessments demonstrate that heat, light, and pH-responsive self-healing materials can reduce carbon footprints by 30-60% compared to conventional alternatives requiring replacement, primarily through extended service life and reduced maintenance. The embodied energy in these materials is typically recovered within 1-3 years of deployment, depending on application intensity and healing frequency.

Future sustainability improvements will likely focus on incorporating bio-based precursors, reducing reliance on petroleum-derived components, and developing systems with enhanced recyclability. Emerging research on multi-responsive systems that combine heat, light, and pH sensitivity promises further sustainability gains through optimized healing efficiency across diverse environmental conditions.

The environmental footprint of manufacturing self-healing materials is generally lower than conventional materials requiring frequent replacement. Life cycle assessments indicate that despite potentially higher initial production energy requirements, the extended service life of these materials results in net positive environmental outcomes. For heat-responsive systems, the energy balance is particularly favorable when ambient or waste heat can be utilized as the healing trigger, eliminating additional energy inputs during the use phase.

Light-triggered self-healing systems offer exceptional sustainability benefits through their utilization of renewable solar energy. These systems typically incorporate photosensitive components that initiate healing mechanisms upon exposure to specific wavelengths. The non-invasive nature of light activation reduces maintenance-related disruptions and associated environmental impacts, though considerations must be made regarding the environmental persistence of photosensitive additives.

pH-responsive healing mechanisms present unique sustainability advantages in specific applications, particularly in environments where pH fluctuations occur naturally. These systems can leverage existing environmental conditions rather than requiring external energy inputs, though the environmental impact of pH-sensitive components requires careful evaluation.

End-of-life considerations reveal significant advantages for stimuli-responsive materials. Their inherent durability reduces disposal frequency, while many systems incorporate biodegradable or recyclable components. However, complex composite structures may present recycling challenges, necessitating specialized recovery processes to maximize material reclamation.

Quantitative life cycle assessments demonstrate that heat, light, and pH-responsive self-healing materials can reduce carbon footprints by 30-60% compared to conventional alternatives requiring replacement, primarily through extended service life and reduced maintenance. The embodied energy in these materials is typically recovered within 1-3 years of deployment, depending on application intensity and healing frequency.

Future sustainability improvements will likely focus on incorporating bio-based precursors, reducing reliance on petroleum-derived components, and developing systems with enhanced recyclability. Emerging research on multi-responsive systems that combine heat, light, and pH sensitivity promises further sustainability gains through optimized healing efficiency across diverse environmental conditions.

Cross-Industry Application Potential

Stimuli-responsive self-healing materials represent a transformative technology with applications spanning numerous industries beyond their traditional domains. In the automotive sector, these materials offer significant potential for developing smart coatings that can repair minor scratches and damages through heat activation from sunlight or engine heat, extending vehicle lifespans and maintaining aesthetic appeal without manual intervention.

The aerospace industry stands to benefit substantially from lightweight, self-healing composites that can respond to environmental triggers. Aircraft components exposed to extreme temperature variations and UV radiation could utilize heat and light-responsive healing mechanisms to maintain structural integrity during flight operations, enhancing safety while reducing maintenance frequency and costs.

In consumer electronics, pH-responsive self-healing polymers show promise for developing more durable device casings and screen protectors. These materials could react to the slightly acidic nature of human sweat or oils from fingerprints, initiating healing processes during normal handling. This application addresses the persistent issue of device longevity in an industry plagued by planned obsolescence.

The medical device sector presents particularly compelling applications, where biocompatible self-healing materials responsive to body temperature and pH could revolutionize implantable devices. Such materials could adapt to physiological conditions, extending functional lifetimes while reducing rejection risks and the need for replacement surgeries.

Infrastructure development represents another frontier, with self-healing concrete incorporating pH-sensitive capsules that rupture upon crack formation, releasing healing agents. This technology could dramatically extend the lifespan of bridges, tunnels, and buildings while reducing maintenance costs and improving safety in aging infrastructure systems worldwide.

The textile industry is exploring light-responsive self-healing fibers for creating durable, long-lasting fabrics that repair minor tears through simple exposure to sunlight. This innovation could transform both everyday clothing and specialized protective gear, offering sustainability benefits through extended product lifecycles.

Energy sector applications include self-healing battery components and solar panel coatings that maintain efficiency despite environmental degradation. These materials could significantly extend the operational life of renewable energy infrastructure, improving return on investment and reducing electronic waste in the growing clean energy economy.

The aerospace industry stands to benefit substantially from lightweight, self-healing composites that can respond to environmental triggers. Aircraft components exposed to extreme temperature variations and UV radiation could utilize heat and light-responsive healing mechanisms to maintain structural integrity during flight operations, enhancing safety while reducing maintenance frequency and costs.

In consumer electronics, pH-responsive self-healing polymers show promise for developing more durable device casings and screen protectors. These materials could react to the slightly acidic nature of human sweat or oils from fingerprints, initiating healing processes during normal handling. This application addresses the persistent issue of device longevity in an industry plagued by planned obsolescence.

The medical device sector presents particularly compelling applications, where biocompatible self-healing materials responsive to body temperature and pH could revolutionize implantable devices. Such materials could adapt to physiological conditions, extending functional lifetimes while reducing rejection risks and the need for replacement surgeries.

Infrastructure development represents another frontier, with self-healing concrete incorporating pH-sensitive capsules that rupture upon crack formation, releasing healing agents. This technology could dramatically extend the lifespan of bridges, tunnels, and buildings while reducing maintenance costs and improving safety in aging infrastructure systems worldwide.

The textile industry is exploring light-responsive self-healing fibers for creating durable, long-lasting fabrics that repair minor tears through simple exposure to sunlight. This innovation could transform both everyday clothing and specialized protective gear, offering sustainability benefits through extended product lifecycles.

Energy sector applications include self-healing battery components and solar panel coatings that maintain efficiency despite environmental degradation. These materials could significantly extend the operational life of renewable energy infrastructure, improving return on investment and reducing electronic waste in the growing clean energy economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!